Professional Documents

Culture Documents

Cool Down With N2

Cool Down With N2

Uploaded by

Andres Gerena CortesCopyright:

Available Formats

You might also like

- K-Tron Premier Rep Catalog Dec 2010 PDFDocument429 pagesK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- Glutaraldehyde Bulk HandlingDocument4 pagesGlutaraldehyde Bulk HandlingnubblerNo ratings yet

- Clinical Research in IndiaDocument20 pagesClinical Research in IndiaHarshad More100% (1)

- Iso 22716Document3 pagesIso 22716alkey100% (1)

- Solvent Losses in Batch Distillation and Subsequent Condensation of Vapors and How To SaveDocument5 pagesSolvent Losses in Batch Distillation and Subsequent Condensation of Vapors and How To SavesrshahNo ratings yet

- Conveying Bends Article Paul SoltDocument8 pagesConveying Bends Article Paul SoltJoel Olson100% (1)

- 29 CFR 1910.1000 - Air ContaminantsDocument11 pages29 CFR 1910.1000 - Air ContaminantsMuhammad MujahidNo ratings yet

- 22 Cryometrix Ultra Low Temp Freezers - End UserDocument11 pages22 Cryometrix Ultra Low Temp Freezers - End Userapi-220622714No ratings yet

- Din Reactors CEDocument3 pagesDin Reactors CEvallamreddyNo ratings yet

- Process Applications: Calcium Chloride-Based Heat Transfer FluidsDocument3 pagesProcess Applications: Calcium Chloride-Based Heat Transfer FluidszhyhhNo ratings yet

- Drying of Solid BasicsDocument5 pagesDrying of Solid BasicsMuhammad SaadullahNo ratings yet

- Hapman - Bulk Bag UnloaderDocument2 pagesHapman - Bulk Bag UnloaderangelsiddhartaNo ratings yet

- Review Paper On CFD Analysis of Cyclone Separator With Discrete Phase ModellingDocument4 pagesReview Paper On CFD Analysis of Cyclone Separator With Discrete Phase ModellingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- GP-198 Gas Coalescing FilterDocument4 pagesGP-198 Gas Coalescing Filteramol shindeNo ratings yet

- Aultons Pharmaceuticals Drying PDFDocument18 pagesAultons Pharmaceuticals Drying PDFAdrián L ValladaresNo ratings yet

- Main Components USG 900 VDocument13 pagesMain Components USG 900 Vhafiz_hayat_44190215No ratings yet

- Alfa Laval Gasketed Plate Heat ExchangersDocument14 pagesAlfa Laval Gasketed Plate Heat Exchangersrajpvik100% (1)

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- Iso Propyl Acetate ManufacturersDocument7 pagesIso Propyl Acetate ManufacturersSomuSolventsNo ratings yet

- 050 Vacuum Pump Systems 2021Document190 pages050 Vacuum Pump Systems 2021Balamurugan Arumugam100% (1)

- Refrigerant Piping PDFDocument9 pagesRefrigerant Piping PDFzikhail93No ratings yet

- 02 12 Solving Closed Loop Pneumatic Conveying System ProblemsDocument4 pages02 12 Solving Closed Loop Pneumatic Conveying System Problemsleekiangyen100% (1)

- Air-Liquid Heat ExchangersDocument6 pagesAir-Liquid Heat ExchangersUnilab100% (17)

- Behaviour of Water in Jet Fuel-A Literature ReviewDocument10 pagesBehaviour of Water in Jet Fuel-A Literature ReviewYan JiangNo ratings yet

- Cryogenic Tanks CatalogueDocument14 pagesCryogenic Tanks Cataloguejayakumar04985No ratings yet

- Zeppelin - Rotary Valve - dx5 160-2,6 HCDocument27 pagesZeppelin - Rotary Valve - dx5 160-2,6 HCThanh Xuan100% (1)

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- AS401COL (195kta) Aspen ReportDocument102 pagesAS401COL (195kta) Aspen ReportNoman AshrafNo ratings yet

- Astm D 1267Document1 pageAstm D 1267Alejandro MerinoNo ratings yet

- Solid Gas Separation1Document48 pagesSolid Gas Separation1krizel100% (1)

- Minimum Maximum LPG Energy Content (Btu/f)Document5 pagesMinimum Maximum LPG Energy Content (Btu/f)Mirza Aatir SalmanNo ratings yet

- SEPARATOR Design ConsiderationsDocument1 pageSEPARATOR Design ConsiderationsjokishNo ratings yet

- Furnace Design and Operation: Industrial BurnersDocument60 pagesFurnace Design and Operation: Industrial BurnerskINGNo ratings yet

- Acid Dew Point - Encyclopedia Article - CitizendiumDocument4 pagesAcid Dew Point - Encyclopedia Article - Citizendiuminsult2injury100% (1)

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyDocument6 pagesUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriNo ratings yet

- 97 03 EDocument28 pages97 03 EAgustin CesanNo ratings yet

- Diverter ValveDocument2 pagesDiverter ValveAdhi NugrohoNo ratings yet

- Paddle Batch Mixer 629Document2 pagesPaddle Batch Mixer 629saxhornNo ratings yet

- Spray Dryer & Freeze DryerDocument20 pagesSpray Dryer & Freeze DryerHaroon RahimNo ratings yet

- Industrial Basket Simples Duplex Type Strainers Filters and SievesDocument28 pagesIndustrial Basket Simples Duplex Type Strainers Filters and Sievesmokie305No ratings yet

- BTPDocument15 pagesBTPPARTH NAGARNo ratings yet

- Salty Matters Salty Matters: Calcium Chloride (Cacl) Article 1 of 2: Usage and Brine ChemistryDocument9 pagesSalty Matters Salty Matters: Calcium Chloride (Cacl) Article 1 of 2: Usage and Brine ChemistryAli KhanNo ratings yet

- Steam Distillation - SopDocument4 pagesSteam Distillation - Sopinvooo prabamadhanNo ratings yet

- ACS Montz BrochureDocument11 pagesACS Montz BrochureMarcoAlbaNo ratings yet

- Liquid Seal Drums: AdvantagesDocument1 pageLiquid Seal Drums: Advantagesbinapaniki6520No ratings yet

- PROJECT STANDARDS and SPECIFICATIONS Heat Tracing and Winterizing Systems Rev01Document12 pagesPROJECT STANDARDS and SPECIFICATIONS Heat Tracing and Winterizing Systems Rev01t_rajith1179No ratings yet

- Recommended Procedure For Alkali Boil OutDocument18 pagesRecommended Procedure For Alkali Boil OutsprotkarNo ratings yet

- DemisterDocument4 pagesDemistermariniabrahanNo ratings yet

- Rating and Design of Tubular Heat Exchangers Using HTRI PDFDocument4 pagesRating and Design of Tubular Heat Exchangers Using HTRI PDFshridharNo ratings yet

- Predicting Dew Points of Acid Dew PointsDocument7 pagesPredicting Dew Points of Acid Dew PointsJia JingNo ratings yet

- Water Hammer in Steam LinesDocument5 pagesWater Hammer in Steam LinesVijaita Vikas GandhiNo ratings yet

- The Ins and Outs Indirect OrvinuDocument8 pagesThe Ins and Outs Indirect OrvinusatishNo ratings yet

- Vapor PressureDocument120 pagesVapor PressureDonesh VarshneyNo ratings yet

- Cryogenic Valves For Industrial Gas Applications PDFDocument88 pagesCryogenic Valves For Industrial Gas Applications PDFmhientbNo ratings yet

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocument6 pagesShell and Tube Heat Exchanger Design: Fluid AllocationLungeloNo ratings yet

- Use Cold Nitrogen Vapour To Pre-Cool LNG Unloading Lines - 1552997214Document4 pagesUse Cold Nitrogen Vapour To Pre-Cool LNG Unloading Lines - 1552997214Hypar JeloamNo ratings yet

- Polymer Strain Stress CurveDocument15 pagesPolymer Strain Stress CurvearelanopNo ratings yet

- Evaporation SBDocument84 pagesEvaporation SBMirza Salman BaigNo ratings yet

- Cryogenic Freezing Technology: Yogesh Kumar, Soumitra Tiwari and Yashwant KumarDocument4 pagesCryogenic Freezing Technology: Yogesh Kumar, Soumitra Tiwari and Yashwant KumarAditya DiwediNo ratings yet

- Seminar Report On Magnetic RefrigerationDocument24 pagesSeminar Report On Magnetic Refrigerationsanjay dev50% (2)

- Thermodynamic Performance Analysis of Cascade Refrigeration System - A ReviewDocument5 pagesThermodynamic Performance Analysis of Cascade Refrigeration System - A ReviewOnofreNo ratings yet

- Glass Transition and Phase Transitions in Food and Biological MaterialsFrom EverandGlass Transition and Phase Transitions in Food and Biological MaterialsNo ratings yet

- Ijpab 2015 3 1 224 235 PDFDocument12 pagesIjpab 2015 3 1 224 235 PDFDrAmit VermaNo ratings yet

- Antimicrobial FinalDocument227 pagesAntimicrobial FinalAbdulrhman MekawyNo ratings yet

- Colegio de San Gabriel ArcangelDocument5 pagesColegio de San Gabriel ArcangelJonille EchevarriaNo ratings yet

- Done By: Neha Jain Priya Upadhyay Saanchi AroraDocument13 pagesDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayNo ratings yet

- Pharmacology ReviewerDocument24 pagesPharmacology ReviewergreinabelNo ratings yet

- MalamedDocument7 pagesMalamedProgynanika BarmanNo ratings yet

- GMP GuidelinesDocument40 pagesGMP Guidelinesmrgsguy100% (2)

- Enc 1102 Research ProposalDocument4 pagesEnc 1102 Research Proposalapi-317153884No ratings yet

- International Journal of Universal Pharmacy and Bio SciencesDocument9 pagesInternational Journal of Universal Pharmacy and Bio SciencesPallavi PrakashNo ratings yet

- Pharmaceutical Patents in India: Issues and ConcernsDocument18 pagesPharmaceutical Patents in India: Issues and ConcernsBalaji P Nadar75% (4)

- AnxietyDocument4 pagesAnxietyAnn DassNo ratings yet

- Implementation of Standards of Good Pharmacy Practice in The World - A ReviewDocument5 pagesImplementation of Standards of Good Pharmacy Practice in The World - A ReviewDewa GedeNo ratings yet

- Chapter 4 (Cosmetic Act)Document10 pagesChapter 4 (Cosmetic Act)ashmun nishaNo ratings yet

- Parabens 2Document29 pagesParabens 2Vincze BoglárkaNo ratings yet

- Drug StudyDocument7 pagesDrug StudyGladys NacionNo ratings yet

- Module Iii-H..alcohol and Other Drugs of AbuseDocument5 pagesModule Iii-H..alcohol and Other Drugs of AbuseKenneth NuñezNo ratings yet

- PV India DCGI Presentation R3Document18 pagesPV India DCGI Presentation R3Arun NairNo ratings yet

- Adventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyDocument58 pagesAdventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyRC DomeNo ratings yet

- Pepcid AC - Group1 - AnalysisDocument2 pagesPepcid AC - Group1 - AnalysisRini RafiNo ratings yet

- Wharton Consulting Case Interview GuideDocument47 pagesWharton Consulting Case Interview GuideBrian Ny Wong100% (4)

- Development and Validation of The UV Spectroscopic Method For Varenicline Determination in Pharmaceutical PreparationDocument9 pagesDevelopment and Validation of The UV Spectroscopic Method For Varenicline Determination in Pharmaceutical PreparationJournal of Pharmaceutical Research InternationalNo ratings yet

- Development and Validation of UV Spectrophotometric Method For Simultaneous Estimation of Melatonin and Quercetin in Liposome FormulationDocument6 pagesDevelopment and Validation of UV Spectrophotometric Method For Simultaneous Estimation of Melatonin and Quercetin in Liposome FormulationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Barang Ed DekatDocument12 pagesBarang Ed DekatAkhmad “Billy Rafi” HambaliNo ratings yet

- Pharmacy Daily 30th Nov 2023Document3 pagesPharmacy Daily 30th Nov 2023Marinero CzarNo ratings yet

- Participating Vendor ListDocument119 pagesParticipating Vendor ListWWaahhiidd KhanNo ratings yet

- Infografia Inglés Del OmeprazolDocument1 pageInfografia Inglés Del OmeprazolAriadna SantaellaNo ratings yet

- Non Clinical Drug DevelopmentDocument75 pagesNon Clinical Drug DevelopmentalexNo ratings yet

- Onychomycosis in ChildrenDocument28 pagesOnychomycosis in ChildrenAstuti Clara SimanjuntakNo ratings yet

Cool Down With N2

Cool Down With N2

Uploaded by

Andres Gerena CortesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cool Down With N2

Cool Down With N2

Uploaded by

Andres Gerena CortesCopyright:

Available Formats

Heat Transfer

Cool Down

with Liquid Nitrogen

Oscar Beteta Many low-temperature processes leverage

Svetlana Ivanova

Air Products nitrogens cooling and freezing capabilities.

Find out what methods are used

in what applications and why.

T

he chemical process industries (CPI) employ nitrogen LIN refrigeration methods

as a gas or liquid in a wide range of applica- Several cooling techniques take advantage of LINs

tions (1, 2). Gaseous nitrogen (GAN) can inert vessels refrigeration capabilities in batch or continuous processes.

and purge lines to eliminate explosion hazards and prevent direct surface (semi-indirect) cooling (Figure 1a). LIN

undesired oxidation reactions that can reduce product qual- provides cooling via a single conductive wall, the cold sur-

ity. Liquid nitrogen (LIN) is used in innovative cooling and face of which freezes or cools liquid or gas streams.

freezing technologies. secondary circuit (indirect) cooling (Figure 1b). The

LIN is an effective and convenient refrigerant due to its boiling temperature of LIN is buffered with an intermediate

availability, low cost, and inert properties. It is also a practi- heat-transfer fluid (HTF) to enhance temperature control.

cal cryogen for most low-temperature applications because The HTF temperature can be tuned to the desired process

of its extremely low boiling temperature (195.8C) and temperature, as low as the boiling point of LIN. The HTF

high refrigeration capacity at atmospheric pressure. Even at then provides refrigeration through a conductive wall to

elevated pressures, the thermal properties of LIN (Table 1) freeze materials or cool fluids.

make it an effective refrigeration medium to rapidly cool cold GAN cooling (Figure 1c). LIN vaporizes, and the

processes to low temperatures. sensible heat capacity of the cold GAN is used for refrigera-

This article describes methods for employing liquid and tion. Additional LIN is injected to control the temperature.

gaseous nitrogens cooling and freezing capabilities, as well Cooling occurs via a conductive surface, or by blowing the

as some specific applications in the chemical and pharma- cold GAN directly onto the materials to be cooled.

ceutical industries. direct LIN injection/spray cooling (Figure 1d). LIN is

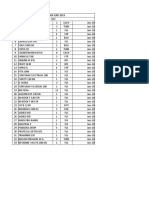

Table 1. The thermal properties of liquid nitrogen at various pressures.

Boiling Liquid Thermal Heat Capacity Vapor Thermal

Temperature (Tsat), Heat of Conductivity, at Tsat, Conductivity,

Pressure, atm C Vaporization, kJ/kg J/m-s-C kJ/kg-C J/m-s-C

1 195.8 5,592.8 0.137 1.08 0.007

3 185.1 5,157.5 0.118 1.15 0.009

6 176.6 4,720.3 0.102 1.16 0.011

9 170.8 4,351.5 0.091 1.38 0.012

12 166.3 4,005.4 0.083 1.53 0.013

30 www.aiche.org/cep September 2015 CEP

injected or sprayed directly onto materials or into processes. Cryogenic milling and grinding

Materials and processes are cooled by the latent heat of LIN refrigeration enables cryogenic milling and grinding

vaporization of LIN; depending on the design of the cooling to pulverize, to micron- or submicron-sized powders, materi-

system, the sensible heat capacity of the cold GAN may also als that would otherwise be difficult to mill at ambient tem-

contribute to the cooling. This is an efficient use of LINs perature. The process is suitable for materials that have high

refrigeration value. viscoelasticity, adhesive properties, or thermal sensitivity.

immersion cooling (Figure 1e). Direct immersion in Viscoelasticity. Materials like rubber and elastomeric gels

LIN cools or freezes a material. The rate of cooling depends have high viscoelasticity i.e., they resist shear flow, stretch

almost entirely on the latent heat of vaporization of LIN. when impacted, and return to their original state when stress

The overall heat-transfer rate is generally lower than that of is removed. Viscoelastic properties are directly proportional

direct LIN injection/spray cooling, because the GAN has a to temperature; therefore, lowering the temperature embrittles

blanketing effect the bubbles generated by the turbulent the material, which makes milling easier and more effective.

boiling of the LIN create a vapor boundary layer around Adhesive properties. Sticky materials like waxes and oily

the immersed material, thereby lowering the overall heat- biological samples have a tendency to cling to other materi-

transfer coefficient. als and surfaces. When milled at ambient conditions, they

The suitability of a particular cooling method depends on build up in the mill, thereby lowering the mill throughput,

the application and the nature of the materials or processes spiking power consumption, and eventually plugging the

to be cooled. Cold GAN cooling, for example, is an attrac- process. Low temperatures inhibit the adhesion mechanisms

tive option for cooling delicate materials, whereas direct responsible for stickiness and increase cohesive inter

LIN injection/spray or immersion cooling may damage molecular forces, making the materials more brittle and less

the structure of the material. Additionally, cold GAN and sticky and thus easier to mill.

secondary-circuit cooling can be employed when it is critical Thermal sensitivity. Some materials lose their chemical,

to operate above the freezing point of materials or fluids to biological, or electrochemical activity at elevated tempera-

avoid freezing that could damage the material or plug the tures; for example, heat may damage protein-based pharma-

process. Applications where flash freezing is desired often ceuticals. Because milling processes generate heat, refrigera-

use direct LIN injection/spray cooling or immersion cooling. tion is needed to control the temperature when processing

These LIN freezing and cooling methods are deployed these sensitive materials.

in a variety of applications. The remainder of this article The heat generated by milling also makes it more

provides an overview of some LIN cooling/freezing applica- difficult to process viscoelastic and adhesive materials.

tions in the chemical and pharmaceutical industries. Therefore, it is critical to control the temperature of the

HTF LIN GAN

LIN HTF

LIN GAN

LIN

Cold GAN

a. Direct Surface Cooling b. Secondary Circuit Cooling c. Cold GAN Cooling

z Figure 1. LIN refrigeration methods. (a) A

LIN conductive wall, cooled by LIN, freezes or cools

fluids that contact it. (b) A heat-transfer fluid (HTF)

serves as an intermediate cooling agent between

the LIN and fluid to enhance temperature control.

(c) Cold GAN cools through a conductive wall or can

be directly blown onto the fluid to be cooled. (d) LIN

LIN is directly injected or sprayed onto a material or into

a process. (e) When a material is directly immersed

LIN in LIN, bubbles generated from turbulent boiling

d. Direct LIN Injection/Spray Cooling e. Immersion Cooling

create a vapor boundary around the material, which

lowers the overall heat-transfer coefficient.

CEP September 2015 www.aiche.org/cep 31

Heat Transfer

mill as well as the temperature of the material being milled. Cryopelletization

Cryogenic milling involves cooling the materials and/or the Cryopelletization is a low-temperature technique for

mill, generally through direct LIN injection (Figure 2). The manufacturing pellets that are most often spherical or semi-

injected LIN also inerts the atmosphere, which prevents spherical and range from 0.5 mm to 5 mm in diameter (4).

undesired oxidation reactions. It is often used to pelletize heat-sensitive materials, such

as bacterial cultures and probiotics. Because cryopelletiza-

Lyophilization tion effectively flash-freezes materials, it is used to prevent

Lyophilization, or freeze-drying, dehydrates thermally phase separation of components in solutions, colloids, or

sensitive materials (e.g., proteins) by freezing the mate- suspensions, as well as to form pellets with a high degree

rial with LIN, followed by controlled sublimation under of homogeneity. The three common forms of LIN-cooled

vacuum. Materials may be freeze-dried to preserve micro- cryopelletization are direct surface freezing, LIN immersion

scopic structures (e.g., cell structures) and to enhance freezing, and cold GAN freezing.

product stability for prolonged storage and transportation. Direct surface freezing (Figure 4a). Droplets freeze on

Mechanical refrigeration by compressors has been used for a cold surface, such as a rotating stainless steel drum that is

freeze-drying applications, but LIN has gained popularity cooled by direct LIN injection inside of the drum. The pel-

because it enables better control of the freezing process and lets formed are consistently semi-spherical with a flat base.

a broader range of operating parameters (3). The size and shape can be modified by adjusting process

In small-scale operations, materials may be frozen variables, such as the distance the droplets fall and the rate

through LIN immersion or direct surface cooling prior to of freezing.

being placed in a vacuum chamber. In larger-scale operations LIN immersion freezing (Figure 4b). Droplets freeze as

(Figure 3), LIN secondary circuit cooling (using a heat- they are immersed in LIN. As droplets are immersed, the

transfer fluid) is the most economic and effective method of LIN boils turbulently, which makes it more difficult to con-

freezing, as it offers quick, cryogenic-temperature freezing trol the size distribution and the shape of pellets. Neverthe-

and flexible temperature control to speed up vacuum drying. less, this method generally produces a high percentage of

After freezing, a vacuum pump causes sublimation of most spherical pellets.

of the frozen solvent in the primary drying step. A cryogenic Cold GAN freezing (Figure 4c). Cold GAN freezes

condenser, cooled via LIN direct surface cooling, maximizes droplets as they free-fall, producing spherical pellets with

the rate of mass transfer of solvent from the frozen mate- a narrow size distribution. However, it is critical to control

rial to the condenser surface. Any physicochemically bound process variables, such as droplet size, GAN temperature,

solvent (e.g., water) not removed during primary drying and freezing chamber geometry, to prevent droplets from

is removed during secondary drying, where the material agglomerating or sticking to sidewalls as they fall.

temperature and vacuum are increased. If the material being Pelletization is advantageous because it improves prod-

freeze-dried is oxygen-sensitive, an inert gas backfill breaks uct flowability and blendability. Enhanced flowability makes

the vacuum while maintaining an inert atmosphere. downstream conveying and packaging easier. Pellets can

GAN

LIN Tank Vacuum

Pump

LIN

Vacuum

Product Feed LIN Condenser

GAN

LIN

Tank HTF Loop

Heat Exchanger

Cooling Conveyor

Cryogenic

To Vent Vials

Grinding

Mill

GAN

LIN Heater Freeze-Drying

Powdered Product Chamber

Pump

p Figure 2. In cryogenic milling, LIN cools materials that are difficult to p Figure 3. LIN provides refrigeration to vials of sample via a secondary

mill at ambient temperature. Because the milling process generates heat, heat-transfer fluid (HTF) circuit. During vacuum drying, LIN also cools the

the temperature of the mill is also regulated with direct LIN injection. condenser to create a low-temperature cold trap for solvent removal.

32 www.aiche.org/cep September 2015 CEP

be easily and accurately blended or mixed to form products be reconstituted faster than materials dried by traditional

with a variety of properties. Additionally, pelletization mini- lyophilization and spray drying methods, which is important

mizes the creation of fines and dust, reducing the risk of dust for pharmaceuticals with low water solubility.

explosions and respiratory health effects.

Cryogenic thin-film freezing

Cryogenic spray freeze-drying Cryogenic thin-film freezing (TFF) is a relatively new

Cryogenic spray freeze-drying (SFD) creates fine (usu- low-temperature process that produces highly porous,

ally smaller than 100 m), low-density, dry powders (e.g., micron- and submicron-sized dry particles of heat-sensitive

inhalable pharmaceuticals) at low temperature. It combines materials, such as proteins, that are suitable for pulmonary

the principles of lyophilization and spray drying. and parenteral drug-delivery applications. The process is

Fine droplets are created from a solution, suspension, similar to cryogenic pelletization by direct surface cooling

or colloid, and then rapidly frozen via direct LIN spraying using a rotating stainless steel drum. Drops of a solution,

(Figure 5a) or LIN immersion (Figure 5b). Single-fluid or suspension, or colloid fall onto a cold stainless steel surface

two-fluid atomizing and ultrasonic piezoelectric nozzles from a distance that allows the droplets to collapse into

create the micro- or nano-sized droplets. The liquid-product flat, thin (micron- or submicron-thick) films as they rapidly

formulation, atomizing parameters, and freezing rate can freeze (Figure 6). The film thickness can be modified by

be modified to control dry particle characteristics, such as adjusting the free-fall distance and the physical properties of

shape, size, size distribution, and overall morphology. the liquid feed. The frozen films are freeze-dried to produce

The frozen powder may be the final product, but typi- dry powders.

cally a gentle drying process, such as vacuum (lyophili- In TFF processing, the gas-liquid interface is minimized

zation) or atmospheric drying, follows the freezing step. during freezing (in contrast to SFD), which reduces protein

Atmospheric drying introduces temperature-controlled, denaturation (5). TFF is used at the laboratory scale, espe-

cold, dry GAN to dry the frozen powder through convective cially for research on the reconstitution of insoluble drugs.

mass transfer under atmospheric pressure. The moist, cold It is not clear whether it will be a cost-effective solution for

GAN is then vented from the process or dehumidified and large-scale manufacturing.

recycled.

The dry powder particles produced by SFD are spherical, Cryogenic reaction cooling

light, and highly porous, and they have attractive aero Cryogenic reaction cooling provides refrigeration and

dynamic properties, making them well-suited for inhalable low-temperature control for temperature-sensitive processes,

powdered drugs that are administered through the nasal or such as highly exothermic and cold-chemistry reactions.

pulmonary pathways. Additionally, the dry powders can For example, in organic and organometallic synthesis,

Liquid

Feed

Liquid Atomizing

Feed Gas

LIN

Liquid Atomizing

Liquid Feed Gas

Feed Frozen Pellets

b. LIN Immersion Freezing

LIN LIN

Liquid

Feed

LIN LIN

Frozen Pellets

Side Top Frozen Powder

Cold Cold b. Direct LIN Immersion

a. Direct Surface Freezing GAN GAN

Frozen Powder

a. Direct LIN Spraying

Frozen Pellets

c. Cold GAN Freezing

p Figure 5. In cryogenic spray freeze-drying, atomizing gas

p Figure 4. Cryopelletization can employ (a) direct surface freezing, (b) LIN immersion creates fine droplets that freeze as they are (a) sprayed with LIN

freezing, or (c) cold GAN freezing. or (b) immersed in LIN.

CEP September 2015 www.aiche.org/cep 33

Heat Transfer

low-temperature operation is important to balance reactiv- The heart of a cryocondensation system is a heat

ity, selectivity, and yield. For highly exothermic reactions, exchanger, which provides LIN refrigeration, typically

cooling is critical to control heat release and avoid runaway through secondary circuit cooling with a heat-transfer fluid

reactions. Direct injection cooling, semi-indirect cooling, or direct LIN injection cooling, to condense solvent vapors

and indirect cooling with HTF are the three primary options or VOCs.

for cooling reaction vessels with LIN. Direct surface cooling, which involves passing LIN

Direct injection cooling (Figure 7a). LIN is injected through a traditional shell-and-tube heat exchanger, is

directly into the reaction. This method achieves maximum generally not recommended for VOC recovery operations,

efficiency and is inexpensive to install, but solvent entrain- especially those driven by environmental regulations. These

ment, foaming, and localized freezing can occur. It is often applications require a higher degree of temperature control

used in emergencies, because vaporizing LIN can rapidly and reliability than direct surface cooling can offer. Unstable

cool an unsafe or runaway reaction. VOC freezing or heat exchanger plugging can result in a

Semi-indirect cooling (Figure 7b). LIN flows through breach in VOC compliance or an unplanned process shut-

either a coil inside the reactor or a reactor cooling jacket. down, both of which can be serious and expensive incidents.

This simple method enables fast cooling and nitrogen Secondary circuit cooling with a heat-transfer fluid is

recycle. However, drawbacks include lower cooling effi- a more suitable method, as it allows precise temperature

ciency and higher costs for cryogenic construction and tuning to meet the desired VOC recovery efficiencies. The

corrosion-resistant materials. HTF is loaded into the shell side of the low-temperature

Indirect cooling with HTF (Figure 7c). In an external condenser, where the temperature is precisely controlled

heat exchanger, LIN cools a heat-transfer fluid, which then via LIN heat exchange. Concurrently, the VOCs or solvent

flows through a secondary circuit to cool the reactor. This vapors are condensed inside the condenser by the refriger-

flexible approach provides accurate temperature control and ated HTF.

accommodates large heat loads. Direct LIN injection cooling for VOC recovery is a newer

technique that is still under development. LIN is directly

Cryogenic solvent and VOC recovery injected into the VOC-laden vent streams to freeze the VOCs.

Organic solvents and volatile organic compounds A downstream filter collects and separates the frozen VOCs

(VOCs) can be condensed with LIN and recovered. The from the vent stream. This technique is especially useful for

ability to recover and reuse evaporated solvents reduces the VOC streams that are subject to strict regulations.

amount of solvent that must be purchased. The cost sav-

ings is typically significant enough for recovery systems Cryopreservation

to pay for themselves in only a few years. Cryogenic VOC Cryopreservation (or cryoconservation) preserves bio-

recovery is often a more environmentally friendly and logical samples at cryogenic temperatures for the purpose

cost-effective way to control VOC emissions than oxidation of prolonged or indefinite storage. The process operates on

techniques. the principle that low temperatures exponentially reduce the

Liquid

Feed LIN GAN

LIN GAN GAN

Cryogenic

Stainless Steel

Drum LIN

Heat Exchanger

LIN GAN

Lyophilization HTF

Frozen Films

Side LIN

Top Dry LIN

Powder

a. Direct Injection b. Semi-Indirect c. Indirect Cooling

Cooling Cooling with HTF

p Figure 6. In cryogenic thin-film freezing, droplets fall onto a LIN-cooled,

rotating, stainless steel drum, where they collapse into flat, thin films as p Figure 7. LIN can provide refrigeration to highly exothermic or cold-

they quickly freeze. Lyophilization dries the frozen films to produce dry chemistry reactions through (a) direct injection cooling, (b) semi-indirect

powders. cooling, or (c) indirect cooling with a heat-transfer fluid (HTF).

34 www.aiche.org/cep September 2015 CEP

rate of reactions associated with biological activity. Thus, is challenging because of heat leakage to the environment,

the biological activity of samples at cryogenic temperatures even with vacuum insulation. Efforts are underway to

is slowed to the extent that time is, in effect, stopped for the develop more robust control systems capable of delivering

sample. The intention is that the stabilized sample can be extremely low-temperature liquid nitrogen refrigeration in a

warmed to ambient temperature at some point in the future more precise, yet cost-effective, manner. CEP

in some cases, up to 1,000 years later (6) to resume

normal activity.

Cryopreservation is a growing practice used to store Literature Cited

many types of biological materials, including proteins, 1. Carlson, B., et al., Nitrogen: A Security Blanket for the Chemi-

nucleic acids, cellular structures, single-cell or multicellular cal Industry, Chemical Engineering Progress, 107 (11),

pp. 5055 (Nov. 2011).

organisms, tissues, and organs.

2. Croll, D., and P. Yanisko, Use Nitrogen Safely, Chemical

For most samples, the most critical part of the cryo- Engineering Progress, 108 (3), pp. 4448 (Mar. 2012).

preservation process is the freezing step. If it is too slow, 3. Liue, J., and D. Rouse, Using Liquid Nitrogen to Maximize

water freezing outside the cell draws out intracellular water Lyophilization Manufacturing Capacity, BioProcess Inter

molecules through osmotic pressure. The decrease in intra- national, pp. 5660 (Feb. 2005).

cellular water increases the solute concentration inside the 4. Ratul, R., and A. A. Baquee, Pellets and Pelletization Tech-

niques: A Critical Review, International Research Journal of

cell to potentially lethal levels. Also, slow freezing causes Pharmacy, 4 (4), pp. 9095 (Apr. 2013).

intracellular water molecules to arrange in large crystal 5. Williams III, R. O., et al., eds., Formulating Poorly Water

structures that can pierce cell membranes and cause irre- Soluble Drugs, Springer, New York, NY, pp. 486490 (2012).

versible damage to the sample. In general, faster freezing 6. Lopez, E., et al., Current Frontiers in Cryobiology, Chapter 19

forms smaller ice crystals, which are less damaging to cell in Technologies for Cryopreservation, InTech, Rijeka, Croatia,

pp. 527540 (2012).

structures.

7. Thermo Fisher Scientific, Inc., Thermo Scientific Nalgene and

Typically, cryoprotectants (e.g., glycerol, glucose, Nuc Cryopreservation Guide, www.fisher.co.uk/index.php/en/

dimethylsulfoxide) and a cooling rate of 1C per minute technical-support?view=kb&kbartid=263, pp. 112 (Apr. 2011).

are standard protocols for cryogenic freezing of biological

samples (7). Additional Resources

Vitrification is a novel approach for freezing samples for Jha, A. R., Cryogenic Technology and Applications, Butterworth-

cryopreservation. Cryoprotectants reduce the freezing tem- Heinemann, Burlington, MA, pp. 1013 (2006).

perature, and additives increase the viscosity of the sample. Polidoro, J., et al., Advancing the Art of Spray Drying, Manufac-

The sample is then exposed to an extremely fast freezing turing Chemist, pp. 3537 (June 2012).

regime to vitrify it in amorphous ice and prevent water Trembley, J., and S. Ivanova, Liquid Nitrogen Reaction Cooling,

Process Cooling, pp. 1113 (Oct. 2012).

crystal formation. It is critical that these samples be stored

Boland, T., and B. Nyland, Practical Low-Temperature Size Reduc-

at a cryogenic temperature below the point at which water tion, Powder/Bulk Solids, pp. 3237 (July 2014).

molecules begin to crystallize.

A general rule of thumb for most cryopreserved samples

is to store them below 130C. The most effective and eco- OSCAR BETETA is an applied research and development engineer in

the advanced technology research facility at Air Products (7201

nomical way to store samples is by immersing them in LIN Hamilton Blvd., Allentown, PA 18195-1501; Phone: (610) 481-7576;

or by cooling them with cold GAN vapor inside a specially Email: betetaog@airproducts.com; Website: www.airproducts.com). His

focus is on new commercial applications of liquefied gases, particularly

designed cryochamber. liquid nitrogen, in the chemicals, pharmaceuticals, rubber, and plastics

industries. In addition, he promotes new technology offerings and pro-

Closing thoughts vides technical support to customers. He is a member of AIChE and the

Tau Beta Pi engineering honor society. Beteta holds a BSE in chemical

Since its large-scale commercialization at the turn of the engineering from Bucknell Univ.

20th century, nitrogen has become essential to the CPI. Its SVETLANA IVANOVA, PhD, is a marketing and applications development

inerting capability enhances the safety of many operations manager at Air Products (7201 Hamilton Blvd., Allentown, PA 18195-

1501; Phone: (610) 481-1474; Email: ivanovsm@airproducts.com;

and the quality of many products. Its use as a cryogen for Website: www.airproducts.com). She has over 20 years of experience in

extremely low-temperature refrigeration continues to grow technology, marketing, and business development. Her technical exper-

tise is in developing new materials and processes for applications such

as cryogenic processes are developed and improved. as gas adsorption, water treatment and analysis, and personal care.

The optimization of advanced process controls for She is currently responsible for developing and providing industrial

gas-related technologies and solutions to the chemical, pharmaceu-

liquid nitrogen cooling and freezing systems is an ongoing ticals, and biotech industries. Ivanova earned her MS in chemical

area of research. Precise control of temperature setpoints engineering from Moscow Chemical Technological Univ. and PhD in

chemistry from Moscow Institute of General and Inorganic Chemistry of

(e.g., 0.5C) and heat-transfer rates during extremely the Russian Academy of Sciences.

low-temperature operation (between 150C and 196C)

CEP September 2015 www.aiche.org/cep 35

You might also like

- K-Tron Premier Rep Catalog Dec 2010 PDFDocument429 pagesK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- Glutaraldehyde Bulk HandlingDocument4 pagesGlutaraldehyde Bulk HandlingnubblerNo ratings yet

- Clinical Research in IndiaDocument20 pagesClinical Research in IndiaHarshad More100% (1)

- Iso 22716Document3 pagesIso 22716alkey100% (1)

- Solvent Losses in Batch Distillation and Subsequent Condensation of Vapors and How To SaveDocument5 pagesSolvent Losses in Batch Distillation and Subsequent Condensation of Vapors and How To SavesrshahNo ratings yet

- Conveying Bends Article Paul SoltDocument8 pagesConveying Bends Article Paul SoltJoel Olson100% (1)

- 29 CFR 1910.1000 - Air ContaminantsDocument11 pages29 CFR 1910.1000 - Air ContaminantsMuhammad MujahidNo ratings yet

- 22 Cryometrix Ultra Low Temp Freezers - End UserDocument11 pages22 Cryometrix Ultra Low Temp Freezers - End Userapi-220622714No ratings yet

- Din Reactors CEDocument3 pagesDin Reactors CEvallamreddyNo ratings yet

- Process Applications: Calcium Chloride-Based Heat Transfer FluidsDocument3 pagesProcess Applications: Calcium Chloride-Based Heat Transfer FluidszhyhhNo ratings yet

- Drying of Solid BasicsDocument5 pagesDrying of Solid BasicsMuhammad SaadullahNo ratings yet

- Hapman - Bulk Bag UnloaderDocument2 pagesHapman - Bulk Bag UnloaderangelsiddhartaNo ratings yet

- Review Paper On CFD Analysis of Cyclone Separator With Discrete Phase ModellingDocument4 pagesReview Paper On CFD Analysis of Cyclone Separator With Discrete Phase ModellingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- GP-198 Gas Coalescing FilterDocument4 pagesGP-198 Gas Coalescing Filteramol shindeNo ratings yet

- Aultons Pharmaceuticals Drying PDFDocument18 pagesAultons Pharmaceuticals Drying PDFAdrián L ValladaresNo ratings yet

- Main Components USG 900 VDocument13 pagesMain Components USG 900 Vhafiz_hayat_44190215No ratings yet

- Alfa Laval Gasketed Plate Heat ExchangersDocument14 pagesAlfa Laval Gasketed Plate Heat Exchangersrajpvik100% (1)

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- Iso Propyl Acetate ManufacturersDocument7 pagesIso Propyl Acetate ManufacturersSomuSolventsNo ratings yet

- 050 Vacuum Pump Systems 2021Document190 pages050 Vacuum Pump Systems 2021Balamurugan Arumugam100% (1)

- Refrigerant Piping PDFDocument9 pagesRefrigerant Piping PDFzikhail93No ratings yet

- 02 12 Solving Closed Loop Pneumatic Conveying System ProblemsDocument4 pages02 12 Solving Closed Loop Pneumatic Conveying System Problemsleekiangyen100% (1)

- Air-Liquid Heat ExchangersDocument6 pagesAir-Liquid Heat ExchangersUnilab100% (17)

- Behaviour of Water in Jet Fuel-A Literature ReviewDocument10 pagesBehaviour of Water in Jet Fuel-A Literature ReviewYan JiangNo ratings yet

- Cryogenic Tanks CatalogueDocument14 pagesCryogenic Tanks Cataloguejayakumar04985No ratings yet

- Zeppelin - Rotary Valve - dx5 160-2,6 HCDocument27 pagesZeppelin - Rotary Valve - dx5 160-2,6 HCThanh Xuan100% (1)

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- AS401COL (195kta) Aspen ReportDocument102 pagesAS401COL (195kta) Aspen ReportNoman AshrafNo ratings yet

- Astm D 1267Document1 pageAstm D 1267Alejandro MerinoNo ratings yet

- Solid Gas Separation1Document48 pagesSolid Gas Separation1krizel100% (1)

- Minimum Maximum LPG Energy Content (Btu/f)Document5 pagesMinimum Maximum LPG Energy Content (Btu/f)Mirza Aatir SalmanNo ratings yet

- SEPARATOR Design ConsiderationsDocument1 pageSEPARATOR Design ConsiderationsjokishNo ratings yet

- Furnace Design and Operation: Industrial BurnersDocument60 pagesFurnace Design and Operation: Industrial BurnerskINGNo ratings yet

- Acid Dew Point - Encyclopedia Article - CitizendiumDocument4 pagesAcid Dew Point - Encyclopedia Article - Citizendiuminsult2injury100% (1)

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyDocument6 pagesUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriNo ratings yet

- 97 03 EDocument28 pages97 03 EAgustin CesanNo ratings yet

- Diverter ValveDocument2 pagesDiverter ValveAdhi NugrohoNo ratings yet

- Paddle Batch Mixer 629Document2 pagesPaddle Batch Mixer 629saxhornNo ratings yet

- Spray Dryer & Freeze DryerDocument20 pagesSpray Dryer & Freeze DryerHaroon RahimNo ratings yet

- Industrial Basket Simples Duplex Type Strainers Filters and SievesDocument28 pagesIndustrial Basket Simples Duplex Type Strainers Filters and Sievesmokie305No ratings yet

- BTPDocument15 pagesBTPPARTH NAGARNo ratings yet

- Salty Matters Salty Matters: Calcium Chloride (Cacl) Article 1 of 2: Usage and Brine ChemistryDocument9 pagesSalty Matters Salty Matters: Calcium Chloride (Cacl) Article 1 of 2: Usage and Brine ChemistryAli KhanNo ratings yet

- Steam Distillation - SopDocument4 pagesSteam Distillation - Sopinvooo prabamadhanNo ratings yet

- ACS Montz BrochureDocument11 pagesACS Montz BrochureMarcoAlbaNo ratings yet

- Liquid Seal Drums: AdvantagesDocument1 pageLiquid Seal Drums: Advantagesbinapaniki6520No ratings yet

- PROJECT STANDARDS and SPECIFICATIONS Heat Tracing and Winterizing Systems Rev01Document12 pagesPROJECT STANDARDS and SPECIFICATIONS Heat Tracing and Winterizing Systems Rev01t_rajith1179No ratings yet

- Recommended Procedure For Alkali Boil OutDocument18 pagesRecommended Procedure For Alkali Boil OutsprotkarNo ratings yet

- DemisterDocument4 pagesDemistermariniabrahanNo ratings yet

- Rating and Design of Tubular Heat Exchangers Using HTRI PDFDocument4 pagesRating and Design of Tubular Heat Exchangers Using HTRI PDFshridharNo ratings yet

- Predicting Dew Points of Acid Dew PointsDocument7 pagesPredicting Dew Points of Acid Dew PointsJia JingNo ratings yet

- Water Hammer in Steam LinesDocument5 pagesWater Hammer in Steam LinesVijaita Vikas GandhiNo ratings yet

- The Ins and Outs Indirect OrvinuDocument8 pagesThe Ins and Outs Indirect OrvinusatishNo ratings yet

- Vapor PressureDocument120 pagesVapor PressureDonesh VarshneyNo ratings yet

- Cryogenic Valves For Industrial Gas Applications PDFDocument88 pagesCryogenic Valves For Industrial Gas Applications PDFmhientbNo ratings yet

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocument6 pagesShell and Tube Heat Exchanger Design: Fluid AllocationLungeloNo ratings yet

- Use Cold Nitrogen Vapour To Pre-Cool LNG Unloading Lines - 1552997214Document4 pagesUse Cold Nitrogen Vapour To Pre-Cool LNG Unloading Lines - 1552997214Hypar JeloamNo ratings yet

- Polymer Strain Stress CurveDocument15 pagesPolymer Strain Stress CurvearelanopNo ratings yet

- Evaporation SBDocument84 pagesEvaporation SBMirza Salman BaigNo ratings yet

- Cryogenic Freezing Technology: Yogesh Kumar, Soumitra Tiwari and Yashwant KumarDocument4 pagesCryogenic Freezing Technology: Yogesh Kumar, Soumitra Tiwari and Yashwant KumarAditya DiwediNo ratings yet

- Seminar Report On Magnetic RefrigerationDocument24 pagesSeminar Report On Magnetic Refrigerationsanjay dev50% (2)

- Thermodynamic Performance Analysis of Cascade Refrigeration System - A ReviewDocument5 pagesThermodynamic Performance Analysis of Cascade Refrigeration System - A ReviewOnofreNo ratings yet

- Glass Transition and Phase Transitions in Food and Biological MaterialsFrom EverandGlass Transition and Phase Transitions in Food and Biological MaterialsNo ratings yet

- Ijpab 2015 3 1 224 235 PDFDocument12 pagesIjpab 2015 3 1 224 235 PDFDrAmit VermaNo ratings yet

- Antimicrobial FinalDocument227 pagesAntimicrobial FinalAbdulrhman MekawyNo ratings yet

- Colegio de San Gabriel ArcangelDocument5 pagesColegio de San Gabriel ArcangelJonille EchevarriaNo ratings yet

- Done By: Neha Jain Priya Upadhyay Saanchi AroraDocument13 pagesDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayNo ratings yet

- Pharmacology ReviewerDocument24 pagesPharmacology ReviewergreinabelNo ratings yet

- MalamedDocument7 pagesMalamedProgynanika BarmanNo ratings yet

- GMP GuidelinesDocument40 pagesGMP Guidelinesmrgsguy100% (2)

- Enc 1102 Research ProposalDocument4 pagesEnc 1102 Research Proposalapi-317153884No ratings yet

- International Journal of Universal Pharmacy and Bio SciencesDocument9 pagesInternational Journal of Universal Pharmacy and Bio SciencesPallavi PrakashNo ratings yet

- Pharmaceutical Patents in India: Issues and ConcernsDocument18 pagesPharmaceutical Patents in India: Issues and ConcernsBalaji P Nadar75% (4)

- AnxietyDocument4 pagesAnxietyAnn DassNo ratings yet

- Implementation of Standards of Good Pharmacy Practice in The World - A ReviewDocument5 pagesImplementation of Standards of Good Pharmacy Practice in The World - A ReviewDewa GedeNo ratings yet

- Chapter 4 (Cosmetic Act)Document10 pagesChapter 4 (Cosmetic Act)ashmun nishaNo ratings yet

- Parabens 2Document29 pagesParabens 2Vincze BoglárkaNo ratings yet

- Drug StudyDocument7 pagesDrug StudyGladys NacionNo ratings yet

- Module Iii-H..alcohol and Other Drugs of AbuseDocument5 pagesModule Iii-H..alcohol and Other Drugs of AbuseKenneth NuñezNo ratings yet

- PV India DCGI Presentation R3Document18 pagesPV India DCGI Presentation R3Arun NairNo ratings yet

- Adventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyDocument58 pagesAdventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyRC DomeNo ratings yet

- Pepcid AC - Group1 - AnalysisDocument2 pagesPepcid AC - Group1 - AnalysisRini RafiNo ratings yet

- Wharton Consulting Case Interview GuideDocument47 pagesWharton Consulting Case Interview GuideBrian Ny Wong100% (4)

- Development and Validation of The UV Spectroscopic Method For Varenicline Determination in Pharmaceutical PreparationDocument9 pagesDevelopment and Validation of The UV Spectroscopic Method For Varenicline Determination in Pharmaceutical PreparationJournal of Pharmaceutical Research InternationalNo ratings yet

- Development and Validation of UV Spectrophotometric Method For Simultaneous Estimation of Melatonin and Quercetin in Liposome FormulationDocument6 pagesDevelopment and Validation of UV Spectrophotometric Method For Simultaneous Estimation of Melatonin and Quercetin in Liposome FormulationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Barang Ed DekatDocument12 pagesBarang Ed DekatAkhmad “Billy Rafi” HambaliNo ratings yet

- Pharmacy Daily 30th Nov 2023Document3 pagesPharmacy Daily 30th Nov 2023Marinero CzarNo ratings yet

- Participating Vendor ListDocument119 pagesParticipating Vendor ListWWaahhiidd KhanNo ratings yet

- Infografia Inglés Del OmeprazolDocument1 pageInfografia Inglés Del OmeprazolAriadna SantaellaNo ratings yet

- Non Clinical Drug DevelopmentDocument75 pagesNon Clinical Drug DevelopmentalexNo ratings yet

- Onychomycosis in ChildrenDocument28 pagesOnychomycosis in ChildrenAstuti Clara SimanjuntakNo ratings yet