Professional Documents

Culture Documents

MS - Gondola System Rev 2

MS - Gondola System Rev 2

Uploaded by

Non Etabas GadnatamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS - Gondola System Rev 2

MS - Gondola System Rev 2

Uploaded by

Non Etabas GadnatamCopyright:

Available Formats

Contractors Logo

METHOD STATEMENT

FOR

TESTING AND COMMISSIONING

GONDOLA SYSTEM

T&C Procedure Gondola System Page 1

Vector Three

Revision History

Issue Prepared Reviewed

Rev Date

Purpose By:

Signature By

Signature Approved By Signature

Table of Contents

A. OBJECTIVES...............................................................................................3

B. GENERAL CRITERIA...................................................................................3

C. EQUIPMENT AND DEVICES.......................................................................3

D. SET-UP OF DAVIT AND SOCKET...............................................................3

E. GROUND RIGGING OF GONDOLA (CHAMELEON BASKET)..................4

F. PARKING OF THE GONDOLA (CHAMELEON BASKET)...........................4

G. TESTING PROCEDURE OF DAVIT AND SOCKET GONDOLA SYSTEM. 5

1. Visual Inspection.....................................................................................5

2. Functional Test Form..............................................................................5

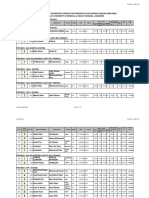

H. TESTING AND COMMISSIONING FORMS................................................6

T&C Procedure Gondola System Page 2

Vector Three

A. OBJECTIVES

The purpose of this method statement is to establish the davit system installation if

complies with the specified design requirements. To ensure that the equipment is

functioning properly; complying with the safety features stated on the design and be ready

for final testing acceptance.

The process includes the following:

1. Visual inspection of the davit and socket gondola system for completeness and

safety of operation.

2. Set-up of Davit and Socket.

3. Ground Rigging of Gondola (Chameleon Basket).

4. Functional test of controls and safety circuits.

5. Parking of Gondola (Chameleon Basket).

B. GENERAL CRITERIA

For operating: The use of swinging stage should accord with the relative working rules for

upper air, and it should be restricted from any operation during bad weather, such as in

the climate of thunder storm, fog day, and if the wind speed or velocity is greater than

10.8 m/s.

For Gondola: Ensure that the operational and all safety features of the Gondola system

are being met. If the operated building has some out-opening windows, they cannot to be

open during operation period, which shall be agreed by both operators and management

staff of the building. The system is able to reach and maintain the designated exterior

faade of the building.

Restraints to prevent swaying: The location of female restraints falls vertically along the

location of the cradle at each position. Per EN1808, the vertical spacing of female

restraints above 40 meters from the ground shall not exceed 20 meters.

C. EQUIPMENT AND DEVICES

T&C Procedure Gondola System Page 3

Vector Three

1. Clamp Amp Meter

2. Stop Watch

3. Measuring Tape

4. Full-body Safety Harness

D. SET-UP OF DAVIT AND SOCKET

1. Set-up mobile socket davit post, davit arm accordingly.

2. Assemble Davit Arm by connecting pieces together and tighten all bolts and nuts

accordingly.

3. Using a manual erection winch, mount davit arm to hinge pipe and winch

appropriately until it stands within the mobile socket. While mounting the davit arm 4

person will assist the installation.

4. Once the davit arm is installed, position the Chameleon (Gondola) basket at the

designated area for ground rigging.

E. GROUND RIGGING OF GONDOLA (CHAMELEON BASKET)

1. Drop tag line (3/4 inch diameter nylon rope) from the location of davit arm/post in

order to pull up the power supply cord of the Chameleon basket.

2. Upon reaching the davit arm/post, check the available power supply outlet to

where the male plug will be inserted; make sure there is available power supply.

3. Plug-in power to energized Chameleon basket. Release the safety block to free

wire rope; Tie tag line at the hook of the wire rope for pulling.

4. Pull tag line in order to stretch wire rope until reaching the spreader beam of davit

arm.

5. Hook wire rope to attachment at spreader beam.

6. Slowly test Chameleon basket for proper tensioning before operating upwards.

7. With the set-up of the Chameleon basket, functionality test may be administered

based on the provided checklist.

8. Once the Chameleon basket is operational, the operator can now operate the

basket. With the use of the tag line as life line for the operator and wearing a full-body

harness.

9. Operate the Chameleon basket within the faade of the building.

10. Do the same procedure when transferring to another location of the building.

NOTE: DO NOT OPERATE THE GONDOLA WITHOUT LIFELINE.

T&C Procedure Gondola System Page 4

Vector Three

F. PARKING OF THE GONDOLA (CHAMELEON BASKET)

1. For parking of the Chameleon basket, once the testing is done (cleaning for

normal operation) for the particular location. The Chameleon basket may be placed

within the designated parking area by swinging the davit arm inside the building.

2. Dismantle hook of wire ropes from the spreader beam to disengage the basket

accordingly.

3. Position the Chameleon basket to the location where an adjacent davit arm is

located.

4. With the davit arm assembled at the corresponding location (similar to assembly

procedure at item IV & V) lower tag line in order to transfer power supply cord and

wire rope accordingly.

5. Mount power cord and power up Chameleon basket to retrieve wire rope and

hook to spreader beam.

6. Once wire rope is tensioned and ready for operation, operate chameleon basket

up to the level of davit arm/post, then swing in Chameleon basket and park on the

floor level.

7. Disengage wire rope hooks and place Chameleon basket to designated parking

area.

8. Disassemble davit arms and stage at parking area accordingly.

NOTE: DO NOT OPERATE THE GONDOLA WITHOUT LIFELINE.

G. TESTING PROCEDURE OF DAVIT AND SOCKET GONDOLA SYSTEM

1. Visual Inspection

1.1 Check the completeness of assembly of Davit and Socket Gondola (Chameleon

Basket) as approved equipment submittal and design requirements.

1.2 Check the availability of power supply.

1.3 Check the area where the Gondola is to be place for testing for safety and

readiness.

1.4 Check if the davit arm is properly installed and bolts and nuts are tightened

properly.

1.5 Check the length and size of power cable or cord if correct as per building height

requirement.

2. Functional Test Form

Upon completion of all the system requirements and the equipment is safe for

operations the following item are subject for functional testing.

T&C Procedure Gondola System Page 5

Vector Three

2.1 Run the Chameleon basket upward and record the travel time for a certain level.

Run the Chameleon basket downward and record the travel time for a certain

level.

2.2 After running the basket upward and downward and no deficiencies was found or

observed the following hoist safety features should be check:

o Overload protection / audible alarm

o Double stop-block safety system

o Anti-rotation rope suspension

o 100% load equalizer on ropes

o Rope layering with spooling lever arm

o Full drum type winch

o Auto cradle tilt detector

o Spring cushion suspension

o Speed limiter when descending

o Upper and Lower limit switch

o Manual descent

o Slack rope protection

o Quick fix rope attachment

o Emergency stop button

o Phase protection

2.3 After checking all the safety features Run the Gondola from top most level down

to the lowest level and then from lowest level up to the top most level Observe

and record the performance of Gondola.

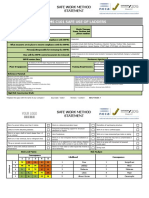

H. TESTING AND COMMISSIONING FORMS

1. Visual Inspection Checklist

2. Setting to Work Checklist

3. Functional and Operational Test

T&C Procedure Gondola System Page 6

Vector Three

You might also like

- Riiwhs204e Work Safely at Heights Training ManualDocument57 pagesRiiwhs204e Work Safely at Heights Training Manualmastergimp1981No ratings yet

- Crane Safety Handbook ARAMCO PDFDocument100 pagesCrane Safety Handbook ARAMCO PDFNon Etabas Gadnatam100% (2)

- PPL 6 Day Gym Workout ScheduleDocument5 pagesPPL 6 Day Gym Workout ScheduleBiplab Shankar100% (1)

- Asu Map Tempe CurrentDocument1 pageAsu Map Tempe CurrentJavier ValverdeNo ratings yet

- Working at Heights Practical ModuleDocument2 pagesWorking at Heights Practical ModuleMadalina FoteaNo ratings yet

- GondolaDocument20 pagesGondolatkofaiNo ratings yet

- SOP Scaffold AustralianDocument3 pagesSOP Scaffold Australiantemter100% (2)

- En397 Info SheetDocument2 pagesEn397 Info SheetAhmed AbdelrahimNo ratings yet

- HDB Safety8GondolaDocument9 pagesHDB Safety8GondolaNg RickyNo ratings yet

- Gamasutra - Jason Bakker's Blog - A GDD Template For The Indie DeveloperDocument5 pagesGamasutra - Jason Bakker's Blog - A GDD Template For The Indie DeveloperDaniel HuertaNo ratings yet

- Esp Test 1-2019Document2 pagesEsp Test 1-2019Jose Luis Gatillon SotoNo ratings yet

- GONDOLADocument26 pagesGONDOLAMarvanNo ratings yet

- Fall Prevention Plan: (Only Applicable To Contractor That Have Work Activities More Than 03 Meters and Above.)Document21 pagesFall Prevention Plan: (Only Applicable To Contractor That Have Work Activities More Than 03 Meters and Above.)Md ShahinNo ratings yet

- Pera Saw Radial ArmDocument7 pagesPera Saw Radial ArmHussainNo ratings yet

- WSH (Work at Heights) Regulations 2013Document22 pagesWSH (Work at Heights) Regulations 201388sanNo ratings yet

- Edge Protection Manual With ApprovalDocument12 pagesEdge Protection Manual With ApprovalClaudioKAD100% (1)

- WSH Guidelines Safe Operation of Forklift TrucksDocument35 pagesWSH Guidelines Safe Operation of Forklift TrucksERICK VILLAFANANo ratings yet

- Mast Climber SafetyDocument60 pagesMast Climber SafetyAwojobi Alexander Habeeb OloladeNo ratings yet

- Method StatementDocument4 pagesMethod StatementRichmond SantiagoNo ratings yet

- CPCCPB3026 PresentationDocument85 pagesCPCCPB3026 PresentationAbdul Haseeb100% (1)

- Environmental Consultant Scope of Work - FinalDocument10 pagesEnvironmental Consultant Scope of Work - FinalborrowmanaNo ratings yet

- As 2400.13-1983 Packaging Tensional StrappingDocument6 pagesAs 2400.13-1983 Packaging Tensional StrappingSAI Global - APACNo ratings yet

- General Procedures Poster V3Document1 pageGeneral Procedures Poster V3Mark BrewardNo ratings yet

- Roller Shurter Door Maintenance 2021Document28 pagesRoller Shurter Door Maintenance 2021Abiodun IloriNo ratings yet

- Gondola CalculationDocument6 pagesGondola CalculationBudi SusantoNo ratings yet

- Alexander County: What To Do in Case of An On-The-Job InjuryDocument12 pagesAlexander County: What To Do in Case of An On-The-Job InjuryAli JalilNo ratings yet

- Edge Protection - Epf-Cop-32-33 PDFDocument37 pagesEdge Protection - Epf-Cop-32-33 PDFcisyabNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- Lathe Operation SafetyDocument1 pageLathe Operation Safetymustafa_staj8367No ratings yet

- Safety Guidance For Roller Shutter or Other Industrial DoorsDocument3 pagesSafety Guidance For Roller Shutter or Other Industrial DoorsKeshav Arote100% (1)

- Adia No-Load TestingDocument7 pagesAdia No-Load TestingjillianixNo ratings yet

- 8-22 Roller Shutter Door OHS TemplateDocument11 pages8-22 Roller Shutter Door OHS Templatemsc920138No ratings yet

- 02-00 Doka Climbing SystemsDocument28 pages02-00 Doka Climbing SystemsJae Min Hwang100% (1)

- Dbi Sala Catalog PDFDocument60 pagesDbi Sala Catalog PDFvikrant911No ratings yet

- RingLock Brocure 110812Document17 pagesRingLock Brocure 110812Mohammed AdnanNo ratings yet

- Safety Line SystemsDocument16 pagesSafety Line Systemsakubestlah100% (2)

- E 28 GP 001 Working at Heights - Scaffolding StandardsDocument20 pagesE 28 GP 001 Working at Heights - Scaffolding StandardsMounir Boutaghane100% (1)

- Scissor Lift ProcedureDocument2 pagesScissor Lift ProcedureAdhi LatifNo ratings yet

- Skylark Skygondola PresentationDocument87 pagesSkylark Skygondola PresentationrohanbagadiyaNo ratings yet

- Crane Mounted On Truck Inspection Report MH 12 FC8311Document12 pagesCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNo ratings yet

- Cegelec Fall Protection Plan & Emergency Rescue ProcedureDocument12 pagesCegelec Fall Protection Plan & Emergency Rescue ProcedureREHOBOTH YAMBO KAHILUNo ratings yet

- CG-1000 Series - Powered Sliding Davit Product RangeDocument29 pagesCG-1000 Series - Powered Sliding Davit Product RangeFrancis BautistaNo ratings yet

- Method Statement For Test and Inspection of An Existing Lightning Protection/Earthing SystemDocument4 pagesMethod Statement For Test and Inspection of An Existing Lightning Protection/Earthing Systemdangtuan27No ratings yet

- 1868 Sop Work at HeightDocument10 pages1868 Sop Work at HeightAbid AzizNo ratings yet

- Scissor Lift - HseDocument4 pagesScissor Lift - HserassdriverNo ratings yet

- Safe Scaffold1Document40 pagesSafe Scaffold1Anonymous 3VTQm3Tgyb100% (1)

- Code of Practive For Safe Use and Operation of Suspended Working PlatformDocument62 pagesCode of Practive For Safe Use and Operation of Suspended Working PlatformthowchinNo ratings yet

- Induction Training PDFDocument51 pagesInduction Training PDFupender007100% (1)

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistIvan Dave TorrecampoNo ratings yet

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDocument6 pagesHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineNo ratings yet

- 2010 10 OnlineDocument72 pages2010 10 OnlineSanja RadovicNo ratings yet

- Evr J0100 Msra CL 02Document10 pagesEvr J0100 Msra CL 02Marwan NizarNo ratings yet

- PASMA Toolbox TalksDocument5 pagesPASMA Toolbox TalksUlviyye Cavid-Umid Elesgerova100% (1)

- Working On, Over, in or Near Water ProcedureDocument6 pagesWorking On, Over, in or Near Water ProcedureAly ShahNo ratings yet

- Gondola Installation ProcedureDocument2 pagesGondola Installation Procedureapi-326320317No ratings yet

- CPA CIG0801 Excavators Used As Cranes Rev2 090301Document7 pagesCPA CIG0801 Excavators Used As Cranes Rev2 090301dursosonoNo ratings yet

- Delay Starting MechanismDocument1 pageDelay Starting MechanismSaravanan KcNo ratings yet

- Essence of Good HousekeepingDocument26 pagesEssence of Good HousekeepingPritta VioletaNo ratings yet

- SWMS C101 Safe Use of LaddersDocument6 pagesSWMS C101 Safe Use of LadderssouravrobinNo ratings yet

- SG016.02 Lifting Equipment and Lifting OperationsDocument3 pagesSG016.02 Lifting Equipment and Lifting OperationsRey-an A. MorenoNo ratings yet

- Confined Spaces: Guidance Note 5Document16 pagesConfined Spaces: Guidance Note 5Bill Paxton100% (1)

- Crane Work Method Statement - Compressed NewDocument15 pagesCrane Work Method Statement - Compressed NewAvinashNo ratings yet

- Tarpaulin Installation MSDocument6 pagesTarpaulin Installation MSBilal100% (1)

- Canny Instalacion Mecanica Manual InglesDocument57 pagesCanny Instalacion Mecanica Manual InglesBeltran Héctor100% (1)

- Escalator and Moving Walks Test Method (Dood)Document9 pagesEscalator and Moving Walks Test Method (Dood)ThomasNo ratings yet

- A554 D 455 PM Sow Con 005Document4 pagesA554 D 455 PM Sow Con 005Non Etabas GadnatamNo ratings yet

- The Dow Chemical Company: Concrete Details Detail 101 Detail 101Document1 pageThe Dow Chemical Company: Concrete Details Detail 101 Detail 101Non Etabas GadnatamNo ratings yet

- 1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeDocument3 pages1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeNon Etabas GadnatamNo ratings yet

- 633559-M-E-D010-Stage 4 Pavilion-IFC SetDocument7 pages633559-M-E-D010-Stage 4 Pavilion-IFC SetNon Etabas GadnatamNo ratings yet

- PLV Pav Lasc 100DDDocument25 pagesPLV Pav Lasc 100DDNon Etabas GadnatamNo ratings yet

- PLDM Plumbing FCD PlanDocument34 pagesPLDM Plumbing FCD PlanNon Etabas GadnatamNo ratings yet

- 24 Vibration IsolatorDocument22 pages24 Vibration IsolatorNon Etabas Gadnatam100% (1)

- 39CQ Iom 06302014Document20 pages39CQ Iom 06302014Non Etabas GadnatamNo ratings yet

- 1065 Electronic Safety Security Comprehensive Quality Plan SampleDocument20 pages1065 Electronic Safety Security Comprehensive Quality Plan SampleNon Etabas GadnatamNo ratings yet

- 1 Gala CI Y-Strainer Cast Iron Fig 7101Document1 page1 Gala CI Y-Strainer Cast Iron Fig 7101Non Etabas GadnatamNo ratings yet

- (FDA) - Progef Standard PPDocument1 page(FDA) - Progef Standard PPNon Etabas GadnatamNo ratings yet

- 1 Gala Bronze Y-Strainer Fig 7654 SMDocument1 page1 Gala Bronze Y-Strainer Fig 7654 SMNon Etabas Gadnatam100% (1)

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument1 pageQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- 1 Gala Bronze Gate Nrs Valve Fig 3152Document1 page1 Gala Bronze Gate Nrs Valve Fig 3152Non Etabas GadnatamNo ratings yet

- Equipment Schedule & Technical Summary Ests 1 PE-11 & PE-12 Passenger ElevatorsDocument5 pagesEquipment Schedule & Technical Summary Ests 1 PE-11 & PE-12 Passenger ElevatorsNon Etabas GadnatamNo ratings yet

- Aramco Safety Comments-FormDocument1 pageAramco Safety Comments-FormNon Etabas GadnatamNo ratings yet

- 1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDDocument2 pages1 FT Gala Rubber Flexible Connector Double Bellows GFLEX-GS THREADEDNon Etabas GadnatamNo ratings yet

- 1 Balancing Valve Bronze GALA-smDocument1 page1 Balancing Valve Bronze GALA-smNon Etabas GadnatamNo ratings yet

- CoverDocument1 pageCoverNon Etabas GadnatamNo ratings yet

- 1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmDocument1 page1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmNon Etabas GadnatamNo ratings yet

- Owner: Project: Location: Group A: Group B: Subject: File No .Document10 pagesOwner: Project: Location: Group A: Group B: Subject: File No .Non Etabas GadnatamNo ratings yet

- Master Electrician Exam™Document179 pagesMaster Electrician Exam™Non Etabas Gadnatam100% (2)

- Plumbing and Fire Fighting Sample BoqDocument30 pagesPlumbing and Fire Fighting Sample BoqNon Etabas GadnatamNo ratings yet

- 14210-Electric Traction ElevatorsDocument52 pages14210-Electric Traction ElevatorsNon Etabas GadnatamNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument1 pageQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- Muscular SystemDocument28 pagesMuscular SystemPridas GidNo ratings yet

- Jacobi Progressive Speed Agility Training For High School Middle School AthletesDocument39 pagesJacobi Progressive Speed Agility Training For High School Middle School AthletesAnthony Mckay100% (1)

- Final Merit List of Candidates Applied For Admission in Bs - Nursing (Session 2020-2021) Liaquat University of Medical & Health Sciences, JamshoroDocument74 pagesFinal Merit List of Candidates Applied For Admission in Bs - Nursing (Session 2020-2021) Liaquat University of Medical & Health Sciences, Jamshorowaqar AhmedNo ratings yet

- Despiece Completo IMDocument38 pagesDespiece Completo IMSantiago CruzNo ratings yet

- 09-350 TCN GOLD SD LJDocument2 pages09-350 TCN GOLD SD LJAditya KumarNo ratings yet

- Sr. No. Symbol Warning Lamp/Tell Tale Lamp Pre-Check Lamp Status After Engine ON Action/RemarksDocument1 pageSr. No. Symbol Warning Lamp/Tell Tale Lamp Pre-Check Lamp Status After Engine ON Action/RemarksabhibawaNo ratings yet

- Kraby - RulebookDocument12 pagesKraby - RulebookZach BythewayNo ratings yet

- Gear Coupling FGCDocument4 pagesGear Coupling FGCananthdeva0% (1)

- Armcat PDFDocument36 pagesArmcat PDFdedelamenaceNo ratings yet

- Wacky LassieDocument4 pagesWacky LassieAlphamatrix01No ratings yet

- Stage 9 Grow Taller Pyramid SecretsDocument39 pagesStage 9 Grow Taller Pyramid SecretsToni Pineda100% (1)

- Panduan Praktik Klinis Dokter Fasyankes PrimerDocument18,642 pagesPanduan Praktik Klinis Dokter Fasyankes PrimerMelly MerlisahNo ratings yet

- Cardiorespiratory Fitness (CRF)Document21 pagesCardiorespiratory Fitness (CRF)Belle AmourNo ratings yet

- Downloaded From Manuals Search EngineDocument92 pagesDownloaded From Manuals Search EngineZoran KastelaNo ratings yet

- Basket BallDocument12 pagesBasket BallHafiz Mubashar AhmadNo ratings yet

- Geronimo Bianqui Pinero - BailecitoDocument2 pagesGeronimo Bianqui Pinero - BailecitoOniscoidNo ratings yet

- Zakk Wylde Guitar MetodoDocument8 pagesZakk Wylde Guitar MetodoJosé Silvestre MontellanoNo ratings yet

- Nintendo Switch Joy-Con Drift Lawsuit (Amended)Document101 pagesNintendo Switch Joy-Con Drift Lawsuit (Amended)PolygondotcomNo ratings yet

- EBBR ChartsDocument1 pageEBBR ChartsElton CacefoNo ratings yet

- Pokemon Emerald All Cheats2Document254 pagesPokemon Emerald All Cheats2Rezza R ZeleninNo ratings yet

- Database 02 Branch of IMADocument268 pagesDatabase 02 Branch of IMAapi-384612233% (3)

- (Top 20) Sexiest Female Cosplayer From All Over The World! - GondezoDocument13 pages(Top 20) Sexiest Female Cosplayer From All Over The World! - GondezoSeno Aji PrasetyoNo ratings yet

- Required Materials For CNC Plotter Pen AssemblyDocument1 pageRequired Materials For CNC Plotter Pen AssemblyTimothyMooresNo ratings yet

- Workout ProgramDocument4 pagesWorkout ProgramReniel RodriguezNo ratings yet

- Daxx PDFDocument22 pagesDaxx PDFDamion HaleNo ratings yet

- Zero Point CalibrationDocument4 pagesZero Point CalibrationMike Tsai100% (1)