Professional Documents

Culture Documents

Tutorial

Tutorial

Uploaded by

situmbeko undiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial

Tutorial

Uploaded by

situmbeko undiCopyright:

Available Formats

THE COPPERBELT UNIVERSITY

SCHOOL OF ENGINEERING

Mechanical Department

COURSE: TRIBOLOGY EM 560 Tutorial Date: 19.12.2016

QUESTION ONE

An infinitely long linear wedge bearing of length L = 100 [mm] and width B = 20 [mm] is operating

under an inlet film thickness of h0 = 20 [m]. Assuming constant velocity U = 10 [m/s] and constant

oil viscosity =3.5x10-3 [Pas]

i. Find the maximum load the bearing can support,

ii. Find the non-dimensional load

iii. Calculate the inlet film thickness.

QUESTION TWO

A journal bearing of 0.06 [m] diameter, 0.015 [m] length and 10 [m] clearance operating at 1000

[rpm] supports a load of 10 [kN]. Assuming isothermal conditions and optimal eccentricity ratio of

= 0.7, find the oil viscosity needed to lubricate this bearing.

QUESTION THREE

A journal bearing has to be designed to support a radial load of 1280 N which is placed on a shaft of

96mm diameter. The shaft rotates at 1800 rpm and its eccentricity is 0.038 mm. The desired

temperature rise of the lubricant is to be 10 oC. As the bearing will be well cooled, it may be assumed

that 70% of the heat generated will be convected by the oil.

Design the bearing by determining its performance characteristics if the following parameters are

given:

L = 0.102; c = 5.1 x 10-5m; = 4.1 x 10-2Nsm-2; Specific heat = 1800 J/Kg0C; density = 880 Kg/m3

QUESTION FOUR

A plain bearing with hydrodynamic lubrication is to be designed to carry a load of 2500 N at a shaft

speed of 30 revs per second. Initial assumptions are that a SAE grade 40 oil will be used and the

mean oil temperature in the bearing is 68.3oC. At this temperature the oil has an absolute viscosity of

0.0275 Pa.s.

The density is assumed to be 850 kg/m3 and the specific heat 1800 J/kg oC .

As a starting point it will be assumed that the: length / diameter ratio = 1 and for a first calculation

length = diameter = 2 radius = 40 mm will be used. l = d = 2 r = 40mm

It is also assumed that the bearing has a radial clearance of 0.04 mm.

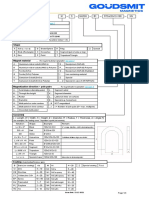

Determine the operating characteristics of the bearing. (Use the graph in Fig. 1 for analysis)

You might also like

- MECH4407 Past Exams 002Document7 pagesMECH4407 Past Exams 002Abhi MoharanaNo ratings yet

- What Are Different Tests For Concrete Quality CheckDocument7 pagesWhat Are Different Tests For Concrete Quality CheckZahid EmuNo ratings yet

- Skempto 1961 Effective Stress in Soils Concrete and RocksDocument13 pagesSkempto 1961 Effective Stress in Soils Concrete and RocksSaid_Lopez_Mx100% (1)

- The Copperbelt University School of EngiDocument3 pagesThe Copperbelt University School of Engiyousef mohamedNo ratings yet

- DMM-2 Question BankDocument3 pagesDMM-2 Question BankrajuNo ratings yet

- Mechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Document4 pagesMechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Harpinder GotraaNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- Homework 2 - Thrust BearingsDocument1 pageHomework 2 - Thrust BearingsNur Hanim Abd GhaniNo ratings yet

- Cycle Test 2 Rocket PropulsionDocument3 pagesCycle Test 2 Rocket Propulsionapi-271354682No ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- ME2303Document3 pagesME2303Ganesh RamNo ratings yet

- Question Bank For CA-IDocument1 pageQuestion Bank For CA-ISamarth PatilNo ratings yet

- Dme Model Set BDocument3 pagesDme Model Set BSAMUEL SANJAY RAJA R MECHNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- Chapter Wise Questions Bank MD-iiDocument6 pagesChapter Wise Questions Bank MD-iiinderpreet singhNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- WWW Manaresults Co inDocument3 pagesWWW Manaresults Co inGod deva123No ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- DMM 2Document6 pagesDMM 2Shubham MahajanNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model Paperlalamramesh78No ratings yet

- Design of Machine ElementsDocument3 pagesDesign of Machine ElementsHariharanAutoNo ratings yet

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Question PapersDocument89 pagesQuestion PapersDreamer ChavanNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Me8593 - Dme - Model QPDocument3 pagesMe8593 - Dme - Model QPChandrasekhar PrabhakaranNo ratings yet

- Tutorial 1 - Chapter 1 Fluid PropertiesDocument2 pagesTutorial 1 - Chapter 1 Fluid Propertieszul hilmiNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- 6C0034Document5 pages6C0034Joshua prabuNo ratings yet

- Sliding Contact BearingDocument4 pagesSliding Contact BearingSp PatelNo ratings yet

- r05320305 Design of Machine Members IIDocument9 pagesr05320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- MD-III - TUT - 5 and 6Document5 pagesMD-III - TUT - 5 and 6Sushil ThakkarNo ratings yet

- DMM2 I Mid 2024Document1 pageDMM2 I Mid 2024Rkrishna ANo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- Possible Exercise On Machine Element Two Flat BeltDocument4 pagesPossible Exercise On Machine Element Two Flat BeltAbebaw AyeleNo ratings yet

- Date: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinDocument2 pagesDate: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinsathishskymechNo ratings yet

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsDocument5 pagesMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SNo ratings yet

- ME-311 Belt 2018Document2 pagesME-311 Belt 2018VishnuNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Question Paper Code:: Reg. NoDocument3 pagesQuestion Paper Code:: Reg. NoSURESH KUMAR APNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- R5310305-Design of Machine Members - IDocument4 pagesR5310305-Design of Machine Members - IsivabharathamurthyNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- DMM Ii Slip Test Unit 1Document1 pageDMM Ii Slip Test Unit 1jeevankchNo ratings yet

- Design of Machine Elements Question Paper SampleDocument6 pagesDesign of Machine Elements Question Paper SampleK V SATHEESHKUMAR MECHNo ratings yet

- rr312404 Design of Machine ElementsDocument8 pagesrr312404 Design of Machine ElementsSRINIVASA RAO GANTANo ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- Gujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70Document3 pagesGujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70NILESH SUTHARNo ratings yet

- Instructions:: No of Pages Course CodeDocument2 pagesInstructions:: No of Pages Course CodeCRAZY PIANO PLAYERNo ratings yet

- WWW Manaresults Co inDocument3 pagesWWW Manaresults Co inTanniru AnjibabuNo ratings yet

- Akışkanlar Mek.Document6 pagesAkışkanlar Mek.Sai PranayNo ratings yet

- MECH5265 Tutorial 06Document1 pageMECH5265 Tutorial 06hnyjd2No ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Prestressed Concrete: Lecture No. (9) DateDocument29 pagesPrestressed Concrete: Lecture No. (9) DateNA PoNo ratings yet

- Classifications of Dental Ceramics (Autosaved)Document52 pagesClassifications of Dental Ceramics (Autosaved)Muralidharan100% (1)

- Effects of Welding Speeds and Power Inputs On The Hardness Property of Type 304L Austenitic Stainless Steel Heat-Affected Zone (HAZ)Document6 pagesEffects of Welding Speeds and Power Inputs On The Hardness Property of Type 304L Austenitic Stainless Steel Heat-Affected Zone (HAZ)SEP-PublisherNo ratings yet

- Copper Brass Bronze CW721R High Tensile Brass Manganese Bronze - CZ114Document2 pagesCopper Brass Bronze CW721R High Tensile Brass Manganese Bronze - CZ114alextentwentyNo ratings yet

- Moment-Rotation Characterization of Cold-Formed Steel Beam in Box SectionDocument1 pageMoment-Rotation Characterization of Cold-Formed Steel Beam in Box SectionXavier NietoNo ratings yet

- Grade 7 Mixtures and Solutions Full ReviewDocument28 pagesGrade 7 Mixtures and Solutions Full Reviewblackcat657No ratings yet

- Inorganic Photovoltaics - Planar and Nanostructured DevicesDocument111 pagesInorganic Photovoltaics - Planar and Nanostructured DevicesUdai SinghNo ratings yet

- Mathematical Formulation and Numerical Modeling of Wax Deposition in Pipelines From Enthalpy-Porosity Approach and Irreversible ThermodynamicsDocument12 pagesMathematical Formulation and Numerical Modeling of Wax Deposition in Pipelines From Enthalpy-Porosity Approach and Irreversible ThermodynamicspedroNo ratings yet

- CSH Calcium Silicate Hydrates (Luc Nicoleau)Document27 pagesCSH Calcium Silicate Hydrates (Luc Nicoleau)José Luis CampelloNo ratings yet

- CuO Decoration Controls Nb2O5 Photocatalyst Selectivity in CO2 ReductionDocument30 pagesCuO Decoration Controls Nb2O5 Photocatalyst Selectivity in CO2 ReductionAlejandro SifuentesNo ratings yet

- Diagrama de FasesDocument19 pagesDiagrama de FasesMarcelo S SilvaNo ratings yet

- Irl 3705 NDocument9 pagesIrl 3705 NMeunome99No ratings yet

- Lecture 13 - Angular DeformationDocument9 pagesLecture 13 - Angular DeformationjaggumeenaiitdNo ratings yet

- Physics B 2009 Free ResponseDocument40 pagesPhysics B 2009 Free ResponseChandlerNo ratings yet

- Cantilever ReportDocument7 pagesCantilever ReportDenny MoranNo ratings yet

- ASTM C 120 Standard Test Methods of Flexure Testing of Slate (Modulus of Rupture, Modulus of ElasDocument3 pagesASTM C 120 Standard Test Methods of Flexure Testing of Slate (Modulus of Rupture, Modulus of ElasRyan LasacaNo ratings yet

- Resistance Measurement July 22Document11 pagesResistance Measurement July 22abhrajitsahaNo ratings yet

- Page 0002Document1 pagePage 0002has sas100% (1)

- Bearing CapacityDocument59 pagesBearing CapacityAryan Arora67% (3)

- CHAPTER 1 2.0 Low Voltage SystemDocument21 pagesCHAPTER 1 2.0 Low Voltage SystemfahmiNo ratings yet

- Magnetic Particle Testing - 1Document128 pagesMagnetic Particle Testing - 1Shankara100% (1)

- 01-01 Metallography - An IntroductionDocument18 pages01-01 Metallography - An IntroductionidanfriNo ratings yet

- Residual Embrittlement in Metallic Coated, Externally Threaded Articles, Fasteners, and Rod-Inclined Wedge MethodDocument4 pagesResidual Embrittlement in Metallic Coated, Externally Threaded Articles, Fasteners, and Rod-Inclined Wedge MethodROHITNo ratings yet

- ST KPS 10Document2 pagesST KPS 10ecosistemisolariNo ratings yet

- Simulation and Experimental Validation of Heat Transfer in A Novel Hybrid Solar PanelDocument7 pagesSimulation and Experimental Validation of Heat Transfer in A Novel Hybrid Solar PanelVicky RajasekharanNo ratings yet

- TDS - Epolam 2015 US Rev-04Document3 pagesTDS - Epolam 2015 US Rev-04McFlyNo ratings yet

- Product Key MX - Magnet PermanentDocument4 pagesProduct Key MX - Magnet PermanentFooNo ratings yet

- Kristalisasi: 342 1600 4 Vσ 4 x 0.21375 x 0.003 1 x 8.314 x 293 x LDocument2 pagesKristalisasi: 342 1600 4 Vσ 4 x 0.21375 x 0.003 1 x 8.314 x 293 x LArsyika Oktaviani100% (2)