Professional Documents

Culture Documents

ME2410 Notes-1

ME2410 Notes-1

Uploaded by

vamsiCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Briggs and Stratton Small Engine CareDocument8 pagesBriggs and Stratton Small Engine Carejankop100% (2)

- BW211D-3 svctrgBF4M2012C PDFDocument164 pagesBW211D-3 svctrgBF4M2012C PDFJUNA RUSANDI S100% (4)

- Service Manual Picanto Ion g3hgDocument13 pagesService Manual Picanto Ion g3hgrectificamosNo ratings yet

- Komatsu Parts BookDocument3 pagesKomatsu Parts Bookvamsi65% (17)

- Y62 Patrol Full EditionDocument163 pagesY62 Patrol Full EditionEric Golden100% (8)

- Huafengdongli 495 4100 Series OperationmanualDocument126 pagesHuafengdongli 495 4100 Series OperationmanualEngr Osama Khan100% (6)

- Gowtham 2021 IOP Conf. Ser. Mater. Sci. Eng. 1123 012015Document9 pagesGowtham 2021 IOP Conf. Ser. Mater. Sci. Eng. 1123 012015vamsiNo ratings yet

- Tire Model For Longitudinal ForcesDocument17 pagesTire Model For Longitudinal ForcesvamsiNo ratings yet

- Single Row Cylindrical Roller Bearings - SKF RNU Type 1Document5 pagesSingle Row Cylindrical Roller Bearings - SKF RNU Type 1vamsiNo ratings yet

- Welcome To Hindi VerbsDocument17 pagesWelcome To Hindi VerbsvamsiNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Cam Timing DDEC S50Document4 pagesCam Timing DDEC S50Hamilton mirandaNo ratings yet

- Especificaciones de Volvo D13BDocument71 pagesEspecificaciones de Volvo D13Bmarcos asteteNo ratings yet

- Mt01'06 (5yu3) Brazil (Cor Vdvm1)Document91 pagesMt01'06 (5yu3) Brazil (Cor Vdvm1)Pablo HenriqueNo ratings yet

- Continental A65 Aircraft Engine SpecsDocument12 pagesContinental A65 Aircraft Engine SpecsAIRCRAFTS89% (9)

- BT1100Document117 pagesBT1100Robert WarehamNo ratings yet

- Apache RTR180 PDFDocument61 pagesApache RTR180 PDFJimJiang100% (3)

- DDC S60 Tune-UpDocument2 pagesDDC S60 Tune-UpSonthi MooljindaNo ratings yet

- 6BV 28197 3M 11 PDFDocument202 pages6BV 28197 3M 11 PDFAlex Vdbussche100% (1)

- zxr400 H 04Document23 pageszxr400 H 04hugo_bikerNo ratings yet

- 1 Test 924G, Relief Valve (Line)Document33 pages1 Test 924G, Relief Valve (Line)mijael1393No ratings yet

- C80D-9678 Catalogo ClarkDocument155 pagesC80D-9678 Catalogo ClarkJose Angel Basanta HernandezNo ratings yet

- Axial Piston Closed Circuit Pumps: Series 42Document76 pagesAxial Piston Closed Circuit Pumps: Series 42Евгений ГубаревNo ratings yet

- 4 Kia Spotage 2010Document13 pages4 Kia Spotage 2010Jorge VillamilNo ratings yet

- Guangzhou Yuxing Catalogue CGL, GN125, CG125Document45 pagesGuangzhou Yuxing Catalogue CGL, GN125, CG125Marilin Agrais100% (1)

- Daelim S4 50cc Service ManualDocument188 pagesDaelim S4 50cc Service ManualMoppie HofstedeNo ratings yet

- 001-049 Timing Pin Housing: Preparatory StepsDocument7 pages001-049 Timing Pin Housing: Preparatory Stepsvictor manuelNo ratings yet

- Dq6h Ufaa60 ProposalDocument10 pagesDq6h Ufaa60 Proposaledward baskaraNo ratings yet

- Basic Engine PrinciplesDocument31 pagesBasic Engine PrinciplesRayge HarbskyNo ratings yet

- REG841 - Disassembly and Assembly (D6C TRACTOR ENGINE)Document178 pagesREG841 - Disassembly and Assembly (D6C TRACTOR ENGINE)jeffreyguy1No ratings yet

- The V12 Engine by Karl Ludvigsen - Chapter 13: Cat, Roundel and StarDocument42 pagesThe V12 Engine by Karl Ludvigsen - Chapter 13: Cat, Roundel and StarBentley Publishers80% (5)

- Genima 380-385 Parts CatalogueDocument57 pagesGenima 380-385 Parts Cataloguecupid75No ratings yet

- Pulsar 200 Dts-I Parts CatalogueDocument44 pagesPulsar 200 Dts-I Parts CatalogueforwardktmNo ratings yet

- CIAZDocument20 pagesCIAZFelipe Stang González0% (1)

ME2410 Notes-1

ME2410 Notes-1

Uploaded by

vamsiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME2410 Notes-1

ME2410 Notes-1

Uploaded by

vamsiCopyright:

Available Formats

GMRIT APPLIED THERMAL ENGINEERING Unit-I

NOTES-1

Heat Engine

Engine is a device which converts one form of energy to another form. Engine is classified into

many types. Heat engine is a device which converts heat energy to mechanical energy. The

internal combustion engine qualifies as heat engine as the chemical energy in a fuel is converted

into mechanical energy, usually made available on a rotating output shaft. Chemical energy of

the fuel is first converted to thermal energy by means of combustion or oxidation with air inside

the engine. This thermal energy raises the temperature and pressure of the gases within the

engine and the high-pressure gas then expands against the mechanical mechanisms of the engine.

This expansion is converted by the mechanical linkages of the engine to a rotating crankshaft,

which is the output of the engine. The crankshaft, in turn, is connected to a transmission and/or

power train to transmit the rotating mechanical energy to the desired final use.

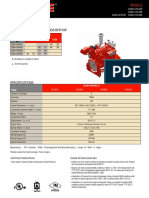

Fig. Heat engine classification

P. SAI CHAITANYA Page 1

APPLIED THERMAL ENGINEERING Unit-I

Classification of I C Engines:

Internal combustion engines can be classified in a number of different ways. Some of them are

classified as given below:

1. Types of Ignition

(a) Spark Ignition (SI). An SI engine starts the combustion process in each cycle by use of a

spark plug. The spark plug gives a high-voltage electrical discharge between two electrodes

which ignites the air-fuel mixture in the combustion chamber surrounding the plug. In early

engine development, before the invention of the electric spark plug, many forms of torch holes

were used to initiate combustion from an external flame.

(b) Compression Ignition (CI). The combustion process in a CI engine starts when the air-fuel

mixture self-ignites due to high temperature in the combustion chamber caused by high

compression.

2. Engine Cycle

(a) Four-Stroke Cycle: A four-stroke cycle experiences four piston movements over two engine

revolutions for each cycle.

(b) Two-Stroke Cycle: A two-stroke cycle has two piston movements over one revolution for

each cycle.

3. Valve Location

(a) Valves in head (overhead valve), also called I Head engine.

(b) Valves in block (flat head), also called L Head engine. Some historic engines with valves in

block had the intake valve on one side of the cylinder and the exhaust valve on the other side.

These were called T Head engines.

4. Basic Design

(a) Reciprocating. Engine has one or more cylinders in which pistons reciprocate back and forth.

The combustion chamber is located in the closed end of each cylinder. Power is delivered to a

rotating output crankshaft by mechanical linkage with the pistons.

(b) Rotary. Engine is made of a block (stator) built around a large non-concentric rotor and

crankshaft. The combustion chambers are built into the non rotating block.

5. Number of cylinders

(a) Single cylinder engine

P. SAI CHAITANYA Page 2

APPLIED THERMAL ENGINEERING

(b) Multi cylinder engine

6. Type of thermodynamic cycle

(a) Otto Cycle for petrol engines

(b) Diesel cycle for diesel engines

7. Cooling System

(a) Air cooled engine

(b) Water cooled engine

P. SAI CHAITANYA Page 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Briggs and Stratton Small Engine CareDocument8 pagesBriggs and Stratton Small Engine Carejankop100% (2)

- BW211D-3 svctrgBF4M2012C PDFDocument164 pagesBW211D-3 svctrgBF4M2012C PDFJUNA RUSANDI S100% (4)

- Service Manual Picanto Ion g3hgDocument13 pagesService Manual Picanto Ion g3hgrectificamosNo ratings yet

- Komatsu Parts BookDocument3 pagesKomatsu Parts Bookvamsi65% (17)

- Y62 Patrol Full EditionDocument163 pagesY62 Patrol Full EditionEric Golden100% (8)

- Huafengdongli 495 4100 Series OperationmanualDocument126 pagesHuafengdongli 495 4100 Series OperationmanualEngr Osama Khan100% (6)

- Gowtham 2021 IOP Conf. Ser. Mater. Sci. Eng. 1123 012015Document9 pagesGowtham 2021 IOP Conf. Ser. Mater. Sci. Eng. 1123 012015vamsiNo ratings yet

- Tire Model For Longitudinal ForcesDocument17 pagesTire Model For Longitudinal ForcesvamsiNo ratings yet

- Single Row Cylindrical Roller Bearings - SKF RNU Type 1Document5 pagesSingle Row Cylindrical Roller Bearings - SKF RNU Type 1vamsiNo ratings yet

- Welcome To Hindi VerbsDocument17 pagesWelcome To Hindi VerbsvamsiNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Cam Timing DDEC S50Document4 pagesCam Timing DDEC S50Hamilton mirandaNo ratings yet

- Especificaciones de Volvo D13BDocument71 pagesEspecificaciones de Volvo D13Bmarcos asteteNo ratings yet

- Mt01'06 (5yu3) Brazil (Cor Vdvm1)Document91 pagesMt01'06 (5yu3) Brazil (Cor Vdvm1)Pablo HenriqueNo ratings yet

- Continental A65 Aircraft Engine SpecsDocument12 pagesContinental A65 Aircraft Engine SpecsAIRCRAFTS89% (9)

- BT1100Document117 pagesBT1100Robert WarehamNo ratings yet

- Apache RTR180 PDFDocument61 pagesApache RTR180 PDFJimJiang100% (3)

- DDC S60 Tune-UpDocument2 pagesDDC S60 Tune-UpSonthi MooljindaNo ratings yet

- 6BV 28197 3M 11 PDFDocument202 pages6BV 28197 3M 11 PDFAlex Vdbussche100% (1)

- zxr400 H 04Document23 pageszxr400 H 04hugo_bikerNo ratings yet

- 1 Test 924G, Relief Valve (Line)Document33 pages1 Test 924G, Relief Valve (Line)mijael1393No ratings yet

- C80D-9678 Catalogo ClarkDocument155 pagesC80D-9678 Catalogo ClarkJose Angel Basanta HernandezNo ratings yet

- Axial Piston Closed Circuit Pumps: Series 42Document76 pagesAxial Piston Closed Circuit Pumps: Series 42Евгений ГубаревNo ratings yet

- 4 Kia Spotage 2010Document13 pages4 Kia Spotage 2010Jorge VillamilNo ratings yet

- Guangzhou Yuxing Catalogue CGL, GN125, CG125Document45 pagesGuangzhou Yuxing Catalogue CGL, GN125, CG125Marilin Agrais100% (1)

- Daelim S4 50cc Service ManualDocument188 pagesDaelim S4 50cc Service ManualMoppie HofstedeNo ratings yet

- 001-049 Timing Pin Housing: Preparatory StepsDocument7 pages001-049 Timing Pin Housing: Preparatory Stepsvictor manuelNo ratings yet

- Dq6h Ufaa60 ProposalDocument10 pagesDq6h Ufaa60 Proposaledward baskaraNo ratings yet

- Basic Engine PrinciplesDocument31 pagesBasic Engine PrinciplesRayge HarbskyNo ratings yet

- REG841 - Disassembly and Assembly (D6C TRACTOR ENGINE)Document178 pagesREG841 - Disassembly and Assembly (D6C TRACTOR ENGINE)jeffreyguy1No ratings yet

- The V12 Engine by Karl Ludvigsen - Chapter 13: Cat, Roundel and StarDocument42 pagesThe V12 Engine by Karl Ludvigsen - Chapter 13: Cat, Roundel and StarBentley Publishers80% (5)

- Genima 380-385 Parts CatalogueDocument57 pagesGenima 380-385 Parts Cataloguecupid75No ratings yet

- Pulsar 200 Dts-I Parts CatalogueDocument44 pagesPulsar 200 Dts-I Parts CatalogueforwardktmNo ratings yet

- CIAZDocument20 pagesCIAZFelipe Stang González0% (1)