Professional Documents

Culture Documents

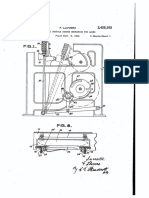

United States Patent (191: Ouellette

United States Patent (191: Ouellette

Uploaded by

cxzczxOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent (191: Ouellette

United States Patent (191: Ouellette

Uploaded by

cxzczxCopyright:

Available Formats

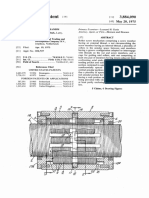

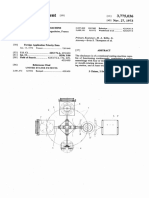

United States Patent [191 [111 3,747,249

Ouellette [451 July 24, 1973

[54] FEEDING SYSTEM FOR AUTOMATIC EXEMPLARY CLAIM

FIREARMS WITH A ROTARY DRUM

1. In a ?rearm, the combination comprising a rotatable

[75] Inventor: Herve J. Ouellette, Spring?eld, Mass. drum, annular channels in the drum, a plurality of

[73] Assignee: The United States of America as chambers formed in said drum ?or radially receiving

represented by the Secretary of the cartridges thereinto, and a magazine arranged for re

Army, Washington, DC. placeable installation in the ?rearm in communication

with said chambers, said magazine including a feeding

[221 Filed: Dec. 13, 1963 compartment for holding a stack of cartridges, means

[211 App]. No.: 330,506 for biasing the stack of cartridges towards said cham

bers, a retrieval compartment for receiving ?red cases

of the cartridges, a spring-biased follower slidingly dis

[52] U.S. Cl. .............. .. 42/50, 89/33 MC, 89/33 BA posed in said retrieval compartment for controlling the

[5l] Int. Cl. ............................................ .. F4ld 7/04 positions of the ?red cases therein, a partition separat

[58] Field of Search .................... .. 89/33; 42/49, 50, ing said supply compartment and said retrieval com

42/22, 18 partment, and ?ngers extending from said partition into

said channels for guiding the cartridges into said cham

Primary Examiner~Stephen C. Bentley bers and ejecting the fired cases therefrom into said re

Attorney-Harry M. Saragovitz, Edward J. Kelly, trieval compartment.

Herbert Berl and Albert E. Arnold, Jr.

5 Claims, 9 Drawing Figures

3,747,249

I 2

FEEDING SYSTEM FOR AUTOMATIC FIREARMS cles drum 22, except where interrupted by magazine

WITH A ROTARY DRUM well 20, to form the perimeter of drum cavity 18.

The invention described herein may be manufac Cartridges 14 are fed to chambers 32 from a maga

tured and used by or for the Government for govern zine 40, the upper end of which is received by magazine

mental purposes without the payment to me of any roy well 20, and ?red cases 36 are returned into the maga

alty thereon. zine, as hereinafter described.

This invention relates to ?rearms and pertains more Magazine 40 is of a box-type and includes two com

particularly to the feeding mechanisms thereof which partments including a feeding compartment 42 and a

include box-type magazines. retrieval compartment 44. Feeding compartment 42 is

It is one object of this invention to provide for ?re for storing a stack of cartridges l4 and it is positioned

arms having a chambered drum adapted for receiving for feeding the cartridges to drum 22. Retrieval com

cartridges radially thereinto a magazine which feeds partment 44 is for receiving the ?red cases 36 from

cartridges radially to the drum and receives the ?red drum 22. Compartments 42 and 44 are separated by a

cases radially therefrom. partition 46. A pair of fingers 48 extend outwardly

It is another object of this invention to provide such 15 from partition 46 so as to be received by a pair of annu

a magazine with retainers for releasably holding the lar channels 49 formed in drum 22 to aid in guiding car

cartridges and/or ?red cases in the magazine when re tridges 14 into chambers 32 and extracting ?red cases

moved from the gun. 36 therefrom.

It is a further object of this invention to arrange the Slidingly mounted in feeding compartment 42 is a

retainers so as to automatically release the cartridges 20 first follower 50 which is biased upwardly by a spring

for feeding when the magazine is fully installed in the 52 to push the cartridges 14 from the feeding compart

?rearm. ment into chambers 32. A second follower 54 is slid

It is still another object of this invention to arrange ingly mounted in retrieval compartment 44 and is bi_

the retainers so that they will also act to hold the maga ased upwardly therein by a spring 56 to control the po

zine in the ?rearm when fully installed therein. 25 sitions of ?red cases 36 when received therein.

The speci?c nature of the invention as well as other With cartrides 14 having to be delivered radially

objects and advantages thereof will clearly appear from from magazine 40 into chambers 32, the problem arises

a description of a preferred embodiment as shown in as to means for retaining the cartridges in feeding com

the accompanying drawings in which: partment 42 against the bias of spring 52 when the

FIG. 1 is a fragmentary, longitudinally cross magazine is not fully installed in the ri?e 12 and for re

sectioned side view of a ri?e showing the feeding mech leasing the cartridges so as to feed into the chambers

anism of this invention installed therein; when the magazine is fully installed in magazine well

FIGS. 2-4 are taken along line 2-2 of FIG. 1 and 20. That problem is successfully resolved by rotatively

progressively show the feeding of the cartridges in the 35 mounting on opposite sides of magazine 40 a pair of re

magazine to the drum and the ejection of the ?red tainers 58 which releasably hold cartridges l4 and ?red

cases from the drum into the magazine; cases 36 in the magazine and which are respectively

FIG. 5 is a fragmentary side view of the magazine disposed for cooperation with a pair of latches 60 for

showing one of the retainers mounted therein; releasably holding the magazine in; magazine well 20 as

FIG. 6 is an enlarged, fragmentary end view of the hereinafter described.

magazine; and Formed in each side of magazine well 20, where

FIGS. 7-9 are enlarged fragmentary views similar to joined to receiver 16, is a U-shaped channel 62 which

FIGS. 2-4 but progressively showing the cooperation is longitudinally disposed and which opens laterally

between the channels in the magazine well and the re into the magazine well. Channels 62 respectively in

tainers during installation of the magazine. 45

clude a bottom side 63 and a top side 64 which over

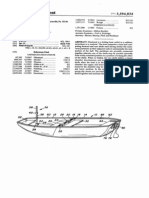

Shown in the figures is an automatic rifle 12 designed hang the bottom side, for a reason to be hereinafter ex

for use with self-supporting cartridges 14 which do not plained, and a planar surface 66 extends upwardly and

need chamber support when discharged to prevent inwardly from each of the top sides to form a fulcrum

point 67.

eruption of the case. Ri?e 12 includes a receiver 16

having a drum cavity 18 and a magazine well 20 which 50 Latches 60 are each pivotally mounted intermediate

the ends thereof on the outside of magazine well 20 so

extends upwardly into communication therewith, a

as to form a lower actuator portion 68 and an upper

drum 22 rotatively mounted in the drum cavity, a recoil

actuated sliding member 28 adapted to successively ro latching portion 70. The upper ends of latching por

tions 70 are received by corresponding slots 72 in chan

tate the drum, through means not shown, 120 in a

counterclockwise direction responsive to each dis 55 nels 62 to engageably cooperate with the related ones

charge of the ri?e, and a barrel 30. of the retainers 58. A lug 74 protrudes inwardly from

the end of each of the latching portions 70 and a spring

Drum 22 is provided with three semicylindrical

76 operationally cooperates with each of the latches 60

chambers 32 which are spaced 120 apart therein and

to press the lug into the respective one of the channels

are arranged to be alignable with barrel 30 when in the

l2 o'clock firing position. Each of the chambers 32 is 60 62. Lugs 74 are displaced from channels 62 by pressing

inwardly against the actuator portions 68.

provided with a mouth portion 34 which permits radial

Retainers 58 include a right-hand retainer 78 and a

entry of the cartridges 14 thereinto and the ejection of lefthand retainer 80 which are associated respectively

the fired cases 36 therefrom as shown in FIGS. 2-4.

with feeding compartment 42 and retrieval compart

Cartridges 14 are retained in the associated chambers

32 during rotation to the 12 oclock ?ring position and 65 ment 44. Retainers 58 are each mounted for limited ro

tational displacement on a pin 82 which is held by the

?red cases 36 are retained in the chambers during rota outwardly rolled edge of the respective side of maga

tion therefrom by a circular guide wall 38 which encir zine 40 so that the axes of the retainers are located out~

3,747,249

3 4

side such sides. A clearance 84 with an edge 85 is pro ment 42 any cartridges 14 which may remain therein

vided in each of the rolled edges to receive the respec and holding wing 98 will retain in retrieval compart

tive one of the retainers 58. Right-hand retainer 78 is ment 44 any ?red cases 36 therein.

of triangular con?guration in cross-section and in Although a particular embodiment of the invention

cludes a holding wing 90, which extends into feeding has been described in detail herein, it is evident that

compartment 42 for blocking contact by the top car many variations may be devised within the spirit and

tridge 14 therein, an actuator-locking wing 92, and a scope thereof and the following claims are intended to

connecting side 93. A spring 94 biases righthand re include such variations.

tainer 78 in a counterclockwise direction which move I claim:

ment is limited by contact of holding wing 90 with the 1. In a ?rearm, the combination comprising a rotat

associated edge 85. When right-hand retainer 78 is in able drum, annular channels in the drum, a plurality of

contact with the associated edge 85, holding wing 90 is chambers formed in said drum for radially receiving

so angularly related to the radius of cartridge 14 at the cartridges thereinto, and a magazine arranged for re

1 point of contact (see FIG..6) that the upper thrust of placeable installation in the firearm in communication '

the cartridges by spring 52 is converted to counter with said chambers, said magazine including a feeding

clockwise bias of right-hand retainer 78 against such compartment for holding a stack of cartridges, means

edge to securely block the cartridges against upward for biasing the stack of cartridges towards said cham

displacement. bers, a retrieval compartment for receiving ?red cases

Left-hand retainer 80 is oppositely similar to right of the cartridges, a spring-biased follower slidingly dis

hand retainer 78 and includes a holding wing 98, which 20 posed in said retrieval compartment for controlling the

extends into retrieval compartment 44 for blocking positions of the ?red cases therein, a partition separat

contact with the top one of the ?red cases 36 therein, ing said supply compartment and said retrieval com

an actuator-locking wing 100 and a connecting side partment, and fingers extending from said partition into

10]. A spring 102 biases left-hand retainer 80 in a said channels for guiding the cartridges into said cham

clockwise direction with such movement being limited 25 bers and ejecting the ?red cases therefrom into said re

by contact of holding wing 90 with the associated edge trieval compartment.

85. 2. The combination as de?ned in claim 1 and includ

Thus, when magazine 40 is loaded, the stack of car ing a pair of retainers arranged for releasably holding

tridges 14 in feeding compartment 42 is releasably held the cartridges in the feeding compartment and the ?red

therein by right-hand retainer 78 and retrieval com- 30 cases in the retrieval compartment when said magazine

partment 44 is empty. Magazine 40 is installed in rifle is removed from the ?rearm, and means for actuating

12 by inserting top of the magazine into magazine well said retainers to release the cartridges in said feeding

20' and pressing inwardly. When magazine 40 is nearly compartment and to permit entry of the fired cases into

pressed into fully installed position, the ends of the ac said retrieval compartment when said magazine is in

tuatorlock wings 92 and 100 contact the overhanging 35 stalled in the ?rearm.

portions of top sides 64 of channels 62 (FIG. 7) to com 3. The combination as de?ned in claim 2 and includ

mence rotation of retainers 58. Continued inward ing a pair of channels respectively'disposed in the fire

movement of magazine 40 transfers the points of con arm in cooperation with said retainers for actuation

tact between retainers 58 and top sides 64 to fulcrum thereof when said magazine is installed in the ?rearm,

points 67 and sides 93 and 101 (FIG. 8) so that rotation and a pair of latches arranged in cooperation with said

of the retainers is continued. As right-hand retainer 78 retainers for releasably holding said magazine against

and left-hand retainer 80 are rotated, actuator-holding displacement in the ?rearm from a fully installed posi

wings 92 and 100 are rotated against lugs 74 of the tion after being moved thereto.

latches 60 causing the lugs to be displaced outwardly. 4. The combination as defined in claim 2 and includ

When magazine 40 is fully inserted, actuator holding 45 ing in the ?rearm a magazine well for receiving said

wings 92 and 100 are in contact with the related bot magazine, a pair of channels'formed in said magazine

tom sides 63 of the channels 62 with the ends of such well for respective cooperation with said retainers, bot

wings positioned under the lugs 74. Springs 76 are ar tom sides of said channels disposed for contact by said

ranged to overpower springs 94 and 102 so that retain retainers when actuated by installation of said maga

ers 58 are resiliently held against displacement and 50 zine into said magazine well to releasably hold said

magazine 40 is locked thereby in fully installed position magazine therein, a lug formed on each of said latches

(FIG. 9). Also, holding wings 90 and 98 are displaced for cooperation with the associated one of said retain

so as to free cartridges 14 in supply compartment 42 ' ers for holding said retainers in contact with said bot

for feeding into chambers 32 and so as to permit the tom sides, and top sides of said channels arranged to

entry'of fired cases 36 into retrieval compartment 44. 55 overhang said bottom sides so as to be contactable by

During operation of ri?e l2, cartridges 14 are fed said retainers when said magazine is installed in said

into the chambers 32 from feeding compartment 42, magazine well for actuating said retainers to hold said

rotated to the twelve o'clock position to be ?red, and magazine in the fully installed position.

then the ?red cases 36 are rotated away from the 12 o 5. The combination as de?ned in claim 4 and includ

clock position with fingers 48 acting to eject the ?red 60

ing means for rotatively mounting said retainers, hold

cases into retrieval compartment 44. Magazine 40 is ing wings respectively formed in said retainers so as to

removed by pressing inwardly on actuator portions 68 be displaceable into the associated feeding compart

of latches 60 which displaces lugs 74 thereon out ment and retrieval compartment for blocking upward

wardly, thus freeing retainers 58 for rotation to permit displacement of the cartridges and the ?red cases

withdrawal of the magazine. Springs 94 and 102 rotate 65 therein, and actuator-locking wings respectively

retainers 58, when freed from lugs 74, so that the hold formed in said retainers so as to be contactable with

ing wing 90 is positioned to retain in feeding compart said top sides when said magazine is moved to the fully

3,747,249

5 6

installed position in said magazine well for rotating said of said retainers for biasing said retainers to a position

retainers and so as to be contactable with saidbottom

sides when said magazine is in the fully installed posi wherein said holding wings project into the associated

tion for releasably holding said magazine therein, and feeding and retrieval compartments.

a spring disposed in operational cooperation with each 5 Ill ll * It :1

15

20

25

30

35

40

45

50

55

60

65

You might also like

- Graflex Muzzle Boresight DevicesDocument5 pagesGraflex Muzzle Boresight DevicesNorm PhillipsNo ratings yet

- 2011 LWRC CatalogDocument11 pages2011 LWRC CatalogMario LopezNo ratings yet

- 40 70Document6 pages40 70cicogna76100% (1)

- Equipment Inspection and Examination Data: Pistol, 9 MM, Semi-Automatic, Mk3Document11 pagesEquipment Inspection and Examination Data: Pistol, 9 MM, Semi-Automatic, Mk3luca ardenziNo ratings yet

- 2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Document4 pages2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Vijayakumar G VNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- Siled Sept. 8, 1966: T, N. NccomeDocument5 pagesSiled Sept. 8, 1966: T, N. NccomeliNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- Diseño ElectricoDocument5 pagesDiseño ElectricoemernelsonmanNo ratings yet

- United States Patent 19) : BealeDocument7 pagesUnited States Patent 19) : BealePaul PorrasNo ratings yet

- Rat Hole DiggerDocument4 pagesRat Hole DiggerDarshan MakwanaNo ratings yet

- No. 640,627. Patented Jan. 2, 1900Document5 pagesNo. 640,627. Patented Jan. 2, 1900Слэйтер Строительная компанияNo ratings yet

- United States Patent (19) : Gazalel, 72 8Document7 pagesUnited States Patent (19) : Gazalel, 72 8Mihai RobertNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Filed Sept. 8, l942Document4 pagesFiled Sept. 8, l942HaithemNo ratings yet

- United States Patent: AlterDocument5 pagesUnited States Patent: Alter9887845454No ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Bottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Document8 pagesBottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Luis Enrique Barreto GarciaNo ratings yet

- US2525422Document6 pagesUS2525422Rambabu ChNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- 1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????Document3 pages1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????fernando Ancaya AncayaNo ratings yet

- Berthier Us1446635Document12 pagesBerthier Us1446635cll19680% (1)

- Us2935914 PDFDocument14 pagesUs2935914 PDFMichael LaneNo ratings yet

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Document9 pages8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899No ratings yet

- C Walton Recoiless Rifle US2970519Document4 pagesC Walton Recoiless Rifle US2970519apoorva singhNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- United States Patent (191: SeecampDocument4 pagesUnited States Patent (191: Seecamp9aszerfNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208Document9 pagesViii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208mohammadreza91No ratings yet

- Us 1401667Document11 pagesUs 1401667kissaNo ratings yet

- US2182002Document5 pagesUS2182002Jhonnatan E Avendaño FlorezNo ratings yet

- Us3432107 PDFDocument3 pagesUs3432107 PDFasssssNo ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Nun M.: BC BM 0000Document12 pagesNun M.: BC BM 0000shdhsjkNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- Arts5.: in RunDocument4 pagesArts5.: in RunMuzammil AmirNo ratings yet

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- United States Patent (19) : JohnsonDocument6 pagesUnited States Patent (19) : JohnsongorgiNo ratings yet

- Us 2710632Document3 pagesUs 2710632emernelsonmanNo ratings yet

- (1966, May 3) US3248803 Rotary Drum Heat ExchangerDocument6 pages(1966, May 3) US3248803 Rotary Drum Heat ExchangeraegosmithNo ratings yet

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- Fig 2. A More: March 28, 1961 W. D. Edwards Eta, 2,977,146Document5 pagesFig 2. A More: March 28, 1961 W. D. Edwards Eta, 2,977,146zgregzNo ratings yet

- US4335764Document7 pagesUS4335764Jorge ArbelaezNo ratings yet

- Us 2425103Document6 pagesUs 2425103Muhamad HasanNo ratings yet

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Document3 pagesUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06No ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- United States PatentDocument8 pagesUnited States PatentClaudinei MayerNo ratings yet

- R.T MM MS: ' Filed July 28, 1965Document6 pagesR.T MM MS: ' Filed July 28, 1965Alexcel CorporalNo ratings yet

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- Another Corn Dog Machine PatentDocument14 pagesAnother Corn Dog Machine PatentMinnesota Public RadioNo ratings yet

- BOΤTLE LABELING MACHINEDocument4 pagesBOΤTLE LABELING MACHINEq12wertyNo ratings yet

- United States Patent: (54) SailboatDocument5 pagesUnited States Patent: (54) Sailboat155No ratings yet

- United States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsDocument8 pagesUnited States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsUvxtalNo ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- United States Patent (19) : Filed: Feb. 14, 1972Document5 pagesUnited States Patent (19) : Filed: Feb. 14, 1972zgregzNo ratings yet

- European Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Document13 pagesEuropean Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Lenti TiborNo ratings yet

- Us 5546957Document7 pagesUs 5546957SurgaveryNo ratings yet

- Patented May 4:, 1915.: (Nven ForDocument4 pagesPatented May 4:, 1915.: (Nven Forbelchior alvaroNo ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- Us 2543888Document5 pagesUs 2543888Juan Sebastian PrietoNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Browning Model M1919 Machine GunDocument12 pagesBrowning Model M1919 Machine Gunblowmeasshole1911100% (1)

- German Explosive Ordnance PDFDocument281 pagesGerman Explosive Ordnance PDFX20XER94% (16)

- Kubota M7500-A-CL Parts Diagrams 12Document4 pagesKubota M7500-A-CL Parts Diagrams 12mario santiagoNo ratings yet

- ARMSCOR Pricelist PDF Shotgun Pistol and RiDocument1 pageARMSCOR Pricelist PDF Shotgun Pistol and RiBobby BarbaNo ratings yet

- Armi Sport CatalogueDocument68 pagesArmi Sport CataloguergpaaaNo ratings yet

- Nigcoy 8 Ecomig Arms and Ammunition HoldingDocument7 pagesNigcoy 8 Ecomig Arms and Ammunition HoldingWisdom AbrahamNo ratings yet

- Beretta Law Enforce Catalog 2003Document24 pagesBeretta Law Enforce Catalog 2003Anton MihailovNo ratings yet

- Ballistic Gelatin ReportDocument28 pagesBallistic Gelatin ReportHerson ValenzuelaNo ratings yet

- Type 98 20mm Machine CannonDocument1 pageType 98 20mm Machine CannonWilliam MyersNo ratings yet

- CleosRealm Type10 PDFDocument7 pagesCleosRealm Type10 PDFsupermoto nightNo ratings yet

- Sedition Wars - Alabaster Cards 2nded v1Document14 pagesSedition Wars - Alabaster Cards 2nded v1Billy Pistole100% (1)

- Lyman 2018 Public 1Document50 pagesLyman 2018 Public 1Anonymous w6GMxAPOYBNo ratings yet

- HR1808Document128 pagesHR1808Jeremy TurleyNo ratings yet

- The 5.56 X 45mm - 1968 - 1969 - A Chronology of Development (Part 6) - by Daniel WattersDocument38 pagesThe 5.56 X 45mm - 1968 - 1969 - A Chronology of Development (Part 6) - by Daniel Wattersblowmeasshole1911No ratings yet

- 1605 PS90 Owners Manual v3Document36 pages1605 PS90 Owners Manual v3Anonymous cCQKlG0Rq100% (1)

- The SA80 A2 (Iron Sight)Document3 pagesThe SA80 A2 (Iron Sight)luca ardenziNo ratings yet

- And The Winner Is... : Ruger Mini-14 vs. The Ar-15Document4 pagesAnd The Winner Is... : Ruger Mini-14 vs. The Ar-15James McEwen100% (1)

- SDMDocument5 pagesSDMPaulo SilvNo ratings yet

- Snider-Enfield Breech Loading RifleDocument8 pagesSnider-Enfield Breech Loading Rifleblowmeasshole1911No ratings yet

- Build Skill Aika NM, SNDocument3 pagesBuild Skill Aika NM, SNKhalyd MukhtarNo ratings yet

- Gta CheatsDocument2 pagesGta CheatsRAJASEKAR176No ratings yet

- COMELEC Resolution No. 10015Document32 pagesCOMELEC Resolution No. 10015Rbr PixNo ratings yet

- Shooting Times 02.2022 PDFDocument68 pagesShooting Times 02.2022 PDFNacho García100% (1)

- BallisticsDocument14 pagesBallisticsMarinel Padilla PinedaNo ratings yet

- CM 162MI IngleseDocument11 pagesCM 162MI Ingleseapi-3695814No ratings yet

- Ammunition DataDocument201 pagesAmmunition Datahakan56915691100% (1)