Professional Documents

Culture Documents

Grinding PDF

Grinding PDF

Uploaded by

Afzaal FiazCopyright:

Available Formats

You might also like

- Chris Marine Surface Grinder Type CPLDocument22 pagesChris Marine Surface Grinder Type CPLSamer Saliba100% (1)

- Grinding MachineDocument1 pageGrinding Machinevenkateshyadav2116No ratings yet

- Types: Numerical ControlsDocument1 pageTypes: Numerical ControlskhalifawhanNo ratings yet

- Grinding MachineDocument22 pagesGrinding MachineImGlobalCitizenNo ratings yet

- Project Assigmnet 1Document7 pagesProject Assigmnet 1Jaja MangzNo ratings yet

- GrindingDocument3 pagesGrindingmukeshkatarnavareNo ratings yet

- Cipet Bhubaneswar FombDocument15 pagesCipet Bhubaneswar Fombcipet imphalNo ratings yet

- Grinding Machine - WikipediaDocument6 pagesGrinding Machine - WikipediaWamara CalebNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineKeeru BossNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineTan Jun Zhe0% (1)

- Grinding MachineDocument34 pagesGrinding MachineThakur ShakilNo ratings yet

- Fabrication Methods and ProcessesDocument27 pagesFabrication Methods and ProcessesSivaNo ratings yet

- Surface GrinderDocument7 pagesSurface Grinderaryariqtariq704100% (1)

- Grinding Machine: Navigation Search List of References External Links ImproveDocument13 pagesGrinding Machine: Navigation Search List of References External Links ImprovePruthviKashiNo ratings yet

- Grinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousDocument16 pagesGrinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousMudassar AkhtarNo ratings yet

- Grinding Wheels Lab ReportDocument18 pagesGrinding Wheels Lab ReportUsman CheemaNo ratings yet

- Grinding Machine: Difqi Faza Umary MuhdoriDocument8 pagesGrinding Machine: Difqi Faza Umary MuhdoriSATRIA MUSTHOFFA ADDIWANINo ratings yet

- Machine Tool Grinding Machining Abrasive Wheel Cutting Tool Chip Surface Roughness AccuracyDocument1 pageMachine Tool Grinding Machining Abrasive Wheel Cutting Tool Chip Surface Roughness AccuracyjinggascribdNo ratings yet

- Lecture 5Document39 pagesLecture 5Ishtiaq AhmedNo ratings yet

- Quad Processing MachineDocument6 pagesQuad Processing MachineSulfikkar100% (1)

- Elements of Technology: - Grinding Machines (Grinder)Document14 pagesElements of Technology: - Grinding Machines (Grinder)SushantNo ratings yet

- Manufacturing TechnologyDocument35 pagesManufacturing Technologybuntypatel7405No ratings yet

- Grindin MachinesDocument13 pagesGrindin Machinestesfaye ayeleNo ratings yet

- Prof. Sourabh ShuklaDocument9 pagesProf. Sourabh ShuklaOmkar BhoyarNo ratings yet

- André Grinding Machine AssemblyDocument4 pagesAndré Grinding Machine AssemblyBruno SpezziNo ratings yet

- GrindingmachineDocument11 pagesGrindingmachinecipet imphalNo ratings yet

- GrindingmachineDocument11 pagesGrindingmachinecipet imphalNo ratings yet

- Grinding Machine DefinitionDocument8 pagesGrinding Machine DefinitionOmkar BhoyarNo ratings yet

- Gear ShaperDocument4 pagesGear ShaperKailas KatharNo ratings yet

- Module II - GrindingDocument73 pagesModule II - GrindingHARI KRISHNANNo ratings yet

- Machining Operations: Word Meaning Context More InformationDocument4 pagesMachining Operations: Word Meaning Context More InformationabyzenNo ratings yet

- Grinding and Grinding OperationsDocument14 pagesGrinding and Grinding OperationsRitik Pothare0% (2)

- What Is Machine ToolsDocument5 pagesWhat Is Machine ToolsOsama AsifNo ratings yet

- Grinding MachineDocument6 pagesGrinding Machinegirma workuNo ratings yet

- V Machining ConventionalDocument22 pagesV Machining Conventionalroamer10No ratings yet

- MFT Lab - 1 - Surface GrindingDocument3 pagesMFT Lab - 1 - Surface GrindingsivaeinfoNo ratings yet

- Machine OperationDocument4 pagesMachine OperationMaster BomboNo ratings yet

- Grinding MachineDocument9 pagesGrinding Machinejineesha p jNo ratings yet

- Grinding Machine All PDFDocument90 pagesGrinding Machine All PDFRohit Ghulanavar100% (2)

- Mehran University of Engineering and Technology, Jamshoro: Noshad AliDocument8 pagesMehran University of Engineering and Technology, Jamshoro: Noshad AliArsalan SidikiNo ratings yet

- Lathe Helping SidesDocument27 pagesLathe Helping Sidest75zswxgwfNo ratings yet

- Grinding AssignmentDocument4 pagesGrinding AssignmentSyed Ashmal Hashmi100% (1)

- Surface Grinding MachineDocument26 pagesSurface Grinding MachinejohnNo ratings yet

- 2.0: Grinding Machine (Advanced)Document10 pages2.0: Grinding Machine (Advanced)Mahfuzah MustaphaNo ratings yet

- Grinding in MachiningDocument10 pagesGrinding in MachiningNick AhrenNo ratings yet

- Grinding Machine Definition Types Parts Working Operations With PDFDocument10 pagesGrinding Machine Definition Types Parts Working Operations With PDF2K19-ME-281 Ishan MishraNo ratings yet

- For More Presentation Go To: Metal Cutting LatheDocument74 pagesFor More Presentation Go To: Metal Cutting Lathebabu319No ratings yet

- Materi Presentasi ManufakturDocument4 pagesMateri Presentasi ManufakturAquila Fadhila ArifiantiNo ratings yet

- Unit - Iv: Manufacturing TechnologyDocument39 pagesUnit - Iv: Manufacturing TechnologyAniket KharpateNo ratings yet

- SurfacefinishingproDocument38 pagesSurfacefinishingproraviraj20082No ratings yet

- Manufacturing Technology: Unit - IvDocument37 pagesManufacturing Technology: Unit - IvramadanNo ratings yet

- Ch-1 Part-I TurningDocument27 pagesCh-1 Part-I TurningStephen WeiNo ratings yet

- MM Unit 4Document21 pagesMM Unit 4Spartan 117100% (1)

- Milling NotesDocument20 pagesMilling NotesleoandresmessiNo ratings yet

- Grinding Machine Definition Types Parts Working Operations With PDFDocument10 pagesGrinding Machine Definition Types Parts Working Operations With PDFChester Evangelista Iman IINo ratings yet

- Abrasive Machining ProcessDocument13 pagesAbrasive Machining ProcessAbdulRehman Ahmed SoomroNo ratings yet

- Lathe Machine ReportDocument10 pagesLathe Machine ReportJohn Paul DomingoNo ratings yet

- CNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqDocument51 pagesCNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqEngr.shamiNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Rules Keep It Saada Amal Kia Hasil Hua Kyu Kyu Kyu Ruqiyya RocksDocument2 pagesRules Keep It Saada Amal Kia Hasil Hua Kyu Kyu Kyu Ruqiyya RocksAfzaal FiazNo ratings yet

- Submitted To Mam Amna Noor Submitted by 14-MCE-42,44,46 Subject Lab ManualDocument2 pagesSubmitted To Mam Amna Noor Submitted by 14-MCE-42,44,46 Subject Lab ManualAfzaal FiazNo ratings yet

- New Doc 2017-03-05Document2 pagesNew Doc 2017-03-05Afzaal FiazNo ratings yet

- Assignment n1Document1 pageAssignment n1Afzaal FiazNo ratings yet

- Experiment No: Objective: ApparatusDocument3 pagesExperiment No: Objective: ApparatusAfzaal FiazNo ratings yet

- Multi Evaporator Compressio N System: Automatic AC Doo RDocument1 pageMulti Evaporator Compressio N System: Automatic AC Doo RAfzaal FiazNo ratings yet

- Procedure: Experiment #2 ObjectiveDocument2 pagesProcedure: Experiment #2 ObjectiveAfzaal FiazNo ratings yet

- Book Reviews: ContrastsDocument2 pagesBook Reviews: ContrastsAfzaal FiazNo ratings yet

- Heat Pump TrainerDocument6 pagesHeat Pump TrainerAfzaal FiazNo ratings yet

- TorrentDocument10 pagesTorrentAfzaal FiazNo ratings yet

- Strategy For Simplifying MatricesDocument1 pageStrategy For Simplifying MatricesAfzaal FiazNo ratings yet

- 2-Stage Reciprocating Air CompressorDocument3 pages2-Stage Reciprocating Air CompressorAfzaal Fiaz100% (1)

- Bernoulli EquationDocument49 pagesBernoulli EquationAfzaal Fiaz100% (1)

- Grindin MachinesDocument13 pagesGrindin Machinestesfaye ayeleNo ratings yet

- 3m SUPERABRASIVESDocument40 pages3m SUPERABRASIVESGaurav BediNo ratings yet

- Grinding WheelsDocument54 pagesGrinding Wheelsvelavansu100% (1)

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- Roadways Workshop Internship File RSRTC, JodhpurDocument38 pagesRoadways Workshop Internship File RSRTC, Jodhpurashish0% (1)

- Bajrangi Project ReportDocument46 pagesBajrangi Project ReportAmodTKvideosNo ratings yet

- General GrindingDocument28 pagesGeneral GrindingRavi Arjun Kumar100% (1)

- l09 Grinding 1 PDFDocument66 pagesl09 Grinding 1 PDFKarim N. SalloomiNo ratings yet

- Surface GrinderDocument7 pagesSurface Grinderaryariqtariq704100% (1)

- Abrasive Machining and Finishing OperationsDocument27 pagesAbrasive Machining and Finishing Operationsfazli98418No ratings yet

- 9179Document8 pages9179Ranjith CLNo ratings yet

- CBC Machining NC IDocument79 pagesCBC Machining NC IKaren Mae Altarejos AlocNo ratings yet

- Mamam601 Part IIDocument55 pagesMamam601 Part IIHirwa jean de DieuNo ratings yet

- Grinding MachinesDocument74 pagesGrinding MachinesRandy EsoleNo ratings yet

- Abrasive Machining and Finishing OperationsDocument53 pagesAbrasive Machining and Finishing OperationssengcanNo ratings yet

- Study of Grinding MachinesDocument16 pagesStudy of Grinding MachinesRethish BalakrishnanNo ratings yet

- Experiment 1Document16 pagesExperiment 1samayNo ratings yet

- Grinding, Lapping, Polishing, EDM, Laser Cut, Water Jest, EtcDocument32 pagesGrinding, Lapping, Polishing, EDM, Laser Cut, Water Jest, EtceliiiiiiNo ratings yet

- Jigs and FixturesDocument85 pagesJigs and FixturesNithin Mathew Eyyalil100% (2)

- GRINDING and Other Abrasive ProcessesDocument30 pagesGRINDING and Other Abrasive Processesshishir acharyaNo ratings yet

- Nicon Price List January 2021Document12 pagesNicon Price List January 2021niket0No ratings yet

- NFL Naya Nangal Six MonthTraining ReportDocument35 pagesNFL Naya Nangal Six MonthTraining ReportAnonymous Np8cI0wNo ratings yet

- Chromium Coated Piston Head Liner RingDocument56 pagesChromium Coated Piston Head Liner RingtechfiNo ratings yet

- ASTM D4543-19 en-USDocument13 pagesASTM D4543-19 en-USr9mirandaqNo ratings yet

- Semi Automatic Ceramic Sleeve Surface Finishing MachineDocument2 pagesSemi Automatic Ceramic Sleeve Surface Finishing MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Grinding 6893 9Document8 pagesGrinding 6893 9Rajasekaran MuruganNo ratings yet

- Grinding MachineDocument4 pagesGrinding MachineSridhar BhagavatullaNo ratings yet

- Chapter 2: Conventional and Non-Conventional: Dma1112: Machining TechnologyDocument26 pagesChapter 2: Conventional and Non-Conventional: Dma1112: Machining TechnologyKayshiraaj RavichandranNo ratings yet

- Ch-10 Grinding and FinishingDocument121 pagesCh-10 Grinding and FinishingMANJEET KUMARNo ratings yet

Grinding PDF

Grinding PDF

Uploaded by

Afzaal FiazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grinding PDF

Grinding PDF

Uploaded by

Afzaal FiazCopyright:

Available Formats

Grinding machine

A grinding machine is a machine tool used for producing very fine finishes or making

very light cuts, using an abrasive wheel as the cutting device. This wheel can be made up of

various sizes and types of stones, diamonds or of inorganic materials. For machines used to

reduce particle size in materials processing see grinding.

Construction

The grinding machine consists of a power driven grinding wheel spinning at the

required speed (which is determined by the wheels diameter and manufacturers rating, usually

by a formula) and a bed with a fixture to guide and hold the work-piece. The grinding head can

be controlled to travel across a fixed work piece or the workpiece can be moved whilst the grind

head stays in a fixed position. Very fine control of the grinding head or tables position is possible

using a vernier calibrated hand wheel, or using the features of NC or CNC controls.

Grinding machines remove material from the workpiece by abrasion, which can

generate substantial amounts of heat; they therefore incorporate a coolant to cool the workpiece

so that it does not overheat and go outside its tolerance. The coolant also benefits the machinist

as the heat generated may cause burns in some cases. In very high-precision grinding machines

(most cylindrical and surface grinders) the final grinding stages are usually set up so that they

remove about 2/10000mm (less than 1/100000 in) per pass - this generates so little heat that even

with no coolant, the temperature rise is negligible.

Types of grinders

These machines include the

Belt grinder, which is usually used as a machining method to process metals and other

materials, with the aid of coated abrasives. Sanding is the machining of wood; grinding is

the common name for machining metals. Belt grinding is a versatile process suitable for

all kind of applications like finishing, deburring, and stock removal

Bench grinder, which usually has two wheels of different grain sizes for roughing and

finishing operations and is secured to a workbench. It is used for shaping tool bits or

various tools that need to be made or repaired. Bench grinders are manually operated.

Cylindrical grinder which includes the centerless grinder. A cylindrical grinder may

have multiple grinding wheels. The workpiece is rotated and fed past the wheel/s to form

a cylinder. It is used to make precision rods.

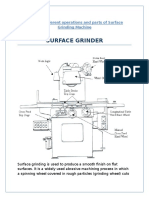

Surface grinder which includes the wash grinder. A surface grinder has a "head" which

is lowered, and the workpiece is moved back and forth past the grinding wheel on a table

that has a permanent magnet for use with magnetic stock. Surface grinders can be

manually operated or have CNC controls.

Tool and Cutter grinder and the D-bit grinder. These usually can perform the minor

function of the drill bit grinder, or other specialist toolroom grinding operations.

Jig grinder, which as the name implies, has a variety of uses when finishing jigs, dies,

and fixtures. Its primary function is in the realm of grinding holes and pins. It can also be

used for complex surface grinding to finish work started on a mill.

You might also like

- Chris Marine Surface Grinder Type CPLDocument22 pagesChris Marine Surface Grinder Type CPLSamer Saliba100% (1)

- Grinding MachineDocument1 pageGrinding Machinevenkateshyadav2116No ratings yet

- Types: Numerical ControlsDocument1 pageTypes: Numerical ControlskhalifawhanNo ratings yet

- Grinding MachineDocument22 pagesGrinding MachineImGlobalCitizenNo ratings yet

- Project Assigmnet 1Document7 pagesProject Assigmnet 1Jaja MangzNo ratings yet

- GrindingDocument3 pagesGrindingmukeshkatarnavareNo ratings yet

- Cipet Bhubaneswar FombDocument15 pagesCipet Bhubaneswar Fombcipet imphalNo ratings yet

- Grinding Machine - WikipediaDocument6 pagesGrinding Machine - WikipediaWamara CalebNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineKeeru BossNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineTan Jun Zhe0% (1)

- Grinding MachineDocument34 pagesGrinding MachineThakur ShakilNo ratings yet

- Fabrication Methods and ProcessesDocument27 pagesFabrication Methods and ProcessesSivaNo ratings yet

- Surface GrinderDocument7 pagesSurface Grinderaryariqtariq704100% (1)

- Grinding Machine: Navigation Search List of References External Links ImproveDocument13 pagesGrinding Machine: Navigation Search List of References External Links ImprovePruthviKashiNo ratings yet

- Grinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousDocument16 pagesGrinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousMudassar AkhtarNo ratings yet

- Grinding Wheels Lab ReportDocument18 pagesGrinding Wheels Lab ReportUsman CheemaNo ratings yet

- Grinding Machine: Difqi Faza Umary MuhdoriDocument8 pagesGrinding Machine: Difqi Faza Umary MuhdoriSATRIA MUSTHOFFA ADDIWANINo ratings yet

- Machine Tool Grinding Machining Abrasive Wheel Cutting Tool Chip Surface Roughness AccuracyDocument1 pageMachine Tool Grinding Machining Abrasive Wheel Cutting Tool Chip Surface Roughness AccuracyjinggascribdNo ratings yet

- Lecture 5Document39 pagesLecture 5Ishtiaq AhmedNo ratings yet

- Quad Processing MachineDocument6 pagesQuad Processing MachineSulfikkar100% (1)

- Elements of Technology: - Grinding Machines (Grinder)Document14 pagesElements of Technology: - Grinding Machines (Grinder)SushantNo ratings yet

- Manufacturing TechnologyDocument35 pagesManufacturing Technologybuntypatel7405No ratings yet

- Grindin MachinesDocument13 pagesGrindin Machinestesfaye ayeleNo ratings yet

- Prof. Sourabh ShuklaDocument9 pagesProf. Sourabh ShuklaOmkar BhoyarNo ratings yet

- André Grinding Machine AssemblyDocument4 pagesAndré Grinding Machine AssemblyBruno SpezziNo ratings yet

- GrindingmachineDocument11 pagesGrindingmachinecipet imphalNo ratings yet

- GrindingmachineDocument11 pagesGrindingmachinecipet imphalNo ratings yet

- Grinding Machine DefinitionDocument8 pagesGrinding Machine DefinitionOmkar BhoyarNo ratings yet

- Gear ShaperDocument4 pagesGear ShaperKailas KatharNo ratings yet

- Module II - GrindingDocument73 pagesModule II - GrindingHARI KRISHNANNo ratings yet

- Machining Operations: Word Meaning Context More InformationDocument4 pagesMachining Operations: Word Meaning Context More InformationabyzenNo ratings yet

- Grinding and Grinding OperationsDocument14 pagesGrinding and Grinding OperationsRitik Pothare0% (2)

- What Is Machine ToolsDocument5 pagesWhat Is Machine ToolsOsama AsifNo ratings yet

- Grinding MachineDocument6 pagesGrinding Machinegirma workuNo ratings yet

- V Machining ConventionalDocument22 pagesV Machining Conventionalroamer10No ratings yet

- MFT Lab - 1 - Surface GrindingDocument3 pagesMFT Lab - 1 - Surface GrindingsivaeinfoNo ratings yet

- Machine OperationDocument4 pagesMachine OperationMaster BomboNo ratings yet

- Grinding MachineDocument9 pagesGrinding Machinejineesha p jNo ratings yet

- Grinding Machine All PDFDocument90 pagesGrinding Machine All PDFRohit Ghulanavar100% (2)

- Mehran University of Engineering and Technology, Jamshoro: Noshad AliDocument8 pagesMehran University of Engineering and Technology, Jamshoro: Noshad AliArsalan SidikiNo ratings yet

- Lathe Helping SidesDocument27 pagesLathe Helping Sidest75zswxgwfNo ratings yet

- Grinding AssignmentDocument4 pagesGrinding AssignmentSyed Ashmal Hashmi100% (1)

- Surface Grinding MachineDocument26 pagesSurface Grinding MachinejohnNo ratings yet

- 2.0: Grinding Machine (Advanced)Document10 pages2.0: Grinding Machine (Advanced)Mahfuzah MustaphaNo ratings yet

- Grinding in MachiningDocument10 pagesGrinding in MachiningNick AhrenNo ratings yet

- Grinding Machine Definition Types Parts Working Operations With PDFDocument10 pagesGrinding Machine Definition Types Parts Working Operations With PDF2K19-ME-281 Ishan MishraNo ratings yet

- For More Presentation Go To: Metal Cutting LatheDocument74 pagesFor More Presentation Go To: Metal Cutting Lathebabu319No ratings yet

- Materi Presentasi ManufakturDocument4 pagesMateri Presentasi ManufakturAquila Fadhila ArifiantiNo ratings yet

- Unit - Iv: Manufacturing TechnologyDocument39 pagesUnit - Iv: Manufacturing TechnologyAniket KharpateNo ratings yet

- SurfacefinishingproDocument38 pagesSurfacefinishingproraviraj20082No ratings yet

- Manufacturing Technology: Unit - IvDocument37 pagesManufacturing Technology: Unit - IvramadanNo ratings yet

- Ch-1 Part-I TurningDocument27 pagesCh-1 Part-I TurningStephen WeiNo ratings yet

- MM Unit 4Document21 pagesMM Unit 4Spartan 117100% (1)

- Milling NotesDocument20 pagesMilling NotesleoandresmessiNo ratings yet

- Grinding Machine Definition Types Parts Working Operations With PDFDocument10 pagesGrinding Machine Definition Types Parts Working Operations With PDFChester Evangelista Iman IINo ratings yet

- Abrasive Machining ProcessDocument13 pagesAbrasive Machining ProcessAbdulRehman Ahmed SoomroNo ratings yet

- Lathe Machine ReportDocument10 pagesLathe Machine ReportJohn Paul DomingoNo ratings yet

- CNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqDocument51 pagesCNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqEngr.shamiNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Rules Keep It Saada Amal Kia Hasil Hua Kyu Kyu Kyu Ruqiyya RocksDocument2 pagesRules Keep It Saada Amal Kia Hasil Hua Kyu Kyu Kyu Ruqiyya RocksAfzaal FiazNo ratings yet

- Submitted To Mam Amna Noor Submitted by 14-MCE-42,44,46 Subject Lab ManualDocument2 pagesSubmitted To Mam Amna Noor Submitted by 14-MCE-42,44,46 Subject Lab ManualAfzaal FiazNo ratings yet

- New Doc 2017-03-05Document2 pagesNew Doc 2017-03-05Afzaal FiazNo ratings yet

- Assignment n1Document1 pageAssignment n1Afzaal FiazNo ratings yet

- Experiment No: Objective: ApparatusDocument3 pagesExperiment No: Objective: ApparatusAfzaal FiazNo ratings yet

- Multi Evaporator Compressio N System: Automatic AC Doo RDocument1 pageMulti Evaporator Compressio N System: Automatic AC Doo RAfzaal FiazNo ratings yet

- Procedure: Experiment #2 ObjectiveDocument2 pagesProcedure: Experiment #2 ObjectiveAfzaal FiazNo ratings yet

- Book Reviews: ContrastsDocument2 pagesBook Reviews: ContrastsAfzaal FiazNo ratings yet

- Heat Pump TrainerDocument6 pagesHeat Pump TrainerAfzaal FiazNo ratings yet

- TorrentDocument10 pagesTorrentAfzaal FiazNo ratings yet

- Strategy For Simplifying MatricesDocument1 pageStrategy For Simplifying MatricesAfzaal FiazNo ratings yet

- 2-Stage Reciprocating Air CompressorDocument3 pages2-Stage Reciprocating Air CompressorAfzaal Fiaz100% (1)

- Bernoulli EquationDocument49 pagesBernoulli EquationAfzaal Fiaz100% (1)

- Grindin MachinesDocument13 pagesGrindin Machinestesfaye ayeleNo ratings yet

- 3m SUPERABRASIVESDocument40 pages3m SUPERABRASIVESGaurav BediNo ratings yet

- Grinding WheelsDocument54 pagesGrinding Wheelsvelavansu100% (1)

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- Roadways Workshop Internship File RSRTC, JodhpurDocument38 pagesRoadways Workshop Internship File RSRTC, Jodhpurashish0% (1)

- Bajrangi Project ReportDocument46 pagesBajrangi Project ReportAmodTKvideosNo ratings yet

- General GrindingDocument28 pagesGeneral GrindingRavi Arjun Kumar100% (1)

- l09 Grinding 1 PDFDocument66 pagesl09 Grinding 1 PDFKarim N. SalloomiNo ratings yet

- Surface GrinderDocument7 pagesSurface Grinderaryariqtariq704100% (1)

- Abrasive Machining and Finishing OperationsDocument27 pagesAbrasive Machining and Finishing Operationsfazli98418No ratings yet

- 9179Document8 pages9179Ranjith CLNo ratings yet

- CBC Machining NC IDocument79 pagesCBC Machining NC IKaren Mae Altarejos AlocNo ratings yet

- Mamam601 Part IIDocument55 pagesMamam601 Part IIHirwa jean de DieuNo ratings yet

- Grinding MachinesDocument74 pagesGrinding MachinesRandy EsoleNo ratings yet

- Abrasive Machining and Finishing OperationsDocument53 pagesAbrasive Machining and Finishing OperationssengcanNo ratings yet

- Study of Grinding MachinesDocument16 pagesStudy of Grinding MachinesRethish BalakrishnanNo ratings yet

- Experiment 1Document16 pagesExperiment 1samayNo ratings yet

- Grinding, Lapping, Polishing, EDM, Laser Cut, Water Jest, EtcDocument32 pagesGrinding, Lapping, Polishing, EDM, Laser Cut, Water Jest, EtceliiiiiiNo ratings yet

- Jigs and FixturesDocument85 pagesJigs and FixturesNithin Mathew Eyyalil100% (2)

- GRINDING and Other Abrasive ProcessesDocument30 pagesGRINDING and Other Abrasive Processesshishir acharyaNo ratings yet

- Nicon Price List January 2021Document12 pagesNicon Price List January 2021niket0No ratings yet

- NFL Naya Nangal Six MonthTraining ReportDocument35 pagesNFL Naya Nangal Six MonthTraining ReportAnonymous Np8cI0wNo ratings yet

- Chromium Coated Piston Head Liner RingDocument56 pagesChromium Coated Piston Head Liner RingtechfiNo ratings yet

- ASTM D4543-19 en-USDocument13 pagesASTM D4543-19 en-USr9mirandaqNo ratings yet

- Semi Automatic Ceramic Sleeve Surface Finishing MachineDocument2 pagesSemi Automatic Ceramic Sleeve Surface Finishing MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Grinding 6893 9Document8 pagesGrinding 6893 9Rajasekaran MuruganNo ratings yet

- Grinding MachineDocument4 pagesGrinding MachineSridhar BhagavatullaNo ratings yet

- Chapter 2: Conventional and Non-Conventional: Dma1112: Machining TechnologyDocument26 pagesChapter 2: Conventional and Non-Conventional: Dma1112: Machining TechnologyKayshiraaj RavichandranNo ratings yet

- Ch-10 Grinding and FinishingDocument121 pagesCh-10 Grinding and FinishingMANJEET KUMARNo ratings yet