Professional Documents

Culture Documents

Pouzitie Oceli Podla Teplot

Pouzitie Oceli Podla Teplot

Uploaded by

Ján KožičkaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pouzitie Oceli Podla Teplot

Pouzitie Oceli Podla Teplot

Uploaded by

Ján KožičkaCopyright:

Available Formats

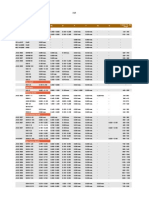

Max USAGE temperature air

for some materials

Designation

Steel Heat AlloyIng elements TEMP.

FAMILY Treatment N EN AISI %~ MAX C

Nickel alloy +AT 2.4889 NiCr28FeSiCe Ni46-Cr28-Si2,8-Ce0,06 +1200

Austenitic steel +AT 1.4854 X6NiCrSiNCe35-25 Ni35-Cr25-Si1,6-Ce0,05 +1170

Nickel alloy +AT 2.4951 NiCr20Ti Ni74-Cr20-Ti0,40 +1150

Ferritic steel +A 1.4749 X18CrN28 Cr28-N0,20 +1100

Ferritic steel +A 1.4762 X10CrAlSi25 446 Cr25-Si1-Al1,4 +1095

Austenitic steel +AT 1.4841 ~ X15CrNiSi25-21 310 Cr25-Ni20-Si2 +1095

Ferritic steel +A 1.2780 X16CrNiSi20-12 442 ~ Cr20-Ni12-Si2 +1050

Austenitic steel +AT 1.4950 ~ X6CrNi23-13 ~ 309Cb Cr24-Ni14-Nb0,8 +1040

Martensitic steel +QT 1.4112 X90CrMoV18 440 Cr18-Mo1-V0,10 +970

Austenitic steel +AT 1.4550 X6CrNiNb18-10 347 Cr18-Ni10-Nb +930

Austenitic steel +AT 1.4401 X5CrNiMo17-12-2 316 Cr16-Ni12-Mo2 +900

Austenitic steel +AT 1.4310 X10CrNi18-8 302 Cr18-Ni8 +900

Austenitic steel +AT 1.4306 X2CrNi19-11 304L Cr19-Ni11 +870

Ferritic steel +A 1.4016 X6Cr17 430 Cr17 +845

Ferritic steel +A 1.4002 X6CrAl13 405 Cr12-Al0,20 +815

Austenitic steel +AT 1.4307 X2CrNi18-9 304 Cr18-Ni9 +800

Martensitic steel +QT 1.4006 X12Cr13 410 Cr12 +705

Alloy steel +NT 1.7362 X12CrMo5 A 182 F5 Cr5-Mo0,5 + 620

Alloy steel +NT 1.5415 16Mo3 A 204 gr. A ~ Mo0,30 +500

Non alloy spec. steel +N 1.0345 P235GH A 414 gr. B +400

Carbon steel +N 1.1191 C45E 1045 +300

Carbon steel +N 1.1133 20Mn5 1022 ~ +250

Carbon steel +N 1.1181 C35E 1035 +200

Non alloy +N 1.0577 S355J2 A 350 LF2 +120

Non alloy +N 1.0038 S235JR A 252 ~ +20

Non alloy +N 1.0143 S275J0 A 572 gr. 42 ~ 0

Non alloy +N 1.0577 S355J2 A 350 LF2 Mn1,25 -20

Alloy steel +QT 1.7218 25CrMo4 4130 Cr1-Mo0,20 -30

Alloy steel +QT 1.7225 42CrMo4 A 320 L7 Cr1 -40

Alloy steel +QT 1.6510 39NiCrMo3 9840 Cr0,80-Ni0,90-Mo0,20 -50

Steel with Mn-B +QT 1.5523 19MnB4 A 320 L1 Mn1-B0,003 -60

Alloy steel +QT 1.6580 30CrNiMo8 A 320 L43 Cr2-Ni2-Mo0,40 -80

Nickel alloy steel +QT 1.5637 12Ni14 A 203 gr. D ~ Ni3,5 -90

Nickel alloy steel +NT 1.5680 X12Ni5 A 2515 ~ Ni5 -100

Nickel alloy steel +QT 1.5682 X10Ni9 Ni9 -120

Nickel alloy steel +QT 1.5662 X8Ni9 A 353 ~ Ni9 -140

Austenitic steel +AT 1.4301 X5CrNi18-10 304 ~ Cr18-Ni9 -196

Austenitic steel +AT 1.4429 X2CrNiMoN17-13-3 F316 LN Cr17-Ni12-Mo2,8-N0,14 -271,36 *

+QT Quenching and Tempering. +A Annealing. * Temp. of liquified gas employed in the space sector.

+NT Normalization and Tempering. +AT Solubilization. +N Normalization

Materials MAX C Materials MAX C

Hot work tool steels +650 Paper, board, silk, polyamide fibers +90

Cold work tool steels +200 Impregnated paper to mineral oil +105

Superalloy - oxidation begins at 750 C +1100 Polyester resins, polyurethan enamels +120

Case-hardening +200 Asphaltic sealers +130

Titanium alloy +540 Thermosetting composition +155

Intermetallic compounds Ni-Al +1150 Insulating silicone compounds +180

Intermetallic compounds Ti-Al +650

Aluminium alloy +220

Magnesium alloy +250

Glass When exposed to direct flame, it breaks immediately. For irradiation/action on gas +180

Toughened glass +600

In the joint field, carbon steels are used in the temperature range of -20 to +120 C. For temperatures over 50 C and up to 100 C, the nominal pressure that the steel can bear should be decreased by 4

%; for temperatures over 100 C, the nominal pressure should be decreased by 11%. Note: high sulphur content weakens steel, especially at low temperatures

* Temperature of liquefied gas employees in the field spaces them

You might also like

- OznaÄ ovánà materiálÅ Dle Ä SN A ENDocument45 pagesOznaÄ ovánà materiálÅ Dle Ä SN A ENPavel DobiasNo ratings yet

- Otazky-11 20Document7 pagesOtazky-11 20KhoaNo ratings yet

- ŽelezoDocument39 pagesŽelezofat.pandaNo ratings yet

- Otázky 31-40-MKADocument3 pagesOtázky 31-40-MKAKhoaNo ratings yet

- 1 ZnacenioceliDocument14 pages1 ZnacenioceliPavel DobiasNo ratings yet

- 1) Technické Kovové MateriályDocument4 pages1) Technické Kovové Materiálygxzpcmqs27No ratings yet

- Katalog Trgovska JeklaDocument22 pagesKatalog Trgovska JeklaMarko LikarNo ratings yet

- Cuttig ParametersDocument7 pagesCuttig Parametersmojtaba ranjbarNo ratings yet

- Hustota Chemických PrvkůDocument3 pagesHustota Chemických PrvkůnikyketNo ratings yet

- Vysokofrekvenční Lanka: Materiály VodičůDocument1 pageVysokofrekvenční Lanka: Materiály VodičůPukraDastNo ratings yet

- Prezentace Praskova MetalurgieDocument26 pagesPrezentace Praskova Metalurgienobady.slovakNo ratings yet

- K1456 Datasheet 21764 Epy S Otvorem Pro Z Vla Ku Vhodn Pro Vidlicov Hlavice - CsDocument2 pagesK1456 Datasheet 21764 Epy S Otvorem Pro Z Vla Ku Vhodn Pro Vidlicov Hlavice - CsVratislav Němec ml.No ratings yet

- Nizkouhlikove OceliDocument39 pagesNizkouhlikove OceliKristýna DočekalováNo ratings yet

- Bohler ProspektDocument2 pagesBohler ProspektDusan FetakNo ratings yet

- Oceli - RozděleníDocument3 pagesOceli - Rozdělenívicery91No ratings yet

- Rod End PDFDocument12 pagesRod End PDFhiscoke69No ratings yet

- Nepovratne Klapne Sa Dvodelnom PlocomDocument2 pagesNepovratne Klapne Sa Dvodelnom PlocomKristina Markovic RadicNo ratings yet

- +II +iii +VIDocument4 pages+II +iii +VIAni Star WadeNo ratings yet

- Specifikacija Materijala Č.4134 - 1.7034 - 37Cr4Document5 pagesSpecifikacija Materijala Č.4134 - 1.7034 - 37Cr4McLemiNo ratings yet

- 04a Pưehled Tư¡d Technick Ho ElezaDocument34 pages04a Pưehled Tư¡d Technick Ho ElezaHonza KejvalNo ratings yet

- Značení Ocelí: Antonín KřížDocument118 pagesZnačení Ocelí: Antonín KřížMichal JNo ratings yet

- VZ EN Zehnder-Vzornik-BarevDocument4 pagesVZ EN Zehnder-Vzornik-BarevshinobisefirotNo ratings yet

- Datasheet 18361 Z Vla Ky Din en Iso 1234 CsDocument3 pagesDatasheet 18361 Z Vla Ky Din en Iso 1234 CsVratislav Němec ml.No ratings yet

- DprvkyDocument5 pagesDprvkylambada.tipsNo ratings yet

- Normy Pro Pásy A Pruhy Válcované Za Studena - 1Document1 pageNormy Pro Pásy A Pruhy Válcované Za Studena - 1Petr HavelNo ratings yet

- Kovy A Kovová Vazba, D-PrvkyDocument11 pagesKovy A Kovová Vazba, D-Prvkyzuzana777provazNo ratings yet

- 5 Elektricke NapetiDocument19 pages5 Elektricke NapetiagentmaxekNo ratings yet

- Pracovni List - Vyroba ZelezaDocument2 pagesPracovni List - Vyroba ZelezaAnhelina PaliukhNo ratings yet

- PrvkyIII Aa-IV A-SkupinyDocument20 pagesPrvkyIII Aa-IV A-Skupinysotkovska.katerinaNo ratings yet

- Nezelezne Kovy 1Document46 pagesNezelezne Kovy 1olivo2489No ratings yet

- Druhy Tepelneho ZpracovaniDocument37 pagesDruhy Tepelneho Zpracovaniolivo2489No ratings yet

- Otázky 41 50 MKADocument9 pagesOtázky 41 50 MKAKhoaNo ratings yet

- TitanDocument5 pagesTitan9pyzsbp9qbNo ratings yet

- Charakteristika A Pouziti Dane Oceli Dle Normy Ferona Online - Material Ocel A SlitinyDocument12 pagesCharakteristika A Pouziti Dane Oceli Dle Normy Ferona Online - Material Ocel A Slitinyv.kotekNo ratings yet

- Réz És Rézötvözet Anyagszabványok ENDocument2 pagesRéz És Rézötvözet Anyagszabványok ENKrisztina KaszásNo ratings yet

- PM8515 RozpiskaDocument2 pagesPM8515 Rozpiskaapi-3768280No ratings yet

- Base Oil - YUBASE - 8Document1 pageBase Oil - YUBASE - 8ismoyoNo ratings yet

- SOLARDocument1 pageSOLARJan JíchaNo ratings yet

- 8 CH 30-46 SloučeninyDocument20 pages8 CH 30-46 SloučeninymatysekkarvanNo ratings yet

- Otázky 51-60-MKADocument3 pagesOtázky 51-60-MKAKhoaNo ratings yet

- KIPP Federnde Druckstuecke Arretierbolzen Kugelsperrbolzen 2016 CZDocument128 pagesKIPP Federnde Druckstuecke Arretierbolzen Kugelsperrbolzen 2016 CZLuHa1No ratings yet

- Zápis D-Prvky I.B, II.BDocument5 pagesZápis D-Prvky I.B, II.BSebastián KusýNo ratings yet

- Wire RodDocument1 pageWire RodnorrysonNo ratings yet

- Vykaz VyztuzeDocument1 pageVykaz VyztuzetheoNo ratings yet

- Katalog Komponentu ESTADocument29 pagesKatalog Komponentu ESTALelkesBNo ratings yet

- D PrvkyDocument3 pagesD Prvkyhanka.gepardNo ratings yet

- SurTec ČR - Povrchové Úpravy Hliníku - Technologické Novinky, Moderní Trendy A Nové AplikaceDocument24 pagesSurTec ČR - Povrchové Úpravy Hliníku - Technologické Novinky, Moderní Trendy A Nové AplikaceRoman KNo ratings yet

- Přednáška Sklo, KeramikaDocument6 pagesPřednáška Sklo, KeramikaAutistaNo ratings yet

- Oxidy - Názvosloví - CZDocument1 pageOxidy - Názvosloví - CZAdel NguyenováNo ratings yet

- OCEL 16220 Datovy List CSNDocument1 pageOCEL 16220 Datovy List CSNv.kotekNo ratings yet

- Materialový List 1-0425 (P265GH)Document3 pagesMaterialový List 1-0425 (P265GH)Daniel StuparekNo ratings yet

- TetrelyDocument5 pagesTetrelyhanapluskalova1No ratings yet