Professional Documents

Culture Documents

Difference Ether Ester - 111010

Difference Ether Ester - 111010

Uploaded by

8612106535Copyright:

Available Formats

You might also like

- Polyester: History Forms Manufacturing Process Properties Future UsesDocument28 pagesPolyester: History Forms Manufacturing Process Properties Future UsesAron Solanki100% (3)

- Adhesives and SealantsDocument40 pagesAdhesives and SealantsEmie Grace Villavicencio Moting100% (2)

- Polyester, Cobalt Particulate and Rockwool FiberDocument66 pagesPolyester, Cobalt Particulate and Rockwool FiberShashank Singh100% (1)

- What Is Pet (Polyethylene Terephthalate) : Melting Temperature: 254-256 C Crystallinity: 45%Document32 pagesWhat Is Pet (Polyethylene Terephthalate) : Melting Temperature: 254-256 C Crystallinity: 45%Sky ValleyNo ratings yet

- What Is PET PolyEthylene TerephthalateDocument6 pagesWhat Is PET PolyEthylene TerephthalateAnandKuttiyanNo ratings yet

- Handout Packaging MaterialsDocument15 pagesHandout Packaging MaterialsShahnasNo ratings yet

- What Is PETDocument7 pagesWhat Is PETAza_AzlinAizri_2765No ratings yet

- PolyesterDocument28 pagesPolyesterAobscNo ratings yet

- Composites: Fibre Reinforcement (Types of Resins & Types of Fibres)Document5 pagesComposites: Fibre Reinforcement (Types of Resins & Types of Fibres)GUNNAJ SINGH DUGGALNo ratings yet

- Polyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Document8 pagesPolyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Ahmad Shah 8999No ratings yet

- Plastic Bottles and Bottle CapsDocument10 pagesPlastic Bottles and Bottle Capsikki kuroganeNo ratings yet

- Basics of CompositeDocument16 pagesBasics of Compositemythsunni5No ratings yet

- Plastic MaterialsDocument8 pagesPlastic MaterialsHailu BeyechaNo ratings yet

- Polyisocyanurate vs. Polyurethane InsulationDocument2 pagesPolyisocyanurate vs. Polyurethane Insulationhamza awanNo ratings yet

- Polyethylene TerephthalateDocument2 pagesPolyethylene TerephthalatesabbysamuraNo ratings yet

- Lec 8 PlasticDocument3 pagesLec 8 PlasticAsghar Hussain ShahNo ratings yet

- Polyester FiberDocument28 pagesPolyester FiberRashedul IslamNo ratings yet

- Material Description: PolyvinylsDocument13 pagesMaterial Description: Polyvinylsyuvaraja.dhanabalNo ratings yet

- Plastic Lumber ReportDocument6 pagesPlastic Lumber ReportsonakshiNo ratings yet

- Polyester FiberDocument8 pagesPolyester FiberAhasn HabibNo ratings yet

- What Is Polyester Fiber? What Is Understood by Thermoplastic and Thermoset Polyester?Document5 pagesWhat Is Polyester Fiber? What Is Understood by Thermoplastic and Thermoset Polyester?MOJAHID HASAN Fall 19No ratings yet

- Adhesives and SealantsDocument8 pagesAdhesives and SealantsJosephus GallardoNo ratings yet

- Acetal Info FinalDocument3 pagesAcetal Info FinalSteven WhitacreNo ratings yet

- POLYESTERDocument5 pagesPOLYESTERAhmed AlbayatiNo ratings yet

- Fundamentals of Pet Stretch Blow Molded Containers: Container Performance RequirementsDocument7 pagesFundamentals of Pet Stretch Blow Molded Containers: Container Performance RequirementsPrashant SoniNo ratings yet

- Polyethylene Terephthalate (Pet) : HistoryDocument3 pagesPolyethylene Terephthalate (Pet) : HistoryMaleha SalimNo ratings yet

- Materials For RepairDocument11 pagesMaterials For RepairKunwar Apoorv Singh PariharNo ratings yet

- Ethylene Vinyl AcetateDocument5 pagesEthylene Vinyl AcetateAli RazuNo ratings yet

- 104 Aia Eps XPS - 17Document47 pages104 Aia Eps XPS - 17RobNo ratings yet

- Plastics Thermoplastics Thermosetting: Rivera, Patrick Joshua D. Perez, JaysonDocument13 pagesPlastics Thermoplastics Thermosetting: Rivera, Patrick Joshua D. Perez, Jaysonpatrick1101No ratings yet

- Types of PlasticsDocument6 pagesTypes of PlasticsFarrukh ShahzadNo ratings yet

- Vinyl Ester ResinDocument8 pagesVinyl Ester ResinSangeetha RangarajanNo ratings yet

- IJERTV1IS7535Document19 pagesIJERTV1IS7535skgolbanNo ratings yet

- Group No. 6 EVOH AssignmentDocument31 pagesGroup No. 6 EVOH AssignmentGursevak SinghNo ratings yet

- Critical Properties For Specific ApplicationsDocument21 pagesCritical Properties For Specific ApplicationsRANJITHNo ratings yet

- 1) Plastics PackagingDocument29 pages1) Plastics Packaginglightbulboooo1No ratings yet

- PolymerProperties From CESDocument23 pagesPolymerProperties From CESskc3128No ratings yet

- E.G. E.G. E.G. E.G. I.E. Etc. Etc. E.GDocument13 pagesE.G. E.G. E.G. E.G. I.E. Etc. Etc. E.GjoshigautaNo ratings yet

- Polymer Biomaterial (06.10.21)Document3 pagesPolymer Biomaterial (06.10.21)spam accountNo ratings yet

- PolyesterDocument15 pagesPolyesterxavier781999No ratings yet

- Polyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Document11 pagesPolyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Muhammad TanweerNo ratings yet

- One Vendor Complete List of Materials Available For Plastic Nuts and BoltsDocument5 pagesOne Vendor Complete List of Materials Available For Plastic Nuts and BoltsChristopher HartmanNo ratings yet

- 1020 PPTDocument15 pages1020 PPTUMANSHU GUPTANo ratings yet

- Products: Azote AzoteDocument4 pagesProducts: Azote Azotequinny88No ratings yet

- CRD The Use and Application of Epoxy Resin Vs Vinylester Vs PolyesterDocument4 pagesCRD The Use and Application of Epoxy Resin Vs Vinylester Vs PolyesterArjun PrasadNo ratings yet

- High Performance Plastics Materials Guide: Craftech Industries'Document20 pagesHigh Performance Plastics Materials Guide: Craftech Industries'akirloskarNo ratings yet

- ResinDocument2 pagesResinrizwan56992No ratings yet

- Plastic TypesDocument7 pagesPlastic TypesMiguel ArriecheNo ratings yet

- Thermoplasti &thermosetDocument25 pagesThermoplasti &thermosetabasoudaNo ratings yet

- RUBBER NewDocument10 pagesRUBBER NewAleem AhmedNo ratings yet

- Case of Study: 1. Toe SupportDocument6 pagesCase of Study: 1. Toe SupportEduardo Labastida ArceNo ratings yet

- Filtros de Mangas para DespoeiramentoDocument3 pagesFiltros de Mangas para DespoeiramentoEder PereiraNo ratings yet

- 003 FAIRMATE - Construction ChemicalsDocument8 pages003 FAIRMATE - Construction Chemicalsfairmatechemical100% (1)

- Chemical Modification of PolyestersDocument11 pagesChemical Modification of PolyestersVASANHF1No ratings yet

- 1 ThermoplasticDocument8 pages1 ThermoplasticabasoudaNo ratings yet

- New Fibres For Home Textile - PTT Triexta FibreDocument5 pagesNew Fibres For Home Textile - PTT Triexta FibreVasant KothariNo ratings yet

- Polyester ResinDocument36 pagesPolyester ResinaliNo ratings yet

- DIY Resin Crafting Projects: A Beginner's Guide to Making Clear Resin Jewelry, Paperweights, Coasters, and Other KeepsakesFrom EverandDIY Resin Crafting Projects: A Beginner's Guide to Making Clear Resin Jewelry, Paperweights, Coasters, and Other KeepsakesRating: 5 out of 5 stars5/5 (2)

- Leather Investigations - The Composition of Some Sole LeathersFrom EverandLeather Investigations - The Composition of Some Sole LeathersNo ratings yet

- Acrylol SynthesisDocument2 pagesAcrylol Synthesis8612106535No ratings yet

- Self-Adhesive Materials For Plastic Surfaces: Technical Info #7Document2 pagesSelf-Adhesive Materials For Plastic Surfaces: Technical Info #78612106535No ratings yet

- Surfactants Emulsion PolymersDocument2 pagesSurfactants Emulsion Polymers8612106535100% (2)

- Phenolic Resins Specification: Condition ConditionDocument1 pagePhenolic Resins Specification: Condition Condition8612106535No ratings yet

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document9 pagesEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)8612106535No ratings yet

- 15885Document1 page158858612106535No ratings yet

- Morpholine PDFDocument2 pagesMorpholine PDF8612106535No ratings yet

- TDS SR238 2Document1 pageTDS SR238 28612106535No ratings yet

- 1K Blocked Series BULLETIN PDFDocument1 page1K Blocked Series BULLETIN PDF8612106535No ratings yet

- EDTA Manganese Sodium (EDTA-MnNa2)Document2 pagesEDTA Manganese Sodium (EDTA-MnNa2)8612106535No ratings yet

- EDTA Magnesium Sodium (EDTA-MgNa2)Document2 pagesEDTA Magnesium Sodium (EDTA-MgNa2)8612106535No ratings yet

- Morpholine PDFDocument2 pagesMorpholine PDF8612106535No ratings yet

- DAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and AdditivesDocument2 pagesDAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and Additives8612106535No ratings yet

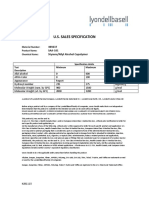

- Sales Specification - US - 2Document1 pageSales Specification - US - 28612106535No ratings yet

- 3D Formpress Technologie GB US PDFDocument2 pages3D Formpress Technologie GB US PDF8612106535No ratings yet

- Desmocoll 400-1Document3 pagesDesmocoll 400-18612106535No ratings yet

- HI-THANE A-3310D: Technical InformationDocument1 pageHI-THANE A-3310D: Technical Information8612106535No ratings yet

Difference Ether Ester - 111010

Difference Ether Ester - 111010

Uploaded by

8612106535Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Difference Ether Ester - 111010

Difference Ether Ester - 111010

Uploaded by

8612106535Copyright:

Available Formats

Information Sheet

SUBJECT: DIFFERENCE BETWEEN POLYETHER & POLYESTER

POLYETHER: Conventional & Polymer Polyol (Grafted) Products:

Ether foams have excellent memory. When compressed, ethers return to the original shape.

Ether die-cuts cleanly and, because of good memory, recovers with crisp, clean edges.

Ethers are more hydrolytically stable, therefore, will not break down when subjected to heat and moisture.

Conventional ethers are generally less expensive than grafted polyol ethers and polyesters.

From a fabricating standpoint, ether buns are much larger; therefore, produce better yields with less

handling.

Ether densities range from < l.0 pcf (pounds per cubic foot) through & including 6.0 pcf.

Ether IFD (indent force defection), an indication of firmness, can range from 15 through 200 lbs./50 in.2

By varying the combination of density and IFD, a broad range of products can be developed.

Ethers are more resistant to acids and bases.

Grafted products have the strength and firmness of esters with the positive characteristics of ethers.

POLYESTER:

Esters can be produced in either clickable (i.e., they die cut easily and cleanly) or non-clickable (i.e., the

edges could crimp or seal when cut) formulations.

Esters are available in densities from 1.5 pcf through 6.0 pcf.

Esters have excellent physical properties of tensile, tear and elongation, therefore, can withstand

stretching and abrasive handling.

Esters swell less than ethers when subject to hydrocarbons, alcohols, etc..

Esters have a more uniform controlled cell structure.

Esters can be thermally or chemically reticulated for value-added properties for filtration.

Note: Flexible polyurethane foam is tested in accordance with ASTM D 3574.

You might also like

- Polyester: History Forms Manufacturing Process Properties Future UsesDocument28 pagesPolyester: History Forms Manufacturing Process Properties Future UsesAron Solanki100% (3)

- Adhesives and SealantsDocument40 pagesAdhesives and SealantsEmie Grace Villavicencio Moting100% (2)

- Polyester, Cobalt Particulate and Rockwool FiberDocument66 pagesPolyester, Cobalt Particulate and Rockwool FiberShashank Singh100% (1)

- What Is Pet (Polyethylene Terephthalate) : Melting Temperature: 254-256 C Crystallinity: 45%Document32 pagesWhat Is Pet (Polyethylene Terephthalate) : Melting Temperature: 254-256 C Crystallinity: 45%Sky ValleyNo ratings yet

- What Is PET PolyEthylene TerephthalateDocument6 pagesWhat Is PET PolyEthylene TerephthalateAnandKuttiyanNo ratings yet

- Handout Packaging MaterialsDocument15 pagesHandout Packaging MaterialsShahnasNo ratings yet

- What Is PETDocument7 pagesWhat Is PETAza_AzlinAizri_2765No ratings yet

- PolyesterDocument28 pagesPolyesterAobscNo ratings yet

- Composites: Fibre Reinforcement (Types of Resins & Types of Fibres)Document5 pagesComposites: Fibre Reinforcement (Types of Resins & Types of Fibres)GUNNAJ SINGH DUGGALNo ratings yet

- Polyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Document8 pagesPolyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Ahmad Shah 8999No ratings yet

- Plastic Bottles and Bottle CapsDocument10 pagesPlastic Bottles and Bottle Capsikki kuroganeNo ratings yet

- Basics of CompositeDocument16 pagesBasics of Compositemythsunni5No ratings yet

- Plastic MaterialsDocument8 pagesPlastic MaterialsHailu BeyechaNo ratings yet

- Polyisocyanurate vs. Polyurethane InsulationDocument2 pagesPolyisocyanurate vs. Polyurethane Insulationhamza awanNo ratings yet

- Polyethylene TerephthalateDocument2 pagesPolyethylene TerephthalatesabbysamuraNo ratings yet

- Lec 8 PlasticDocument3 pagesLec 8 PlasticAsghar Hussain ShahNo ratings yet

- Polyester FiberDocument28 pagesPolyester FiberRashedul IslamNo ratings yet

- Material Description: PolyvinylsDocument13 pagesMaterial Description: Polyvinylsyuvaraja.dhanabalNo ratings yet

- Plastic Lumber ReportDocument6 pagesPlastic Lumber ReportsonakshiNo ratings yet

- Polyester FiberDocument8 pagesPolyester FiberAhasn HabibNo ratings yet

- What Is Polyester Fiber? What Is Understood by Thermoplastic and Thermoset Polyester?Document5 pagesWhat Is Polyester Fiber? What Is Understood by Thermoplastic and Thermoset Polyester?MOJAHID HASAN Fall 19No ratings yet

- Adhesives and SealantsDocument8 pagesAdhesives and SealantsJosephus GallardoNo ratings yet

- Acetal Info FinalDocument3 pagesAcetal Info FinalSteven WhitacreNo ratings yet

- POLYESTERDocument5 pagesPOLYESTERAhmed AlbayatiNo ratings yet

- Fundamentals of Pet Stretch Blow Molded Containers: Container Performance RequirementsDocument7 pagesFundamentals of Pet Stretch Blow Molded Containers: Container Performance RequirementsPrashant SoniNo ratings yet

- Polyethylene Terephthalate (Pet) : HistoryDocument3 pagesPolyethylene Terephthalate (Pet) : HistoryMaleha SalimNo ratings yet

- Materials For RepairDocument11 pagesMaterials For RepairKunwar Apoorv Singh PariharNo ratings yet

- Ethylene Vinyl AcetateDocument5 pagesEthylene Vinyl AcetateAli RazuNo ratings yet

- 104 Aia Eps XPS - 17Document47 pages104 Aia Eps XPS - 17RobNo ratings yet

- Plastics Thermoplastics Thermosetting: Rivera, Patrick Joshua D. Perez, JaysonDocument13 pagesPlastics Thermoplastics Thermosetting: Rivera, Patrick Joshua D. Perez, Jaysonpatrick1101No ratings yet

- Types of PlasticsDocument6 pagesTypes of PlasticsFarrukh ShahzadNo ratings yet

- Vinyl Ester ResinDocument8 pagesVinyl Ester ResinSangeetha RangarajanNo ratings yet

- IJERTV1IS7535Document19 pagesIJERTV1IS7535skgolbanNo ratings yet

- Group No. 6 EVOH AssignmentDocument31 pagesGroup No. 6 EVOH AssignmentGursevak SinghNo ratings yet

- Critical Properties For Specific ApplicationsDocument21 pagesCritical Properties For Specific ApplicationsRANJITHNo ratings yet

- 1) Plastics PackagingDocument29 pages1) Plastics Packaginglightbulboooo1No ratings yet

- PolymerProperties From CESDocument23 pagesPolymerProperties From CESskc3128No ratings yet

- E.G. E.G. E.G. E.G. I.E. Etc. Etc. E.GDocument13 pagesE.G. E.G. E.G. E.G. I.E. Etc. Etc. E.GjoshigautaNo ratings yet

- Polymer Biomaterial (06.10.21)Document3 pagesPolymer Biomaterial (06.10.21)spam accountNo ratings yet

- PolyesterDocument15 pagesPolyesterxavier781999No ratings yet

- Polyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Document11 pagesPolyethylene: Industrial Polymers 1.polyethylene Terephthalate (PET, PETE)Muhammad TanweerNo ratings yet

- One Vendor Complete List of Materials Available For Plastic Nuts and BoltsDocument5 pagesOne Vendor Complete List of Materials Available For Plastic Nuts and BoltsChristopher HartmanNo ratings yet

- 1020 PPTDocument15 pages1020 PPTUMANSHU GUPTANo ratings yet

- Products: Azote AzoteDocument4 pagesProducts: Azote Azotequinny88No ratings yet

- CRD The Use and Application of Epoxy Resin Vs Vinylester Vs PolyesterDocument4 pagesCRD The Use and Application of Epoxy Resin Vs Vinylester Vs PolyesterArjun PrasadNo ratings yet

- High Performance Plastics Materials Guide: Craftech Industries'Document20 pagesHigh Performance Plastics Materials Guide: Craftech Industries'akirloskarNo ratings yet

- ResinDocument2 pagesResinrizwan56992No ratings yet

- Plastic TypesDocument7 pagesPlastic TypesMiguel ArriecheNo ratings yet

- Thermoplasti &thermosetDocument25 pagesThermoplasti &thermosetabasoudaNo ratings yet

- RUBBER NewDocument10 pagesRUBBER NewAleem AhmedNo ratings yet

- Case of Study: 1. Toe SupportDocument6 pagesCase of Study: 1. Toe SupportEduardo Labastida ArceNo ratings yet

- Filtros de Mangas para DespoeiramentoDocument3 pagesFiltros de Mangas para DespoeiramentoEder PereiraNo ratings yet

- 003 FAIRMATE - Construction ChemicalsDocument8 pages003 FAIRMATE - Construction Chemicalsfairmatechemical100% (1)

- Chemical Modification of PolyestersDocument11 pagesChemical Modification of PolyestersVASANHF1No ratings yet

- 1 ThermoplasticDocument8 pages1 ThermoplasticabasoudaNo ratings yet

- New Fibres For Home Textile - PTT Triexta FibreDocument5 pagesNew Fibres For Home Textile - PTT Triexta FibreVasant KothariNo ratings yet

- Polyester ResinDocument36 pagesPolyester ResinaliNo ratings yet

- DIY Resin Crafting Projects: A Beginner's Guide to Making Clear Resin Jewelry, Paperweights, Coasters, and Other KeepsakesFrom EverandDIY Resin Crafting Projects: A Beginner's Guide to Making Clear Resin Jewelry, Paperweights, Coasters, and Other KeepsakesRating: 5 out of 5 stars5/5 (2)

- Leather Investigations - The Composition of Some Sole LeathersFrom EverandLeather Investigations - The Composition of Some Sole LeathersNo ratings yet

- Acrylol SynthesisDocument2 pagesAcrylol Synthesis8612106535No ratings yet

- Self-Adhesive Materials For Plastic Surfaces: Technical Info #7Document2 pagesSelf-Adhesive Materials For Plastic Surfaces: Technical Info #78612106535No ratings yet

- Surfactants Emulsion PolymersDocument2 pagesSurfactants Emulsion Polymers8612106535100% (2)

- Phenolic Resins Specification: Condition ConditionDocument1 pagePhenolic Resins Specification: Condition Condition8612106535No ratings yet

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document9 pagesEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)8612106535No ratings yet

- 15885Document1 page158858612106535No ratings yet

- Morpholine PDFDocument2 pagesMorpholine PDF8612106535No ratings yet

- TDS SR238 2Document1 pageTDS SR238 28612106535No ratings yet

- 1K Blocked Series BULLETIN PDFDocument1 page1K Blocked Series BULLETIN PDF8612106535No ratings yet

- EDTA Manganese Sodium (EDTA-MnNa2)Document2 pagesEDTA Manganese Sodium (EDTA-MnNa2)8612106535No ratings yet

- EDTA Magnesium Sodium (EDTA-MgNa2)Document2 pagesEDTA Magnesium Sodium (EDTA-MgNa2)8612106535No ratings yet

- Morpholine PDFDocument2 pagesMorpholine PDF8612106535No ratings yet

- DAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and AdditivesDocument2 pagesDAOTAN VTW 1265/36WA: Technical Datasheet Liquid Coating Resins and Additives8612106535No ratings yet

- Sales Specification - US - 2Document1 pageSales Specification - US - 28612106535No ratings yet

- 3D Formpress Technologie GB US PDFDocument2 pages3D Formpress Technologie GB US PDF8612106535No ratings yet

- Desmocoll 400-1Document3 pagesDesmocoll 400-18612106535No ratings yet

- HI-THANE A-3310D: Technical InformationDocument1 pageHI-THANE A-3310D: Technical Information8612106535No ratings yet