Professional Documents

Culture Documents

Rectification of Defective High Mast Lighting in Cast House Yard Lighting

Rectification of Defective High Mast Lighting in Cast House Yard Lighting

Uploaded by

nsadnanCopyright:

Available Formats

You might also like

- IdipNEBOSH Unit A Past Exam QuestionsDocument16 pagesIdipNEBOSH Unit A Past Exam Questionskrunalb@in89% (28)

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan67% (9)

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan80% (5)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocument6 pagesRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (22)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Nursing Care Plan For Acute Gastrointestinal HemorrhageDocument2 pagesNursing Care Plan For Acute Gastrointestinal HemorrhageCyrus De Asis92% (25)

- MS - Installation - of - Containments - QC - REV - 2Document7 pagesMS - Installation - of - Containments - QC - REV - 2irfan vpNo ratings yet

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Risk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONDocument6 pagesRisk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONnsadnan100% (1)

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocument20 pagesRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanNo ratings yet

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead Cranensadnan100% (1)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- ABCDE Approach To The Critically Ill Patient - Nick SmithDocument40 pagesABCDE Approach To The Critically Ill Patient - Nick SmithBadrul Hisyam Alias100% (1)

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocument6 pagesRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanNo ratings yet

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 pagesPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanNo ratings yet

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDocument8 pagesContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanNo ratings yet

- Cable Pulling, Glanding and TerminationsDocument6 pagesCable Pulling, Glanding and TerminationsnsadnanNo ratings yet

- Modification of Cable Ladder in Bath Processing PlantDocument14 pagesModification of Cable Ladder in Bath Processing PlantnsadnanNo ratings yet

- Contractor Work Method Statement (Ehs)Document11 pagesContractor Work Method Statement (Ehs)nsadnanNo ratings yet

- Risk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001Document12 pagesRisk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001nsadnanNo ratings yet

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDocument16 pagesRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanNo ratings yet

- RA For Fixing Warning LabelsDocument5 pagesRA For Fixing Warning LabelsnsadnanNo ratings yet

- D02 MS Ra Pov PDFDocument35 pagesD02 MS Ra Pov PDFnsadnanNo ratings yet

- Risk Ass. - Load Current Measurement and Cleaning of Oil CoolerDocument7 pagesRisk Ass. - Load Current Measurement and Cleaning of Oil CoolernsadnanNo ratings yet

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Document8 pagesFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanNo ratings yet

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNo ratings yet

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDocument9 pagesRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanNo ratings yet

- Cable PullingDocument10 pagesCable PullingnsadnanNo ratings yet

- Risk Ass. - AD 417 - Installation of SocketDocument6 pagesRisk Ass. - AD 417 - Installation of SocketnsadnanNo ratings yet

- Installation of Gi TrunkingDocument7 pagesInstallation of Gi TrunkingnsadnanNo ratings yet

- C00M04 HPL E - MC 304a XX MDS 0001 PDFDocument18 pagesC00M04 HPL E - MC 304a XX MDS 0001 PDFRUPESH KUMARNo ratings yet

- Method Statement - Erection of Secondary TrussDocument2 pagesMethod Statement - Erection of Secondary TrussAli WaqasNo ratings yet

- Manual Handling ChartDocument20 pagesManual Handling ChartTatak Bay Ahmed100% (1)

- 19-JMS - Installation Cable Tray or Cable Ladder and Support Installatio...Document10 pages19-JMS - Installation Cable Tray or Cable Ladder and Support Installatio...Mohd KhaidirNo ratings yet

- 4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1Document4 pages4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1loveson709No ratings yet

- Chipping REV1Document2 pagesChipping REV1anon_781855461No ratings yet

- Basic Safety Procedures in High Risk Activities andDocument14 pagesBasic Safety Procedures in High Risk Activities andEzekiel Domini Quintal0% (2)

- SPI HSE FR 03 Stringing ChecklistDocument1 pageSPI HSE FR 03 Stringing ChecklistChandan KumarNo ratings yet

- RA Ug Fire Pipe Installation and Hyrant SystemDocument17 pagesRA Ug Fire Pipe Installation and Hyrant SystemvinayNo ratings yet

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Critical Task Inventory (CTI)Document1 pageCritical Task Inventory (CTI)Salman FareesNo ratings yet

- Method Statement - Solar Ground Mounting, Car Park Structure Installation & Mounting of PV Panels - Cocacola - Al AinDocument10 pagesMethod Statement - Solar Ground Mounting, Car Park Structure Installation & Mounting of PV Panels - Cocacola - Al AinKarimo KilaniNo ratings yet

- Ra Lightning Protection SystemDocument16 pagesRa Lightning Protection Systemamal100% (1)

- EHS Calendar For October 2019: SUN MON TUE WED THU FRI SATDocument1 pageEHS Calendar For October 2019: SUN MON TUE WED THU FRI SATSiddharth RanaNo ratings yet

- Procedures For Safe Working and Testing of Energized Electrical EquipmentDocument25 pagesProcedures For Safe Working and Testing of Energized Electrical EquipmentSelvn SubramanianNo ratings yet

- Substation Earth Testing Job Safety AnalysisDocument5 pagesSubstation Earth Testing Job Safety AnalysishkaruvathilNo ratings yet

- 37 Material StorageDocument5 pages37 Material StorageCaron KarlosNo ratings yet

- Batching Plant Project: Initial Environmental Examination (Iee) ReportDocument16 pagesBatching Plant Project: Initial Environmental Examination (Iee) ReportavieNo ratings yet

- ChecklistDocument14 pagesChecklistInstrument SCINo ratings yet

- Method Statement For Dressing of Steel PoleDocument3 pagesMethod Statement For Dressing of Steel PoleMary Grace LagundinoNo ratings yet

- Philip Bates: Piling Method Statement For Willmott Dixon Riverside Court, Birstall, Leicestershire LE4 4EHDocument11 pagesPhilip Bates: Piling Method Statement For Willmott Dixon Riverside Court, Birstall, Leicestershire LE4 4EHYap Yee FooNo ratings yet

- Fire Safety ChecklistDocument2 pagesFire Safety ChecklistbenzentenNo ratings yet

- 4.5.3!01!06 First Aid Property Environmental ReportDocument4 pages4.5.3!01!06 First Aid Property Environmental Reportloveson709No ratings yet

- HVT Group AssignmentDocument17 pagesHVT Group AssignmentSiti Farhana100% (2)

- PT Indocool Solusi Cemerlang: Personal Protecion Recomenden/RequiredDocument2 pagesPT Indocool Solusi Cemerlang: Personal Protecion Recomenden/RequiredridhowibiiNo ratings yet

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- (New) NEC AccreditationSuite Hong Kong v3 (Web)Document6 pages(New) NEC AccreditationSuite Hong Kong v3 (Web)chong pak limNo ratings yet

- PTW - Electrical PermitDocument2 pagesPTW - Electrical PermitJahanzaib KhanNo ratings yet

- MS For Installation of Cable Tray Support-048Document3 pagesMS For Installation of Cable Tray Support-048Mohammad Fazal Khan100% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- JSA Trunks InstallationDocument9 pagesJSA Trunks InstallationWeru MorrisNo ratings yet

- Check List For Transformers: Contract No: DateDocument2 pagesCheck List For Transformers: Contract No: DateKarthick NatrajanNo ratings yet

- Method Statement - BWWP - V1Document18 pagesMethod Statement - BWWP - V1RICHARD FUNUENo ratings yet

- Defense Acquisition GuidebookDocument969 pagesDefense Acquisition GuidebookDarius PeytonNo ratings yet

- Cable ScheduleDocument38 pagesCable SchedulemaniannanNo ratings yet

- TEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Document7 pagesTEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Aryaa ArrNo ratings yet

- Js1077-Xx-Bni-001-W01-0006 - Cable Trays, Trunking & Cable LaddersDocument15 pagesJs1077-Xx-Bni-001-W01-0006 - Cable Trays, Trunking & Cable LaddersRashidMallickNo ratings yet

- Cable TerminationsDocument6 pagesCable TerminationsnsadnanNo ratings yet

- Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMDocument8 pagesRisk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMnsadnan100% (1)

- Risk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003ADocument6 pagesRisk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003AnsadnanNo ratings yet

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- 1 45Document3 pages1 45nsadnan0% (1)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment For GIS Preparation For HV Cable TestDocument11 pagesRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- How To Overcome Perfectionism Personal Excellence EbookDocument43 pagesHow To Overcome Perfectionism Personal Excellence EbookDeepak SinghNo ratings yet

- Everyday English For Nursing PDFDocument2 pagesEveryday English For Nursing PDFMargario50% (2)

- Artikel Bahasa Inggris Dengan Topik BerbedaDocument2 pagesArtikel Bahasa Inggris Dengan Topik Berbedakikin wandaNo ratings yet

- Review Article On Acharya TechDocument5 pagesReview Article On Acharya Techrahul yadavNo ratings yet

- Breast Cancer Diagnosed During PregnancyDocument3 pagesBreast Cancer Diagnosed During PregnancyJonny CardenasNo ratings yet

- DrugsDocument2 pagesDrugsJeff MarekNo ratings yet

- Andi Mawar Nirmalasari Asning 2017 Autumn Online 917905056Document28 pagesAndi Mawar Nirmalasari Asning 2017 Autumn Online 917905056Ronaldo Theodorus Azikin JapariNo ratings yet

- Nutrients 14 03205Document15 pagesNutrients 14 03205Bogdan A. GireadăNo ratings yet

- DiabetesDocument2 pagesDiabetesBABLU ROYNo ratings yet

- About Hanna Kroeger PDFDocument4 pagesAbout Hanna Kroeger PDFAnnelie RabieNo ratings yet

- Adverse Effects of Nutraceuticals and Dietary SupplementsDocument22 pagesAdverse Effects of Nutraceuticals and Dietary Supplementsrhmiii10No ratings yet

- Immune Script-Fullscript Rebuttals-CentersDocument8 pagesImmune Script-Fullscript Rebuttals-CentersNewpath IndiaNo ratings yet

- The Immune System Game: (A Large Group Game That Resembles "Human Chess")Document5 pagesThe Immune System Game: (A Large Group Game That Resembles "Human Chess")kiki19841984No ratings yet

- Plan Your Practice Perfect Your PostureDocument6 pagesPlan Your Practice Perfect Your PostureDr FarhatNo ratings yet

- P.E and Health ReviewerrDocument14 pagesP.E and Health ReviewerrJoyce Anne Mae AdorioNo ratings yet

- 4 Compassion Video - Follow-Up and TestingDocument2 pages4 Compassion Video - Follow-Up and TestingAngelo CiardellaNo ratings yet

- 2020 Gastro - Annc Format PDFDocument4 pages2020 Gastro - Annc Format PDFhalikalifhayaNo ratings yet

- Mapeh ReviewerDocument3 pagesMapeh ReviewerPrincess Charlea MirandaNo ratings yet

- Exercise About NewsitemDocument3 pagesExercise About NewsitemVincent RenoNo ratings yet

- Epilepsy in PregnancyDocument20 pagesEpilepsy in Pregnancytenri olaNo ratings yet

- Swot Kelompok 3Document9 pagesSwot Kelompok 3ilhamcitrahamidiNo ratings yet

- PL-PBI-HSE 001 Project HSE PlanDocument22 pagesPL-PBI-HSE 001 Project HSE PlanTadaya KasaharaNo ratings yet

- 12 Points To Answering Pharmacology QuestionsDocument5 pages12 Points To Answering Pharmacology QuestionsUptd Puskesmas Batuatas100% (1)

- Detailed DLP LS2Document4 pagesDetailed DLP LS2Ian BarrugaNo ratings yet

- Gujarat State Immunization FactsheetDocument32 pagesGujarat State Immunization FactsheetNIRAV JOSHINo ratings yet

- NURS 1124 Sp17Document81 pagesNURS 1124 Sp17Orange AlvarezNo ratings yet

- City Gets A Covid-19 Hospital It Deserves, and So Badly NeedsDocument16 pagesCity Gets A Covid-19 Hospital It Deserves, and So Badly NeedsHindutav aryaNo ratings yet

Rectification of Defective High Mast Lighting in Cast House Yard Lighting

Rectification of Defective High Mast Lighting in Cast House Yard Lighting

Uploaded by

nsadnanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rectification of Defective High Mast Lighting in Cast House Yard Lighting

Rectification of Defective High Mast Lighting in Cast House Yard Lighting

Uploaded by

nsadnanCopyright:

Available Formats

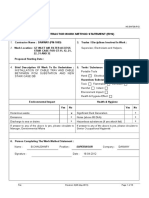

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY 3. Trades / Disciplines Involved In Work :

2. Work Location : CAST HOUSE YARD Engineer, Supervisor, Electricians and Helpers.

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : 5. Tools / Substance

Portable Tools

RECTIFICATION OF DEFECTIVE HIGH MAST

LIGHTING IN CAST HOUSE YARD LIGHTING. Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste Significant Dust Generation

Emissions Noise (above 85 DbA)

Discharge to sea or drains Hazardous substances (if yes attach list)

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : SAJI JOHN Position : SUPERVISOR Company : DANWAY

Signature : Date :

File: Revision: 0(26-May-2011) Page 1 of 6

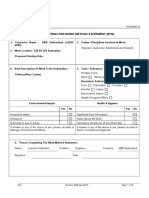

HS.SAF.09.F12

7. Approvals

Contractor Site Rep. Name PRAVEEN Signature : Date :

EMAL Representative Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low Severity LP x MS LP x HS

1x1=1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

File: Revision: 0(26-May-2011) Page 2 of 6

SM-CMS.TSK.01.F02

8. Safety Analysis

Identified Hazard(s) Persons Exposed To Precautions and Plan of actions To Be Taken Severity x Probability =

Individual Activities To Associated With Activity Hazard To Remove / Control Hazards Risk

Complete Work. List In

Sequence of Activity Residual Risk

(Use Risk Estimator

Chart)

Maintain housekeeping around in the working

PREPARATION. Slips, trips and fall at the Emal rep., Engr., Supv. area. 1x2=2

same level. Elec, helpers.

All workers involve in the activity must be

Emal rep., Engr., Supv.

Hot weather. aware of heat stress, supervisor to ensure 2x2=4

Elec,helpers

drinking cold water is available.

Supervisor to give tool box talk regarding

Manual handling hazards Supv. Elec,helpers 1x1=2

proper manual handling.

Unauthorized person Emal rep., Engr., Supv. Supervisor to ensure approved PTW, MS and

TESTING OF DEFECTIVE 2x2=4

electrocution / Fire Elec, helpers. RA are available on site.

HIGH MAST LIGHTING

Ensure that working crew does not enter into the

operational area.

Complete the pre-work check list on a daily

basis.

Daily toolbox meetings to be conducted on

days activity, which will include TRA for the

activity.

Barricade live panel area with warning tapes.

Access towards to the testing area to be

barricaded and watchman to be posted.

Testing area to be barricaded and proper sign

File: Revision: 0(26-May-2011) Page 3 of 6

SM-CMS.TSK.01.F02

boards to be placed which read "TESTING IN

PROGRESS KEEP AWAY".

All testing equipments must be in good

condition and with valid test calibration.

Avoid cable joint.

Clear everybody from the area where testing is

in progress.

Request for appropriate safety bulletin IF

REQUIRED

Using unsafe / Ensure manlift is inspected by Emal with

Emal rep., Engr., Supv.

damaged manlift Elec,Helpers,workers inspection sticker on it and valid certificates

Fire nearby are available for the equipment & competent

Incompetent manlift operator.

operator. Provide fire extinguisher.

USING OF MANLIFT (IF Ensure personnel inside the man basket wear

REQUIRED) their full body safety harness and 100% tie off. 3x2=6

Manlift operator should take extra care while

moving the equipment.

Banks man to be assigned on the ground to

give warning to other workers nearby.

Unwanted fall of

Cordon the work area to avoid unauthorized

objects, tools, and Supv. Elec & helpers entry.

materials may cause

head injury to workers Provide applicable safety warning signboards. 2 x2=4

underneath Use appropriate PPEs

File: Revision: 0(26-May-2011) Page 4 of 6

SM-CMS.TSK.01.F02

All hand tools must be in good condition, no

Using damaged hand Electricians & Helpers homemade hand tools to be used at site, 2 x 1 =2

tools.. supervisor to ensure.

Competent workers to be deployed,

Incompetent workers. Electricians & Helpers supervisor to check the competency of the 2 x 1 =2

workers.

Slips, trips and fall at the Electricians , supervisor Maintain housekeeping around the working 2 x 1 =2

same level. & Helpers area.

All workers involve in working at height must

Elect & helpers

wear their full body harness and 100% tie off.

Barricade the working area by using safety 2 x2=4

Fall from height cones warning tape / signboard.

No materials or hand tools to be stocked on the

top of ladder/mainlift

Clear all debris after the completion of work

Bad house keeping Emal rep., Engr., Supv.

Walkway and gangway to be kept free of

1x3=3

Elec,Helpers,workers

nearby obstruction

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

File: Revision: 0(26-May-2011) Page 5 of 6

SM-CMS.TSK.01.F02

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

File: Revision: 0(26-May-2011) Page 6 of 6

You might also like

- IdipNEBOSH Unit A Past Exam QuestionsDocument16 pagesIdipNEBOSH Unit A Past Exam Questionskrunalb@in89% (28)

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan67% (9)

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan80% (5)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocument6 pagesRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (22)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Nursing Care Plan For Acute Gastrointestinal HemorrhageDocument2 pagesNursing Care Plan For Acute Gastrointestinal HemorrhageCyrus De Asis92% (25)

- MS - Installation - of - Containments - QC - REV - 2Document7 pagesMS - Installation - of - Containments - QC - REV - 2irfan vpNo ratings yet

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Risk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONDocument6 pagesRisk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONnsadnan100% (1)

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocument20 pagesRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanNo ratings yet

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead Cranensadnan100% (1)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- ABCDE Approach To The Critically Ill Patient - Nick SmithDocument40 pagesABCDE Approach To The Critically Ill Patient - Nick SmithBadrul Hisyam Alias100% (1)

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocument6 pagesRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanNo ratings yet

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 pagesPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanNo ratings yet

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDocument8 pagesContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanNo ratings yet

- Cable Pulling, Glanding and TerminationsDocument6 pagesCable Pulling, Glanding and TerminationsnsadnanNo ratings yet

- Modification of Cable Ladder in Bath Processing PlantDocument14 pagesModification of Cable Ladder in Bath Processing PlantnsadnanNo ratings yet

- Contractor Work Method Statement (Ehs)Document11 pagesContractor Work Method Statement (Ehs)nsadnanNo ratings yet

- Risk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001Document12 pagesRisk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001nsadnanNo ratings yet

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDocument16 pagesRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanNo ratings yet

- RA For Fixing Warning LabelsDocument5 pagesRA For Fixing Warning LabelsnsadnanNo ratings yet

- D02 MS Ra Pov PDFDocument35 pagesD02 MS Ra Pov PDFnsadnanNo ratings yet

- Risk Ass. - Load Current Measurement and Cleaning of Oil CoolerDocument7 pagesRisk Ass. - Load Current Measurement and Cleaning of Oil CoolernsadnanNo ratings yet

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Document8 pagesFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanNo ratings yet

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNo ratings yet

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDocument9 pagesRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanNo ratings yet

- Cable PullingDocument10 pagesCable PullingnsadnanNo ratings yet

- Risk Ass. - AD 417 - Installation of SocketDocument6 pagesRisk Ass. - AD 417 - Installation of SocketnsadnanNo ratings yet

- Installation of Gi TrunkingDocument7 pagesInstallation of Gi TrunkingnsadnanNo ratings yet

- C00M04 HPL E - MC 304a XX MDS 0001 PDFDocument18 pagesC00M04 HPL E - MC 304a XX MDS 0001 PDFRUPESH KUMARNo ratings yet

- Method Statement - Erection of Secondary TrussDocument2 pagesMethod Statement - Erection of Secondary TrussAli WaqasNo ratings yet

- Manual Handling ChartDocument20 pagesManual Handling ChartTatak Bay Ahmed100% (1)

- 19-JMS - Installation Cable Tray or Cable Ladder and Support Installatio...Document10 pages19-JMS - Installation Cable Tray or Cable Ladder and Support Installatio...Mohd KhaidirNo ratings yet

- 4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1Document4 pages4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1loveson709No ratings yet

- Chipping REV1Document2 pagesChipping REV1anon_781855461No ratings yet

- Basic Safety Procedures in High Risk Activities andDocument14 pagesBasic Safety Procedures in High Risk Activities andEzekiel Domini Quintal0% (2)

- SPI HSE FR 03 Stringing ChecklistDocument1 pageSPI HSE FR 03 Stringing ChecklistChandan KumarNo ratings yet

- RA Ug Fire Pipe Installation and Hyrant SystemDocument17 pagesRA Ug Fire Pipe Installation and Hyrant SystemvinayNo ratings yet

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Critical Task Inventory (CTI)Document1 pageCritical Task Inventory (CTI)Salman FareesNo ratings yet

- Method Statement - Solar Ground Mounting, Car Park Structure Installation & Mounting of PV Panels - Cocacola - Al AinDocument10 pagesMethod Statement - Solar Ground Mounting, Car Park Structure Installation & Mounting of PV Panels - Cocacola - Al AinKarimo KilaniNo ratings yet

- Ra Lightning Protection SystemDocument16 pagesRa Lightning Protection Systemamal100% (1)

- EHS Calendar For October 2019: SUN MON TUE WED THU FRI SATDocument1 pageEHS Calendar For October 2019: SUN MON TUE WED THU FRI SATSiddharth RanaNo ratings yet

- Procedures For Safe Working and Testing of Energized Electrical EquipmentDocument25 pagesProcedures For Safe Working and Testing of Energized Electrical EquipmentSelvn SubramanianNo ratings yet

- Substation Earth Testing Job Safety AnalysisDocument5 pagesSubstation Earth Testing Job Safety AnalysishkaruvathilNo ratings yet

- 37 Material StorageDocument5 pages37 Material StorageCaron KarlosNo ratings yet

- Batching Plant Project: Initial Environmental Examination (Iee) ReportDocument16 pagesBatching Plant Project: Initial Environmental Examination (Iee) ReportavieNo ratings yet

- ChecklistDocument14 pagesChecklistInstrument SCINo ratings yet

- Method Statement For Dressing of Steel PoleDocument3 pagesMethod Statement For Dressing of Steel PoleMary Grace LagundinoNo ratings yet

- Philip Bates: Piling Method Statement For Willmott Dixon Riverside Court, Birstall, Leicestershire LE4 4EHDocument11 pagesPhilip Bates: Piling Method Statement For Willmott Dixon Riverside Court, Birstall, Leicestershire LE4 4EHYap Yee FooNo ratings yet

- Fire Safety ChecklistDocument2 pagesFire Safety ChecklistbenzentenNo ratings yet

- 4.5.3!01!06 First Aid Property Environmental ReportDocument4 pages4.5.3!01!06 First Aid Property Environmental Reportloveson709No ratings yet

- HVT Group AssignmentDocument17 pagesHVT Group AssignmentSiti Farhana100% (2)

- PT Indocool Solusi Cemerlang: Personal Protecion Recomenden/RequiredDocument2 pagesPT Indocool Solusi Cemerlang: Personal Protecion Recomenden/RequiredridhowibiiNo ratings yet

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- (New) NEC AccreditationSuite Hong Kong v3 (Web)Document6 pages(New) NEC AccreditationSuite Hong Kong v3 (Web)chong pak limNo ratings yet

- PTW - Electrical PermitDocument2 pagesPTW - Electrical PermitJahanzaib KhanNo ratings yet

- MS For Installation of Cable Tray Support-048Document3 pagesMS For Installation of Cable Tray Support-048Mohammad Fazal Khan100% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- JSA Trunks InstallationDocument9 pagesJSA Trunks InstallationWeru MorrisNo ratings yet

- Check List For Transformers: Contract No: DateDocument2 pagesCheck List For Transformers: Contract No: DateKarthick NatrajanNo ratings yet

- Method Statement - BWWP - V1Document18 pagesMethod Statement - BWWP - V1RICHARD FUNUENo ratings yet

- Defense Acquisition GuidebookDocument969 pagesDefense Acquisition GuidebookDarius PeytonNo ratings yet

- Cable ScheduleDocument38 pagesCable SchedulemaniannanNo ratings yet

- TEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Document7 pagesTEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Aryaa ArrNo ratings yet

- Js1077-Xx-Bni-001-W01-0006 - Cable Trays, Trunking & Cable LaddersDocument15 pagesJs1077-Xx-Bni-001-W01-0006 - Cable Trays, Trunking & Cable LaddersRashidMallickNo ratings yet

- Cable TerminationsDocument6 pagesCable TerminationsnsadnanNo ratings yet

- Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMDocument8 pagesRisk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMnsadnan100% (1)

- Risk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003ADocument6 pagesRisk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003AnsadnanNo ratings yet

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- 1 45Document3 pages1 45nsadnan0% (1)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment For GIS Preparation For HV Cable TestDocument11 pagesRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- How To Overcome Perfectionism Personal Excellence EbookDocument43 pagesHow To Overcome Perfectionism Personal Excellence EbookDeepak SinghNo ratings yet

- Everyday English For Nursing PDFDocument2 pagesEveryday English For Nursing PDFMargario50% (2)

- Artikel Bahasa Inggris Dengan Topik BerbedaDocument2 pagesArtikel Bahasa Inggris Dengan Topik Berbedakikin wandaNo ratings yet

- Review Article On Acharya TechDocument5 pagesReview Article On Acharya Techrahul yadavNo ratings yet

- Breast Cancer Diagnosed During PregnancyDocument3 pagesBreast Cancer Diagnosed During PregnancyJonny CardenasNo ratings yet

- DrugsDocument2 pagesDrugsJeff MarekNo ratings yet

- Andi Mawar Nirmalasari Asning 2017 Autumn Online 917905056Document28 pagesAndi Mawar Nirmalasari Asning 2017 Autumn Online 917905056Ronaldo Theodorus Azikin JapariNo ratings yet

- Nutrients 14 03205Document15 pagesNutrients 14 03205Bogdan A. GireadăNo ratings yet

- DiabetesDocument2 pagesDiabetesBABLU ROYNo ratings yet

- About Hanna Kroeger PDFDocument4 pagesAbout Hanna Kroeger PDFAnnelie RabieNo ratings yet

- Adverse Effects of Nutraceuticals and Dietary SupplementsDocument22 pagesAdverse Effects of Nutraceuticals and Dietary Supplementsrhmiii10No ratings yet

- Immune Script-Fullscript Rebuttals-CentersDocument8 pagesImmune Script-Fullscript Rebuttals-CentersNewpath IndiaNo ratings yet

- The Immune System Game: (A Large Group Game That Resembles "Human Chess")Document5 pagesThe Immune System Game: (A Large Group Game That Resembles "Human Chess")kiki19841984No ratings yet

- Plan Your Practice Perfect Your PostureDocument6 pagesPlan Your Practice Perfect Your PostureDr FarhatNo ratings yet

- P.E and Health ReviewerrDocument14 pagesP.E and Health ReviewerrJoyce Anne Mae AdorioNo ratings yet

- 4 Compassion Video - Follow-Up and TestingDocument2 pages4 Compassion Video - Follow-Up and TestingAngelo CiardellaNo ratings yet

- 2020 Gastro - Annc Format PDFDocument4 pages2020 Gastro - Annc Format PDFhalikalifhayaNo ratings yet

- Mapeh ReviewerDocument3 pagesMapeh ReviewerPrincess Charlea MirandaNo ratings yet

- Exercise About NewsitemDocument3 pagesExercise About NewsitemVincent RenoNo ratings yet

- Epilepsy in PregnancyDocument20 pagesEpilepsy in Pregnancytenri olaNo ratings yet

- Swot Kelompok 3Document9 pagesSwot Kelompok 3ilhamcitrahamidiNo ratings yet

- PL-PBI-HSE 001 Project HSE PlanDocument22 pagesPL-PBI-HSE 001 Project HSE PlanTadaya KasaharaNo ratings yet

- 12 Points To Answering Pharmacology QuestionsDocument5 pages12 Points To Answering Pharmacology QuestionsUptd Puskesmas Batuatas100% (1)

- Detailed DLP LS2Document4 pagesDetailed DLP LS2Ian BarrugaNo ratings yet

- Gujarat State Immunization FactsheetDocument32 pagesGujarat State Immunization FactsheetNIRAV JOSHINo ratings yet

- NURS 1124 Sp17Document81 pagesNURS 1124 Sp17Orange AlvarezNo ratings yet

- City Gets A Covid-19 Hospital It Deserves, and So Badly NeedsDocument16 pagesCity Gets A Covid-19 Hospital It Deserves, and So Badly NeedsHindutav aryaNo ratings yet