Professional Documents

Culture Documents

Terrin Polyols For High Resilience Polyurethane Foam

Terrin Polyols For High Resilience Polyurethane Foam

Uploaded by

8612106535Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Terrin Polyols For High Resilience Polyurethane Foam

Terrin Polyols For High Resilience Polyurethane Foam

Uploaded by

8612106535Copyright:

Available Formats

Technical Data Sheet

INVISTA TERRIN Polyols

Cost-Effective Alternative to Conventional Polyether and Polyester Polyols

Introduction TERRIN polyols can be used in lieu of or in combination with

conventional polyether or polyester polyols to formulate a variety

of polyurethane products designed to be soft and flexibleor hard

and stiff. These versatile, aliphatic, polyester polyols can be used in

applications ranging from viscoelastic foam to spray coatings and

adhesives to elastomeric resins. TERRIN Polyols:

Are cost competitive in comparison to conventional polyols

Contain a minimum of 50% recycled or renewable1 content

Have similar hydroxyl values to castor oil, and can be

substituted on a nearly equal weight basis

Are REACH and TSCA compliant

In addition, TERRIN polyols are an easily handled, low-viscosity

liquid at room temperature. TERRIN product offerings

especially 168 and 168Gremain pourable liquids at -15C/5F and

below2. TERRIN polyols do not crystallize and exhibit Tg in a

range of approximately -60C to -75C.

Application High-Resilience Polyurethane Foam

This This Technical Data Sheet is intended to illustrate how TERRIN polyols can be used in

high-resilience (HR) polyurethane foam. HR foams are typically open-cell, flexible foams

with relatively high resilience and rapid post-deformation recovery compared to low-

resilience or viscoelastic foams. The formulations herein are not optimized for any specific

application and arent intended to cover the entire range of possibilities but are meant to

provide the experienced polyurethane formulator with ideas, performance trends, and

starting points for HR foam formulations. The information set forth herein is furnished free

of charge and is based on technical data that INVISTA believes to be reliable, provided that

INVISTA makes no representation or warranty as to the completeness or accuracy thereof.

It is intended for use by persons having technical skill, at their own discretion and risk, who

will make their own determination as to its suitability for their purposes prior to use. As with

any material, evaluation of any compound under end-use conditions prior to specification is

essential. Nothing herein is to be taken as a license to operate under or a recommendation

to infringe any patents. In no event will INVISTA be responsible for damages of any nature

whatsoever resulting from the use of or reliance upon the information contained herein or

the product to which the information refers.Highlights of the results are summarized below,

followed by full details of the formulations, testing and complete tabulated results.

1

As defined by ISO 14021, Section 7.8; preliminary estimate based on small-scale production.

2

Patents pending; consult the SDS for additional physical-chemical, safety and health information July, 2015

Features TERRIN 170 offers the polyurethane (PU) foam formulator several

potential benefits when partially substituted for conventional

polyols in high-resilience polyurethane foam. Benefits observed in

lab-scale tests include:

Increased strength and load-bearing capability

100% Renewable and recycled content1

Potential to substitute for or use in combination with graft

polyols

Potential to reduce cost

Similar reactivity to conventional polyols

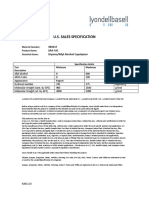

Tear strength Tensile strength 50% CFD

120%

100%

Increase vs base formulation

80%

60%

40%

20%

0%

-20%

20% graft 10% TERRIN 20% TERRIN 30% TERRIN

polyol 170 170 170

Figure 1: Comparison of high-resilience foams made using graft polyol or

TERRIN 170 to the base formulation with no graft or TERRIN polyol (complete

test data in Table).

Results Strength and load-bearing properties

One main benefit from TERRIN 170 in HR foams is increased

strength and load-bearing capability. In both free-rise and molded

foams, tensile strength, tear resistance, and compression force

deflection (CFD) values increased with addition of TERRIN 170

polyol in formulations with or without graft polyol (Figure 1). As

expected, the reference foam with 20% graft polyol had higher

tear strength and CFD than the reference foam without graft

polyol. However, foams made using 10% and higher amounts of

TERRIN 170 polyol prepared without a graft polyol exhibited

tensile strength, tear resistance, and CFD values comparable or

higher than the reference foam prepared with 20% graft polyol.

These observations indicate that TERRIN 170 can improve

mechanical strength and load-bearing properties of HR foams and

have potential to replace graft polyols for this purpose.

Reactivity

Observations of reactivity indicate that TERRIN 170 can be

incorporated into HR foams with little or no change in catalyst

package and that the system responds as expected when catalyst

changes are made. As can be seen from the free-rise foam cream,

gel, and rise times in Table 4, addition of TERRIN 170 had only

small effects on reactivity and density of foams without graft

polyol. Density of foams containing graft polyol and 15 or 20%

TERRIN 170 was higher than desired, but was easily adjusted

back to the desired range by a small increase in diethanolamine,

which is an expected response to that catalyst change. No issues

were encountered in processing molded foams.

Burn Rate

For foams without graft polyol, the results in Table 4 indicate a

trend of decreasing burn rate with increasing TERRIN 170

content. All foams containing graft polyol were self-extinguishing

in the burn rate test.

Other Properties

Addition of increasing amounts of TERRIN 170 polyol reveals

trends of decreasing resilience, increasing hysteresis, and

increasing wet and dry compression set. However, resilience of

foams prepared with 20% TERRIN polyol without graft polyol

was still 55%, the minimum requirement for HR foam according to

ASTM D 3770-91. Molded foams with 10% TERRIN 170 and no

graft polyol exhibited hysteresis loss of 31%, which meets

requirements of the Chrysler Material Standard for Type IV seating

foam.2 Foams prepared with 10% TERRIN 170 polyol meet the

wet compression set requirements for Type III and Type IV and

those prepared with up to 25% TERRIN 170 polyol meet the

requirements for Type IV seating foam of the Chrysler Material

Standard.

As noted earlier, the formulations tested herein were not

optimized nor targeted for any particular application. TERRIN

polyols provide the formulator with cost effective alternatives to

consider when optimizing a HR foam formulation to meet a

balance of performance criteria while minimizing cost.

Preparation A model high-resilience foam (HR foam) formulation based on

toluene diisocyanate (TDI) was used to evaluate performance of

TERRIN 170 polyol when substituted for polyether polyols in free-

rise or molded HR foam. TERRIN 170 was also evaluated in

comparison to and in combination with graft polyol as a means to

improve strength and load-bearing properties of HR foam.

Polyols used in the formulations are described in Table 1, other

materials in Table 2, formulations in Table 3, and foam properties

in Table 4. As TERRIN 170 polyol was substituted into the base

formulation, the two conventional polyether polyols were removed

equally and proportionately to maintain constant weight of polyol.

All foams used 3.6 parts by weight (pbw) water per 100 pbw

polyols. Other ingredients including catalysts were held constant

except that the amount of diethanolamine was increased in two

formulations with graft polyol to maintain density of the resulting

foam close to the reference foam (formulations TERRIN-NC-15DE

and TERRIN-NC-20DE). Isocyanate was adjusted to maintain NCO

index at 90.

Table 1: Polyols

Polyol Description Supplier Equiv. wt.

TERRIN 170 Aliphatic polyester polyol INVISTA 348.8

POLY-G 85-29 Ethylene oxide-capped polyether triol Monument 2141

VORANOL Catalytically active, high-functionality,

Dow 1753

VORACTIV 6340 Ethylene oxide-capped polyether polyol

SPECFLEX NC 701 Grafted polyether polyol Dow 2244

LUMULSE POE 26 Ethoxylated glycerin, cell-opening polyol Lambent Technologies 416.1

POLY-G is a registered trademark of Monument Chemical, LUMULSE is a registered trademark of Lambent

Technologies. TEGOSTAB is a registered trademark of Evonik Industries. DABCO is a registered trademark of

Air Products and Chemicals. VORANOL, VORACTIV, SPECFLEX, and LUPRANATE are trademarks of Dow

Chemical Company.

Table 2: Other materials

Other materials Description Supplier Equiv. wt.

TEGOSTAB B4690 Polyether/Silicone Oil Mix - Surfactant Evonik 1335.7

Triethylenediamine in dipropylene glycol -

DABCO 33LV Air Products

Catalyst 105

Diethanolamine with 15% water - Catalyst,

Diethanolamine LFG 85% Huntsman

cross-linker 35.04

LUPRANATE TD80 Toluene diisocyanate, 48.0% NCO BASF 87.5

All foam preparations reported in Tables 3 and 4 were scaled to

use a total of ~200 g polyol components. To prepare a foam, the

polyols and other non-isocyanate components were combined,

isocyanate added, and the formulation mixed for 5 or 7 seconds

using a high-torque mixer. The mixture was transferred to an open

polyethylene container and allowed to free rise or into a preheated

aluminum mold (12x12x2 inches dimensions, preheated to 65C).

For free-rise foams, cream time, gel time, and rise time were noted

then the foams were placed into a preheated 75C air-circulating

oven for 30 minutes to complete their cure. In the case of molded

foams, de-molding time was 270 seconds.

Foam Foams were aged for at least one week at ambient room

Testing conditions before testing. Full evaluation was carried out on

molded foams. The following properties were measured according

to ASTM D 3574-08:

Foam density (Test A)

Resilience by ball rebound (Test H)

Tensile strength at break (Test E)

Elongation at break (Test E)

Tear strength (Test F)

Compression force deflection (CFD; Test C)

Hysteresis (Procedure B CFD hysteresis loss)

Dry constant deflection compression set (Test D)

Wet constant deflection compression set (Test D and Wet

heat aging, Test L)

Tensile strength and elongation after dry heat aging

(Modified Heat Aging, Test K)

Horizontal burn rate was measured using an in-house method

based on ASTM D 5132-04. Dripping was observed in all cases.

Note that this test is for comparative purposes only within this

study. Results should not be compared to results from other

studies or results using different methods. Results of the above

tests are given in Table 4.

Table 3: High-Resilience Foam Formulations

TERRIN-NC-20DE

TERRIN-NC-15DE

REFERENCE-NC

TERRIN-NC-20

TERRIN-NC-10

TERRIN-NC-15

TERRIN-NC-5

REFERENCE

TERRIN-40

TERRIN-50

TERRIN-20

TERRIN-30

TERRIN-25

TERRIN-10

TERRIN-15

TERRIN-5

Sample designation

% Graft polyol on total

0 0 0 0 0 0 0 0 0 20 20 20 20 20 20 20

polyols

% TERRIN 170 polyol on

0 5 10 15 20 25 30 40 50 0 5 10 15 15 20 20

total polyol

% TERRIN 170 polyol on

0 3.3 6.6 9.9 13.1 16.3 19.4 25.6 31.6 0 3.3 6.6 9.9 9.9 13.1 13.1

total formulation

Polyol part

POLY-G 85-29 polyol 48.5 46 43.5 41 38.5 36 33.5 28.5 23.5 38.8 36.3 33.8 28.8 28.8 28.8 23.8

VORANOL-VORACTIV

48.5 46 43.5 41 38.5 36 33.5 28.5 23.5 38.8 36.3 33.8 33.8 33.8 28.8 33.8

6340 polyol

SPECFLEX NC-701

0 0 0 0 0 0 0 0 0 19.4 19.4 19.4 19.4 19.4 19.4 19.4

polyol

TERRIN 170 polyol 0 5 10 15 20 25 30 40 50 - 5 10 15 15 20 20

LUMULSE POE 26 cell

3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3

opener

Water, surfactant, catalyst

Water added 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6 3.6

TEGOSTAB B 4690 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

DABCO 33LV 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Diethanolamine 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 2 1.5 2

Residual water 0.237 0.237 0.236 0.235 0.234 0.234 0.233 0.231 0.23 0.234 0.233 0.233 0.232 0.306 0.231 0.306

Isocyanate part

LUPRANATE TD80 41.8 42.72 43.64 44.56 45.47 46.39 47.31 49.15 50.98 41.66 42.58 43.5 44.44 46.4 45.34 46.98

Table 4: Reaction profiles and properties of free-rise and molded high-resilience foams

TERRIN-NC-20DE

TERRIN-NC-15DE

REFERENCE-NC

TERRIN-NC-20

TERRIN-NC-10

TERRIN-NC-15

TERRIN-NC-5

REFERENCE

TERRIN-40

TERRIN-50

TERRIN-20

TERRIN-30

TERRIN-25

TERRIN-10

TERRIN-15

TERRIN-5

Sample designation

% Graft polyol on total polyols 0 0 0 0 0 0 0 0 0 20 20 20 20 20 20 20

% TERRIN 170 on total polyol 0 5 10 15 20 25 30 40 50 0 5 10 15 15 20 20

Free-rise foams - reactivity and properties

Cream time, sec. 9 9 9 9 9 9 9 8 8 9 9 9 8 8 8 8

Gel time, sec. 34 38 37 36 34 34 33 28 25 34 34 33 31 25 30 23

Off-gassing time - - 41 38 39 36

Rise time, sec. 52 52 51 51 49 47 47 41 36 44 43 43 - - - -

Free-rise density, pcf 1.79 1.77 1.73 1.76 1.83 1.92 1.92 2.25 2.27 1.89 1.72 1.93 2.21 1.94 2.56 2.27

Resilience via Ball Rebound, % 59 58 57 55 51 46 42 35 28 61 57 53 - 47 - 45

Molded foams - properties

Core density, pcf 2.95 3.12 2.94 3.11 2.95 3.07 2.92 2.88 3.05 2.77 2.9 2.92 - 3.34 - 2.99

Tensile strength at break, psi 12.5 11.1 14.8 15.4 18.3 18.1 25.1 25.7 28.0 11.7 19.3 16.7 - 17.3 - 21.4

Elongation at break, % 107 90 97 93 102 78 93 83 76 82 97 88 - 63 - 73

Tensile after dry heat aging, psi 20.1 14.4 18.6 18.9 20.5 22.3 21.3 25.3 21.7 19.3 20.7 21.0 - 18.8 - 20.3

Elongation after dry heat

186 125 144 128 124 102 93 84 58 124 119 95 - 74 - 80

aging, %

Tear strength, Die C, pli 5.77 5.53 6.92 6.08 7.21 8.97 9.65 10.24 10.95 6.52 7.43 7.72 - 7.27 - 9.01

Compression force deflection (CFD)

At 25% deflection, psi 0.4 0.45 0.46 0.55 0.64 0.85 0.9 1.15 1.58 0.48 0.63 0.65 - 0.89 - 0.98

At 50% deflection, psi 0.57 0.64 0.67 0.79 0.9 1.12 1.23 1.61 2.45 0.7 0.89 0.91 - 1.25 - 1.42

At 65% deflection, psi 0.85 0.95 1.02 1.18 1.37 1.63 1.9 2.37 3.76 1.04 1.29 1.33 - 1.99 - 2.26

Dry compression set, % 3.8 4.6 5.6 11.6 13.4 15.3 18.7 30.7 38.2 6.3 6.7 10.9 - 11.8 - 14.2

Wet compression set, % 14.7 15.5 19 20.2 20.6 21.5 31 39.6 45.1 12 16.2 22.2 - 24.9 - 27.1

Resilience via Ball Rebound, % 64 61 60 57 55 50 45 40 35 66 62 57 - 55 - 50

Hysteresis loss, % 23 29 31 48 48 60 68 73 67 30 56 69 - 82 - 87

Burn rate, mm/minute 73.1 70 68.3 67 62.9 58.7 56.8 55.4 53.9 self extinguished

www.TERRIN.INVISTA.com

For samples and further information please contact:

1.800.231.0998 | TERRIN@INVISTA.com

This Product Data Sheet contains selected information about a specific INVISTA product, or group of

products, and particular uses of the same. It relates only to the identified product and any identified uses,

and is based on information available as of the date hereof. Additional information may be needed to

evaluate other uses of the product, including use of the product in combination with any materials or in any

processes other than those specifically referenced. Information provided herein with respect to any hazards

that may be associated with the product is not meant to suggest that use of the product in a given

application will necessarily result in any exposure or risk to workers or the general public. This product data

sheet does not contain a complete statement of, and does not constitute a representation, warranty or

guaranty with regard to, a product's characteristics, uses, QUALITY, merchantability, FITNESS FOR A

Particular PURPOSE, or the suitability, safety, efficacy, hazards or health effects of the product, whether used

singularly or in combination with any other product, EXCEPT TO THE EXTENT REQUIRED BY THE

RELEVANT LAW AND REGULATIONS. Purchasers and users of the product are responsible for determining

that the product is suitable for the intended use and that their workers and the general public are advised of

any risks resulting from such use. Nothing contained in this Product Data Sheet shall be construed to modify

any of the commercial terms pursuant to which the product was sold by INVISTA including, but not limited

to, terms and conditions addressing each party's respective rights and obligations with regard to warranties,

remedies and indemnification.

If purchasers and users believe or have reason to believe that the Product Data Sheet or other information

provided to them by INVISTA is inaccurate or in any way insufficient for any purpose, they should

immediately notify INVISTA of the same, and of the basis for their belief (for example, studies, data, reports

of incidents, etc.) so that INVISTA can determine whether modification or supplementation of the Product

Data Sheet, or other measures, are appropriate. Failure of purchasers and users to timely provide such

notice shall be deemed a waiver by purchasers and users of any and all claims, demands or causes of action,

including causes of action based on an alleged failure to warn, for personal injury or damage to the

environment or property arising from or attributable to the use of product.

This disclaimer shall be effective to the extent allowed by law. Should any provision be deemed to be

ineffective or unenforceable, that provision shall be deemed severed from the disclaimer and the remaining

provisions shall continue to have full force and effect.

You might also like

- Informed Consent TemplateDocument3 pagesInformed Consent TemplateJan Diel100% (2)

- Polymeric Foams Structure-Property-Performance: A Design GuideFrom EverandPolymeric Foams Structure-Property-Performance: A Design GuideRating: 5 out of 5 stars5/5 (2)

- 14003076us BrochureDocument8 pages14003076us BrochureSundarNo ratings yet

- Vibrathane CompositeDocument10 pagesVibrathane CompositekprsannaNo ratings yet

- Polyurea Spray PDFDocument9 pagesPolyurea Spray PDFSesha GiriNo ratings yet

- CessnaCaravanII F406 POH 1986Document692 pagesCessnaCaravanII F406 POH 1986Eric Francis100% (2)

- SNP QuizDocument4 pagesSNP QuizPrashant Pandey100% (1)

- Smart CitiesDocument2 pagesSmart CitiestlidiaNo ratings yet

- TERRIN Polyols - Viscoelastic FoamsDocument8 pagesTERRIN Polyols - Viscoelastic FoamsPriyanka KhemkaNo ratings yet

- H110MADocument1 pageH110MAGeorgiana CiureaNo ratings yet

- 巴斯夫抗氧剂irganox 5057产品技术资料 宝旭化工Document2 pages巴斯夫抗氧剂irganox 5057产品技术资料 宝旭化工naziri2008No ratings yet

- Irganox 1010: Industrial CoatingsDocument3 pagesIrganox 1010: Industrial CoatingsPrototypeNo ratings yet

- TI EVK 1001e Irganox 1010 Sept2021Document3 pagesTI EVK 1001e Irganox 1010 Sept2021Flash GordonNo ratings yet

- Bentone 38 - TDS - eDocument2 pagesBentone 38 - TDS - eDũng ĐỗNo ratings yet

- XR 1300 English - Ed April - 2020Document2 pagesXR 1300 English - Ed April - 2020Chamakhi AmeurNo ratings yet

- PerstorpDocument8 pagesPerstorpSundarNo ratings yet

- Production of Car Seat Cushion Using Palm OilDocument25 pagesProduction of Car Seat Cushion Using Palm OilSeiswaran PandeinNo ratings yet

- Polyisocyanurate vs. Polyurethane InsulationDocument2 pagesPolyisocyanurate vs. Polyurethane Insulationhamza awanNo ratings yet

- Pura 13161W: Shoe Sole Release AgentDocument1 pagePura 13161W: Shoe Sole Release Agentherry prasetyo0% (1)

- Ficha Tecnica NPT QUICK FLASH ADDITIVE M00009Document1 pageFicha Tecnica NPT QUICK FLASH ADDITIVE M00009Stéphanie BaltazarNo ratings yet

- MB400Document2 pagesMB400Omid LarkiNo ratings yet

- TI EVK 1018e Irgafos 168 Sept2021Document3 pagesTI EVK 1018e Irgafos 168 Sept2021Flash GordonNo ratings yet

- Amt Brochure enDocument12 pagesAmt Brochure enIrfan GaakNo ratings yet

- Duratone eDocument1 pageDuratone ejangriNo ratings yet

- TDS DR Bio 7211 Compostable Filler FilmsDocument3 pagesTDS DR Bio 7211 Compostable Filler FilmsMukul SareenNo ratings yet

- Epon 1007f EpoxyDocument3 pagesEpon 1007f EpoxyOnesany TecnologiasNo ratings yet

- Aula 21 - Irganox 1010Document2 pagesAula 21 - Irganox 1010Kaiomax2000100% (1)

- بخارشوی فرش پاک کنDocument2 pagesبخارشوی فرش پاک کنrezaNo ratings yet

- CP-7540 (Alternate AP-13)Document1 pageCP-7540 (Alternate AP-13)Muhammad AHSAN ISHAQNo ratings yet

- C100 C100H Sulfuric Acid RegenerationDocument28 pagesC100 C100H Sulfuric Acid Regenerationmiladsalmani72No ratings yet

- TDS Irganox B 215Document2 pagesTDS Irganox B 215Jorge David Rojas CardenasNo ratings yet

- Duratone eDocument1 pageDuratone eandreinalicNo ratings yet

- Tinuvin 400 October 2019 R4 IC PPDocument4 pagesTinuvin 400 October 2019 R4 IC PPEmilio HipolaNo ratings yet

- Lineplus PF 150-P - TDSDocument2 pagesLineplus PF 150-P - TDSSAURAVENDRA TOMARNo ratings yet

- Poly WaxDocument4 pagesPoly WaxBharathi RajaNo ratings yet

- Fixapret Resin F-ECO Plus: Technical InformationDocument5 pagesFixapret Resin F-ECO Plus: Technical Informationali4300136No ratings yet

- 6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenDocument4 pages6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenAmeya SavnalNo ratings yet

- TDS Irgafos-168 eDocument2 pagesTDS Irgafos-168 eSteven AhnNo ratings yet

- Basf PolyTHFDocument12 pagesBasf PolyTHFadrianrdeitosNo ratings yet

- SC2045Document4 pagesSC2045A MahmoodNo ratings yet

- Irganox 1076 TdsDocument2 pagesIrganox 1076 TdsMohammad Doost MohammadiNo ratings yet

- DuPont Teflon AF Processing GuideDocument2 pagesDuPont Teflon AF Processing GuidewuaiyouNo ratings yet

- Investor Update - CGS-CIMB Bali Conference - 28 Jun 19Document30 pagesInvestor Update - CGS-CIMB Bali Conference - 28 Jun 19Sandy TyasNo ratings yet

- Desmocoll 540Document2 pagesDesmocoll 540lobocerna100% (3)

- Leave in Conditioner in SprayDocument2 pagesLeave in Conditioner in SprayHoracio GutierrezNo ratings yet

- PETROSTEP KB 1303 BrochureDocument2 pagesPETROSTEP KB 1303 BrochureCesar BarretoNo ratings yet

- 360 PDFDocument2 pages360 PDFA MahmoodNo ratings yet

- Bote 2021Document15 pagesBote 2021ferit.ay.1967No ratings yet

- Dow Hdpe ResinDocument7 pagesDow Hdpe ResinBudyawan SaputraNo ratings yet

- AMBERLITE™ 62i Inert ResinDocument3 pagesAMBERLITE™ 62i Inert ResinFabio Pereira de CarvalhoNo ratings yet

- Formulating Polyurea Coatings and CaulksDocument5 pagesFormulating Polyurea Coatings and CaulksAhmed TahaNo ratings yet

- Comparison Table For LLINsDocument1 pageComparison Table For LLINsJenny CarrilloNo ratings yet

- Product Data Sheet: Dispersion Formulation ScienceDocument3 pagesProduct Data Sheet: Dispersion Formulation ScienceMukesh Kumar VyasNo ratings yet

- Tds DR Bio 7212 Pla FillerDocument3 pagesTds DR Bio 7212 Pla FillerMukul SareenNo ratings yet

- Productionof Flexible Polyurethane Foamusing Soya Bean Oiland Palm Kernel Oilas Surfactantand Polyol RespectivelyDocument10 pagesProductionof Flexible Polyurethane Foamusing Soya Bean Oiland Palm Kernel Oilas Surfactantand Polyol Respectivelysaver mendleevNo ratings yet

- TDS iPolyAid Additive-O 1031Document1 pageTDS iPolyAid Additive-O 1031Popular videos Pinkal Sparsh ShailajaNo ratings yet

- Pergut EDocument17 pagesPergut ECesar MartinezNo ratings yet

- Cetus PAO: Synthetic Air Compressor OilsDocument3 pagesCetus PAO: Synthetic Air Compressor OilsAymanSayedElantableeNo ratings yet

- TDS - Encor 2750 - 01-12Document2 pagesTDS - Encor 2750 - 01-12APEX SONNo ratings yet

- Foamquaity 11Document18 pagesFoamquaity 11MuthumaniNo ratings yet

- Tana Pur One: Soft and Flexible Self-Crosslinking Polyurethane To Upgrade The Quality of Your TextilesDocument4 pagesTana Pur One: Soft and Flexible Self-Crosslinking Polyurethane To Upgrade The Quality of Your TextilesLiu PengNo ratings yet

- TDS - Mergal K20 - 17-07-2014Document2 pagesTDS - Mergal K20 - 17-07-2014APEX SON100% (1)

- TPM - A Route to World Class Performance: A Route to World Class PerformanceFrom EverandTPM - A Route to World Class Performance: A Route to World Class PerformanceRating: 4 out of 5 stars4/5 (5)

- Acrylol SynthesisDocument2 pagesAcrylol Synthesis8612106535No ratings yet

- Surfactants Emulsion PolymersDocument2 pagesSurfactants Emulsion Polymers8612106535100% (2)

- Self-Adhesive Materials For Plastic Surfaces: Technical Info #7Document2 pagesSelf-Adhesive Materials For Plastic Surfaces: Technical Info #78612106535No ratings yet

- Phenolic Resins Specification: Condition ConditionDocument1 pagePhenolic Resins Specification: Condition Condition8612106535No ratings yet

- 15885Document1 page158858612106535No ratings yet

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document9 pagesEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)8612106535No ratings yet

- DAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and AdditivesDocument2 pagesDAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and Additives8612106535No ratings yet

- 1K Blocked Series BULLETIN PDFDocument1 page1K Blocked Series BULLETIN PDF8612106535No ratings yet

- Morpholine PDFDocument2 pagesMorpholine PDF8612106535No ratings yet

- Morpholine PDFDocument2 pagesMorpholine PDF8612106535No ratings yet

- EDTA Manganese Sodium (EDTA-MnNa2)Document2 pagesEDTA Manganese Sodium (EDTA-MnNa2)8612106535No ratings yet

- Desmocoll 400-1Document3 pagesDesmocoll 400-18612106535No ratings yet

- TDS SR238 2Document1 pageTDS SR238 28612106535No ratings yet

- 3D Formpress Technologie GB US PDFDocument2 pages3D Formpress Technologie GB US PDF8612106535No ratings yet

- Difference Ether Ester - 111010Document1 pageDifference Ether Ester - 1110108612106535No ratings yet

- EDTA Magnesium Sodium (EDTA-MgNa2)Document2 pagesEDTA Magnesium Sodium (EDTA-MgNa2)8612106535No ratings yet

- Sales Specification - US - 2Document1 pageSales Specification - US - 28612106535No ratings yet

- HI-THANE A-3310D: Technical InformationDocument1 pageHI-THANE A-3310D: Technical Information8612106535No ratings yet

- Information Security Management SystemDocument3 pagesInformation Security Management SystemShubham SarkarNo ratings yet

- DLC NLC Technical Requirements v3 0 Draft 2 Comment FormDocument10 pagesDLC NLC Technical Requirements v3 0 Draft 2 Comment Formholamundo123No ratings yet

- M5360 V2.20 DatasheetDocument2 pagesM5360 V2.20 DatasheetClayton MartinezNo ratings yet

- Routing SimulatorDocument69 pagesRouting SimulatorQuestionPapersTube67% (3)

- SDH - Ierarhie Digitala SincronaDocument3 pagesSDH - Ierarhie Digitala SincronaRata DanielNo ratings yet

- Cisco SG300Document586 pagesCisco SG300Jnix04No ratings yet

- Manual 3Document52 pagesManual 3josue patriotaNo ratings yet

- DMI FuctionDocument3 pagesDMI FuctiongnmadaviNo ratings yet

- 902, 906 & 908 Compact Wheel L PDFDocument12 pages902, 906 & 908 Compact Wheel L PDFKasidinNo ratings yet

- AscDocument13 pagesAscJessica WynnNo ratings yet

- Specifications of Whap HullDocument31 pagesSpecifications of Whap Hulltwin_bladeNo ratings yet

- ChangehistoryDocument33 pagesChangehistoryMondi ZeniNo ratings yet

- Exploring The Critical Success Factors Influencing BIM Level 2 Implementation in The UK Construction Industry The Case of SMEsDocument9 pagesExploring The Critical Success Factors Influencing BIM Level 2 Implementation in The UK Construction Industry The Case of SMEsAlice Margaret HargestNo ratings yet

- IOTDocument23 pagesIOTShendy Arief PrastyantoNo ratings yet

- 2020 07 16 07Document3 pages2020 07 16 07Akmal MaulanaNo ratings yet

- Warnings and CautionsDocument11 pagesWarnings and Cautionszbc zbc1234568No ratings yet

- Service Creation ProcedureDocument59 pagesService Creation Procedureangadkumar0% (1)

- FM 1635 Plastic Pipe and Fittings For Automatic Sprinkler Systems 2018Document54 pagesFM 1635 Plastic Pipe and Fittings For Automatic Sprinkler Systems 2018andyNo ratings yet

- BT7000 PartsDocument123 pagesBT7000 PartsPilaquinga DiegoNo ratings yet

- Dell Motherboard Scheme E5410Document89 pagesDell Motherboard Scheme E5410Maximiliano2Barac100% (1)

- Capability Maturity Model (CMM) For Software Development: Geir AmsjøDocument74 pagesCapability Maturity Model (CMM) For Software Development: Geir AmsjømicronzxNo ratings yet

- PortScanServiçosRede 1Document5 pagesPortScanServiçosRede 1DouglasNo ratings yet

- DUSTERDocument6 pagesDUSTERRajeshKumarNo ratings yet

- Dahua HDCVI DVR Users Manual V2 3-4-30!1!100Document100 pagesDahua HDCVI DVR Users Manual V2 3-4-30!1!100othmaneNo ratings yet

- Audit of IntangiblesDocument13 pagesAudit of IntangiblesJunhui WenNo ratings yet

- LennoxDocument32 pagesLennoxCharly ColumbNo ratings yet