Professional Documents

Culture Documents

Multistep Synthesis Lab Report

Multistep Synthesis Lab Report

Uploaded by

pianoplayer7242Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multistep Synthesis Lab Report

Multistep Synthesis Lab Report

Uploaded by

pianoplayer7242Copyright:

Available Formats

Bryan Luu

Discussion

The preparation of ethyl acetoacetate ethylene ketal from ethyl acetoacetate as a first step

was essential because it allowed specific addition of the following Grignard reagent. The ketone

of ethyl acetoacetate had to be protected for Grignard addition to the ester. A Dean-Stark trap

was used to extract water, another product, from the reaction in order to keep equilibrium

unbalanced, and therefore, the reaction moving forward. At completion of ketal protecting group

addition, two equivalents of phenyl magnesium bromide were added to ethyl acetoacetate

ethylene ketal reducing the ester to an alcohol and adding two phenyls. After addition of phenyl,

dilute aqueous HCl was added to remove ethylene glycol protecting group resulting in 1,1-

Diphenyl-1-hydroxy-3-butanone. Additional concentrated HCl was added to protonate and

remove the hydroxyl group, forming a double bond at carbon 1.

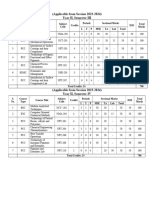

The termination of reaction 1, preparation of ethyl acetoacetate ethylene ketal, yielded

78% product. The principal cause of yield reduction was due to systematic error of the

incomplete extraction of water during the reaction. For complete yield, enough water must be

removed to keep the reaction going until completion. However, this would require longer reflux

time, extending pass the procedural constraints of time. The percent yield dropped even further

in week 2 resulting in 50.4%. It should be noted that a small amount of sample was used for

NMR and IR reading after each stage. Though miniscule, such an amount will contribute

slightly to the reduction in yield. The percent yield of week 3 was maintained in a similar range

at 55.6%. Other loss of product was from careless handling of flasks during transportation from

one work area to the next. After reviewing experimental documentation, an error was discovered

which produced an erred final theoretical and percent yield. At the start of week 4, an incorrect

starting mass of reactant, 0.64g, was used which in turn, led to incorrect scaling of reagents. An

incorrect theoretical yield of 0.59g. Actual theoretical yield should have been based on 0.30g

which would have resulted in a theoretical yield of 27.8g. Product mass at the end of week 4

was 0.42g, a higher yield than should be expected. A likely cause for this high value may be the

neglect of completely drying the round bottom flask after removing it from the rotary evaporator

before weighing.

Conclusion

Despite seemingly error prone procedural technique, end product,1,1-diphenyl-1-buten-3-

one, was formed and purified with a final yield of 0.14g. Success of production of desired

product allowed students to practice and observe commonly used multistep synthesis techniques.

The experiment demonstrated utility of protecting groups in forcing desired addition of Grignard

reagents. In the absence of careless error, the above procedure is a reliable method of

synthesizing 1,1-Diphenyl-1-hydroxy-3-butanone.

You might also like

- Analytical Chemistry Quiz 2Document12 pagesAnalytical Chemistry Quiz 2Lokesh Bhoi100% (1)

- The Diels-Alder ReactionDocument351 pagesThe Diels-Alder ReactionRay Frausto100% (1)

- Introduction MCC Oxo ProcessDocument5 pagesIntroduction MCC Oxo ProcessDeep PatelNo ratings yet

- Ekstraksi: Extraction Theory by W.J.Kelly Solvent Extraction by S. Roy Solvent Extraction Materi Kuliah Pemisahan KimiaDocument12 pagesEkstraksi: Extraction Theory by W.J.Kelly Solvent Extraction by S. Roy Solvent Extraction Materi Kuliah Pemisahan Kimiaminyoon sugarNo ratings yet

- Rheem Furnace ManualDocument12 pagesRheem Furnace Manualmatt12manyNo ratings yet

- FINAL McCabe-Thiele Paper For Nonideal ASEE FORMATDocument24 pagesFINAL McCabe-Thiele Paper For Nonideal ASEE FORMATKatherine Stela Rucabado Llatas100% (1)

- TextbooksDocument20 pagesTextbooksPallavi PatilNo ratings yet

- Fundamentals of Heat and Mass Transfer 7th Edition - Bergman, Lavine, Incropera, DeWitt (1) - p0017Document1 pageFundamentals of Heat and Mass Transfer 7th Edition - Bergman, Lavine, Incropera, DeWitt (1) - p0017Clady100% (1)

- Exam 2010qqqDocument2 pagesExam 2010qqqMohamed AbdullaNo ratings yet

- IMDI MetaData 3.0Document60 pagesIMDI MetaData 3.0api-3693793No ratings yet

- The Sacred Cow ResponseDocument2 pagesThe Sacred Cow Responsepianoplayer7242No ratings yet

- KMMLDocument35 pagesKMMLAJITH SNo ratings yet

- DemineralizationDocument4 pagesDemineralizationJoshuaGideonNo ratings yet

- API RP 571 - Damage Mechanisms SpreadsheetDocument12 pagesAPI RP 571 - Damage Mechanisms SpreadsheetSoftware ManagerNo ratings yet

- Oxo SynthesisDocument1 pageOxo Synthesisdlr1233No ratings yet

- Training The QC Monkey-Webinar by Alex Lau and Baytek QC Plus Slides 041520Document47 pagesTraining The QC Monkey-Webinar by Alex Lau and Baytek QC Plus Slides 041520Nicolette Case100% (1)

- Evaluation of Hydrogen Production Methods UsingDocument10 pagesEvaluation of Hydrogen Production Methods UsingInneke WulandariNo ratings yet

- (Vladimir N. Bashkin) Modern Biogeochemistry EnviDocument446 pages(Vladimir N. Bashkin) Modern Biogeochemistry EnviMirela KlisurićNo ratings yet

- Conductivity Measurement and TheoryDocument7 pagesConductivity Measurement and TheoryezraNo ratings yet

- Hydroformylation of PropyleneDocument4 pagesHydroformylation of Propylenemichelle_tang_9No ratings yet

- Heat Exchanger Application in Food Processing.Document8 pagesHeat Exchanger Application in Food Processing.himanshu Arora100% (1)

- 1.1. Types of PolyelectrolyteDocument10 pages1.1. Types of PolyelectrolytehvpNo ratings yet

- Chemcad 5: The Book of ExamplesDocument66 pagesChemcad 5: The Book of Examplesdanan widjanarkoNo ratings yet

- Isolation of Caffeine From Tea PDFDocument6 pagesIsolation of Caffeine From Tea PDFDaisy Joyce Seroje BuslonNo ratings yet

- Quick Reference - G3430-90009Document34 pagesQuick Reference - G3430-90009bert_avitia_1No ratings yet

- Analysis - Ecological - Data PCA in RDocument126 pagesAnalysis - Ecological - Data PCA in RBolitox ErazoNo ratings yet

- Process Temperature Control Using PID and LabVIEWDocument17 pagesProcess Temperature Control Using PID and LabVIEWManish SinghNo ratings yet

- Geankoplis ch01Document6 pagesGeankoplis ch01richardshu3984No ratings yet

- Tactical Approaches To Interconverting GPCR Agonists and AntagonistsDocument31 pagesTactical Approaches To Interconverting GPCR Agonists and Antagonistssarah paradillahNo ratings yet

- 10.4 Isothermal and Adiabatic ChangesDocument15 pages10.4 Isothermal and Adiabatic ChangesYuvaneshwaran SrinivasanNo ratings yet

- IDL Programming Techniques 2nd EditionDocument465 pagesIDL Programming Techniques 2nd EditionAyorinde T TundeNo ratings yet

- The Handbook of Mathematics and Computational ScienceDocument24 pagesThe Handbook of Mathematics and Computational SciencePrashant SinghNo ratings yet

- Isolation and Purification of Caffeine From Tea Leaves: Experiment # 1Document9 pagesIsolation and Purification of Caffeine From Tea Leaves: Experiment # 1Fatima AhmedNo ratings yet

- MS Applied Computer Science FlyerDocument2 pagesMS Applied Computer Science FlyerKhsddhaNo ratings yet

- Synthesis of AspirinDocument3 pagesSynthesis of AspirinDella Karissa100% (1)

- Imine ReductionDocument4 pagesImine ReductionRatna Siti KhodijahNo ratings yet

- Chemical Engineering Fluid Mechanics Ron Darby Solutions ManualDocument1 pageChemical Engineering Fluid Mechanics Ron Darby Solutions ManualLUIS DAVID SALDARRIAGA CARTAGENANo ratings yet

- Generalized Psychrometric ChartDocument11 pagesGeneralized Psychrometric Chartshoukat14No ratings yet

- Reforming Process PDFDocument4 pagesReforming Process PDFankitsamriaNo ratings yet

- Comsol Tutorial Heat Conduction in A SlabDocument15 pagesComsol Tutorial Heat Conduction in A Slabjohnnytulip100% (2)

- Organic AcidDocument38 pagesOrganic AcidMuhammad Adeel JavedNo ratings yet

- 313 Lab Manual NewDocument155 pages313 Lab Manual NewEzhilarasiPazhanivel100% (1)

- Combustion Data Acquisition and Analysis: Department of Aeronautical and Automotive EngineeringDocument75 pagesCombustion Data Acquisition and Analysis: Department of Aeronautical and Automotive EngineeringKidus DawitNo ratings yet

- Genetic AlgorithmDocument105 pagesGenetic AlgorithmManish MadhurajNo ratings yet

- State of The Art of Global Dimethyl Ether ProductionDocument12 pagesState of The Art of Global Dimethyl Ether ProductiondanaosajoNo ratings yet

- Sinusitis & Its TreatmentDocument20 pagesSinusitis & Its Treatmentfarmasi_hmNo ratings yet

- Halogenated Benzenes, Toluenes and Phenols with Water: Solubility Data SeriesFrom EverandHalogenated Benzenes, Toluenes and Phenols with Water: Solubility Data SeriesAri L. HorvathRating: 5 out of 5 stars5/5 (1)

- Inhibitor Sourcebook Third EditionDocument234 pagesInhibitor Sourcebook Third Editionchristina_finkeNo ratings yet

- CH323 Physical Chemistry 1 Practical 2Document2 pagesCH323 Physical Chemistry 1 Practical 2Hungum KUWIMB100% (1)

- CEIC3002 Project Description 2011Document6 pagesCEIC3002 Project Description 2011MF_WANZNo ratings yet

- Netcdf Qgis GGDocument15 pagesNetcdf Qgis GGRosu AdrianNo ratings yet

- Polymers Plus User Guide Volume 1Document452 pagesPolymers Plus User Guide Volume 1Adnaloh KistortNo ratings yet

- Cubic Phase Particles in Drug DeliveryDocument4 pagesCubic Phase Particles in Drug DeliveryPhelia KosasihNo ratings yet

- (Lecture Notes in Computer Science 5692 _ Information Systems and Applications, Incl. Internet_Web, And HCI) Edith Elkind (Auth.), Tommaso Di Noia, Francesco Buccafurri (Eds.)-E-Commerce and Web TechnDocument386 pages(Lecture Notes in Computer Science 5692 _ Information Systems and Applications, Incl. Internet_Web, And HCI) Edith Elkind (Auth.), Tommaso Di Noia, Francesco Buccafurri (Eds.)-E-Commerce and Web TechnRobert BuruleanuNo ratings yet

- Lectures On Differential Equations: Department of Mathematics University of California Davis, CA 95616Document169 pagesLectures On Differential Equations: Department of Mathematics University of California Davis, CA 95616osmanfıratNo ratings yet

- M.Tech CS 2014 PDFDocument17 pagesM.Tech CS 2014 PDFraa2010No ratings yet

- Super Critical Fluids Apps BrunnerDocument24 pagesSuper Critical Fluids Apps Brunnerharisaiganesh2000No ratings yet

- Principal Components AnalysisDocument16 pagesPrincipal Components AnalysisShangeetha TangarajNo ratings yet

- Klasifikasi Mesin 2Document55 pagesKlasifikasi Mesin 2Muhammad Iqbal OktavinNo ratings yet

- Ode GreenDocument1,125 pagesOde GreenSumalinog G. Gelson100% (1)

- Factorization Methods for Discrete Sequential EstimationFrom EverandFactorization Methods for Discrete Sequential EstimationNo ratings yet

- Thermo Lab Report3Document2 pagesThermo Lab Report3pianoplayer7242No ratings yet

- Bomb Calorimetry LabDocument8 pagesBomb Calorimetry Labpianoplayer7242100% (1)

- Gulliver's Travels Literary Analysis - DraftDocument6 pagesGulliver's Travels Literary Analysis - Draftpianoplayer7242No ratings yet

- Monuments Men PaperDocument4 pagesMonuments Men Paperpianoplayer7242No ratings yet

- Bryan Luu Mike AxlerDocument1 pageBryan Luu Mike Axlerpianoplayer7242No ratings yet

- Literary Analysis - A Valediction Forbidding Mourning - John DonneDocument4 pagesLiterary Analysis - A Valediction Forbidding Mourning - John Donnepianoplayer7242No ratings yet

- Senior Class Trip: Rancocas Valley Regional High SchoolDocument22 pagesSenior Class Trip: Rancocas Valley Regional High Schoolpianoplayer7242No ratings yet

- OligomerDocument3 pagesOligomerRommelBaldagoNo ratings yet

- Ib PPT 7 SL PDFDocument24 pagesIb PPT 7 SL PDFzarna nirmal rawalNo ratings yet

- Organic ChemistryDocument39 pagesOrganic ChemistryAurora JimenezNo ratings yet

- Sikagrout - 295: Cement-Base Fluid Expanding Mortar, With High Mechanical ResistanceDocument2 pagesSikagrout - 295: Cement-Base Fluid Expanding Mortar, With High Mechanical Resistancethe pilotNo ratings yet

- Fire Protection and Arson InvestigationDocument16 pagesFire Protection and Arson InvestigationBenhur malok MangindalatNo ratings yet

- 4th Sem SyllabusDocument16 pages4th Sem Syllabus220112034No ratings yet

- Crescent PPG Lining Pvt. LTD: We Define Trust...... ... RelaxDocument29 pagesCrescent PPG Lining Pvt. LTD: We Define Trust...... ... RelaxKamatchi NathanNo ratings yet

- Advance Construction Material - Micro Silica in ConcreteDocument9 pagesAdvance Construction Material - Micro Silica in ConcreteSubbaReddyNo ratings yet

- Siphin Samson Chemistry Investigatory Project FileDocument14 pagesSiphin Samson Chemistry Investigatory Project FileSIPHIN SAMSONNo ratings yet

- Amines and ThiolsDocument103 pagesAmines and ThiolsKarla Joy P. SucgangNo ratings yet

- Quarter 1 AssessmentDocument6 pagesQuarter 1 AssessmentlkNo ratings yet

- 4ch1 2cr Que 20230119Document19 pages4ch1 2cr Que 20230119Fathima ulfathNo ratings yet

- 13 Carbohydrates Part I 2023Document33 pages13 Carbohydrates Part I 2023Kurstein FerriolNo ratings yet

- Introduction To Analytical SeparationDocument75 pagesIntroduction To Analytical SeparationVincentius EkyNo ratings yet

- Mining EDocument24 pagesMining EJay-R EspinosaNo ratings yet

- WIT-PE 500 Design Manual RBDocument24 pagesWIT-PE 500 Design Manual RBMadusha TisseraNo ratings yet

- Verzosa, Earl Beann G. Bsce-2B STUDENT NO. 191752Document7 pagesVerzosa, Earl Beann G. Bsce-2B STUDENT NO. 191752Earl averzosaNo ratings yet

- 03 Electrochemistry Study Guide - Multiple ChoiceDocument22 pages03 Electrochemistry Study Guide - Multiple ChoiceGopal Penjarla100% (1)

- Chapter 2 Summary and Model Answers:: 3.2.1 Cell StructureDocument22 pagesChapter 2 Summary and Model Answers:: 3.2.1 Cell Structureteee100% (1)

- Potato Plastic Lab ModuleDocument4 pagesPotato Plastic Lab ModuleAnoif Naputo AidnamNo ratings yet

- Inorganic Chemistry Laboratory Report: I. Data and ResultsDocument4 pagesInorganic Chemistry Laboratory Report: I. Data and Resultskim allysaNo ratings yet

- MC-chemical (Specification)Document7 pagesMC-chemical (Specification)Saumya ShresthaNo ratings yet

- CSEC Chemistry June 2017 P1Document10 pagesCSEC Chemistry June 2017 P1Princess Jay50% (2)

- Acid, Base, and SaltDocument12 pagesAcid, Base, and SaltTamoghna DeyNo ratings yet

- 5.111 Principles of Chemical Science: Mit OpencoursewareDocument7 pages5.111 Principles of Chemical Science: Mit OpencoursewareAndrea Faye BelenNo ratings yet

- Hair Straightening CompositionDocument13 pagesHair Straightening Compositionzorro21072107No ratings yet