Professional Documents

Culture Documents

Calculation of Electrode Mass Pipe - Single "V" Groove (GTAW And/or SMAW Preferred)

Calculation of Electrode Mass Pipe - Single "V" Groove (GTAW And/or SMAW Preferred)

Uploaded by

Yopy HendraCopyright:

Available Formats

You might also like

- 11-Division 2-Section 02300 Sewage Works-Version 2.0Document24 pages11-Division 2-Section 02300 Sewage Works-Version 2.0Avaan Ivaan50% (2)

- HR Om11 ch16Document63 pagesHR Om11 ch16Anisa WPNo ratings yet

- Directiva - ATEX - 1999-92-EC - Doc 134 05 EDocument22 pagesDirectiva - ATEX - 1999-92-EC - Doc 134 05 ENathan Morales100% (1)

- Deflection CalculationDocument2 pagesDeflection CalculationYUVARAJ SAMPATHNo ratings yet

- 3-Stress Check - Rectangular AbutDocument6 pages3-Stress Check - Rectangular Abutsanjay vermaNo ratings yet

- Roof Beam Design CalculationDocument11 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- Magnetics AppBDocument8 pagesMagnetics AppBsmkeshkamatNo ratings yet

- F3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboDocument29 pagesF3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboKhim KhadkaNo ratings yet

- Column Reinforcement Design: Uex UeyDocument15 pagesColumn Reinforcement Design: Uex Ueyswargadwari consultancyNo ratings yet

- Design of Embeded Plate (INDIAN STANDARD)Document3 pagesDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- F-Table Slab and Staircase (ALWAYS)Document15 pagesF-Table Slab and Staircase (ALWAYS)Santosh BasnetNo ratings yet

- Torsional Strength As Per 5100.5.2017: Beam DataDocument8 pagesTorsional Strength As Per 5100.5.2017: Beam DataSambhav PoddarNo ratings yet

- Composite Steel GirderDocument10 pagesComposite Steel GirdersorowareNo ratings yet

- Plate 2Document3 pagesPlate 2snoariNo ratings yet

- Tinh Toan Do Gian Dai DUL - V2Document18 pagesTinh Toan Do Gian Dai DUL - V2Lan HạNo ratings yet

- (123doc) BTL Ket Cau ThepDocument50 pages(123doc) BTL Ket Cau ThepTrương Ngọc TraiNo ratings yet

- Design Calculation of Current Transformer and Voltage TransformerDocument21 pagesDesign Calculation of Current Transformer and Voltage TransformerMoe Thant OoNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Bearing DesignDocument5 pagesBearing DesignVenkat RaoNo ratings yet

- KKKH3353 - Structural Steel Design - Joints 2Document26 pagesKKKH3353 - Structural Steel Design - Joints 2Zeyad Tareq Al SaroriNo ratings yet

- MotorDocument51 pagesMotorp_ignatiusNo ratings yet

- Prof. Kamble A.S.: Sub: Quantity Surveying, Contracts & Tenders. BE CivilDocument15 pagesProf. Kamble A.S.: Sub: Quantity Surveying, Contracts & Tenders. BE CivilShinde vishalNo ratings yet

- Case Study ppt11Document25 pagesCase Study ppt11WHATS APP STATUSNo ratings yet

- 230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Document4 pages230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Mustafa RupawalaNo ratings yet

- Short Term Deflection Calculation (Subramanyam Example 12.4)Document9 pagesShort Term Deflection Calculation (Subramanyam Example 12.4)Saugat ThapaNo ratings yet

- Design of Deck Girder BridgesDocument65 pagesDesign of Deck Girder BridgesEna Mie CambaNo ratings yet

- CV610 Design of Flexural Member 2Document36 pagesCV610 Design of Flexural Member 2Livinston JosephNo ratings yet

- Beam-Column Hunch-End Plate Moment Conn PDFDocument11 pagesBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedNo ratings yet

- Fixed Base Anchor Bolt DesignDocument3 pagesFixed Base Anchor Bolt Designkhan84mind50% (2)

- SCBDocument14 pagesSCBselvaganeshNo ratings yet

- Example 1: Simply Supported Rectangular Beam: Referent Calculation ResultDocument5 pagesExample 1: Simply Supported Rectangular Beam: Referent Calculation ResultMohd NazwalNo ratings yet

- Design of Tubular WeldingDocument2 pagesDesign of Tubular WeldinghiteshNo ratings yet

- Roof Beam Design CalculationDocument5 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- Post-Tensioning Format For Pscgirder General InformationDocument1 pagePost-Tensioning Format For Pscgirder General InformationTirthajit RoyNo ratings yet

- Job No Name Calculation For Long Term Deflection: CK 2 y 2 2 S 2Document4 pagesJob No Name Calculation For Long Term Deflection: CK 2 y 2 2 S 2Gaurav MalyaNo ratings yet

- Experiment Lab Sheet j2020Document8 pagesExperiment Lab Sheet j2020nur nazatul najwaNo ratings yet

- Pile Cap (2 Piles)Document4 pagesPile Cap (2 Piles)KH ChungNo ratings yet

- Cantilever Beam 450x600Document27 pagesCantilever Beam 450x600Shivaranjan HJNo ratings yet

- RCC One Way SlabDocument2 pagesRCC One Way SlabAniket GunjalNo ratings yet

- UntitledDocument19 pagesUntitledniranjan paudelNo ratings yet

- Pile Cap 8P-PC6Document6 pagesPile Cap 8P-PC6balaji gmscNo ratings yet

- Built Up Section Design SheetDocument12 pagesBuilt Up Section Design SheetBikal BastakotiNo ratings yet

- DC Machine Design Problem With SolutionDocument36 pagesDC Machine Design Problem With Solutionlvb123No ratings yet

- Third Floor Beam Design CalculationDocument5 pagesThird Floor Beam Design CalculationArnold VercelesNo ratings yet

- Longitudinal BearingDocument6 pagesLongitudinal BearingDPJAIN INFRASTRUCTURENo ratings yet

- Steel Pile API (LRFD) - Primary DesignDocument2 pagesSteel Pile API (LRFD) - Primary Designbhavdip_shahNo ratings yet

- 1way SlabDocument20 pages1way SlabAbdul AzeemNo ratings yet

- Timber Truss Design: ProjectDocument8 pagesTimber Truss Design: ProjectEvello MercanoNo ratings yet

- Self Supporting Chimney Problem1Document17 pagesSelf Supporting Chimney Problem1GOVINDARAJU SNo ratings yet

- American Wire Gauge (AWG) To Square MMDocument40 pagesAmerican Wire Gauge (AWG) To Square MMLuckie IbrahimNo ratings yet

- Roof Beam Design CalculationDocument7 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- DeflectionDocument5 pagesDeflectionJai ThakkarNo ratings yet

- DGN - SGL - GayatriDocument2 pagesDGN - SGL - GayatriSaurav KumarNo ratings yet

- Channel Steel Beam Torsion Design (EN1993)Document5 pagesChannel Steel Beam Torsion Design (EN1993)Anupam AjayanNo ratings yet

- Ast BeamDocument13 pagesAst Beamabdul kareeNo ratings yet

- SS Connection For "W" Shapes A572 Grade 50 Steel Is Used Whoes Properties Are As Below: Fy 345 Mpa, Fu 450 MpaDocument31 pagesSS Connection For "W" Shapes A572 Grade 50 Steel Is Used Whoes Properties Are As Below: Fy 345 Mpa, Fu 450 MpaNats SantosNo ratings yet

- Design of CorbelDocument3 pagesDesign of CorbelAkshay KumarNo ratings yet

- Ume 1312 Som Lab Ese QP - A2 Batch PDFDocument19 pagesUme 1312 Som Lab Ese QP - A2 Batch PDFDhanush NatesanNo ratings yet

- SL No Item Cost/piece Quantity TotalDocument8 pagesSL No Item Cost/piece Quantity TotalSUNIL KUMAR K S Civil, KLEIThubballiNo ratings yet

- Curved BeamDocument11 pagesCurved BeamVirat DesaiNo ratings yet

- Electrical Machine Design: Design 1: DC Generator Armature DesignDocument8 pagesElectrical Machine Design: Design 1: DC Generator Armature DesignMarvin DacayanNo ratings yet

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Información Sobre El CO2Document0 pagesInformación Sobre El CO2ppklistaNo ratings yet

- 1 Enhanced Photocatalytic Activity of TiO2-Zeolite Composite For Abatement of Pollutants (Zeolita Natural)Document8 pages1 Enhanced Photocatalytic Activity of TiO2-Zeolite Composite For Abatement of Pollutants (Zeolita Natural)VANESANo ratings yet

- 06 BuyLog2013 MoldedCaseCircBrkrsDocument106 pages06 BuyLog2013 MoldedCaseCircBrkrsmarbyNo ratings yet

- AGEPAN OSB 4 PUR Technical Data SheetDocument2 pagesAGEPAN OSB 4 PUR Technical Data SheetDore EmilNo ratings yet

- Carbochlorination of TiO2Document9 pagesCarbochlorination of TiO2Margarita CaceresNo ratings yet

- Model: Designs and Specifications Are Subject To Change For Improvement Without Prior NoticeDocument1 pageModel: Designs and Specifications Are Subject To Change For Improvement Without Prior NoticeTitan KNo ratings yet

- Ugalde (Two Storey Estimate)Document17 pagesUgalde (Two Storey Estimate)Philip Joshua MalitNo ratings yet

- Painting Procedures of Pertamina SurabayaDocument13 pagesPainting Procedures of Pertamina SurabayaUdinHermansyahNo ratings yet

- LSCM Assignment-Term-IVDocument20 pagesLSCM Assignment-Term-IVswathiNo ratings yet

- Tactile SensorDocument15 pagesTactile SensorAnonymous gUjimJK100% (1)

- IPCM Protective Coatings Magazine 28 DecemberDocument76 pagesIPCM Protective Coatings Magazine 28 DecemberAbdul Rahman ObaidNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Pressure Ratings Stainless Steel PipeDocument4 pagesPressure Ratings Stainless Steel PipeduncmcleodNo ratings yet

- Https - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCDocument4 pagesHttps - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCsalamrefighNo ratings yet

- Flexiring Random Packing: Liquid Load, MDocument2 pagesFlexiring Random Packing: Liquid Load, MAlek KrótkiNo ratings yet

- Q&A Energy Sources-1Document22 pagesQ&A Energy Sources-1Gautam GambhirNo ratings yet

- Ebbing 12Document20 pagesEbbing 12Ra MilNo ratings yet

- Upvc Sewer Drainage Systems Product Brochure PDFDocument32 pagesUpvc Sewer Drainage Systems Product Brochure PDFMoriyasu NguyenNo ratings yet

- TCI-Guy Wire FittingsDocument7 pagesTCI-Guy Wire FittingsthanatitosNo ratings yet

- Skid ResistanceDocument7 pagesSkid Resistanceebinsams007No ratings yet

- Weld ToleranceDocument1 pageWeld ToleranceNirav DesaiNo ratings yet

- Dr. Saleem CVDocument8 pagesDr. Saleem CVazeb514No ratings yet

- Vacuum CntactorDocument92 pagesVacuum Cntactorabhi_26t100% (2)

- Tensile Test of Copper Fibers in Conformance With ASTM C1557 Using Agilent UTM T150Document4 pagesTensile Test of Copper Fibers in Conformance With ASTM C1557 Using Agilent UTM T150Celeste LopezNo ratings yet

- RFQ 58 - BWallDocument5 pagesRFQ 58 - BWallMahmoud ShakerNo ratings yet

- Accesorii Si Piese de Schimb Pompe Airless GracoDocument8 pagesAccesorii Si Piese de Schimb Pompe Airless GracoDanaNo ratings yet

- Electromagnetic Flowmeter ProcessMaster FEP300 ABBDocument54 pagesElectromagnetic Flowmeter ProcessMaster FEP300 ABBAnonymous V6n9ZCNo ratings yet

Calculation of Electrode Mass Pipe - Single "V" Groove (GTAW And/or SMAW Preferred)

Calculation of Electrode Mass Pipe - Single "V" Groove (GTAW And/or SMAW Preferred)

Uploaded by

Yopy HendraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation of Electrode Mass Pipe - Single "V" Groove (GTAW And/or SMAW Preferred)

Calculation of Electrode Mass Pipe - Single "V" Groove (GTAW And/or SMAW Preferred)

Uploaded by

Yopy HendraCopyright:

Available Formats

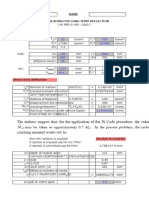

CALCULATION OF ELECTRODE MASS

Pipe - Single "V" Groove (GTAW and/or SMAW Preferred)

1. Provided Data

Diameter-NPS = inch

Outside Diameter (OD) = mm

Thickness (T) = mm

Surface weld (ws) = mm

Root weld (wr) = mm

Weld metal thickness (t) = mm

Bevel degree () =

Triangle base (b) = mm

Welding process =

Deposit efficiency = %

Metal density () = kg/m3

Electrode length = inch

Est. stub loss = inch

Efficiency - stub loss () = %

Total joint of this sub = joints

2. Estimated weld area (mm2), AW = 2 x 1/2 b t

Aw = mm2

3. Circumference of weld area (mm), C = .OD

Cw = mm2

4. Weld volume (m3) = Aw x Cw

Vw = mm3

= m3

5. Total weld metal mass required (kg) = Vw x

Mw = kg

6. Total electrode required (kg) = Mw x

ME = kg

7. Subtotal of electrode mass (kg) = ME x Total joint of this sub

ME SUB = kg

ASS

AW Preferred)

D-NPS OD (inch) OD (mm)

0.5 0.84 21.3

0.75 1.05 26.7

1 1.315 33.4

1.25 1.66 42.2

1.5 1.9 48.3

2 2.375 60.3

2.5 2.875 73.0

3 3.5 88.9

3.5 4 101.6

4 4.5 114.3

5 5.563 141.3

6 6.625 168.3

8 8.625 219.1

10 10.75 273.1

12 12.75 323.9

14 14 355.6

16 16 406.4

18 18 457.2

20 20 508.0

22 22 558.8

24 24 609.6

26 26 660.4

28 28 711.2

30 30 762.0

32 32 812.8

34 34 863.6

36 36 914.4

You might also like

- 11-Division 2-Section 02300 Sewage Works-Version 2.0Document24 pages11-Division 2-Section 02300 Sewage Works-Version 2.0Avaan Ivaan50% (2)

- HR Om11 ch16Document63 pagesHR Om11 ch16Anisa WPNo ratings yet

- Directiva - ATEX - 1999-92-EC - Doc 134 05 EDocument22 pagesDirectiva - ATEX - 1999-92-EC - Doc 134 05 ENathan Morales100% (1)

- Deflection CalculationDocument2 pagesDeflection CalculationYUVARAJ SAMPATHNo ratings yet

- 3-Stress Check - Rectangular AbutDocument6 pages3-Stress Check - Rectangular Abutsanjay vermaNo ratings yet

- Roof Beam Design CalculationDocument11 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- Magnetics AppBDocument8 pagesMagnetics AppBsmkeshkamatNo ratings yet

- F3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboDocument29 pagesF3 (Fact.) F3 (Unfact.) Joint Label Unique Name Load Case/ComboKhim KhadkaNo ratings yet

- Column Reinforcement Design: Uex UeyDocument15 pagesColumn Reinforcement Design: Uex Ueyswargadwari consultancyNo ratings yet

- Design of Embeded Plate (INDIAN STANDARD)Document3 pagesDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- F-Table Slab and Staircase (ALWAYS)Document15 pagesF-Table Slab and Staircase (ALWAYS)Santosh BasnetNo ratings yet

- Torsional Strength As Per 5100.5.2017: Beam DataDocument8 pagesTorsional Strength As Per 5100.5.2017: Beam DataSambhav PoddarNo ratings yet

- Composite Steel GirderDocument10 pagesComposite Steel GirdersorowareNo ratings yet

- Plate 2Document3 pagesPlate 2snoariNo ratings yet

- Tinh Toan Do Gian Dai DUL - V2Document18 pagesTinh Toan Do Gian Dai DUL - V2Lan HạNo ratings yet

- (123doc) BTL Ket Cau ThepDocument50 pages(123doc) BTL Ket Cau ThepTrương Ngọc TraiNo ratings yet

- Design Calculation of Current Transformer and Voltage TransformerDocument21 pagesDesign Calculation of Current Transformer and Voltage TransformerMoe Thant OoNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Bearing DesignDocument5 pagesBearing DesignVenkat RaoNo ratings yet

- KKKH3353 - Structural Steel Design - Joints 2Document26 pagesKKKH3353 - Structural Steel Design - Joints 2Zeyad Tareq Al SaroriNo ratings yet

- MotorDocument51 pagesMotorp_ignatiusNo ratings yet

- Prof. Kamble A.S.: Sub: Quantity Surveying, Contracts & Tenders. BE CivilDocument15 pagesProf. Kamble A.S.: Sub: Quantity Surveying, Contracts & Tenders. BE CivilShinde vishalNo ratings yet

- Case Study ppt11Document25 pagesCase Study ppt11WHATS APP STATUSNo ratings yet

- 230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Document4 pages230 600 3.975 S2 Shorter Edge S5 Shorter Edge: Mulim 0.36 FCK B Xulim (d-0.42 Xulim)Mustafa RupawalaNo ratings yet

- Short Term Deflection Calculation (Subramanyam Example 12.4)Document9 pagesShort Term Deflection Calculation (Subramanyam Example 12.4)Saugat ThapaNo ratings yet

- Design of Deck Girder BridgesDocument65 pagesDesign of Deck Girder BridgesEna Mie CambaNo ratings yet

- CV610 Design of Flexural Member 2Document36 pagesCV610 Design of Flexural Member 2Livinston JosephNo ratings yet

- Beam-Column Hunch-End Plate Moment Conn PDFDocument11 pagesBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedNo ratings yet

- Fixed Base Anchor Bolt DesignDocument3 pagesFixed Base Anchor Bolt Designkhan84mind50% (2)

- SCBDocument14 pagesSCBselvaganeshNo ratings yet

- Example 1: Simply Supported Rectangular Beam: Referent Calculation ResultDocument5 pagesExample 1: Simply Supported Rectangular Beam: Referent Calculation ResultMohd NazwalNo ratings yet

- Design of Tubular WeldingDocument2 pagesDesign of Tubular WeldinghiteshNo ratings yet

- Roof Beam Design CalculationDocument5 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- Post-Tensioning Format For Pscgirder General InformationDocument1 pagePost-Tensioning Format For Pscgirder General InformationTirthajit RoyNo ratings yet

- Job No Name Calculation For Long Term Deflection: CK 2 y 2 2 S 2Document4 pagesJob No Name Calculation For Long Term Deflection: CK 2 y 2 2 S 2Gaurav MalyaNo ratings yet

- Experiment Lab Sheet j2020Document8 pagesExperiment Lab Sheet j2020nur nazatul najwaNo ratings yet

- Pile Cap (2 Piles)Document4 pagesPile Cap (2 Piles)KH ChungNo ratings yet

- Cantilever Beam 450x600Document27 pagesCantilever Beam 450x600Shivaranjan HJNo ratings yet

- RCC One Way SlabDocument2 pagesRCC One Way SlabAniket GunjalNo ratings yet

- UntitledDocument19 pagesUntitledniranjan paudelNo ratings yet

- Pile Cap 8P-PC6Document6 pagesPile Cap 8P-PC6balaji gmscNo ratings yet

- Built Up Section Design SheetDocument12 pagesBuilt Up Section Design SheetBikal BastakotiNo ratings yet

- DC Machine Design Problem With SolutionDocument36 pagesDC Machine Design Problem With Solutionlvb123No ratings yet

- Third Floor Beam Design CalculationDocument5 pagesThird Floor Beam Design CalculationArnold VercelesNo ratings yet

- Longitudinal BearingDocument6 pagesLongitudinal BearingDPJAIN INFRASTRUCTURENo ratings yet

- Steel Pile API (LRFD) - Primary DesignDocument2 pagesSteel Pile API (LRFD) - Primary Designbhavdip_shahNo ratings yet

- 1way SlabDocument20 pages1way SlabAbdul AzeemNo ratings yet

- Timber Truss Design: ProjectDocument8 pagesTimber Truss Design: ProjectEvello MercanoNo ratings yet

- Self Supporting Chimney Problem1Document17 pagesSelf Supporting Chimney Problem1GOVINDARAJU SNo ratings yet

- American Wire Gauge (AWG) To Square MMDocument40 pagesAmerican Wire Gauge (AWG) To Square MMLuckie IbrahimNo ratings yet

- Roof Beam Design CalculationDocument7 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- DeflectionDocument5 pagesDeflectionJai ThakkarNo ratings yet

- DGN - SGL - GayatriDocument2 pagesDGN - SGL - GayatriSaurav KumarNo ratings yet

- Channel Steel Beam Torsion Design (EN1993)Document5 pagesChannel Steel Beam Torsion Design (EN1993)Anupam AjayanNo ratings yet

- Ast BeamDocument13 pagesAst Beamabdul kareeNo ratings yet

- SS Connection For "W" Shapes A572 Grade 50 Steel Is Used Whoes Properties Are As Below: Fy 345 Mpa, Fu 450 MpaDocument31 pagesSS Connection For "W" Shapes A572 Grade 50 Steel Is Used Whoes Properties Are As Below: Fy 345 Mpa, Fu 450 MpaNats SantosNo ratings yet

- Design of CorbelDocument3 pagesDesign of CorbelAkshay KumarNo ratings yet

- Ume 1312 Som Lab Ese QP - A2 Batch PDFDocument19 pagesUme 1312 Som Lab Ese QP - A2 Batch PDFDhanush NatesanNo ratings yet

- SL No Item Cost/piece Quantity TotalDocument8 pagesSL No Item Cost/piece Quantity TotalSUNIL KUMAR K S Civil, KLEIThubballiNo ratings yet

- Curved BeamDocument11 pagesCurved BeamVirat DesaiNo ratings yet

- Electrical Machine Design: Design 1: DC Generator Armature DesignDocument8 pagesElectrical Machine Design: Design 1: DC Generator Armature DesignMarvin DacayanNo ratings yet

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Información Sobre El CO2Document0 pagesInformación Sobre El CO2ppklistaNo ratings yet

- 1 Enhanced Photocatalytic Activity of TiO2-Zeolite Composite For Abatement of Pollutants (Zeolita Natural)Document8 pages1 Enhanced Photocatalytic Activity of TiO2-Zeolite Composite For Abatement of Pollutants (Zeolita Natural)VANESANo ratings yet

- 06 BuyLog2013 MoldedCaseCircBrkrsDocument106 pages06 BuyLog2013 MoldedCaseCircBrkrsmarbyNo ratings yet

- AGEPAN OSB 4 PUR Technical Data SheetDocument2 pagesAGEPAN OSB 4 PUR Technical Data SheetDore EmilNo ratings yet

- Carbochlorination of TiO2Document9 pagesCarbochlorination of TiO2Margarita CaceresNo ratings yet

- Model: Designs and Specifications Are Subject To Change For Improvement Without Prior NoticeDocument1 pageModel: Designs and Specifications Are Subject To Change For Improvement Without Prior NoticeTitan KNo ratings yet

- Ugalde (Two Storey Estimate)Document17 pagesUgalde (Two Storey Estimate)Philip Joshua MalitNo ratings yet

- Painting Procedures of Pertamina SurabayaDocument13 pagesPainting Procedures of Pertamina SurabayaUdinHermansyahNo ratings yet

- LSCM Assignment-Term-IVDocument20 pagesLSCM Assignment-Term-IVswathiNo ratings yet

- Tactile SensorDocument15 pagesTactile SensorAnonymous gUjimJK100% (1)

- IPCM Protective Coatings Magazine 28 DecemberDocument76 pagesIPCM Protective Coatings Magazine 28 DecemberAbdul Rahman ObaidNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Pressure Ratings Stainless Steel PipeDocument4 pagesPressure Ratings Stainless Steel PipeduncmcleodNo ratings yet

- Https - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCDocument4 pagesHttps - WWW - Johncrane.com - Media - J - Johncrane - Com - Files - Products - Specification Sheets - S-28SCsalamrefighNo ratings yet

- Flexiring Random Packing: Liquid Load, MDocument2 pagesFlexiring Random Packing: Liquid Load, MAlek KrótkiNo ratings yet

- Q&A Energy Sources-1Document22 pagesQ&A Energy Sources-1Gautam GambhirNo ratings yet

- Ebbing 12Document20 pagesEbbing 12Ra MilNo ratings yet

- Upvc Sewer Drainage Systems Product Brochure PDFDocument32 pagesUpvc Sewer Drainage Systems Product Brochure PDFMoriyasu NguyenNo ratings yet

- TCI-Guy Wire FittingsDocument7 pagesTCI-Guy Wire FittingsthanatitosNo ratings yet

- Skid ResistanceDocument7 pagesSkid Resistanceebinsams007No ratings yet

- Weld ToleranceDocument1 pageWeld ToleranceNirav DesaiNo ratings yet

- Dr. Saleem CVDocument8 pagesDr. Saleem CVazeb514No ratings yet

- Vacuum CntactorDocument92 pagesVacuum Cntactorabhi_26t100% (2)

- Tensile Test of Copper Fibers in Conformance With ASTM C1557 Using Agilent UTM T150Document4 pagesTensile Test of Copper Fibers in Conformance With ASTM C1557 Using Agilent UTM T150Celeste LopezNo ratings yet

- RFQ 58 - BWallDocument5 pagesRFQ 58 - BWallMahmoud ShakerNo ratings yet

- Accesorii Si Piese de Schimb Pompe Airless GracoDocument8 pagesAccesorii Si Piese de Schimb Pompe Airless GracoDanaNo ratings yet

- Electromagnetic Flowmeter ProcessMaster FEP300 ABBDocument54 pagesElectromagnetic Flowmeter ProcessMaster FEP300 ABBAnonymous V6n9ZCNo ratings yet