Professional Documents

Culture Documents

Table

Table

Uploaded by

Anonymous iVQKBpXbTOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table

Table

Uploaded by

Anonymous iVQKBpXbTCopyright:

Available Formats

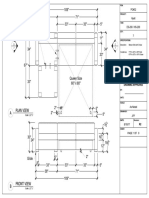

Low lines, an interesting surfboard shape and a

slight tilt to the end panel give this useful piece

character and grace.

The sturdy, unusual legs can be fabricated easily

from ordinary mild steel rod by any metal working

shop. This plan gives all the information required.

To take care of minor variations in angle and dimen-

sions, you probably will save yourself extra work by

having legs bent before beveling and drilling the

bottom shelf and cutting partition "C" to proper

height.

Paint legs with flat black enamel or in a color to

contrast with the shelves.

Cut, rabbet, dado and drill all parts as required.

Sand and fill exposed edges, and fit mating parts PARTS SCHEDULE

together. Glue and nail all joints. CODE NO. REQ"D SIZE PART IDENTIFICATION

Fasten end "D" to bottom shelf "A." Nail parti-

A 1 16"x44%" Bottom Shelf

tion "C" in slot, then support shelf "B" on a block

B 16"x32" Top Shelf

while attaching to "C." Some adjustment for length

of legs can be obtained by drilling blind holes under- c 7V."x14" Divider

D sv,"x 16" End

neath top shelf; plates can be threaded up or down

2 Sets 1f2" Diameter Wrought Iron Legs

a few turns for positive location.

2 Eo . 1"x21f2"xVs" Leg Plates

Install legs after finishing as recommended, making

sure the threaded ends of legs at open end of rack Miscellcneous-6d Finish Neils end Glue

are exactly vertical. 1" No. 8 R. H. Screws as required

48"

3" ---- -;,

____

-------

/ /

DRILL HOLES TO

RECEIVE LEGS

SIDE ELEVATION

1/2" BLACK-

IRON LEGS

END ELEVATION

NTERIOR A-D

.-/I

A B

c

D

LEG PLATES SCREWED 10

CUTTING DIAGRAM PLAN OF TOP UNDERSIDE OF TOP

17

You might also like

- Building The Wood Duck KayakDocument72 pagesBuilding The Wood Duck Kayaktallerbioarq100% (1)

- Heavy Duty Plank WorkbenchDocument7 pagesHeavy Duty Plank WorkbenchJeff DNo ratings yet

- Lumber Storage RackDocument7 pagesLumber Storage Rackorodz1No ratings yet

- 967 Fire Protection Essentials Quality Plan SampleDocument10 pages967 Fire Protection Essentials Quality Plan SampleOliver Reazon RueloNo ratings yet

- Heritage ConservationDocument33 pagesHeritage Conservationapi-386028814No ratings yet

- WS24830 - Heavy Duty Miter Saw StationDocument8 pagesWS24830 - Heavy Duty Miter Saw StationJasmine Vaaltyn100% (3)

- Pine Shelves PDFDocument3 pagesPine Shelves PDFFe TusNo ratings yet

- WoodPlans Online - Drill Press TableDocument6 pagesWoodPlans Online - Drill Press TableЧедомир Арнаут100% (1)

- Arca de NoeDocument12 pagesArca de NoeEduardo H. HernandezNo ratings yet

- RSteps and StairsDocument32 pagesRSteps and Stairspawanshrestha1No ratings yet

- Handcart - David Tresemer USA 1985Document10 pagesHandcart - David Tresemer USA 1985SPYDERSKILLNo ratings yet

- DrumsanderDocument7 pagesDrumsanderEssen Davis100% (1)

- Turning Radius Info: On Eighteen WheelersDocument3 pagesTurning Radius Info: On Eighteen WheelerssamNo ratings yet

- Redneck Golf PlanDocument7 pagesRedneck Golf PlanAndré SilvaNo ratings yet

- Wood Magazine - 3 in One Bed For All Ages Part 3Document5 pagesWood Magazine - 3 in One Bed For All Ages Part 3clnieto24No ratings yet

- Slab/Mat Curtailment - Column Strip: 'A' 'C' Top BarsDocument9 pagesSlab/Mat Curtailment - Column Strip: 'A' 'C' Top BarsHimang JainNo ratings yet

- Imagenes Producto Archivo L-sd180Document7 pagesImagenes Producto Archivo L-sd180Doble AlNo ratings yet

- Fire Hydrant DrawingDocument3 pagesFire Hydrant DrawingAshar HassanNo ratings yet

- Galva PWL Install 9 11 15Document6 pagesGalva PWL Install 9 11 15michaelNo ratings yet

- SeaHawk 11 15Document8 pagesSeaHawk 11 15pastronauta23No ratings yet

- Plan Bed Heirloom Arts and Crafts PDFDocument13 pagesPlan Bed Heirloom Arts and Crafts PDFSorin CraciunNo ratings yet

- ESCHandbook Chapter3 3.16Document7 pagesESCHandbook Chapter3 3.16Larry Wayne Sumpter, JrNo ratings yet

- SDW 151Document3 pagesSDW 151shineysuraj1No ratings yet

- Wood TrellisDocument3 pagesWood TrellisfrlefrleNo ratings yet

- 7419S12 Sample 2 PDFDocument7 pages7419S12 Sample 2 PDFJosia Irwan RastandiNo ratings yet

- 1994 V 01Document54 pages1994 V 01Ignacio Hiram M RoqueNo ratings yet

- FEMA Home Fallout Shelter (Plan A) H-12-A WWDocument8 pagesFEMA Home Fallout Shelter (Plan A) H-12-A WWapi-3708163No ratings yet

- Capcana RoiDocument6 pagesCapcana RoiJuly MorariuNo ratings yet

- Craft Woodworking - Router Table #2Document12 pagesCraft Woodworking - Router Table #2dandrade_213231100% (3)

- PM Aug 72 Hobby Work TableDocument2 pagesPM Aug 72 Hobby Work TableJimNo ratings yet

- Cornhole: Build A Regulation Size Cornhole Set and Start Perfecting Your GameDocument14 pagesCornhole: Build A Regulation Size Cornhole Set and Start Perfecting Your GameJason SayersNo ratings yet

- GratingDocument3 pagesGratingSubash SNo ratings yet

- Beam RevisedccDocument44 pagesBeam RevisedccHimang JainNo ratings yet

- Step 1: Select Shell Material: EX S-13-3 - C - 20-332 P N K - 01 - BSDocument17 pagesStep 1: Select Shell Material: EX S-13-3 - C - 20-332 P N K - 01 - BSJorge Ignacio Brito de la CruzNo ratings yet

- Dream Shed 2013 Shed Construction DrawingsDocument13 pagesDream Shed 2013 Shed Construction DrawingsvscribNo ratings yet

- Hatzalah of The CatskillsDocument12 pagesHatzalah of The CatskillsJohnStaCruzNo ratings yet

- Ground Floor Plan E-1: 3' ProjectionDocument1 pageGround Floor Plan E-1: 3' ProjectionHammad SalahuddinNo ratings yet

- Alum Box Culvert - Design GuideDocument17 pagesAlum Box Culvert - Design GuidemuhannedNo ratings yet

- WoodPlans Online - It's A KeeperDocument12 pagesWoodPlans Online - It's A KeeperЧедомир Арнаут100% (2)

- 1600 GalDocument1 page1600 GalZK KTNo ratings yet

- Glider Rocker Base PlansDocument3 pagesGlider Rocker Base Plansquique1967.ecNo ratings yet

- Picture BoxDocument3 pagesPicture BoxEmilian Baluta100% (1)

- R FencesDocument82 pagesR FencesArman Man100% (1)

- Arched Aurora NightstandDocument7 pagesArched Aurora NightstandRoberto LandaNo ratings yet

- Typical Deck EdgeDocument1 pageTypical Deck EdgeShane AndersonNo ratings yet

- GSWC STANDARD DRAWINGS 2016 (Final Version) - Part 2Document104 pagesGSWC STANDARD DRAWINGS 2016 (Final Version) - Part 2Hussein MohamedNo ratings yet

- DP 00478 1Document11 pagesDP 00478 1mariamNo ratings yet

- Plan Bed Heirloom Arts and CraftsDocument13 pagesPlan Bed Heirloom Arts and Craftspoimandres0% (1)

- Woodworking Plans - Compact Disc TowerDocument6 pagesWoodworking Plans - Compact Disc Tower_Godfather100% (1)

- Foundation Layout and Reinforcement Details: 16D@10" CC 16D@10" CC 16D@10" CCDocument3 pagesFoundation Layout and Reinforcement Details: 16D@10" CC 16D@10" CC 16D@10" CCkiranNo ratings yet

- Shop Drawings 1Document9 pagesShop Drawings 1Jay JarrahNo ratings yet

- Delta 12a 2-WayDocument28 pagesDelta 12a 2-WayTran Quoc DatNo ratings yet

- 20x40 ModelDocument1 page20x40 Modelyebexa3845No ratings yet

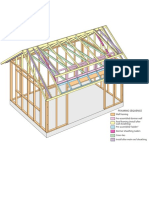

- Figure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingDocument13 pagesFigure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingMúsica viajera MX0% (1)

- Lemonade Stand Project Diagram RevDocument6 pagesLemonade Stand Project Diagram Revmel ChiffonNo ratings yet

- Figure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingDocument13 pagesFigure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingMúsica viajera MXNo ratings yet

- Piper J-3 CubDocument15 pagesPiper J-3 CubAviation/Space History Library100% (8)

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Inventing the American Guitar: The Pre-Civil War Innovations of C.F. Martin and His ContemporariesFrom EverandInventing the American Guitar: The Pre-Civil War Innovations of C.F. Martin and His ContemporariesNo ratings yet

- Pianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsFrom EverandPianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsRating: 5 out of 5 stars5/5 (2)

- The Maddest Idea: An Isaac Biddlecomb NovelFrom EverandThe Maddest Idea: An Isaac Biddlecomb NovelRating: 3.5 out of 5 stars3.5/5 (9)

- MindManager 15 User GuideDocument404 pagesMindManager 15 User GuideKent LysellNo ratings yet

- Pressman 7 CH 26Document28 pagesPressman 7 CH 26kyuuNo ratings yet

- 2 Ways To Find Out When A Partition Was Created in Windows - Digital CitizenDocument9 pages2 Ways To Find Out When A Partition Was Created in Windows - Digital CitizenSelvakumar RNo ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselsMarcelo Chaves RestrepoNo ratings yet

- Parquet AdhesivesDocument46 pagesParquet AdhesivesFernando Perez UrrutiaNo ratings yet

- FPGADocument33 pagesFPGAmuhammad100% (5)

- Aws Sap 2023 ProDocument2 pagesAws Sap 2023 Promario.ochoa.rNo ratings yet

- BORALEVI - Turkish Carpets in Italy XDocument45 pagesBORALEVI - Turkish Carpets in Italy XR. John HoweNo ratings yet

- KPMG - Buiness Guidelines To Cloud Computing and BeyondDocument40 pagesKPMG - Buiness Guidelines To Cloud Computing and BeyondDavid LynchNo ratings yet

- Formliner BrochureDocument12 pagesFormliner BrochureAdrianna ColonaNo ratings yet

- ACER D270 Service ManualDocument405 pagesACER D270 Service Manualjuanp1020100% (1)

- Rad Etx 205aDocument4 pagesRad Etx 205aJohn DOENo ratings yet

- Montez CatalougeDoorsDocument20 pagesMontez CatalougeDoorsSaif LaherNo ratings yet

- Essay - Sofia Kosheleva - How The Current Architecture Can Treat Sustainable Problems With 20-Year PerspectiveDocument9 pagesEssay - Sofia Kosheleva - How The Current Architecture Can Treat Sustainable Problems With 20-Year PerspectiveSofiaNo ratings yet

- Trane WCC-IOMDocument20 pagesTrane WCC-IOMDaveEgerNo ratings yet

- Holtek Flash MCU Introduction 1005043 - NewDocument20 pagesHoltek Flash MCU Introduction 1005043 - NewNorival MaskeNo ratings yet

- VNX DP Upgrading Disk FirmwareDocument6 pagesVNX DP Upgrading Disk FirmwarePrakash LakheraNo ratings yet

- Opinion Size Physical Quality Shape Age Color Origin Material Type PurposeDocument2 pagesOpinion Size Physical Quality Shape Age Color Origin Material Type PurposeSatriaNo ratings yet

- Git Version Control CertificationDocument6 pagesGit Version Control CertificationVskills CertificationNo ratings yet

- (Anderson) The Search For An In-BetweenDocument9 pages(Anderson) The Search For An In-BetweenPedro AntonioNo ratings yet

- AWC STD342 1 WFCM2015 WindLoads 160922Document55 pagesAWC STD342 1 WFCM2015 WindLoads 1609226Bisnaga100% (1)

- Vitek BCIDocument124 pagesVitek BCIRonan Colobong100% (1)

- Huawei FusionServer IBMC Software White PaperDocument57 pagesHuawei FusionServer IBMC Software White PaperАндрей ИвановNo ratings yet

- Shopping Buddy: Cellular Networks and Mobile Computing COMS E6998 Final Project ReportDocument9 pagesShopping Buddy: Cellular Networks and Mobile Computing COMS E6998 Final Project ReportzakeermasNo ratings yet

- 150 SQ MDocument2 pages150 SQ MYuuki RitoNo ratings yet

- BPM Main Brochure 13286 001 (Updated 12062008)Document16 pagesBPM Main Brochure 13286 001 (Updated 12062008)CharitynNo ratings yet

- FRP Fabrication ManualDocument26 pagesFRP Fabrication ManualTanmay Majhi100% (1)

- 2.3-1 Setting Up RouterDocument20 pages2.3-1 Setting Up RouterMarj Demesa PaloNo ratings yet