Professional Documents

Culture Documents

Conceptos para La Selección de Zarandas en El Proceso de Semillas Oleaginosas Cru1

Conceptos para La Selección de Zarandas en El Proceso de Semillas Oleaginosas Cru1

Uploaded by

estramilsolutionCopyright:

Available Formats

You might also like

- Screen OneDocument2 pagesScreen OneMtyghm Tymmt100% (1)

- Compavtadora AsfaltadoraDocument224 pagesCompavtadora AsfaltadoraestramilsolutionNo ratings yet

- Av Vibrating Screens PDFDocument2 pagesAv Vibrating Screens PDFArnaldo BenitezNo ratings yet

- Principles of Screening and Sizing PDFDocument63 pagesPrinciples of Screening and Sizing PDFestramilsolutionNo ratings yet

- ViPA Training Manual - Rev I For V4.7xxDocument80 pagesViPA Training Manual - Rev I For V4.7xxJoan Albet Serra100% (2)

- 426 ScreeningDocument53 pages426 ScreeningmseaNo ratings yet

- Size ControlDocument24 pagesSize ControlepaccoyNo ratings yet

- Flyer LAGA GrainPlus 4-Seiter en LQDocument4 pagesFlyer LAGA GrainPlus 4-Seiter en LQCộc CộcNo ratings yet

- Flyer LAGA GrainPlus 4-Seiter en LQDocument4 pagesFlyer LAGA GrainPlus 4-Seiter en LQCộc CộcNo ratings yet

- Flyer LAGA GrainPlus 4-Seiter EN LQDocument4 pagesFlyer LAGA GrainPlus 4-Seiter EN LQCộc CộcNo ratings yet

- Answers To Questions/Problems: Ceramics IndustryDocument3 pagesAnswers To Questions/Problems: Ceramics IndustryIvy TovilloNo ratings yet

- DryWay Pulp Drying Line ConceptDocument21 pagesDryWay Pulp Drying Line ConceptLuis ValenzuelaNo ratings yet

- Screening ConsiderationsDocument23 pagesScreening ConsiderationsJames MNo ratings yet

- Flyer LAGADocument4 pagesFlyer LAGASanidad Los ReyesNo ratings yet

- Lecture 6 ScreeningDocument25 pagesLecture 6 ScreeningLAURENT JIBUNGENo ratings yet

- Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonDocument53 pagesJae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-Madisonscelo buthelezi100% (1)

- Flotation of Cleaner Rejects Removes High Density StickiesDocument16 pagesFlotation of Cleaner Rejects Removes High Density Stickiespaperravi2000No ratings yet

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009No ratings yet

- Guia Diseño RejasDocument10 pagesGuia Diseño RejasJose Alberto Muñoz FloresNo ratings yet

- Size Reduction ControlDocument24 pagesSize Reduction ControlJohn Israel R. CatedralNo ratings yet

- Brochure Assisting enDocument16 pagesBrochure Assisting enlucianchiritaNo ratings yet

- F CA-drawframes Combingsection Lowres MarzoliDocument32 pagesF CA-drawframes Combingsection Lowres MarzoliAshiqueNo ratings yet

- Material SugargrdDocument2 pagesMaterial Sugargrdarun2386No ratings yet

- Huber - Rotamat Pro Ue Ro enDocument16 pagesHuber - Rotamat Pro Ue Ro enlalo_2788No ratings yet

- Micronization of Active Pharmaceutical Ingredients (API) From R&D To The Production ScaleDocument1 pageMicronization of Active Pharmaceutical Ingredients (API) From R&D To The Production ScalesandragiaNo ratings yet

- Vibrating Screen DesignDocument12 pagesVibrating Screen DesignAinur Rohman100% (2)

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeNo ratings yet

- Linearschwingsieb enDocument12 pagesLinearschwingsieb enBrunoNo ratings yet

- Vibroscreen BrochureDocument12 pagesVibroscreen BrochureVarun MalhotraNo ratings yet

- Preliminary Treatment Process of Waste WaDocument9 pagesPreliminary Treatment Process of Waste WaArjun MulluNo ratings yet

- WWTP Chap 5 (p28-41) - Mech PurificationDocument14 pagesWWTP Chap 5 (p28-41) - Mech PurificationKaustav PatnaikNo ratings yet

- High-Frequency Vibrating ScreensDocument9 pagesHigh-Frequency Vibrating ScreensBayer Mitrovic100% (1)

- ScreeningDocument3 pagesScreeningPratik BansalNo ratings yet

- Lec No.5 Screening RevDocument11 pagesLec No.5 Screening Revnoel50% (2)

- CDE ProductsDocument5 pagesCDE ProductsFiras MaitigNo ratings yet

- DPF Oscillating ScreenDocument5 pagesDPF Oscillating ScreenolivefaNo ratings yet

- ScreeningDocument30 pagesScreeningPatricia de Leon100% (2)

- Máquina Moer Alumina PDFDocument36 pagesMáquina Moer Alumina PDFDulce GabrielNo ratings yet

- Cyclotec-Brochure-pdfDocument2 pagesCyclotec-Brochure-pdfFranchii HubillaNo ratings yet

- Design & Selection Criteria For StrainersDocument4 pagesDesign & Selection Criteria For StrainersKamal ChokshiNo ratings yet

- Recycling - Waste - Screen - Eng - 09 10Document2 pagesRecycling - Waste - Screen - Eng - 09 10Ziggy GregoryNo ratings yet

- Tailor Made Screening Technology For Different Screening Tasks in The Phosphate IndustryDocument6 pagesTailor Made Screening Technology For Different Screening Tasks in The Phosphate IndustryJavier Alejandro RodriguezNo ratings yet

- Jordy Maquilan TERDocument18 pagesJordy Maquilan TERHanah Kryss CastreNo ratings yet

- Paper Screen WireDocument7 pagesPaper Screen Wirexiaochi1989No ratings yet

- ScreeningDocument30 pagesScreeningVishnu RajeswaranNo ratings yet

- Sweepers CatalogDocument56 pagesSweepers CatalogNewVersion_FacilityManagementNo ratings yet

- Vibrating Screen Experimental ManualDocument16 pagesVibrating Screen Experimental ManualShoaib Pathan50% (2)

- Evisceration UKDocument16 pagesEvisceration UKHelton OliveiraNo ratings yet

- CornWetMilling BrochureDocument8 pagesCornWetMilling BrochureAndrea HernandezNo ratings yet

- Screen EquipmentDocument22 pagesScreen EquipmentmutiNo ratings yet

- Dip PDFDocument27 pagesDip PDFolenin64No ratings yet

- Bar Screen Chamber: 1.1 FunctionDocument2 pagesBar Screen Chamber: 1.1 Functionsatria hidayatNo ratings yet

- SA BuhlerDocument6 pagesSA BuhlerAndreea BenteaNo ratings yet

- REMU XO CrossoverBucketDocument6 pagesREMU XO CrossoverBucketScott GuimondNo ratings yet

- Bar Screening Environmental EngineeringDocument11 pagesBar Screening Environmental EngineeringRajat Kushwaha100% (1)

- Intake Screens For Cooling and Heating Coils: DurhamDocument8 pagesIntake Screens For Cooling and Heating Coils: DurhamDony RamdhaniNo ratings yet

- Milliken Maintenance InstructionDocument7 pagesMilliken Maintenance InstructionM_VILANo ratings yet

- Industrial Screening: Rajan Kumar MISHRA (2019UGMM005) Anshuman Mishra (2019ugmm037) KOTALLA VINAY (2019UGMM089)Document26 pagesIndustrial Screening: Rajan Kumar MISHRA (2019UGMM005) Anshuman Mishra (2019ugmm037) KOTALLA VINAY (2019UGMM089)Anshuman MishraNo ratings yet

- REMU ScreeningBucketDocument12 pagesREMU ScreeningBucketScott GuimondNo ratings yet

- Screening Jae K. (Jim) Park, Professor - PPT Video Online DownloadDocument12 pagesScreening Jae K. (Jim) Park, Professor - PPT Video Online Downloadmimoun nbennaceurNo ratings yet

- ScreeningDocument16 pagesScreeninganthony ijigaNo ratings yet

- Preliminary TreatmentDocument18 pagesPreliminary TreatmentLaurensius MarcellNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- CSD Rise Ultra Wrap ManualDocument36 pagesCSD Rise Ultra Wrap ManualestramilsolutionNo ratings yet

- 973-0014-1 ALLIS-CHALMERS 3500 MK2 Engine Drive & Optional Equipment Parts Manual (09-1974)Document44 pages973-0014-1 ALLIS-CHALMERS 3500 MK2 Engine Drive & Optional Equipment Parts Manual (09-1974)estramilsolutionNo ratings yet

- World Famous Tiles Recycled in World Famous VSI - MetsoDocument4 pagesWorld Famous Tiles Recycled in World Famous VSI - MetsoestramilsolutionNo ratings yet

- Metal Detectors MA 3000Document4 pagesMetal Detectors MA 3000estramilsolution100% (1)

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDocument6 pagesTerex Simplicity Vibrating Feeders: Terex Minerals Processing Systemsestramilsolution100% (1)

- VSI Crushers-2010-HistoryBuildup PhotosDocument76 pagesVSI Crushers-2010-HistoryBuildup PhotosestramilsolutionNo ratings yet

- Conceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsDocument221 pagesConceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsestramilsolutionNo ratings yet

- ManganesDocument118 pagesManganesestramilsolutionNo ratings yet

- Alimentateur PDFDocument4 pagesAlimentateur PDFestramilsolutionNo ratings yet

- ExtraDocument1 pageExtraestramilsolutionNo ratings yet

- Vltraflo Vibrating Feeders & ScreenDocument4 pagesVltraflo Vibrating Feeders & ScreenestramilsolutionNo ratings yet

- NEW ConesGyraRollDocument4 pagesNEW ConesGyraRollestramilsolutionNo ratings yet

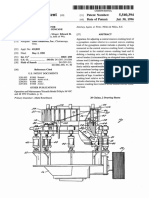

- Us 5540394Document10 pagesUs 5540394estramilsolutionNo ratings yet

- Rotex Brochure PDFDocument4 pagesRotex Brochure PDFestramilsolutionNo ratings yet

- Chapter1 10 PDFDocument84 pagesChapter1 10 PDFestramilsolutionNo ratings yet

- Chapter1 10 PDFDocument84 pagesChapter1 10 PDFestramilsolutionNo ratings yet

- 39 ConeCrushersDocument8 pages39 ConeCrushersestramilsolutionNo ratings yet

- Biobaler LP 2014Document124 pagesBiobaler LP 2014estramilsolutionNo ratings yet

- LT3387 Loctite Nordback Backing MaterialsDocument4 pagesLT3387 Loctite Nordback Backing MaterialsestramilsolutionNo ratings yet

- EMMA User Guide PDFDocument33 pagesEMMA User Guide PDFKarnalPreethNo ratings yet

- Sspc-Ab 1 PDF PDFDocument5 pagesSspc-Ab 1 PDF PDFLetth Dur'No ratings yet

- Base Course AggregateDocument15 pagesBase Course AggregateSallam MohammedNo ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualDocument5 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualZaffira RahmanNo ratings yet

- As 1141.11.2-2008 Methods For Sampling and Testing Aggregates Particle Size Distribution For Vision Sizing SyDocument2 pagesAs 1141.11.2-2008 Methods For Sampling and Testing Aggregates Particle Size Distribution For Vision Sizing SySAI Global - APACNo ratings yet

- Lesson 3.4Document7 pagesLesson 3.4MitzlNo ratings yet

- Particulate Matter in InjectionDocument4 pagesParticulate Matter in InjectionSimona Florina PrecupNo ratings yet

- Sorel Cement Paper-3Document52 pagesSorel Cement Paper-3ahmetsadry1No ratings yet

- Particle Counter CalibrationDocument9 pagesParticle Counter Calibrationdavethebox100% (1)

- The Gully Pot As A Physical, Chemical and Biological ReactorDocument10 pagesThe Gully Pot As A Physical, Chemical and Biological ReactorMohammad Mehdi NorooziNo ratings yet

- Experiment 3Document6 pagesExperiment 3SHAFIKANOR366150% (2)

- Anexo 5.4 Astm d5092Document16 pagesAnexo 5.4 Astm d5092marvin060517No ratings yet

- C92-95 (Reapproved 2015) PDFDocument4 pagesC92-95 (Reapproved 2015) PDFAbdiz Engineering INCNo ratings yet

- Paper Avizo PSDDocument14 pagesPaper Avizo PSDYago PinheiroNo ratings yet

- 2.9.31. Particle Size Analysis by Laser Light Diffraction 20931eDocument4 pages2.9.31. Particle Size Analysis by Laser Light Diffraction 20931eAna Maria100% (1)

- Index 9th Edition PheurDocument34 pagesIndex 9th Edition Pheurpepilloelgrillo50% (2)

- As 4816.1-2002 Determination of Particle Size Distribution by Gravitational Liquid Sedimentation Methods GeneDocument8 pagesAs 4816.1-2002 Determination of Particle Size Distribution by Gravitational Liquid Sedimentation Methods GeneSAI Global - APACNo ratings yet

- PowderDocument62 pagesPowderJinan Muhammed Muhsin AlMousawy - جنان محمد محسن طاهر الموسويNo ratings yet

- Muscovite Grinding and DelaminatingDocument4 pagesMuscovite Grinding and DelaminatingRosielxNo ratings yet

- GRanulatorDocument14 pagesGRanulatormigelNo ratings yet

- SSPC Ab 1Document5 pagesSSPC Ab 1anoopkumarNo ratings yet

- Building Materials Lab ManualDocument21 pagesBuilding Materials Lab Manualapi-348488925100% (3)

- Application of Laser Particle Size System in Pesticide IndustryDocument5 pagesApplication of Laser Particle Size System in Pesticide IndustryRuby AdityoNo ratings yet

- Sieve Analysis Procedure ForDocument2 pagesSieve Analysis Procedure ForzeontitanNo ratings yet

- Unit-I-Aggregate GradingDocument22 pagesUnit-I-Aggregate GradingashoknrNo ratings yet

- Spiral Jet MillDocument8 pagesSpiral Jet MillĐức Linh100% (1)

- Sieve Analysis - An ExperimentDocument7 pagesSieve Analysis - An ExperimentamjadakramNo ratings yet

- SieveanalysisDocument2 pagesSieveanalysisBeverly PacerNo ratings yet

- Kollidon-Cl Technical InformationDocument13 pagesKollidon-Cl Technical InformationRockstarNo ratings yet

Conceptos para La Selección de Zarandas en El Proceso de Semillas Oleaginosas Cru1

Conceptos para La Selección de Zarandas en El Proceso de Semillas Oleaginosas Cru1

Uploaded by

estramilsolutionOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conceptos para La Selección de Zarandas en El Proceso de Semillas Oleaginosas Cru1

Conceptos para La Selección de Zarandas en El Proceso de Semillas Oleaginosas Cru1

Uploaded by

estramilsolutionCopyright:

Available Formats

10/26/2015

Conceptos para la seleccin

de zarandas en el proceso

de semillas oleaginosas

CRU1

Marcelo Niedermann

Sabado 08:15h!!!, 31 de Octubre, 2015

What is Screening?

10/26/2015

Basic Types of Screening

Applications

Scalping

Fines Removal

Grading (Sizing)

Scalping

Removing large foreign

material such as cobs,

sticks, stones Size of

oversize is 50% greater

than the grain size.

Very high capacities are

normally attainable.

Oversize typically 5% or less

10/26/2015

Fines Removal

Removing a small amount

of fine material such as

sand, dirt, small grains and

weed seeds.

Size of fines is less than

50% of the grain size.

Fines typically less than 10%

of the feedstock

Grading

Use of precise screen

openings to remove a

specific size range of

particles as a product

fraction.

Accuracy and efficiency are

critical to process ROI.

10/26/2015

Particle Size Distribution - Sieve Analysis

Test Sieves are identified by

a sieve number or by the

opening of the wire mesh.

An ISO/U.S. #10 sieve has

an opening of 2 mm or 2000

microns.

Particle Size Distribution - Sieve Analysis

10/26/2015

Particle Size Distribution (PSD)

U.S. Sieve No

Opening (mm)

% Retained

10

2.00

4.8%

16

1.18

18.8%

30

0.60

26.3%

60

0.25

28.1%

100

0.15

11.3%

Pan

10.7%

100.0%

PSD and CAPACITY

Capacity

% Retained

Fines

Grading

Scalping

10/26/2015

Screen Opening Selection

Same Opening, Different Wire Diameter

Opening

One

Mesh

65% Open Area

40% Open Area

Screen Comparison Table

Mesh

Wire Diameter

Opening

% Open Area

10

0.020"/0.51 mm

0.080"/2.03 mm

64.0%

10

0.025"/0.64 mm

0.075"/1.91 mm

56.3%

10

0.028"/0.71 mm

0.072"/1.83 mm

51.8%

10

0.032"/0.81 mm

0.068"/1.73 mm

46.2%

Number 10 U.S. Sieve.0.078"/2.00 mm

Number 10 Tyler Sieve0.066"/1.68 mm

10/26/2015

Blinding

The reduction in open area of a screen surface caused by

plugging or coating.

Plugging by Near-Size

Bridging by oil,

moisture or static

Anti-Blinding Ball Mesh

Cleaning System

10/26/2015

Screener Motions and Types

Rectangular Gyratory

Inclined Vibratory

Round Gyratory

Horizontal Vibratory

Centrifugal

Round Vibratory

Gyratory-Reciprocating - Motion

10/26/2015

Stratification and Separation of Material

on a ROTEX Screener

The Trade-Off in Screening

High Product Quality?

Or

High Production Rate?

10/26/2015

Typical Screening Application

Expectation Of Screening System

10

10/26/2015

ROTEX Gyratory Screener

High Production

On-Spec

Low Product Yield

11

10/26/2015

Low Product Quality

Effect of Screener Efficiency on

Milling Circuit Loads

Virgin Feed

100 TPH

25% Oversize

Milled Overs

Screener

Efficiency

Mill

Recycle

Load

Total

Screener

Load

100%

25 TPH

125 TPH

90%

36 TPH

136 TPH

80%

50 TPH

150 TPH

70%

68 TPH

168 TPH

MILL

SCREENER

Screened Overs

(to recycle mill)

Screened Product

100 TPH

0% Oversize

12

10/26/2015

APEX Screeners

Apex screeners are the next evolution of the gyratory

reciprocating screener. Having taken into account feedback from

hundreds of existing Rotex users, the Apex was designed with

advanced ergonomic features for even easier maintenance:

Side access to screens: no heavy lifting

Modular screen panels: <4kg weight per panel

Common panel size: move to distribute wear

APEX SPECIFICATIONS

MIN. SCREEN AREA: 0.8m

MAX. SCREEN AREA: 9.8m

Swap out panels: 1 minutes per panel (1 person)

MEGATEX XD

Independently fed

decks

(Each with ball tray)

External

drive at

rear

Discharge doors

Quick release cams for mesh

removal

Inlet

plenums

with fed

from above

to evenly

distribute

material.

Vertical discharge boxes with

brushes to ensure no leakage.

13

10/26/2015

Screening in Oilseed Processing

Fast, Accurate Screening for

Oilseed Processing Plants

14

10/26/2015

Pre-Cleaning

High Capacity in a Single

Machine

Typical Screen openings

9/16 3/4

Capacities > 85 Bu/sqft

15

10/26/2015

Coarse Overs

Receiving Cleaner

Capacity

% Retained

4 mesh

5/8 opening

16

10/26/2015

Process Cleaner

Prep-room Cleaner

Capacity

% Retained

4 mesh

7/16 opening

17

10/26/2015

Prep-room Cleaner

Typical Screen openings 7/16 1/2

Capacities 60 65 Bu/sqft

Close opening 3/8

Capacity ~ 40 Bu/sqft

Overs

18

10/26/2015

Light Material & Fines

Light Material

Fines

Clean Soybean

19

10/26/2015

Dehulling Process

Soybean Dehulling Process

Cold dehulling

Hot dehulling

20

10/26/2015

Hi-Pro Expected Value

Fiber in Meal < 3.5%

Fat in Hulls < 1.5%

Cracked Hulls and Meats

21

10/26/2015

Key to Effective Dehulling

1. Precise sizing (screening)

2. Precise air separation (aspiration)

Dehulling Process

Hull Sifter

KICE Type Multi-pass

Aspirator

22

10/26/2015

Dehulling Process

KICE Type Multi-pass

Aspirator

Hull Sifter

Hull Sifter

Capacity

% Retained

12 mesh

6 mesh

23

10/26/2015

Meal Sifting

Reasons for Sifting the Meal

before Grinding

Dont grind in spec material

Reduces meal to be ground

Reduces Grinder size

Saves Energy

Saves Grinder maintenance cost

Screener

Efficiency

Mill

Recycle

Load

Total

Screener

Load

100%

25 TPH

125 TPH

90%

36 TPH

136 TPH

80%

50 TPH

150 TPH

70%

68 TPH

168 TPH

24

10/26/2015

Meal Sifting

Sunflower Dehulling

Very high oil content

Specific weight about 1/2 of soybean

Small difference between specific weight of

hulls and meats

25

10/26/2015

Sunflower System

Capacity < 1/2 of soybean system

Gentle cracking - minimizes transfer of oil to

hulls

Precise sizing more critical

Sunflower System

26

10/26/2015

27

You might also like

- Screen OneDocument2 pagesScreen OneMtyghm Tymmt100% (1)

- Compavtadora AsfaltadoraDocument224 pagesCompavtadora AsfaltadoraestramilsolutionNo ratings yet

- Av Vibrating Screens PDFDocument2 pagesAv Vibrating Screens PDFArnaldo BenitezNo ratings yet

- Principles of Screening and Sizing PDFDocument63 pagesPrinciples of Screening and Sizing PDFestramilsolutionNo ratings yet

- ViPA Training Manual - Rev I For V4.7xxDocument80 pagesViPA Training Manual - Rev I For V4.7xxJoan Albet Serra100% (2)

- 426 ScreeningDocument53 pages426 ScreeningmseaNo ratings yet

- Size ControlDocument24 pagesSize ControlepaccoyNo ratings yet

- Flyer LAGA GrainPlus 4-Seiter en LQDocument4 pagesFlyer LAGA GrainPlus 4-Seiter en LQCộc CộcNo ratings yet

- Flyer LAGA GrainPlus 4-Seiter en LQDocument4 pagesFlyer LAGA GrainPlus 4-Seiter en LQCộc CộcNo ratings yet

- Flyer LAGA GrainPlus 4-Seiter EN LQDocument4 pagesFlyer LAGA GrainPlus 4-Seiter EN LQCộc CộcNo ratings yet

- Answers To Questions/Problems: Ceramics IndustryDocument3 pagesAnswers To Questions/Problems: Ceramics IndustryIvy TovilloNo ratings yet

- DryWay Pulp Drying Line ConceptDocument21 pagesDryWay Pulp Drying Line ConceptLuis ValenzuelaNo ratings yet

- Screening ConsiderationsDocument23 pagesScreening ConsiderationsJames MNo ratings yet

- Flyer LAGADocument4 pagesFlyer LAGASanidad Los ReyesNo ratings yet

- Lecture 6 ScreeningDocument25 pagesLecture 6 ScreeningLAURENT JIBUNGENo ratings yet

- Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonDocument53 pagesJae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-Madisonscelo buthelezi100% (1)

- Flotation of Cleaner Rejects Removes High Density StickiesDocument16 pagesFlotation of Cleaner Rejects Removes High Density Stickiespaperravi2000No ratings yet

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009No ratings yet

- Guia Diseño RejasDocument10 pagesGuia Diseño RejasJose Alberto Muñoz FloresNo ratings yet

- Size Reduction ControlDocument24 pagesSize Reduction ControlJohn Israel R. CatedralNo ratings yet

- Brochure Assisting enDocument16 pagesBrochure Assisting enlucianchiritaNo ratings yet

- F CA-drawframes Combingsection Lowres MarzoliDocument32 pagesF CA-drawframes Combingsection Lowres MarzoliAshiqueNo ratings yet

- Material SugargrdDocument2 pagesMaterial Sugargrdarun2386No ratings yet

- Huber - Rotamat Pro Ue Ro enDocument16 pagesHuber - Rotamat Pro Ue Ro enlalo_2788No ratings yet

- Micronization of Active Pharmaceutical Ingredients (API) From R&D To The Production ScaleDocument1 pageMicronization of Active Pharmaceutical Ingredients (API) From R&D To The Production ScalesandragiaNo ratings yet

- Vibrating Screen DesignDocument12 pagesVibrating Screen DesignAinur Rohman100% (2)

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeNo ratings yet

- Linearschwingsieb enDocument12 pagesLinearschwingsieb enBrunoNo ratings yet

- Vibroscreen BrochureDocument12 pagesVibroscreen BrochureVarun MalhotraNo ratings yet

- Preliminary Treatment Process of Waste WaDocument9 pagesPreliminary Treatment Process of Waste WaArjun MulluNo ratings yet

- WWTP Chap 5 (p28-41) - Mech PurificationDocument14 pagesWWTP Chap 5 (p28-41) - Mech PurificationKaustav PatnaikNo ratings yet

- High-Frequency Vibrating ScreensDocument9 pagesHigh-Frequency Vibrating ScreensBayer Mitrovic100% (1)

- ScreeningDocument3 pagesScreeningPratik BansalNo ratings yet

- Lec No.5 Screening RevDocument11 pagesLec No.5 Screening Revnoel50% (2)

- CDE ProductsDocument5 pagesCDE ProductsFiras MaitigNo ratings yet

- DPF Oscillating ScreenDocument5 pagesDPF Oscillating ScreenolivefaNo ratings yet

- ScreeningDocument30 pagesScreeningPatricia de Leon100% (2)

- Máquina Moer Alumina PDFDocument36 pagesMáquina Moer Alumina PDFDulce GabrielNo ratings yet

- Cyclotec-Brochure-pdfDocument2 pagesCyclotec-Brochure-pdfFranchii HubillaNo ratings yet

- Design & Selection Criteria For StrainersDocument4 pagesDesign & Selection Criteria For StrainersKamal ChokshiNo ratings yet

- Recycling - Waste - Screen - Eng - 09 10Document2 pagesRecycling - Waste - Screen - Eng - 09 10Ziggy GregoryNo ratings yet

- Tailor Made Screening Technology For Different Screening Tasks in The Phosphate IndustryDocument6 pagesTailor Made Screening Technology For Different Screening Tasks in The Phosphate IndustryJavier Alejandro RodriguezNo ratings yet

- Jordy Maquilan TERDocument18 pagesJordy Maquilan TERHanah Kryss CastreNo ratings yet

- Paper Screen WireDocument7 pagesPaper Screen Wirexiaochi1989No ratings yet

- ScreeningDocument30 pagesScreeningVishnu RajeswaranNo ratings yet

- Sweepers CatalogDocument56 pagesSweepers CatalogNewVersion_FacilityManagementNo ratings yet

- Vibrating Screen Experimental ManualDocument16 pagesVibrating Screen Experimental ManualShoaib Pathan50% (2)

- Evisceration UKDocument16 pagesEvisceration UKHelton OliveiraNo ratings yet

- CornWetMilling BrochureDocument8 pagesCornWetMilling BrochureAndrea HernandezNo ratings yet

- Screen EquipmentDocument22 pagesScreen EquipmentmutiNo ratings yet

- Dip PDFDocument27 pagesDip PDFolenin64No ratings yet

- Bar Screen Chamber: 1.1 FunctionDocument2 pagesBar Screen Chamber: 1.1 Functionsatria hidayatNo ratings yet

- SA BuhlerDocument6 pagesSA BuhlerAndreea BenteaNo ratings yet

- REMU XO CrossoverBucketDocument6 pagesREMU XO CrossoverBucketScott GuimondNo ratings yet

- Bar Screening Environmental EngineeringDocument11 pagesBar Screening Environmental EngineeringRajat Kushwaha100% (1)

- Intake Screens For Cooling and Heating Coils: DurhamDocument8 pagesIntake Screens For Cooling and Heating Coils: DurhamDony RamdhaniNo ratings yet

- Milliken Maintenance InstructionDocument7 pagesMilliken Maintenance InstructionM_VILANo ratings yet

- Industrial Screening: Rajan Kumar MISHRA (2019UGMM005) Anshuman Mishra (2019ugmm037) KOTALLA VINAY (2019UGMM089)Document26 pagesIndustrial Screening: Rajan Kumar MISHRA (2019UGMM005) Anshuman Mishra (2019ugmm037) KOTALLA VINAY (2019UGMM089)Anshuman MishraNo ratings yet

- REMU ScreeningBucketDocument12 pagesREMU ScreeningBucketScott GuimondNo ratings yet

- Screening Jae K. (Jim) Park, Professor - PPT Video Online DownloadDocument12 pagesScreening Jae K. (Jim) Park, Professor - PPT Video Online Downloadmimoun nbennaceurNo ratings yet

- ScreeningDocument16 pagesScreeninganthony ijigaNo ratings yet

- Preliminary TreatmentDocument18 pagesPreliminary TreatmentLaurensius MarcellNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- CSD Rise Ultra Wrap ManualDocument36 pagesCSD Rise Ultra Wrap ManualestramilsolutionNo ratings yet

- 973-0014-1 ALLIS-CHALMERS 3500 MK2 Engine Drive & Optional Equipment Parts Manual (09-1974)Document44 pages973-0014-1 ALLIS-CHALMERS 3500 MK2 Engine Drive & Optional Equipment Parts Manual (09-1974)estramilsolutionNo ratings yet

- World Famous Tiles Recycled in World Famous VSI - MetsoDocument4 pagesWorld Famous Tiles Recycled in World Famous VSI - MetsoestramilsolutionNo ratings yet

- Metal Detectors MA 3000Document4 pagesMetal Detectors MA 3000estramilsolution100% (1)

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDocument6 pagesTerex Simplicity Vibrating Feeders: Terex Minerals Processing Systemsestramilsolution100% (1)

- VSI Crushers-2010-HistoryBuildup PhotosDocument76 pagesVSI Crushers-2010-HistoryBuildup PhotosestramilsolutionNo ratings yet

- Conceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsDocument221 pagesConceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsestramilsolutionNo ratings yet

- ManganesDocument118 pagesManganesestramilsolutionNo ratings yet

- Alimentateur PDFDocument4 pagesAlimentateur PDFestramilsolutionNo ratings yet

- ExtraDocument1 pageExtraestramilsolutionNo ratings yet

- Vltraflo Vibrating Feeders & ScreenDocument4 pagesVltraflo Vibrating Feeders & ScreenestramilsolutionNo ratings yet

- NEW ConesGyraRollDocument4 pagesNEW ConesGyraRollestramilsolutionNo ratings yet

- Us 5540394Document10 pagesUs 5540394estramilsolutionNo ratings yet

- Rotex Brochure PDFDocument4 pagesRotex Brochure PDFestramilsolutionNo ratings yet

- Chapter1 10 PDFDocument84 pagesChapter1 10 PDFestramilsolutionNo ratings yet

- Chapter1 10 PDFDocument84 pagesChapter1 10 PDFestramilsolutionNo ratings yet

- 39 ConeCrushersDocument8 pages39 ConeCrushersestramilsolutionNo ratings yet

- Biobaler LP 2014Document124 pagesBiobaler LP 2014estramilsolutionNo ratings yet

- LT3387 Loctite Nordback Backing MaterialsDocument4 pagesLT3387 Loctite Nordback Backing MaterialsestramilsolutionNo ratings yet

- EMMA User Guide PDFDocument33 pagesEMMA User Guide PDFKarnalPreethNo ratings yet

- Sspc-Ab 1 PDF PDFDocument5 pagesSspc-Ab 1 PDF PDFLetth Dur'No ratings yet

- Base Course AggregateDocument15 pagesBase Course AggregateSallam MohammedNo ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualDocument5 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualZaffira RahmanNo ratings yet

- As 1141.11.2-2008 Methods For Sampling and Testing Aggregates Particle Size Distribution For Vision Sizing SyDocument2 pagesAs 1141.11.2-2008 Methods For Sampling and Testing Aggregates Particle Size Distribution For Vision Sizing SySAI Global - APACNo ratings yet

- Lesson 3.4Document7 pagesLesson 3.4MitzlNo ratings yet

- Particulate Matter in InjectionDocument4 pagesParticulate Matter in InjectionSimona Florina PrecupNo ratings yet

- Sorel Cement Paper-3Document52 pagesSorel Cement Paper-3ahmetsadry1No ratings yet

- Particle Counter CalibrationDocument9 pagesParticle Counter Calibrationdavethebox100% (1)

- The Gully Pot As A Physical, Chemical and Biological ReactorDocument10 pagesThe Gully Pot As A Physical, Chemical and Biological ReactorMohammad Mehdi NorooziNo ratings yet

- Experiment 3Document6 pagesExperiment 3SHAFIKANOR366150% (2)

- Anexo 5.4 Astm d5092Document16 pagesAnexo 5.4 Astm d5092marvin060517No ratings yet

- C92-95 (Reapproved 2015) PDFDocument4 pagesC92-95 (Reapproved 2015) PDFAbdiz Engineering INCNo ratings yet

- Paper Avizo PSDDocument14 pagesPaper Avizo PSDYago PinheiroNo ratings yet

- 2.9.31. Particle Size Analysis by Laser Light Diffraction 20931eDocument4 pages2.9.31. Particle Size Analysis by Laser Light Diffraction 20931eAna Maria100% (1)

- Index 9th Edition PheurDocument34 pagesIndex 9th Edition Pheurpepilloelgrillo50% (2)

- As 4816.1-2002 Determination of Particle Size Distribution by Gravitational Liquid Sedimentation Methods GeneDocument8 pagesAs 4816.1-2002 Determination of Particle Size Distribution by Gravitational Liquid Sedimentation Methods GeneSAI Global - APACNo ratings yet

- PowderDocument62 pagesPowderJinan Muhammed Muhsin AlMousawy - جنان محمد محسن طاهر الموسويNo ratings yet

- Muscovite Grinding and DelaminatingDocument4 pagesMuscovite Grinding and DelaminatingRosielxNo ratings yet

- GRanulatorDocument14 pagesGRanulatormigelNo ratings yet

- SSPC Ab 1Document5 pagesSSPC Ab 1anoopkumarNo ratings yet

- Building Materials Lab ManualDocument21 pagesBuilding Materials Lab Manualapi-348488925100% (3)

- Application of Laser Particle Size System in Pesticide IndustryDocument5 pagesApplication of Laser Particle Size System in Pesticide IndustryRuby AdityoNo ratings yet

- Sieve Analysis Procedure ForDocument2 pagesSieve Analysis Procedure ForzeontitanNo ratings yet

- Unit-I-Aggregate GradingDocument22 pagesUnit-I-Aggregate GradingashoknrNo ratings yet

- Spiral Jet MillDocument8 pagesSpiral Jet MillĐức Linh100% (1)

- Sieve Analysis - An ExperimentDocument7 pagesSieve Analysis - An ExperimentamjadakramNo ratings yet

- SieveanalysisDocument2 pagesSieveanalysisBeverly PacerNo ratings yet

- Kollidon-Cl Technical InformationDocument13 pagesKollidon-Cl Technical InformationRockstarNo ratings yet