Professional Documents

Culture Documents

PT Test Report

PT Test Report

Uploaded by

Rhoteram VikkuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT Test Report

PT Test Report

Uploaded by

Rhoteram VikkuCopyright:

Available Formats

NORCONTROL PANAM, S.A.

Ciudad del Saber Edificio 223

Ciudad de Panam, Apartado Postal # 6-8648, El Dorado

Tel. (507)265-4150 Fax (507)265-7471

R.U.C. 719769-1-472808 D.V.35

www.appluscorp.com

PT TESTS

1. DESCRIPTION OF WORK

1.1 Objective

1.2 Scope

1.3. Inspection Dates

1.4. Place of Inspection

1.5. Personal

2. APPLICABLE DOCUMENTS

3. EQUIPMENT

4. WORKS CARRIED OUT

5. RESULTS

6. RECOMMENDATIONS

7. CONCLUSIONS

ANNEXES

Customer: SEILS PANAMA

Prepared by: Date / Signature

N / A Reference:

Diana Gonzalez

Ing. Inspector END

Approved by: Date / Signature

Ing. Jos A Tapia

1. DESCRIPTION OF WORK

1.1 Objective

Conduct non destructive testing of Penetrant Inks (PT) in twelve (12) welds of the bottom

plates of the Service water tank belong to SEIL SUB-Contractor, PANAMA COLON

POWER PROJECT.

1.2 Scope

Inspection by non-destructive tests PT to twelve (12) welds of the bottom plates of the

Service water tank belong to SEIL PANAMA SUB-Contractor, PANAMA COLON POWER

PROJECT.

1.3 Inspection Dates

The inspection was performed on 19/01/2017 at the site indicated by SEIL PANAMA

customer.

1.4 Place of Inspection

PANAMA COLON POWER PROJECT Coln, Panam.

1.5 Personal

Metallurgical Engineer Diana Marcela Gonzlez Moreno

2. APPLICABLE DOCUMENTS

The tests have been performed as specified by the inspection test procedure by UT, MT

and PT APPLUS NORCONTROL and other applicable documents.

IT-MEC-003 03 Procedure Test By Ultrasound scan A defectology.

IT-MEC-001.03 Procedure Testing with Penetrant Liquids.

IT-MEC-002 03 Test Procedure by Magnetic Particles.

Asme Code Section VIII division I rules for construccion vessels. Mandatory

appendix 12 Ultrasonic Examination of Welds (UT); Mandatory appendix 6

Methods for Magnetic Particle Examination (MT); Mandatory appendix 8 Methods

for Liquid Penetrant Examination (PT).

Asme Code section V, Article 4.

Standard Practice for Ultrasonic Contact Examination of Weldments (ASTM

E164).

Standard Test Method for Liquid Penetrant Examination (ASTM E 165-2)

(Ao 2017) Pgina 2 de 5

Standard Guide for Magnetic Particle Testing (ASTM E 709)

3. EQUIPMENT

For the accomplishment of the works, the following equipments were used:

Penetrant Ink Kit.

Photographic camera.

Laptop.

4. WORKS CARRIED OUT

Inspection was done using Penetrant Inks to the bottom welds of the small tank FW001,

FW002, FW003, FW005, FW005, FW006, FW007, FW008, FW009, FW010, FW011,

FW012, in the LGN Costa Norte Terminal area belonging to the contractor SEIL Sub-

Contractor.

Imagen 1. Temperature measurement Imagen 2. Mechanical and solvent cleaning

(Ao 2017) Pgina 3 de 5

Imagen 3. Penetrant application. Imagen 4. Application of the developer.

5. RESULTS

During the inspection by Penetrating Inks, no relevant indications were found in the weld

bead, good anchoring, filling and presentation were observed, and mechanical cleaning

allowed a satisfactory test. The temperature control was carried out throughout the

inspection procedure.

6. RECOMMENDATIONS

N/A

7. CONCLUSIONS

The welds inspected on the bottom plates of the tank are in accordance with the

acceptance standard referenced for this non-destructive test.

(Ao 2017) Pgina 4 de 5

ANNEX 1: INSPECTION REPORT

USING PENETRATING INKS

(Ao 2017) Pgina 5 de 5

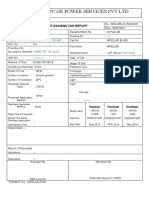

INSPECTION REPORT PENETRANT LIQUID TEST

ODT: REPORT N: PROCESS: P&ID:

Page 1 de 3

OT- PT- PR-END-028.03 N.A.

DATE: ID/TAG: LOCATION: SISTEM:

19-jan-2017 Sheet A1 - Tank Floor Coln - Panama N.A.

PENETRATING LIQUID TEST

USED MATERIAL MANUFACTURER TYPE OF CLASSIFICATION

PENETRATING MAGNAFLUX SKL-SP2

EMULSIFIER - -

CLEANER / REMOVER MAGNAFLUX SKC-S

DEVELOPER MAGNAFLUX SKD-S2

APPLICATION PROCEDURE

CLEANING PENETRATING CLEANING THE PENETRANT DEVELOPER

PENETRANT VISIBLE X X DRY POWDER:

9/5000

MECHANIC X COLORED WATER NON-AQUATIC WET: X

SOLVENT X FLUORESCENT POST-EMULSIFYABLE AQUEOUS SOLUTION.

INSPECTION VARIABLES

ACTIVITY DURATION METHOD OF APPLICATION TEMPERATURE (C) LIGHTING

CLEANING 5 Min TYPE II METHOD C ENVIRONMENT -

PENETRATING 10 Min TYPE II METHOD C ENVIRONMENT -

CLEANING 5 Min TYPE II METHOD C ENVIRONMENT -

DEVELOPER 10 Min TYPE II METHOD C ENVIRONMENT -

GENERAL VIEW

RESULTS

REFERENCE WELDED JOINTS TYPE OF INDICATION SHAPE DIMENSION EVALUATION

JOINT FW 001 of SHEET A1 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A2 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A3 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A4 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A5 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A6 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A7 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A8 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A9 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A10 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A11 NO RELEVANT INDICATIONS - - ACCORDING

JOINT FW 001 of SHEET A12 NO RELEVANT INDICATIONS - - ACCORDING

CONCLUSIONS

EVIDENCE GROUPED POROSITY AT BOARD # 1. Due to the liquid technique, no relevant indications are observed

Elaborated: Diana Marcela Gonzalez Revised: Jose Tapa Revised:

Certificate: Nivel II Lquidos Penetrantes Date: 23/01/2017 Date:

Sign: Sign: Sign:

Position: Ingeniera END Applus Position: Position:

FR-END-053.01 Ensayo de liquidos penetrantes

ODT: REPORT N: PROCEDure: PR-END-028.03 P&ID: SHEET 2 OF 3

PHOTOGRAPHIC RECORD

Area ainspeccionare

identificacindelapieza

Photo 1. Measuring and control instruments. Photo 2. Mechanical cleaning (with pleasure) to the weld to Photo 3. Mechanical cleaning (with pleasure) to the weld to

The temperature of the sheet to be inspected inspect. Surface irregularities that can mask unacceptable inspect. Surface irregularities that can mask unacceptable

was in the range of 46 C - 48.2 C discontinuities are eliminated. discontinuities are eliminated.

Photo 4. Batch revision and date of the Photo 5. Application of the penetrating liquid on the weld to be Photo 6. FW 002 Joint View of Blade A1

penetrant inks kit. inspected. Leave for 10 minutes. A1 Blade View FW 001

Photo 7. Joint view FW 003 of blade A1 Photo 8. A1 joint sight FW 004

Photo 9. Joint view FW 006 of blade A1 Photo 10. A1 Blade View FW 007 Photo 11. Joint view FW 008 of blade A1

FR-END-053.01 Ensayo de liquidos penetrantes

ODT: REPORT N: PROCESS: : PR-END-028.03 P&ID: PAGE 3 OF 3

PHOTOGRAPHIC RECORD

Foto 12. ViewjointFW 009de lasheetA1 Foto 13. ViewjointFW 010de lasheetA1

Foto 14. ViewjointFW 011de lasheetA1 Foto 15. ViewjointFW 0012de lasheetA1

Photo 17. Application of the

developer. It was allowed to

act for 10 minutes monitoring

the behavior of the

indications, this procedure

was carried out with each of

the joints welded in the

lamina A1.

Photo 16. Removal of excess penetrating liquid. Approximately 7 minutes in cleaning with cleaner

Photo 18. View of the developer at the joint FW 001 of Photo 19. View of the developer in the joint FW 002 of the Photo 20. View of the developer at the joint FW 003 of

sheet A1. No indications sheet A1. No indications sheet A1. No indications

FR-END-053.01 Ensayo de liquidos penetrantes

ODT: REPORT N: PROCESS: PR-END-028.03 P&ID: PAGE 3 OF 3

PHOTOGRAPHIC RECORD

Photo 21. View of the developer at the joint FW Photo 22. View of the developer at the joint FW 005 of Photo 23. View of the developer at the joint FW

004 of sheet A1. No indications are observed. the lamina A1. No indications are observed. 006 of sheet A1. No indications are observed.

Due to so much solar illumination a good

photograph was not obtained.

Photo 25. View of the developer at the joint FW 008 Photo 26. View of the developer at the joint FW 009 of

Photo 24. View of the developer at the joint FW 007 of

of sheet A1. No indications are observed. sheet A1. No indications are observed.

sheet A1. No indications

Photo 29. View of the developer at the joint FW 012 of

Photo 27. View of the developer at the joint FW 010 of Photo 28. View of the developer at the joint FW 011 of sheet A1. A pore is observed, it is recommended to

sheet A1. No indications are observed. sheet A1. No indications are observed. remove which is done immediately

FR-END-053.01 Ensayo de liquidos penetrantes

You might also like

- Liquid Dye Penetrant Inspection NDT Sample Test Report FormatDocument2 pagesLiquid Dye Penetrant Inspection NDT Sample Test Report Formatskynyrd7575% (8)

- Elevator Control SystemDocument15 pagesElevator Control SystemAdityaGupta100% (1)

- Method Statement For In-Situ Metallography Test: DCSM Project 2019Document5 pagesMethod Statement For In-Situ Metallography Test: DCSM Project 2019Thinh NguyenNo ratings yet

- Euro NDT PresentationDocument9 pagesEuro NDT PresentationBetoCordeiroNo ratings yet

- Ultrasonic Examination Report: Wayland EngineeringDocument1 pageUltrasonic Examination Report: Wayland EngineeringDeepak100% (1)

- 983 - Welding Comprehensive ASME - Quality Plan Sample PDFDocument19 pages983 - Welding Comprehensive ASME - Quality Plan Sample PDFRhoteram VikkuNo ratings yet

- Emu Bogies DetailsDocument108 pagesEmu Bogies DetailsLokendra80% (5)

- PT ReportDocument49 pagesPT ReportRajesh Owaiyar100% (1)

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- RED-NDT-MT-00001 Rev ADocument11 pagesRED-NDT-MT-00001 Rev ATadaya KasaharaNo ratings yet

- Nde ProceduresDocument66 pagesNde Proceduressoumaya yahyaouiNo ratings yet

- Ndic MFL A 10rev03!26!2010 SignedDocument10 pagesNdic MFL A 10rev03!26!2010 SignedMarcus ThomasNo ratings yet

- Magnetic Particle InspectionDocument47 pagesMagnetic Particle InspectionAlessandro Posillico100% (1)

- Cp16 Issue Renewal and Recertification of PCN Levels 1 & 2 CertificatesDocument19 pagesCp16 Issue Renewal and Recertification of PCN Levels 1 & 2 Certificatesndt_inspectorNo ratings yet

- Magnetic Praticle Inspection ProcedureDocument9 pagesMagnetic Praticle Inspection ProcedureTouil HoussemNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Inspection Report Magnetic Particle Examination (Tupi STR)Document1 pageInspection Report Magnetic Particle Examination (Tupi STR)Jindarat Kasemsooksakul100% (1)

- Welder Qualification Manual Revision 5Document20 pagesWelder Qualification Manual Revision 5Hugo RodriguezNo ratings yet

- NDT PT (NSH Procedure)Document9 pagesNDT PT (NSH Procedure)Midhun K ChandraboseNo ratings yet

- Visual Examination Procedure: 1 - PurposeDocument4 pagesVisual Examination Procedure: 1 - PurposeElvin MenlibaiNo ratings yet

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNo ratings yet

- SSIS VT Procedure Rev 0 25112011Document14 pagesSSIS VT Procedure Rev 0 25112011Salman KhanNo ratings yet

- Ultrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar JhaDocument55 pagesUltrasonic Testing: by Geetanjali Sharma Devendra Singh Amit Kumar Jhajhaamit4100% (2)

- GRP - PM.QA.02A - Prosedur Magnetic Test (AWS) - Rev.01Document14 pagesGRP - PM.QA.02A - Prosedur Magnetic Test (AWS) - Rev.01Riyan to100% (1)

- MPI Procedure For BCEII-FinalDocument10 pagesMPI Procedure For BCEII-FinalBCE DeNo ratings yet

- Flaw Manufacturing TechnologyDocument31 pagesFlaw Manufacturing Technologyツ ツNo ratings yet

- Ut PQRDocument10 pagesUt PQRArvind Sahani100% (1)

- UT Report FormDocument1 pageUT Report FormElisha NguyenNo ratings yet

- Nde Procedure Magnetic Particle TestingDocument20 pagesNde Procedure Magnetic Particle Testingryan.s100% (1)

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- Asnt MTDocument99 pagesAsnt MTGanesh MoorthyNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- CV Hotrungtinh QC-NDT PDFDocument6 pagesCV Hotrungtinh QC-NDT PDFTrung Tinh HoNo ratings yet

- Magnetic Particle Testing Procedure-Rev 1Document20 pagesMagnetic Particle Testing Procedure-Rev 1thongmuadongNo ratings yet

- UTDocument79 pagesUTkumargpalani100% (1)

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Examination Procedures For Ultrasonic Thickness MeasurementDocument13 pagesExamination Procedures For Ultrasonic Thickness MeasurementOsilonya HenryNo ratings yet

- Form PAUTDocument2 pagesForm PAUTLuong Ho Vu100% (1)

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- Alumana Welder IDDocument7 pagesAlumana Welder IDZuberYousufNo ratings yet

- MT Tta NDT Mpi 01 AsmeDocument13 pagesMT Tta NDT Mpi 01 AsmeTuan DangNo ratings yet

- NDT Steel CastingsDocument17 pagesNDT Steel CastingsWoodrow FoxNo ratings yet

- Requirements For Non-Destructive Examination Methods Eddy CurrentDocument21 pagesRequirements For Non-Destructive Examination Methods Eddy Currentzemog001100% (1)

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- UTDocument346 pagesUTramdhani100% (1)

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- MPI Report FormatDocument4 pagesMPI Report Formatpankaj ranaNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Vaccum Box ProcedureDocument4 pagesVaccum Box ProcedureRahul DubeyNo ratings yet

- NDT PT ProcedureDocument13 pagesNDT PT ProcedureSandiSandiiNo ratings yet

- 3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SDocument7 pages3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SFomaa ElsayedNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- Enkon PresentationDocument115 pagesEnkon PresentationSalimNo ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (2)

- Maintenance / Fabrication Process Traceability Card: Part No (Fab. process) (عينصت ةيلمع) ءزجلا مقرDocument1 pageMaintenance / Fabrication Process Traceability Card: Part No (Fab. process) (عينصت ةيلمع) ءزجلا مقرMohamed MossadNo ratings yet

- PT ProcedureDocument14 pagesPT Procedureefmartin21No ratings yet

- 016calibration ProcedurDocument21 pages016calibration ProcedurYudha Andrie Sasi ZenNo ratings yet

- 13 PT ProcedureDocument14 pages13 PT ProcedureThân KhaNo ratings yet

- GaSb - 1996 - Mar Res Bulleyine - GaSb NC From GaCl3 + SB (SiMe3) 3Document11 pagesGaSb - 1996 - Mar Res Bulleyine - GaSb NC From GaCl3 + SB (SiMe3) 3Naufan Nurrosyid PNo ratings yet

- Manual de RouterDocument32 pagesManual de RouterRhoteram Vikku100% (1)

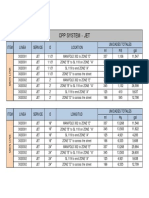

- CPP System - Jet: ML Gal Item Linea Service Ø Location Unidades TotalesDocument1 pageCPP System - Jet: ML Gal Item Linea Service Ø Location Unidades TotalesRhoteram VikkuNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- Status of Supports Sleepers According To Tampa Information - 19 June 2018Document1 pageStatus of Supports Sleepers According To Tampa Information - 19 June 2018Rhoteram VikkuNo ratings yet

- Asme Code IxDocument249 pagesAsme Code IxRhoteram VikkuNo ratings yet

- 6 Settlement Response of A Multi-Story BuildingDocument4 pages6 Settlement Response of A Multi-Story BuildingmazNo ratings yet

- Lec 9Document19 pagesLec 9Aqsa gulNo ratings yet

- Prinsip-Prinsip EkonomiDocument11 pagesPrinsip-Prinsip EkonomiRev AwNo ratings yet

- Ford MotorsDocument4 pagesFord Motorssalman sheikhNo ratings yet

- RAW Character ActivityDocument2 pagesRAW Character ActivityLisa HulmeNo ratings yet

- Lesson+39+ +Business+Idioms+Part+4Document9 pagesLesson+39+ +Business+Idioms+Part+4Styven KyomenNo ratings yet

- SM 4500 OdDocument8 pagesSM 4500 OdThainy BressanNo ratings yet

- Jota Armour Brochure 2007Document6 pagesJota Armour Brochure 2007yudiar2008No ratings yet

- Treasure IslandDocument266 pagesTreasure IslandNader HaddadNo ratings yet

- Jane Eyre Bertha Mason Teachers Notes UpdatedDocument4 pagesJane Eyre Bertha Mason Teachers Notes Updated04. Phan Thi Huyen Trang K17 HLNo ratings yet

- Lesson Plan #5 (Diversity Lesson Plan) Lesson Objective/sDocument7 pagesLesson Plan #5 (Diversity Lesson Plan) Lesson Objective/sapi-198000409No ratings yet

- Group 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsDocument19 pagesGroup 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsandreslionNo ratings yet

- Characteristics of LDCsDocument22 pagesCharacteristics of LDCstinsaeres100% (2)

- Algorithm and Pseudo CodesDocument44 pagesAlgorithm and Pseudo CodesLady GatlabayanNo ratings yet

- Drainage NOTESDocument9 pagesDrainage NOTESAuraNo ratings yet

- Hydraulics Stability (Anyer Geotube Project)Document4 pagesHydraulics Stability (Anyer Geotube Project)Anonymous IWHeUvNo ratings yet

- Vibracord. Vibration Meter Summary Sheet (Graphic) : Record Time: 4 SDocument1 pageVibracord. Vibration Meter Summary Sheet (Graphic) : Record Time: 4 SSadettin BağdatlıNo ratings yet

- Why Is Omkar Called As Pranav MantraDocument6 pagesWhy Is Omkar Called As Pranav Mantraami1577No ratings yet

- Paws of DestinyDocument2 pagesPaws of Destinytest dataNo ratings yet

- Rose GottleibDocument2 pagesRose GottleibHocPoLab TechNo ratings yet

- The Happy PrinceDocument3 pagesThe Happy PrinceLaurence UyNo ratings yet

- Lecture9 Memory OrganizationDocument32 pagesLecture9 Memory Organizationecevitmert1453No ratings yet

- 1.3 Earth's ProcessesDocument4 pages1.3 Earth's ProcessesRufo FelixNo ratings yet

- Elias M. Gutierrez JR.: Education: Seminars AttendedDocument1 pageElias M. Gutierrez JR.: Education: Seminars AttendedRachel Arañes MendozaNo ratings yet

- AsiDocument30 pagesAsikholifahnwNo ratings yet

- Teaching Assistant: Roi YehoshuaDocument17 pagesTeaching Assistant: Roi YehoshuaKarthik RaoNo ratings yet

- Tooling CatalogDocument20 pagesTooling CatalogAlisNo ratings yet

- Ignou Assignment Wala Ehi 1 Solved Assignment 2018-19Document7 pagesIgnou Assignment Wala Ehi 1 Solved Assignment 2018-19NEW THINK CLASSES100% (1)