Professional Documents

Culture Documents

Boilermaking L2 2ed Performance Profiles

Boilermaking L2 2ed Performance Profiles

Uploaded by

nizam1372Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boilermaking L2 2ed Performance Profiles

Boilermaking L2 2ed Performance Profiles

Uploaded by

nizam1372Copyright:

Available Formats

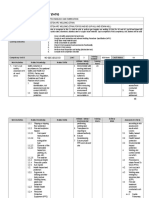

PERFORMANCE PROFILE SHEET NCCER TRAINING

Craft: Boilermaking

Module Number: 34201-11

Module Title: Boiler Systems and Components Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

1, 2 1. Identify at least four different kinds of boilers as determined by the

instructor.

3, 4 2. Identify at least twelve boiler components as determined by the

instructor.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

BOILER SYSTEMS AND COMPONENTS MODULE 34201-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 1 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34202-11

Module Title: Identifying and Installing Valves Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

1 1. Identify types of valves that start and stop flow.

2 2. Identify types of valves that regulate flow.

3 3. Identify valves that relieve pressure.

continued

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

IDENTIFYING AND INSTALLING VALVES MODULE 34202-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 2 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34202-11

Module Title: Identifying and Installing Valves Contren Learning Series

Objective TASK RATING

4 4. Identify valves that regulate the direction of flow.

5 5. Identify valve actuators.

8 6. Given a select number of valves, match the valve to its given

application.

9 7. Interpret valve markings and nameplate information.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

IDENTIFYING AND INSTALLING VALVES MODULE 34202-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 1 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34203-11

Module Title: Pipe Hangers and Supports Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

1 1. Identify types of pipe hangers and supports.

4 2. Identify types of connecting units and attachments.

1 3. Identify types of pipe support.

2 4. Read and interpret support drawings and symbols.

continued

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

PIPE HANGERS AND SUPPORTS MODULE 34203-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 2 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34203-11

Module Title: Pipe Hangers and Supports Contren Learning Series

Objective TASK RATING

4 5. Install nonexpanding concrete fasteners.

4 6. Install expanding concrete fasteners.

5 7. Lay out and mark the cut lines required to fabricate a one-piece

45-degree angle iron bracket.

5 8. Lay out and mark the cut lines required to fabricate a one-piece

30- by 60-degree angle iron bracket.

6, 7 9. Identify spring can support types.

9 10. Read and interpret spring can support detail sheets.

9 11. Install spring can supports.

10 12. Adjust and remove the travel stops from a spring can support.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

PIPE HANGERS AND SUPPORTS MODULE 34203-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 1 OF 3) NCCER TRAINING

Craft: Boilermaking

Module Number: 34204-11

Module Title: Drawings and Detail Sheets Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

1 1. Identify parts of a drawing:

Title block

Scales and measurements

Symbols and abbreviations

Notes

continued

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

DRAWINGS AND DETAIL SHEETS MODULE 34204-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 2 OF 3) NCCER TRAINING

Craft: Boilermaking

Module Number: 34204-11

Module Title: Drawings and Detail Sheets Contren Learning Series

Objective TASK RATING

Revision blocks

Coordinates

4 2. Interpret the following:

Drawing indexes

Line lists

2 3. Identify the following types of drawings:

Plot plans

Structural drawings

Elevation drawings

Equipment arrangement drawings

P&IDs

Isometric drawings

Spool drawings

Pipe support drawings and detail sheets

Orthographic drawings

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

DRAWINGS AND DETAIL SHEETS MODULE 34204-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 3 OF 3) NCCER TRAINING

Craft: Boilermaking

Module Number: 34204-11

Module Title: Drawings and Detail Sheets Contren Learning Series

Objective TASK RATING

3 4. Make field sketches:

Orthographic

Isometric

continued

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

DRAWINGS AND DETAIL SHEETS MODULE 34204-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET NCCER TRAINING

Craft: Boilermaking

Module Number: 34205-11

Module Title: Fasteners and Anchors Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

5 1. Install selected threaded fasteners.

5 2. Install selected screws.

5 3. Install selected anchors.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

FASTENERS AND ANCHORS MODULE 34205-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET NCCER TRAINING

Craft: Boilermaking

Module Number: 34206-11

Module Title: Welding Symbols Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

4 1. Identify and interpret welding symbols on a drawing provided by

the instructor.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

WELDING SYMBOLS MODULE 34206-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 1 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34207-11

Module Title: Socket Weld Pipe Fabrication Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

2 1. Identify various socket weld fittings.

3 2. Interpret a socket weld drawing.

4 3. Calculate pipe lengths from line drawings using the center-to-

center method.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

SOCKET WELD PIPE FABRICATION MODULE 34207-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 2 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34207-11

Module Title: Socket Weld Pipe Fabrication Contren Learning Series

Objective TASK RATING

4 4. Calculate pipe lengths from line drawings using the center-to-face

method.

4 5. Calculate pipe lengths from line drawings using the face-to-face

method.

5 6. Align a 90-degree elbow to the end of a pipe.

5 7. Square a pipe into a 90-degree elbow.

5 8. Align a flange to the end of a pipe.

5 9. Align a 45-degree elbow to the end of a pipe.

5 10. Align pipes joined by a coupling or tee.

5 11. Install a socket weld valve.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

SOCKET WELD PIPE FABRICATION MODULE 34207-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 1 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34208-11

Module Title: Butt Weld Pipe Fabrication Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

1 1. Identify various butt weld fittings.

2 2. Interpret a butt weld drawing.

3 3. Clean a beveled pipe end, using a portable grinder.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

BUTT WELD PIPE FABRICATION MODULE 34208-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET (PAGE 2 OF 2) NCCER TRAINING

Craft: Boilermaking

Module Number: 34208-11

Module Title: Butt Weld Pipe Fabrication Contren Learning Series

Objective TASK RATING

4 4. Calculate pipe lengths from line drawings, using the center-to-

center method.

4 5. Calculate pipe lengths from line drawings, using the center-to-

face method.

4 6. Calculate pipe lengths from line drawings, using the face-to-face

method.

6 7. Align straight pipe.

6 8. Align a pipe to a 45-degree elbow.

6 9. Align a pipe to a 90-degree elbow.

6 10. Square a pipe into a 90-degree elbow.

6 11. Align a pipe to a flange.

6 12. Align a pipe to a tee.

6 13. Install a butt weld valve.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

BUTT WELD PIPE FABRICATION MODULE 34208-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET NCCER TRAINING

Craft: Boilermaking

Module Number: 34209-11

Module Title: Tube Weld Preparation and Fitting Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

2 1. Identify the proper techniques for gaining tube access.

3 2. Remove a tube and prepare a panel for tube replacement.

3 3. Cut, prepare, and fit tube into panel for welding.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

TUBE WELD PREPARATION AND FITTING MODULE 34209-11 PERFORMANCE PROFILE

PERFORMANCE PROFILE SHEET NCCER TRAINING

Craft: Boilermaking

Module Number: 34210-11

Module Title: Air Carbon Arc Cutting and Gouging Contren Learning Series

TRAINEE NAME: _____________________________________________________________

TRAINEE SOCIAL SECURITY NUMBER: _________________________________________

CLASS: ____________________________________________________________________

TRAINING PROGRAM SPONSOR: _______________________________________________

____________________________________________________________________________

INSTRUCTOR: _______________________________________________________________

Rating Levels: (1) Passed: performed task (2) Failed: did not perform task

Also, list the date the testing for each task was completed.

Recognition: When testing for the NCCER Standardized Craft Training Program,

be sure to record Performance testing results on Training Report Form

200, and submit the results to the Training Program Sponsor.

Certified Plus

Credential: Trainees who successfully complete these performance tasks may be

eligible for a Certified Plus Credential. Refer to the Note on Performance

Testing of this Performance Profile for eligibility requirements, or contact

NCCER for more information.

Objective TASK RATING

2 1. Select and install CAC-A electrodes.

3 2. Prepare the work area and CAC-A equipment for safe operation.

4 3. Use CAC-A equipment for washing.

4 4. Use CAC-A equipment for gouging.

4 5. Perform storage and housekeeping activities for CAC-A

equipment.

Copyright 2011 National Center for Construction Education and Research. Permission is granted to reproduce this page

provided that copies are for local use only and that each copy contains this notice.

AIR CARBON ARC CUTTING AND GOUGING MODULE 34210-11 PERFORMANCE PROFILE

You might also like

- Specification For Pedestrian Restraint Systems in Metal: British Standard BS 7818:1995Document44 pagesSpecification For Pedestrian Restraint Systems in Metal: British Standard BS 7818:1995James Ellis60% (5)

- CBLM Plumbing NCII SampleDocument76 pagesCBLM Plumbing NCII SampleEDMAR DINO100% (7)

- ICTNWK540 - Assessment 2 - Practical DemonstrationDocument9 pagesICTNWK540 - Assessment 2 - Practical DemonstrationAhadNo ratings yet

- AWS D1.1-D1.1M-2015 - Structural Welding Code-Steel Sample Form ReportDocument36 pagesAWS D1.1-D1.1M-2015 - Structural Welding Code-Steel Sample Form Reportnizam1372100% (1)

- Pipeline M-M 3E L1 V2 PPSDocument14 pagesPipeline M-M 3E L1 V2 PPSCesar VasquesNo ratings yet

- Motor Vehicle Theory FETACDocument19 pagesMotor Vehicle Theory FETACivanmjwNo ratings yet

- Topic 1Document17 pagesTopic 1Jerliz joy CasabaNo ratings yet

- Course Syllabus Diesel Engine Testing and Repair IDocument12 pagesCourse Syllabus Diesel Engine Testing and Repair IWan NurdyanaNo ratings yet

- Piping Systems Annotated Instructor's Guide: Module OverviewDocument30 pagesPiping Systems Annotated Instructor's Guide: Module OverviewAlex Angeles100% (1)

- Competency-Based Learning MaterialsDocument42 pagesCompetency-Based Learning MaterialsMa Joan Aguilar Rodriguez100% (1)

- RIICPL303D Install Sewer Pipelines LRDocument149 pagesRIICPL303D Install Sewer Pipelines LRFfdsfdsNo ratings yet

- Supervise Work-Based LearningDocument11 pagesSupervise Work-Based LearningMary MairaNo ratings yet

- Competency Based Curriculum in Eim NciiDocument73 pagesCompetency Based Curriculum in Eim NciiModestoNo ratings yet

- CCIL Quality ManualDocument45 pagesCCIL Quality ManualC . P PoudyalNo ratings yet

- Tr-Esplms NC IiiDocument122 pagesTr-Esplms NC IiiAl MoisesNo ratings yet

- Maintenance & Service - I Course Code: 4360201: Page 1 of 12Document12 pagesMaintenance & Service - I Course Code: 4360201: Page 1 of 12Aaqib SurtiNo ratings yet

- TR-Mechatronics Servicing NC IVDocument108 pagesTR-Mechatronics Servicing NC IVCharisse Mae RillortaNo ratings yet

- PLUMBING Competency-Based-Learning-MaterialDocument77 pagesPLUMBING Competency-Based-Learning-MaterialChrist Archer SanchezNo ratings yet

- CMM 2Document22 pagesCMM 2Mr CupuNo ratings yet

- Performance Coding StandardsDocument44 pagesPerformance Coding Standardsssunils7No ratings yet

- A10 0153 (Rev. A 1996.11) EN - TEST METHODS COMPILATIONDocument5 pagesA10 0153 (Rev. A 1996.11) EN - TEST METHODS COMPILATIONDiego CamargoNo ratings yet

- TR Foundry Molding NC IIDocument67 pagesTR Foundry Molding NC IIalfaroq_almsryNo ratings yet

- Sample CBLM - Select and Prepare Eletrical Power and Hdraulic ToolsDocument79 pagesSample CBLM - Select and Prepare Eletrical Power and Hdraulic ToolssilverlutetiumNo ratings yet

- TR - Automotive Electrical Assembly NC IIIDocument78 pagesTR - Automotive Electrical Assembly NC IIINovi EmberNo ratings yet

- Automobile Professional Practice-2 Course Code: 4360206: Page 1 of 9Document9 pagesAutomobile Professional Practice-2 Course Code: 4360206: Page 1 of 9Aaqib SurtiNo ratings yet

- JbcwqoicDocument16 pagesJbcwqoicrodrigoNo ratings yet

- Due Date: 1 Week After CompletionDocument6 pagesDue Date: 1 Week After CompletionRakib UddinNo ratings yet

- CBLM Flat Iron, (Revised)Document49 pagesCBLM Flat Iron, (Revised)sorcererpcNo ratings yet

- Read, Interpret and Apply Specifications and ManualsDocument55 pagesRead, Interpret and Apply Specifications and ManualsClayton Mark Cadampog100% (3)

- CBLM Common Apply Quality Standards 1 (Revised)Document32 pagesCBLM Common Apply Quality Standards 1 (Revised)SSVTC LRCNo ratings yet

- NSE Report 1Document10 pagesNSE Report 1PROFADEV RESOURCESNo ratings yet

- CETOP EduBook GeneralDocument33 pagesCETOP EduBook GeneralManuel VizcarraNo ratings yet

- MODULE COC 1 (ADCEPS) A PDFDocument314 pagesMODULE COC 1 (ADCEPS) A PDFMarlon A. AranasNo ratings yet

- Work Based M 2 Lesson 5 8Document17 pagesWork Based M 2 Lesson 5 8Clarie FontanosNo ratings yet

- 1 3 Reading Interpreting and Applying Specifications and ManualDocument17 pages1 3 Reading Interpreting and Applying Specifications and ManualEZRAMAE TINGCANG100% (1)

- 1 Perform Diesel Engine Tune Up 1Document29 pages1 Perform Diesel Engine Tune Up 1Jheng Delos Reyes Pantoja100% (2)

- TR DPP Operation and Maintenance NC IIIDocument63 pagesTR DPP Operation and Maintenance NC IIICharo GironellaNo ratings yet

- MCARoofingInstallationManual Final FullLinking PDFDocument303 pagesMCARoofingInstallationManual Final FullLinking PDFjovelyn de silvaNo ratings yet

- MMAWNCIVDocument123 pagesMMAWNCIVmichaele keate CabatbatNo ratings yet

- CBC - Automotive Engine Rebuilding NCIIDocument112 pagesCBC - Automotive Engine Rebuilding NCIIGenaro Agustines100% (1)

- TR Electronics-Semicon Production Line Machine Servicing NC IIIDocument121 pagesTR Electronics-Semicon Production Line Machine Servicing NC IIIAljon BalanagNo ratings yet

- CIC BIM Standards - FINAL - ENG - v1 PDFDocument147 pagesCIC BIM Standards - FINAL - ENG - v1 PDFAnonymous 37PvyXC100% (1)

- M05 Piping DesignDocument46 pagesM05 Piping DesignAnbalagan PrabhuNo ratings yet

- MVM OneDocument34 pagesMVM OneBhang BoyNo ratings yet

- Nasa SP 8123Document189 pagesNasa SP 8123Michelle AtkinsNo ratings yet

- Concrete Finishing Level2 QualificationsDocument58 pagesConcrete Finishing Level2 QualificationsDelta akathehuskyNo ratings yet

- NBA Criteria 2Document20 pagesNBA Criteria 2SRAVANNo ratings yet

- Mofhm Lab Manual-2020 FinalDocument66 pagesMofhm Lab Manual-2020 FinalSiraj MohammedNo ratings yet

- 1 Specification WritingDocument31 pages1 Specification Writingprince vargas100% (1)

- Common 4 Apply Quality StandardsDocument46 pagesCommon 4 Apply Quality StandardsGove Mojemer Red100% (3)

- CBLM - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.0Document95 pagesCBLM - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.0Edward RaagasNo ratings yet

- CBLM Video FinalDocument77 pagesCBLM Video FinalsorcererpcNo ratings yet

- Lab Sheet 2 - Split Core Cavity PDFDocument3 pagesLab Sheet 2 - Split Core Cavity PDFAmilin HatiaraNo ratings yet

- Duct Design by CarrierDocument0 pagesDuct Design by Carrierسامح الجاسم100% (2)

- QA QC Manual 2008Document86 pagesQA QC Manual 2008netomeller100% (2)

- Concrete Finishing Level1 QualificationsDocument52 pagesConcrete Finishing Level1 QualificationsDelta akathehuskyNo ratings yet

- Entregable 1.docx OliverDDocument17 pagesEntregable 1.docx OliverDMike Damian RodrigoNo ratings yet

- TR Die Designing NC IVDocument140 pagesTR Die Designing NC IVJefferson MoralesNo ratings yet

- Using Aspect-Oriented Programming for Trustworthy Software DevelopmentFrom EverandUsing Aspect-Oriented Programming for Trustworthy Software DevelopmentRating: 3 out of 5 stars3/5 (1)

- AutoCAD Electrical 2024 for Electrical Control Designers, 15th EditionFrom EverandAutoCAD Electrical 2024 for Electrical Control Designers, 15th EditionNo ratings yet

- Bind The BookDocument22 pagesBind The Booknizam1372100% (1)

- NoteDocument112 pagesNotenizam1372No ratings yet

- Model: Acctig 300 Ac/Dc S/N: C0027 MP1677002: Otc, Gmaw Welding Machine, JapanDocument7 pagesModel: Acctig 300 Ac/Dc S/N: C0027 MP1677002: Otc, Gmaw Welding Machine, Japannizam1372No ratings yet

- Ahmad Khatib Al Minangkabawi Manuscript PDFDocument82 pagesAhmad Khatib Al Minangkabawi Manuscript PDFnizam1372No ratings yet

- Weld Time (Min) Travel Speed Caculator (Input The Time Taken & The Length of Weld)Document3 pagesWeld Time (Min) Travel Speed Caculator (Input The Time Taken & The Length of Weld)nizam1372No ratings yet

- Danau CoCu Welding Operation Level 4Document69 pagesDanau CoCu Welding Operation Level 4nizam1372No ratings yet

- SP Welding Operation Level 4Document18 pagesSP Welding Operation Level 4nizam1372No ratings yet

- Destructive TestingDocument18 pagesDestructive Testingnizam1372No ratings yet

- How To Write A Welding Procedure SpecificationDocument14 pagesHow To Write A Welding Procedure Specificationnizam1372100% (2)

- Bookbinding FundamentalsDocument48 pagesBookbinding Fundamentalsnizam1372100% (3)

- CoCU - CU6Document21 pagesCoCU - CU6nizam1372No ratings yet

- References Follow The American Psychological Association (APA) FormatDocument1 pageReferences Follow The American Psychological Association (APA) Formatnizam1372No ratings yet

- Mechanics of Materials Equation SheetDocument3 pagesMechanics of Materials Equation SheetAramis Kelkelyan100% (1)

- MO Updates For Media December 2023 ResultDocument21 pagesMO Updates For Media December 2023 Resultsinnyen.hengNo ratings yet

- (Goutam Paul Subhamoy Maitra) RC4 Stream Cipher A (B-Ok - Xyz)Document310 pages(Goutam Paul Subhamoy Maitra) RC4 Stream Cipher A (B-Ok - Xyz)HipMorsqNo ratings yet

- 10 Science Chemical Reactions and Equations Test 01Document2 pages10 Science Chemical Reactions and Equations Test 01Himanshu SharmaNo ratings yet

- Retrospective Planning WorksheetDocument2 pagesRetrospective Planning Worksheetzuggo848592No ratings yet

- Reinforced Concrete Design IIDocument52 pagesReinforced Concrete Design II'Izzad Afif100% (1)

- Reducto Res SewDocument216 pagesReducto Res SewLG Milton LuisNo ratings yet

- Demolishing Concrete: Products Examples Pricing Production Rates New FeaturesDocument4 pagesDemolishing Concrete: Products Examples Pricing Production Rates New Featuresruel buntogNo ratings yet

- BS 7072 (1989)Document16 pagesBS 7072 (1989)Yaks ArogeNo ratings yet

- Dynamic PumpsDocument38 pagesDynamic PumpsShayn Shayn100% (3)

- Factors Affected To 3D Image in Digital WatermarkingDocument3 pagesFactors Affected To 3D Image in Digital WatermarkingInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- KAR Products - Penetrating OilDocument5 pagesKAR Products - Penetrating Oiljaredf@jfelectric.com100% (2)

- Product Data Sheet: Dehnguard Modular DG M TT 275 FM (952 315)Document1 pageProduct Data Sheet: Dehnguard Modular DG M TT 275 FM (952 315)dfghjNo ratings yet

- Masonry 9 Second Quarter-Week 3 Select Masonry Measuring ToolsDocument6 pagesMasonry 9 Second Quarter-Week 3 Select Masonry Measuring ToolsSTEPHEN ANDRESNo ratings yet

- Resume Hugo HuamaniDocument2 pagesResume Hugo Huamanihugoluis_hNo ratings yet

- Armv8m Architecture Memory Protection Unit 100699 0100 00 enDocument39 pagesArmv8m Architecture Memory Protection Unit 100699 0100 00 enNilesh DesaiNo ratings yet

- Ninja 650 ManualDocument169 pagesNinja 650 ManualMoises AranzaNo ratings yet

- ANSWER Rule78 SampleExamDocument19 pagesANSWER Rule78 SampleExamrayzlazoNo ratings yet

- Component Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFDocument3 pagesComponent Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFbakhtyar21No ratings yet

- Service Level Agreement Ibm Maximo Asset Management (Saas) : 1. DefinitionsDocument3 pagesService Level Agreement Ibm Maximo Asset Management (Saas) : 1. Definitionssaicharan3979No ratings yet

- Working Platform For Installing and Dismantling Aluminum Formwork PDFDocument9 pagesWorking Platform For Installing and Dismantling Aluminum Formwork PDFmohd zulhafizNo ratings yet

- Plumbing Piping For Building: NIOEC-SP-30-05Document9 pagesPlumbing Piping For Building: NIOEC-SP-30-05masoud132No ratings yet

- Microcontroller Based Anaesthesia Machine: Key Words: Micro-Controller, Syringe Infusion 3.technology: A) ArduinoDocument5 pagesMicrocontroller Based Anaesthesia Machine: Key Words: Micro-Controller, Syringe Infusion 3.technology: A) ArduinocNo ratings yet

- ControllerDocument2 pagesControlleral-if0% (1)

- S03 Rotary Drill RHR50 - ADocument18 pagesS03 Rotary Drill RHR50 - ArolandNo ratings yet

- Kleemann News ISSUE #01 (English Version)Document10 pagesKleemann News ISSUE #01 (English Version)Kleemmann Hellas SANo ratings yet

- Turbojet EnginesDocument22 pagesTurbojet EnginesAldo SamuelNo ratings yet

- MSDS Colacor 600Document3 pagesMSDS Colacor 600mndmatt100% (2)

- Selecion de Fusibles para Proteccion de TransformadoresDocument14 pagesSelecion de Fusibles para Proteccion de TransformadoresfreddyriveraNo ratings yet