Professional Documents

Culture Documents

Drillstring Design

Drillstring Design

Uploaded by

berroui0 ratings0% found this document useful (0 votes)

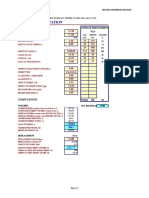

122 views1 pageThis document contains a drill string design for a well with a total depth of 16,256 feet. It provides design data such as maximum weight on bit, margin of overpull, hole deviation, and safety factors. It also contains data for the bottom hole assembly and drill pipe sections, including lengths, weights, and collapse ratings. The results show the maximum drill string length, length to reach total depth, and cumulative string weights in air and mud. Collapse verification is also provided for the first drill pipe section.

Original Description:

Original Title

DrillstringDesign.xls

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a drill string design for a well with a total depth of 16,256 feet. It provides design data such as maximum weight on bit, margin of overpull, hole deviation, and safety factors. It also contains data for the bottom hole assembly and drill pipe sections, including lengths, weights, and collapse ratings. The results show the maximum drill string length, length to reach total depth, and cumulative string weights in air and mud. Collapse verification is also provided for the first drill pipe section.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

122 views1 pageDrillstring Design

Drillstring Design

Uploaded by

berrouiThis document contains a drill string design for a well with a total depth of 16,256 feet. It provides design data such as maximum weight on bit, margin of overpull, hole deviation, and safety factors. It also contains data for the bottom hole assembly and drill pipe sections, including lengths, weights, and collapse ratings. The results show the maximum drill string length, length to reach total depth, and cumulative string weights in air and mud. Collapse verification is also provided for the first drill pipe section.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

Name of Company:

ell Name & Number:

Drilling Application

Microsoft Excel 97 Date: DRILL

DRILL STRING

STRING DESIGN

DESIGN

DESIGN DATA BHA DATA D. Collars Hevi-Wt. BUOYANCY

FACTOR

Depth For This Design, ft? = 16,256 Length, ft? = 0

Density of Fluid for This Design, ppg 8.5 Weight, ppf? = 22 0 0.870

Maximum WOB, lbs? = 2,500 DRILL PIPE DATA Drill Pipe 1 Drill Pipe 2 Drill Pipe 3

Margin of Overpull, lbs? = 100,000 Tensile Rating, lbs? 178,000 387,000 0

Hole Deviation, deg? = 44 Corrected Wt., ppf? 5.95 12.95 0

Neutral Point Design Factor, (0-1.0)? 0.85 Collapse, psi? = 7,500 NP = Neutral Point

Tensile Safety Factor, (0-1.0)? = 0.80 Length DC NP from bit Air Wt BHA

BHA RESULTS

Collapse Safety Factor? = 1.125 214' 182' 4,699

DRILL PIPE RESULTS Drill Pipe 1 Drill Pipe 2 Drill Pipe 3

Maximum Length, ft 7,282 14,339 0

Length to Run or Length to Run and Reach TD, ft 7,282 8,760 0

Cumulative String Weight in Air, lbs 48,028 233,719

Cumulative String Weight in Mud, lbs 41,790 203,362

COLLAPSE VERIFICATION Drill Pipe 1 See Tables starting in cell

Hydrostatic Pressure at Bottom of Drill Pipe 7,091 I5 for properties of Used

Drill Pipe API Premium

Maximum Length, ft 15,083 Class

THE END

Those who use the Margin of Overpull in drill string design do so on the premise the difference between the maximum normal

working load

and the load on each pipe section would be equal. There fore, when tension is applied to free the stuck pipe, each section can

tolerate the

same load in excess of it's weight and no single weaker section will limit the load which can be applied to the pipe. It is best that

the design

start with a pipe that will probably have a better than the anticipated tensile rating.

You might also like

- Intro Logic Teacher SampleDocument34 pagesIntro Logic Teacher Samplecompasscinema100% (1)

- VHDL Digital Full ADDER Logic Using NAND Gate ProgramDocument49 pagesVHDL Digital Full ADDER Logic Using NAND Gate ProgramPreeti Budhiraja100% (1)

- Hands On Training Document For XML Gateway Outbound MessageDocument44 pagesHands On Training Document For XML Gateway Outbound MessageManoj ReddyNo ratings yet

- Cleaning Effectivity of Concentric Coiled TubingDocument7 pagesCleaning Effectivity of Concentric Coiled TubingxavierNo ratings yet

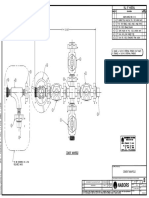

- BOP Drawings by Sections, RevDocument10 pagesBOP Drawings by Sections, RevberrouiNo ratings yet

- Well ControlDocument19 pagesWell ControlberrouiNo ratings yet

- Common Medical Terms Sorted by ArabicDocument16 pagesCommon Medical Terms Sorted by ArabicAhmed El-Saadany100% (1)

- Siemens Win TDCDocument32 pagesSiemens Win TDCBilal Aslam100% (1)

- Poultry Calculator v2.1Document17 pagesPoultry Calculator v2.1Desi Engineer100% (1)

- CementingDocument1 pageCementingmuhammad taufikNo ratings yet

- Final PDFDocument69 pagesFinal PDFbekiri abderahmaneNo ratings yet

- BOP - HandbookDocument52 pagesBOP - HandbookAlex VianaNo ratings yet

- Leak Off TestDocument8 pagesLeak Off TestRizwan FaridNo ratings yet

- SPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDDocument8 pagesSPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDehsanNo ratings yet

- Casing While Drilling PPT (2) - 1Document33 pagesCasing While Drilling PPT (2) - 1Sangam ShiralNo ratings yet

- Homco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealDocument8 pagesHomco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealHamed NazariNo ratings yet

- Wait and Weight MethodDocument2 pagesWait and Weight MethodMubin Ashraf Sheikh100% (1)

- Petroleum Production Technology Tutorial.4 Packer and Tubing Load CalculationDocument3 pagesPetroleum Production Technology Tutorial.4 Packer and Tubing Load CalculationGrant HosieNo ratings yet

- 2 - Reservoir Rock Properties Tutorial - 2Document5 pages2 - Reservoir Rock Properties Tutorial - 2علي جبار كاظم جار اللهNo ratings yet

- Plaster & Wald Consulting Corp.: Fill in Shaded AreasDocument2 pagesPlaster & Wald Consulting Corp.: Fill in Shaded AreasmarvinNo ratings yet

- DRLG 451 - Assignment #3 Well ControlDocument6 pagesDRLG 451 - Assignment #3 Well ControlnijamediaNo ratings yet

- Registered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Document1 pageRegistered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Devia Suswodijoyo100% (1)

- Well Completion and Its TypesDocument14 pagesWell Completion and Its TypesJagdish annayaNo ratings yet

- Chapter 6Document134 pagesChapter 6Deonisio Yohanes Wilfridus HornayNo ratings yet

- EDT Drilling Summary5000.1.7ReleaseNotes PDFDocument423 pagesEDT Drilling Summary5000.1.7ReleaseNotes PDFWilman Enrique Alvarez QuirozNo ratings yet

- Operating Mud WindowDocument35 pagesOperating Mud WindowEmiro OspinoNo ratings yet

- Calculations: 1.1 Hydrostatic PressureDocument10 pagesCalculations: 1.1 Hydrostatic PressureraoofNo ratings yet

- GasGun-BrochureDocument34 pagesGasGun-BrochureJorge Arraiz SanchezNo ratings yet

- Using Hi-Vis Sweep To Clean Hole While DrillingDocument5 pagesUsing Hi-Vis Sweep To Clean Hole While DrillingSAMIRNo ratings yet

- 2022.10.28 3 Phase Decanter CentrifugeDocument14 pages2022.10.28 3 Phase Decanter CentrifugeGeorgeNo ratings yet

- Right Torque at The Connection 5Document4 pagesRight Torque at The Connection 5Shafiqa AlhobaishyNo ratings yet

- TDF DISPAROS HLBDocument88 pagesTDF DISPAROS HLBDanielStiglitzNo ratings yet

- Kicks and Gas MigrationDocument42 pagesKicks and Gas MigrationJohnny Sanchez100% (1)

- Drilling LabDocument7 pagesDrilling Labahmed abdul razaqNo ratings yet

- Cement Slurry Volume (BBL) Cement Plug Height (M) - Cement Plug Height (M)Document7 pagesCement Slurry Volume (BBL) Cement Plug Height (M) - Cement Plug Height (M)Emad JamshidiNo ratings yet

- RFT Vs MDT Vs DSTDocument6 pagesRFT Vs MDT Vs DSTAbdullah IshaqNo ratings yet

- Circulation System: Fundamental PetroleumDocument11 pagesCirculation System: Fundamental PetroleumDAWOD SALiNo ratings yet

- Casing Cement DesignDocument2 pagesCasing Cement DesignMohamad TayeaNo ratings yet

- MDT Formation Pressure DataDocument6 pagesMDT Formation Pressure DataAngelo Kristoff MacarioNo ratings yet

- Formation Integrity TestDocument2 pagesFormation Integrity TestAbdul Hameed OmarNo ratings yet

- Hydril 521™Document4 pagesHydril 521™renatoNo ratings yet

- 12 - Determinations of Cut Off Vshale-Por-SwDocument26 pages12 - Determinations of Cut Off Vshale-Por-SwSyafrin Kultsum Naura AzzaNo ratings yet

- m2 TerraDocument2 pagesm2 TerrainfonexusNo ratings yet

- نسخة من 1252639293TONMILESDocument6 pagesنسخة من 1252639293TONMILESAbdul Hameed OmarNo ratings yet

- Terminology and FormlaeDocument7 pagesTerminology and FormlaenabiNo ratings yet

- Hydraulic FracturingDocument20 pagesHydraulic FracturingRossyana MuchlisNo ratings yet

- Presented By: Kaushik Phukan Jyotishman Dutta Pitagoras SoaresDocument44 pagesPresented By: Kaushik Phukan Jyotishman Dutta Pitagoras SoaresPITAGORAS MANUEL MARTINS SOARESNo ratings yet

- Annular Pressure Loss AnalysisDocument26 pagesAnnular Pressure Loss AnalysisDhruv DasNo ratings yet

- Racture Pressure: Fracture GradientsDocument13 pagesRacture Pressure: Fracture GradientsPrasanti Plaban DashNo ratings yet

- Well LoggingDocument19 pagesWell LoggingLalit PalNo ratings yet

- 24 - OnyxDocument1 page24 - OnyxAbraham RojasNo ratings yet

- XLOT Recommended PracticeDocument5 pagesXLOT Recommended PracticerashidbashirliveNo ratings yet

- Teknik Sondaj Rig#4 BrochureDocument10 pagesTeknik Sondaj Rig#4 BrochureBaris UnalNo ratings yet

- Optimization of Rotary Drilling Configuration and Techniques - Mark BakerDocument57 pagesOptimization of Rotary Drilling Configuration and Techniques - Mark BakerSusy Serrano FlawersNo ratings yet

- Section 7B Well ControlDocument12 pagesSection 7B Well ControlLazharNo ratings yet

- Drilling Bits SPE Series-ADIDocument62 pagesDrilling Bits SPE Series-ADIAlfredo TintayaNo ratings yet

- Cup Type TesterDocument1 pageCup Type TesterJohnsNo ratings yet

- Drilling WorksheetDocument61 pagesDrilling WorksheetKaton AntariksaNo ratings yet

- OsisanyaDocument66 pagesOsisanyaSyed ShaiqNo ratings yet

- 2-1. Rigs, Drilling A WellDocument50 pages2-1. Rigs, Drilling A WellscribddocomNo ratings yet

- The Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)Document45 pagesThe Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)ShourovjossNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Drill String DesignDocument1 pageDrill String DesignmalikshababNo ratings yet

- Drilling Application: Name of Company: Well Name & Number: DateDocument1 pageDrilling Application: Name of Company: Well Name & Number: Datelaxmikant1983No ratings yet

- 19 - Drill String DesignDocument1 page19 - Drill String DesignAseem PandeyNo ratings yet

- Drillstring DesignDocument1 pageDrillstring DesignMobeen MurtazaNo ratings yet

- Drillpipe 3.500 G 105 2.438 ID 15.5ppf NC38Document1 pageDrillpipe 3.500 G 105 2.438 ID 15.5ppf NC38german131418No ratings yet

- Drilling Tools - 1Document269 pagesDrilling Tools - 1berrouiNo ratings yet

- P60440-B (Cement Manifold)Document1 pageP60440-B (Cement Manifold)berrouiNo ratings yet

- Mechanical Seals - FundamentalsDocument49 pagesMechanical Seals - FundamentalsberrouiNo ratings yet

- Mathcad Drilling Cost Per Foot Analysis Worksheet-1Document2 pagesMathcad Drilling Cost Per Foot Analysis Worksheet-1berrouiNo ratings yet

- Control of Well InsuranceDocument21 pagesControl of Well InsuranceberrouiNo ratings yet

- RIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"Document16 pagesRIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"berrouiNo ratings yet

- Washout and Twist OffDocument18 pagesWashout and Twist Offberroui100% (1)

- BOP Drawings by SectionsDocument12 pagesBOP Drawings by Sectionsberroui100% (1)

- 2 5206704521257944466Document2 pages2 5206704521257944466berrouiNo ratings yet

- Manifold ValvesDocument3 pagesManifold ValvesberrouiNo ratings yet

- 2004 CatalogDocument80 pages2004 CatalogberrouiNo ratings yet

- Basic Well Control Course: Course Schedule: Training VenueDocument2 pagesBasic Well Control Course: Course Schedule: Training VenueberrouiNo ratings yet

- We Are Intechopen, The First Native Scientific Publisher of Open Access BooksDocument29 pagesWe Are Intechopen, The First Native Scientific Publisher of Open Access BooksberrouiNo ratings yet

- The Well From HellDocument56 pagesThe Well From HellberrouiNo ratings yet

- IWCF Practical Assessment StepsDocument4 pagesIWCF Practical Assessment StepsberrouiNo ratings yet

- Water,: The Mother of TeaDocument5 pagesWater,: The Mother of TeaViliam RešetkaNo ratings yet

- Tool ManagementDocument6 pagesTool ManagementRoshan RamnaniNo ratings yet

- 100 Interview Questions On Hadoop - Hadoop Online TutorialsDocument22 pages100 Interview Questions On Hadoop - Hadoop Online Tutorialsamarbhai100% (1)

- Nature of NumbersDocument57 pagesNature of NumbersArun Kumar Upadhyay100% (3)

- DDB094R2 and DDB099 Demo BoardsDocument7 pagesDDB094R2 and DDB099 Demo BoardscharlesNo ratings yet

- Direccion 1Document62 pagesDireccion 1Jesús RoseroNo ratings yet

- Drill Bits 06 1685167994Document106 pagesDrill Bits 06 1685167994Leonel PandaNo ratings yet

- Syncfusion File FormatsDocument229 pagesSyncfusion File Formatszuhair haroon KhanNo ratings yet

- Linde C-Matic AutobonicsDocument6 pagesLinde C-Matic AutobonicsJONHHY NGUYEN DANGNo ratings yet

- Embraer Spec E195 web-ENDocument2 pagesEmbraer Spec E195 web-ENIgor MedeirosNo ratings yet

- Campbell Dudek Smith 1970Document10 pagesCampbell Dudek Smith 1970richardvas12No ratings yet

- English Morphosyntax 1: Phrase, Clause, SentenceDocument30 pagesEnglish Morphosyntax 1: Phrase, Clause, SentenceMarijana RankićNo ratings yet

- CA 250 Spare Parts Catalogue Sca250std-1enDocument395 pagesCA 250 Spare Parts Catalogue Sca250std-1enMarleti Longaretti100% (2)

- KSB PUMPS Co. Ama DrainerDocument2 pagesKSB PUMPS Co. Ama DrainerHuzaifa KhanNo ratings yet

- Devinfo E6350v2Document4 pagesDevinfo E6350v2Safi Ud Din KhanNo ratings yet

- Selected Questions Revised 20200305 2HRDocument3 pagesSelected Questions Revised 20200305 2HRTimmy LeeNo ratings yet

- Microsoft Excel 2007 Chris MenardDocument20 pagesMicrosoft Excel 2007 Chris MenardNandeesh GowdaNo ratings yet

- Not Recommended For New Design: Parallel Port Button HolderDocument2 pagesNot Recommended For New Design: Parallel Port Button HolderSaasiNo ratings yet

- FriMar09050680351PM09510072007 ConceptWave Order Care OverviewDocument2 pagesFriMar09050680351PM09510072007 ConceptWave Order Care OverviewMahendra YadavNo ratings yet

- Limit State Design Approach For The Safety Evaluation of The Foundations of Concrete Gravity DamsDocument18 pagesLimit State Design Approach For The Safety Evaluation of The Foundations of Concrete Gravity Damsसूरज कुमार चौधरीNo ratings yet

- Codecademy SQLDocument11 pagesCodecademy SQLapi-362845526No ratings yet

- An Assay of SO3 Through Gravimetric Analysis in A Soluble SulfateDocument12 pagesAn Assay of SO3 Through Gravimetric Analysis in A Soluble SulfateJovel Arne Arquero YadaoNo ratings yet

- Gibson - 1954 - The Visual Perception of Objective Motion and Subjective MovementDocument11 pagesGibson - 1954 - The Visual Perception of Objective Motion and Subjective MovementcentralparkersNo ratings yet

- Test2 Schedule 2020-21 Even SemDocument1 pageTest2 Schedule 2020-21 Even SemkepoNo ratings yet

- Convergence of Random Variables - WikipediaDocument17 pagesConvergence of Random Variables - Wikipediasandeep aNo ratings yet