Professional Documents

Culture Documents

Al Chemical Composition Limits (Table 2.1)

Al Chemical Composition Limits (Table 2.1)

Uploaded by

AnthonyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Al Chemical Composition Limits (Table 2.1)

Al Chemical Composition Limits (Table 2.1)

Uploaded by

AnthonyCopyright:

Available Formats

Chemical Composition Limits

Table 2.1: Chemical Composition Limits of Registered Alloys1,2

International Chemical composition (percent weight)

Registered Aluminium 0thers

3

Designation Silicon Iron Copper Manganese Magnesium Chromium Zinc Titanium

(min) Each Total

1050 99.50

4

0.25 0.40 0.05 0.05 0.05 - 0.05 0.05 V 0.03 0.03 -

1060 99.60

4

0.25 0.35 0.05 0.03 0.03 - 0.05 0.05 V 0.03 0.03 -

4

1070 99.70

4

0.20 0.25 0.04 0.03 0.03 0.04 0.05 V 0.03 0.03 -

1080A 99.80 0.15 0.15 0.03 0.02 0.02 0.06 0.03 Ga 0.02 0.02

4

1100 99.00 0.95 Si + Fe 0.050.20 0.05 0.10 6 0.05 0.15

4

1145 99.45 0.55 Si + Fe 0.05 0.05 0.05 0.05 0.05 V 0.03 0.03

4

1150 99.50 0.45 Si + Fe 0.050.20 0.05 0.05 0.05 0.03 0.03

4

1200 99.00 1.00 Si + Fe 0.05 0.05 0.10 6 0.05 0.05 0.15

4

1230 99.30 0.70 Si + Fe 0.10 0.05 0.05 0.10 0.05 V 0.03 0.03

1235 99.35

4

0.65 Si + Fe 0.05 0.05 0.05 - 0.10 0.05 V 0.06 0.03

4

1350 99.50 0.10 0.40 0.05 0.01 0.01 0.05 0.03 Ga 0.05 B 0.02 V + Ti 0.03 0.10

2011 Rem 0.40 0.7 5.0-6.0 0.30 7 0.05 0.15

2014 Rem 0.50-1.2 0.7 3.9-5.0 0.40-1.2 0.20-0.8 0.10 0.25 0.15 0.05 0.15

2024 Rem 0.50 0.50 3.8-4.9 0.30-0.9 1.2-1.8 0.10 0.25 0.15 0.05 0.15

3003 Rem 0.6 0.7 0.05-0.20 1.0-1.5 0.10 0.05 0.15

3004 Rem 0.30 0.7 0.25 1.0-1.5 0.8-1.3 0.25 0.05 0.15

3005 Rem 0.6 0.7 0.30 1.0-1.5 0.20-0.6 0.10 0.25 0.10 0.05 0.15

3102 Rem 0.40 0.7 0.10 0.05-0.40 0.30 0.10 0.05 0.15

3104 Rem 0.6 0.8 0.05-0.25 0.8-1.4 0.8-1.3 - 0.25 0.05 Ga 0.05 V 0.10 0.05 0.15

3105 Rem 0.6 0.7 0.30 0.30-0.8 0.20-0.8 0.20 0.40 0.10 0.05 0.15

4043 Rem 4.5-6.0 0.8 0.30 0.05 0.05 0.10 6 0.20 0.05 0.15

4047 Rem 11.0-13.0 0.8 0.30 0.15 0.10 0.20 6 0.05 0.15

4343 Rem 6.8-8.2 0.8 0.25 0.10 0.20 0.05 0.15

5005 Rem 0.30 0.7 0.20 0.20 0.50-1.1 0.10 0.25 0.05 0.15

5042 Rem 0.20 0.35 0.15 0.20-0.50 3.0-4.0 0.10 0.25 0.10 0.05 0.15

5052 Rem 0.25 0.40 0.10 0.10 2.2-2.8 0.15-0.35 0.10 0.05 0.15

5059 Rem 0.45 0.50 0.25 0.6-1.2 5.0-6.0 0.25 0.40-0.09 0.05-0.25 Zr 0.20 0.05 0.15

5082 Rem 0.20 0.35 0.15 0.15 4.0-5.0 0.15 0.25 0.10 0.05 0.15

5083 Rem 0.40 0.40 0.10 0.40-1.0 4.0-4.9 0.05-0.25 0.25 0.15 0.05 0.15

5086 Rem 0.40 0.50 0.10 0.20-0.7 3.5-4.5 0.05-0.25 0.25 0.15 0.05 0.15

5182 Rem 0.20 0.35 0.15 0.20-0.50 4.0-5.0 0.10 0.25 0.10 0.05 0.15

5251 Rem 0.40 0.50 0.15 0.10-0.50 1.7-2.4 0.15 0.15 0.15 0.05 0.15

5252 Rem 0.08 0.10 0.10 0.10 2.2-2.8 0.05 0.05 V 0.03 0.10

5356 Rem 0.25 0.40 0.10 0.05-0.20 4.5-5.5 0.05-0.20 0.10 6 0.06-0.20 0.05 0.15

5383 Rem 0.25 0.25 0.20 0.7-1.0 4.0-5.2 0.25 0.40 0.20 Zr 0.15 0.05 0.15

5454 Rem 0.25 0.40 0.10 0.50-1.0 2.4-3.0 0.05-0.20 0.25 0.20 0.05 0.15

5557 Rem 0.10 0.12 0.15 0.10-0.40 0.40-0.8 0.05 V 0.03 0.10

5754 Rem 0.40 0.40 0.10 0.50 2.6-3.6 0.30 0.20 0.10-0.6 Mn+Cr 0.15 0.05 0.15

For Footnotes see page 1.4

Table 2.1: Chemical Composition Limits of Registered Alloys1,2 (continued)

International Chemical composition (percent weight)

3

Registered Aluminium 0thers

Designation Silicon Iron Copper Manganese Magnesium Chromium Zinc Titanium

(min) Each Total

Wrought Products Manual Section 2, Version 2.0.1 (11.08.04)

6005A Rem 0.50-0.9 0.35 0.3 0.50 10 0.40-0.7 0.30 10 0.20 0.10-0.50 Mn+Cr 0.10 0.05 0.15

6060 Rem 0.30-0.6 0.10-0.30 0.10 0.10 0.35-0.6 0.05 0.15 0.10 0.05 0.15

6061 Rem 0.40-0.8 0.7 0.15-0.40 0.15 0.8-1.2 0.04-0.35 0.25 0.15 0.05 0.15

6061A Rem 0.40-0.8 0.7 0.15-0.40 0.15 0.8-1.2 0.04-0.35 0.25 0.003 Pb 0.15 0.05 0.15

6063 Rem 0.20-0.6 0.35 0.10 0.10 0.45-0.9 0.10 0.10 0.10 0.05 0.15

6082 Rem 0.7-1.3 0.50 0.10 0.40-1.0 0.6-1.2 0.25 0.20 0.10 0.05 0.15

6101 Rem 0.30-0.7 0.50 0.10 0.03 0.35-0.8 0.03 0.10 0.06 B 0.03 0.10

6103 Rem 0.35-1.0 0.6 0.20-0.30 0.8 0.8-1.5 0.35 0.20 0.10 0.05 0.15

6106 Rem 0.30-0.6 0.35 0.25 0.05-0.20 0.40-0.8 0.20 0.10 0.05 0.10

6201A Rem 0.50-0.7 0.50 0.04 0.6-0.9 0.06 B 0.03 0.10

6253 Rem 8 0.50 0.10 1.0-1.5 0.04-0.35 1.6-2.4 0.05 0.15

6261 Rem 0.40-0.7 0.40 0.15-0.40 0.20-0.35 0.7-1.0 0.10 0.20 0.10 0.05 0.15

6262 Rem 0.40-0.8 0.7 0.15-0.40 0.15 0.8-1.2 0.04-0.14 0.25 9 0.15 0.05 0.15

6351 Rem 0.7-1.3 0.50 0.10 0.40-0.8 0.40-0.8 0.20 0.20 0.05 0.15

6463A Rem 0.20-0.6 0.15 0.25 0.05 0.30-0.9 0.05 0.05 0.15

7003 Rem 0.30 0.35 0.20 0.30 0.50-1.0 0.20 5.0-6.5 0.05-0.25 Zr 0.20 0.05 0.15

7005 Rem 0.35 0.40 0.10 0.20-0.7 1.0-1.8 0.06-0.20 4.0-5.0 0.08-0.20 Zr 0.01-0.06 0.05 0.15

7072 Rem 0.7 Si + Fe 0.10 0.10 0.10 0.8-1.3 0.05 0.15

7075 Rem 0.40 0.50 1.2-2.0 0.30 2.1-2.9 0.18-0.28 5.1-6.1 0.20 0.05 0.15

8006 Rem 0.40 1.2-2.0 0.30 0.30-1.0 0.10 0.10 0.05 0.15

8008 Rem 0.6 0.9-1.6 0.20 0.50-1.0 0.10 0.10 0.05 0.15

8011 Rem 0.50-0.9 0.6-1.0 0.10 0.20 0.05 0.05 0.10 0.08 0.05 0.15

8150 Rem 0.30 0.9-1.3 0.20-0.7 0.05 0.05 0.15

1

Footnotes Composition in % maximum unless shown as a range or a minimum.

2

For purposes of determining conformance to these limits, an observed value or a calculated value obtained from analysis is rounded off to the nearest unit in the last right hand place of figures used in expressing

the specified limit, in accordance with the following:

When the figure next beyond the last figure or place to be retained is less than 5, the figure in the place retained should be kept unchanged.

When the figure next beyond the last figure or place to be retained is greater than 5, the figure in the last place retained should be increased by 1.

When the figure next beyond the last figure or place to be retained is 5 and (i) there are no figures, or only zeros, beyond this 5, if the figure in the last place to be retained is odd, it should be increased by 1; if

even, it should be kept unchanged; (ii) if the 5 is followed by any figures other than zeros, the figure in the last place retained should be increased by 1 whether odd or even.

3

Analysis is regularly made only for the elements for which specific limits are shown, except for unalloyed aluminium. If, however, the presence of other elements is suspected to be, or in the course of routine

analysis is indicated to be in excess of the specified limits, further analysis is made to determine that these other elements are not in excess of the amount specified.

4

The aluminium content for unalloyed aluminium not made by a refining process is the difference between 100.00% and the sum of all other metallic elements present in amounts of 0.010% or more each, expressed

to the second decimal.

5

The aluminium content for unalloyed aluminium made by a refining process is the difference between 100.00% and the sum of all other metallic elements present in amounts of 0.0010% or more each, expressed to

the third decimal.

6

0.0008% max Be for welding electrodes and filler wire only.

7

0.200.6% Bi, 0.200.6% Pb.

8

4565% of the Magnesium content.

9

0.400.7% Bi, 0.40-0.7% Pb.

10

Mn + Cr must be in the range 0.12 to 0.50

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Axial Fans (Hison) Catalogue (3694 - Catalogs - MISSING - 2009-06-01) PDFDocument90 pagesAxial Fans (Hison) Catalogue (3694 - Catalogs - MISSING - 2009-06-01) PDFAnthonyNo ratings yet

- Axial Fans (Hison) Catalogue (3694 - Catalogs - MISSING - 2009-06-01) PDFDocument90 pagesAxial Fans (Hison) Catalogue (3694 - Catalogs - MISSING - 2009-06-01) PDFAnthonyNo ratings yet

- Welding Advice: High Tech Steel StructuresDocument8 pagesWelding Advice: High Tech Steel StructuresAnthonyNo ratings yet

- Faltinsen - Wave TableDocument1 pageFaltinsen - Wave TableAnthonyNo ratings yet

- Seabed Worker DatasheetDocument2 pagesSeabed Worker DatasheetAnthonyNo ratings yet

- Visualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelDocument13 pagesVisualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelAnthonyNo ratings yet

- Replacement SONNE - Status ReportDocument18 pagesReplacement SONNE - Status ReportAnthonyNo ratings yet

- BB Aquarius Folding Fin Stabilisers HRDocument2 pagesBB Aquarius Folding Fin Stabilisers HRAnthonyNo ratings yet

- Bulk Rename Utility - Manual PDFDocument51 pagesBulk Rename Utility - Manual PDFAnthony100% (1)

- Acid AttackDocument14 pagesAcid Attacksabareesan09No ratings yet

- MATTHEW CORREIA Acids Bases and Salts WORKSHEETDocument4 pagesMATTHEW CORREIA Acids Bases and Salts WORKSHEETFrank MassiahNo ratings yet

- Aluminium ChlorideDocument4 pagesAluminium ChlorideIntanmieyNo ratings yet

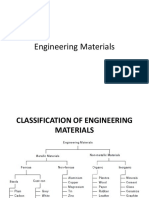

- Engineering MaterialsDocument18 pagesEngineering MaterialsAhmed ElkomyNo ratings yet

- 2.5.11. Complexometric TitrationsDocument1 page2.5.11. Complexometric TitrationsMulayam Singh YadavNo ratings yet

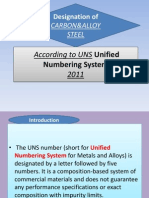

- Steel Designation0Document13 pagesSteel Designation0Palak NaikNo ratings yet

- Uns GXXXXXDocument10 pagesUns GXXXXXMohammed J AlobaidiNo ratings yet

- Module-1 Overview of Civil Engineering SystemsDocument20 pagesModule-1 Overview of Civil Engineering SystemsManvanth B CNo ratings yet

- Second Division: Republic of The Philippines Supreme Court ManilaDocument41 pagesSecond Division: Republic of The Philippines Supreme Court Manilayazi08No ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- DSS Welding Best PracticesDocument8 pagesDSS Welding Best PracticesessnelsonNo ratings yet

- Brain Test System: For Solution Purchase Brain Question Bank 042-37113344Document4 pagesBrain Test System: For Solution Purchase Brain Question Bank 042-37113344Mohammad AshfaqNo ratings yet

- Cutting Tools TypeDocument3 pagesCutting Tools TypeneurraNo ratings yet

- USAG Cap 01toolsDocument42 pagesUSAG Cap 01toolsClayson GomesNo ratings yet

- NANODUR Instructions (English)Document6 pagesNANODUR Instructions (English)JOHN CENANo ratings yet

- Present Trilon BDocument17 pagesPresent Trilon BDzulkifli MuhamadNo ratings yet

- Olimpiade Internasional Topik StoikiometriDocument7 pagesOlimpiade Internasional Topik StoikiometriHeru Christian Strecker AritonangNo ratings yet

- CHP 1 3 FollowalongnotesDocument15 pagesCHP 1 3 FollowalongnotesToby JonesNo ratings yet

- Chemistry Micro ProjectDocument29 pagesChemistry Micro Projectnikhil9923707734No ratings yet

- The Only Method of Recovery Is Aqua Regia or Filters For The Micron StuffDocument4 pagesThe Only Method of Recovery Is Aqua Regia or Filters For The Micron StuffHeather StpierreNo ratings yet

- Hobart CatalogDocument138 pagesHobart CatalogHuỳnh TrươngNo ratings yet

- Atomic Structure NotesDocument23 pagesAtomic Structure NotesAbhi RajNo ratings yet

- Basic Information About BrazingDocument10 pagesBasic Information About BrazingKristian UretaNo ratings yet

- Different Types of Pipes & TubesDocument8 pagesDifferent Types of Pipes & TubesSMSMNo ratings yet

- Acids & AlkalisDocument37 pagesAcids & AlkalisSevenzsciNo ratings yet

- TDS 002 Mech Galvanizing PDFDocument2 pagesTDS 002 Mech Galvanizing PDFQA QCNo ratings yet

- AMCA Standard 99-0401-86 Classification For Spark Resistant ConstructionDocument1 pageAMCA Standard 99-0401-86 Classification For Spark Resistant Constructionhardik033No ratings yet

- H2O2 Safety Presentation Ver 7.0Document41 pagesH2O2 Safety Presentation Ver 7.0odracir091865No ratings yet

- Investigatory Project: Saltwater For EnergyDocument8 pagesInvestigatory Project: Saltwater For EnergyAntoinette RepotenteNo ratings yet

- Erico Master CatelogueDocument72 pagesErico Master CatelogueDokania AnandNo ratings yet