Professional Documents

Culture Documents

Drilling Rig Selection Guide Page 06 of 13

Drilling Rig Selection Guide Page 06 of 13

Uploaded by

Shodji MabungaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drilling Rig Selection Guide Page 06 of 13

Drilling Rig Selection Guide Page 06 of 13

Uploaded by

Shodji MabungaCopyright:

Available Formats

DRILLING RIG SELECTION GUIDE

A drilling rig in which the

Power Equipment source of power is one or

more internal-combustion

Internal combustion engine or a turbine is engine and in which power is

the source of power for driving equipment distributed to rig components

on the Rig. through devices such as

chains, sprockets, clutches

and shaft is said to be a

Mechanical Rig.

Each rig must be equiped with 2 generator set appropriately rated so that one work 12 hours and

in standby. A drilling rig in which the

source of power is effected by

the combination of engines,

A rig rated to 200 tons have following power consumption:

generator set, control system

60-110 Pcs. AC motors rated from 0.25 to 15 Kw that simultaneously works at average 90 kW and electric motors is said to

4 Pcs AC motors rated 75 Kw each (2 Mud hopper, one desilter and one desander) 150 kW be a Electric Drilling Rig.

4 Pcs AC motors rated 35 kW each (two mud pumps, 2 compressor) 35 kW

Heating / Cooling 7 Pcs air conditioner at 3 kW each 21 kW

Rig lighting 10 kW

TOTAL: 306 kW

That means that best selection is 2 generators rated 320 kW Each as minimum and one auhiliary

generator for moving rated 120 kW.

Switch gear box (MCC) to be equiped with air conditioner. Plug in connection out door one to one.

Mud agitators and shale shaker start-stop switch close to consumer.

All electrical instalation EXd protected. DC-DC Power System

COMPRESSOR

One active and one standby compresor electricaly driven by 35kW motor AC.

One air dryer

One air reservoir 6m3

You might also like

- Codigo de Fallas CATERPILLAR c15Document6 pagesCodigo de Fallas CATERPILLAR c15Junior Lester78% (23)

- Hiper2 Tuning GuideDocument4 pagesHiper2 Tuning GuidePandacsöki BoborjánNo ratings yet

- DM-27 Part2Document14 pagesDM-27 Part2Adrian CantaragiuNo ratings yet

- Operator'S Manual: Continental® Aircraft EngineDocument28 pagesOperator'S Manual: Continental® Aircraft EnginePabloLamelaNo ratings yet

- Drawworks Specification: Project Name: 3000 HP Modular Platform Drilling Rig Project Number: 00548Document4 pagesDrawworks Specification: Project Name: 3000 HP Modular Platform Drilling Rig Project Number: 00548sorangel_1230% (1)

- Yokogawa SyncDocument40 pagesYokogawa SyncHumberto Galvez100% (1)

- Volvo Penta AQ150-A-B Workshop Manual PDFDocument40 pagesVolvo Penta AQ150-A-B Workshop Manual PDFUmar Shamsudin100% (1)

- ECI TrainingDocument216 pagesECI TrainingGlenn BholaNo ratings yet

- D392004720 MKT 001 PDFDocument28 pagesD392004720 MKT 001 PDFsorangel_123No ratings yet

- D1992011002 Spider BJDocument4 pagesD1992011002 Spider BJyair_segaNo ratings yet

- Apleton Receptacles-and-Plugs-ExplosionproofDocument39 pagesApleton Receptacles-and-Plugs-ExplosionproofMuhamad Priyatna100% (1)

- Iecex Ces 14.0019XDocument6 pagesIecex Ces 14.0019XFrancesco_CNo ratings yet

- Crouse Hint PDFDocument180 pagesCrouse Hint PDFJEFFERSON ALEJANDRO MURILLO CAPERANo ratings yet

- Rig DescriptionDocument67 pagesRig DescriptionHammad LiaqatNo ratings yet

- Safety Alert: Driller Inattention Results in Dropped BlocksDocument1 pageSafety Alert: Driller Inattention Results in Dropped Blockscase013No ratings yet

- CatalogoDocument2 pagesCatalogoEvelyn Hachiri CoricazaNo ratings yet

- Safety Alert: Tong Incident Results in A FatalityDocument1 pageSafety Alert: Tong Incident Results in A FatalityVimal SinghNo ratings yet

- Baoji Engineering YM-16IIF Hydraulic Cathead Operations ManualDocument22 pagesBaoji Engineering YM-16IIF Hydraulic Cathead Operations ManualDhrubajyoti BoraNo ratings yet

- SA 02 TDS 11 Carriage InterferenceDocument4 pagesSA 02 TDS 11 Carriage InterferenceHayLenLeeNo ratings yet

- 10745350-Pib Sola 24v电源故障Document4 pages10745350-Pib Sola 24v电源故障xlzyydf2015No ratings yet

- Approved Around The World: Bentec RigsDocument20 pagesApproved Around The World: Bentec RigsCesar Gamboa100% (1)

- TDS 10SH BrochureDocument4 pagesTDS 10SH BrochureSuat YamanNo ratings yet

- Top Drive Systems 1Document5 pagesTop Drive Systems 1Akashdeep HazarikaNo ratings yet

- FD100 分Document17 pagesFD100 分Hadi FaisalNo ratings yet

- Predator Flow ChartDocument1 pagePredator Flow ChartJuan DelgadoNo ratings yet

- Canrig-Top Drive 1275AC-681 750 TonDocument17 pagesCanrig-Top Drive 1275AC-681 750 Tonmaomaochong811No ratings yet

- Deterioration and Effect of InspectionDocument8 pagesDeterioration and Effect of Inspectionarkan1976No ratings yet

- Securemount CatalogDocument8 pagesSecuremount CatalogJohn Alexander Bonilla AngelNo ratings yet

- Amphion Standard Operator GuideDocument362 pagesAmphion Standard Operator Guidemohamed mohsenNo ratings yet

- ÅBS Produktblad Elmotor BEVI - 3SIE PDFDocument9 pagesÅBS Produktblad Elmotor BEVI - 3SIE PDFAmandaNo ratings yet

- Top Drive 750 Product SheetDocument2 pagesTop Drive 750 Product SheetMehdi SoltaniNo ratings yet

- CR191102 - Spare Parts Mud Pump 9T1000Document77 pagesCR191102 - Spare Parts Mud Pump 9T1000nickNo ratings yet

- Automated Power CatwalkDocument6 pagesAutomated Power CatwalkianherzogNo ratings yet

- Ohsar PDFDocument40 pagesOhsar PDFMohammed Ali YoussefNo ratings yet

- BX Test Spec TSEL0066Document12 pagesBX Test Spec TSEL0066Jim SharpNo ratings yet

- Top Drive Spare Parts Catalog-2022Document6 pagesTop Drive Spare Parts Catalog-2022Alexander Daniel Gonzalez AguilarNo ratings yet

- CLE14000DPcerev9 09 PDFDocument139 pagesCLE14000DPcerev9 09 PDFAdhie WaelacxhNo ratings yet

- PSC Ergodyne Range 2021Document45 pagesPSC Ergodyne Range 2021Project Sales CorpNo ratings yet

- IDS 350PE Flyer D392004983 MKT 001Document2 pagesIDS 350PE Flyer D392004983 MKT 001Juan Mata100% (1)

- West VencedorDocument1 pageWest Vencedormin thantNo ratings yet

- Candoc - Es 120 Top Drive Electrical System 1Document160 pagesCandoc - Es 120 Top Drive Electrical System 1JHON JAIRO VALENCIA NIÑONo ratings yet

- 90N10Document5 pages90N10Oymy YaseenNo ratings yet

- How Does A Drillship WorkDocument2 pagesHow Does A Drillship WorkrajasekharboNo ratings yet

- CAOIMPEX Drilling EquipmentDocument14 pagesCAOIMPEX Drilling EquipmentRazi AbbasNo ratings yet

- Fce 3000hp RigDocument6 pagesFce 3000hp RigTimothy PopikNo ratings yet

- Lti - Rig 727 SumspecDocument9 pagesLti - Rig 727 Sumspecbeto11beto12No ratings yet

- Itag Ibop ValveDocument23 pagesItag Ibop ValveValmac ServicesNo ratings yet

- Rexroth Devices and Adjustments R419300234-BDL-001-AA - enDocument220 pagesRexroth Devices and Adjustments R419300234-BDL-001-AA - enyjmhuguesNo ratings yet

- Combination Hydraulic Station: Parts List (10-A)Document7 pagesCombination Hydraulic Station: Parts List (10-A)waleed100% (1)

- Especificaciones ST-80CDocument6 pagesEspecificaciones ST-80CAlfonso Ibarra BenavidesNo ratings yet

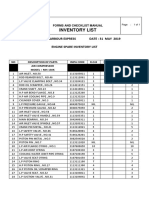

- Rig 12 Inventory SummaryDocument3 pagesRig 12 Inventory Summaryherysyam1980100% (1)

- Pyramid Product Line 1Document9 pagesPyramid Product Line 1John Rong100% (1)

- Sisweb Sisweb Techdoc Techdoc Print Pag - pdf1Document91 pagesSisweb Sisweb Techdoc Techdoc Print Pag - pdf1MatiussChesteerNo ratings yet

- Enerpac S-Series ManualDocument24 pagesEnerpac S-Series ManualTitanplyNo ratings yet

- HH SwivelDocument3 pagesHH SwivelHoracio LafuenteNo ratings yet

- Safety & Operating Manual: Power Crimp 707 CrimperDocument20 pagesSafety & Operating Manual: Power Crimp 707 CrimpervankarpNo ratings yet

- 2.3.B. Manual de Operación y Mantenimiento Bloque ViajeroDocument40 pages2.3.B. Manual de Operación y Mantenimiento Bloque ViajeroD VNo ratings yet

- 130 Kit Deadline Anchor (En)Document19 pages130 Kit Deadline Anchor (En)c.valderrabano81No ratings yet

- Everpure SSFM 100M 25 orDocument2 pagesEverpure SSFM 100M 25 orbigcee64No ratings yet

- Drawworks: Stewart & Stevenson Product SpecificationsDocument4 pagesDrawworks: Stewart & Stevenson Product Specificationsayman akrabNo ratings yet

- OD-Mounted Split Frame Pipe Cutting & Beveling Machine Operation ManualDocument27 pagesOD-Mounted Split Frame Pipe Cutting & Beveling Machine Operation ManualarunmalaichamyNo ratings yet

- 编码器1000012370-PIN REV 01 FinalDocument2 pages编码器1000012370-PIN REV 01 Finalهايتاو لي100% (1)

- Fundamental of Power System Operation and ControlDocument14 pagesFundamental of Power System Operation and ControlAbdelrahman MuadiNo ratings yet

- Introduction To Power System Operation and ControlDocument19 pagesIntroduction To Power System Operation and ControlAbdelrahman MuadiNo ratings yet

- Course Deepwater Well Engineering - DweDocument3 pagesCourse Deepwater Well Engineering - DweShodji MabungaNo ratings yet

- Slide 10Document1 pageSlide 10Shodji MabungaNo ratings yet

- B770 21 2 01 Standard Specification For Copper Beryllium Alloy SandDocument5 pagesB770 21 2 01 Standard Specification For Copper Beryllium Alloy SandShodji MabungaNo ratings yet

- Slide 13Document1 pageSlide 13Shodji MabungaNo ratings yet

- Slide 9Document1 pageSlide 9Shodji MabungaNo ratings yet

- Course Drill String Design and Optimization - DSDDocument2 pagesCourse Drill String Design and Optimization - DSDShodji MabungaNo ratings yet

- Slide 4Document1 pageSlide 4Shodji MabungaNo ratings yet

- B909 21a 2 02 Standard Guide For Plane Strain Fracture ToughnessDocument4 pagesB909 21a 2 02 Standard Guide For Plane Strain Fracture ToughnessShodji MabungaNo ratings yet

- B907 162021 2 04 Standard Specification For Zinc, Tin and CadmiumDocument6 pagesB907 162021 2 04 Standard Specification For Zinc, Tin and CadmiumShodji MabungaNo ratings yet

- Slide 3Document1 pageSlide 3Shodji MabungaNo ratings yet

- B844 982021 2 04 Standard Guide For Silver Tin Oxide Contact MaterialDocument3 pagesB844 982021 2 04 Standard Guide For Silver Tin Oxide Contact MaterialShodji MabungaNo ratings yet

- B899 21 2 04 Standard Terminology Relating To Non Ferrous MetalsDocument4 pagesB899 21 2 04 Standard Terminology Relating To Non Ferrous MetalsShodji MabungaNo ratings yet

- B870 21 2 01 Standard Specification For Copper Beryllium Alloy ForgingsDocument3 pagesB870 21 2 01 Standard Specification For Copper Beryllium Alloy ForgingsShodji MabungaNo ratings yet

- Introduction To Tubulars Page 06 of 10Document1 pageIntroduction To Tubulars Page 06 of 10Shodji MabungaNo ratings yet

- Introduction To Tubulars Page 07 of 10Document1 pageIntroduction To Tubulars Page 07 of 10Shodji MabungaNo ratings yet

- Handling Equipment: Drilling Rig Selection GuideDocument1 pageHandling Equipment: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- B769 112021 2 02 Standard Test Method For Shear Testing of AluminumDocument4 pagesB769 112021 2 02 Standard Test Method For Shear Testing of AluminumShodji MabungaNo ratings yet

- Introduction To Tubulars Page 05 of 10Document1 pageIntroduction To Tubulars Page 05 of 10Shodji MabungaNo ratings yet

- Introduction To Tubulars Page 04 of 10Document1 pageIntroduction To Tubulars Page 04 of 10Shodji MabungaNo ratings yet

- Drilling Rig Selection Guide Page 09 of 13Document1 pageDrilling Rig Selection Guide Page 09 of 13Shodji MabungaNo ratings yet

- Rotary Table: Drilling Rig Selection GuideDocument1 pageRotary Table: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- Introduction To Tubulars Page 03 of 10Document1 pageIntroduction To Tubulars Page 03 of 10Shodji MabungaNo ratings yet

- Mud Pumps: Drilling Rig Selection GuideDocument1 pageMud Pumps: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- Introduction To Tubulars Page 02 of 10 PDFDocument1 pageIntroduction To Tubulars Page 02 of 10 PDFShodji MabungaNo ratings yet

- Introduction To Tubulars Page 01 of 10Document1 pageIntroduction To Tubulars Page 01 of 10Shodji MabungaNo ratings yet

- Handling Equipment: Drilling Rig Selection GuideDocument1 pageHandling Equipment: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- Handling Equipment: Drilling Rig Selection GuideDocument1 pageHandling Equipment: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- Handling Equipment: Drilling Rig Selection GuideDocument1 pageHandling Equipment: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- Drilling Rig Selection Guide Page 08 of 13Document1 pageDrilling Rig Selection Guide Page 08 of 13Shodji MabungaNo ratings yet

- Traveling Block: Drilling Rig Selection GuideDocument1 pageTraveling Block: Drilling Rig Selection GuideShodji MabungaNo ratings yet

- Husky 449-511 - EN - 03 - 2011Document385 pagesHusky 449-511 - EN - 03 - 2011SERVICE7612No ratings yet

- Raftar Formula Racing IIT Madras Powertrain Systems Recruitment 2017 InstructionsDocument2 pagesRaftar Formula Racing IIT Madras Powertrain Systems Recruitment 2017 InstructionsanirudhNo ratings yet

- Toyota Supra - Ignition Systems - 2JZ-GTEDocument13 pagesToyota Supra - Ignition Systems - 2JZ-GTETomislav RupčićNo ratings yet

- He Air Compressor Inventory 1905Document2 pagesHe Air Compressor Inventory 1905Zulhusni Bin Mohd RashidNo ratings yet

- Katalog XD3T 2013Document30 pagesKatalog XD3T 2013Costy DiaconuNo ratings yet

- DENSO O2 Sensor Troubleshooting Tips PDFDocument6 pagesDENSO O2 Sensor Troubleshooting Tips PDFAleksanderDestreFernandezNo ratings yet

- Air Inlet and Exhaust SystemDocument27 pagesAir Inlet and Exhaust SystemFabio MacielNo ratings yet

- Duke Engine SeminarDocument16 pagesDuke Engine Seminaranandu vinodNo ratings yet

- On An 4000 Maintenance ManualDocument158 pagesOn An 4000 Maintenance ManualMiles TetlockNo ratings yet

- BMW Inyeccion 320i-325i Motronic M31 PDFDocument2 pagesBMW Inyeccion 320i-325i Motronic M31 PDFIvoo ooNo ratings yet

- Wheel LoaderDocument127 pagesWheel LoaderDaark Kniight100% (1)

- Rivs Catalogue 2017Document153 pagesRivs Catalogue 2017ForceFieldNo ratings yet

- BMW M3 Aftersales Training InformationDocument112 pagesBMW M3 Aftersales Training InformationPedro100% (2)

- The 1953 Paxton Phoenix Brooks Stevens Designed Steam Car Fiberglass Bodied PrototypeDocument14 pagesThe 1953 Paxton Phoenix Brooks Stevens Designed Steam Car Fiberglass Bodied Prototypetzababagita936No ratings yet

- Locomotive - Cooling Water SystemDocument5 pagesLocomotive - Cooling Water SystemArpan MaheshwariNo ratings yet

- Optimization of Diesel Engine Cylinder Liner Undercut 6Document7 pagesOptimization of Diesel Engine Cylinder Liner Undercut 6International Journal of Innovative Science and Research TechnologyNo ratings yet

- Combustion EngineeringDocument2 pagesCombustion EngineeringChristian M. MortelNo ratings yet

- PWC-S02-SS10-Lubrication System - Shop Manual - 4-TEC - Version 2AA - ENDocument29 pagesPWC-S02-SS10-Lubrication System - Shop Manual - 4-TEC - Version 2AA - ENs4mtk666No ratings yet

- En-Biofuels From Coconuts-Krishna RaghavanDocument111 pagesEn-Biofuels From Coconuts-Krishna RaghavanSakoNo ratings yet

- Df40a 50a 60a PDFDocument496 pagesDf40a 50a 60a PDFpm.....100% (1)

- Tad 1240 GeDocument2 pagesTad 1240 GeFedor GrigorievNo ratings yet

- Specifications: Back2MaintableofcontentsDocument31 pagesSpecifications: Back2MaintableofcontentsRonal MoraNo ratings yet

- 8th Sem Syllabus VTU MECHANICALDocument38 pages8th Sem Syllabus VTU MECHANICALYashasNo ratings yet

- T 580rtsa55626 1 Pmrev0 161212215238Document141 pagesT 580rtsa55626 1 Pmrev0 161212215238Irwin Gonzalez100% (1)

- Carro Golf G21-A JR61Document47 pagesCarro Golf G21-A JR61coquerasNo ratings yet