Professional Documents

Culture Documents

Recommended Torque Value Chart - Sanger Metal

Recommended Torque Value Chart - Sanger Metal

Uploaded by

Musab ShabbirCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lesson Plan in SwotDocument7 pagesLesson Plan in SwotFlorentina Visto100% (2)

- Galaxy at War - Star Wars SagaDocument225 pagesGalaxy at War - Star Wars SagaSebastián Rigoni100% (7)

- SDV, BDV, Esdv ChecklistDocument2 pagesSDV, BDV, Esdv ChecklistMusab Shabbir67% (3)

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 ForkliftsinghajitbNo ratings yet

- InstrManual SCO1-1Document29 pagesInstrManual SCO1-1Juan Felipe AlvarezNo ratings yet

- Expats HmoDocument2 pagesExpats HmoMusab ShabbirNo ratings yet

- Barton 202e 202n 242e J8a Tech DataDocument4 pagesBarton 202e 202n 242e J8a Tech DataMusab Shabbir100% (1)

- Gambat South Gas Processing Facility (Gpf-Iii) : Client ContractorDocument1 pageGambat South Gas Processing Facility (Gpf-Iii) : Client ContractorMusab ShabbirNo ratings yet

- Package Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Document1 pagePackage Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Musab ShabbirNo ratings yet

- E-014B Rev C2 Protection Relay CircuitDocument3 pagesE-014B Rev C2 Protection Relay CircuitMusab ShabbirNo ratings yet

- E019 MV Breaker Function TestDocument10 pagesE019 MV Breaker Function TestMusab ShabbirNo ratings yet

- Package Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Document1 pagePackage Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Musab ShabbirNo ratings yet

- Calibration StickersDocument1 pageCalibration StickersMusab ShabbirNo ratings yet

- IAL Biology SB2 Answers 7CDocument7 pagesIAL Biology SB2 Answers 7CsalmaNo ratings yet

- A Description of Dzә (Jenjo) Nouns and Noun PhrasesDocument15 pagesA Description of Dzә (Jenjo) Nouns and Noun PhrasesSamuel EkpoNo ratings yet

- Emotional IntelligenceDocument15 pagesEmotional IntelligenceMandar Raut100% (1)

- Project 4Document6 pagesProject 4Trai TranNo ratings yet

- Political FactorsDocument4 pagesPolitical FactorsThùyy DunggNo ratings yet

- The Ecology of DragonsDocument2 pagesThe Ecology of DragonsMarti LelisNo ratings yet

- Z:/windchill/codebase Z:/windchill/codebaseDocument3 pagesZ:/windchill/codebase Z:/windchill/codebaseamalNo ratings yet

- Social Anthropology Group AssignmentDocument6 pagesSocial Anthropology Group AssignmentKidus SeleshiNo ratings yet

- Rise of Health and Medical Tourism by John ConnellDocument19 pagesRise of Health and Medical Tourism by John ConnellEren Osman KurnazNo ratings yet

- ExergyDocument27 pagesExergyniralnaikNo ratings yet

- Progress TestDocument9 pagesProgress TestvhtproNo ratings yet

- BD F118S en WW - LDocument12 pagesBD F118S en WW - LyusufNo ratings yet

- FS SSIV ActuatorDocument11 pagesFS SSIV Actuatorscribd_thakurNo ratings yet

- Corona Rotate Lec MachDocument2 pagesCorona Rotate Lec Machr_chulinNo ratings yet

- Construct A Context Data-Flow Diagram, Illustrating The Customer Tracking System's ScopeDocument7 pagesConstruct A Context Data-Flow Diagram, Illustrating The Customer Tracking System's ScopeChristine Corpuz GuzmanNo ratings yet

- Assignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Document1 pageAssignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Krishna Pratap MallNo ratings yet

- Guide Card: Casa Del Niño Montessori School Guinatan, City of Ilagan, IsabelaDocument5 pagesGuide Card: Casa Del Niño Montessori School Guinatan, City of Ilagan, IsabelaManAsseh EustaceNo ratings yet

- Pola Seismic Code CommentaryDocument15 pagesPola Seismic Code Commentary_ARCUL_100% (1)

- Achievement Report PDFDocument4 pagesAchievement Report PDFAnonymous IpBC61ZNo ratings yet

- Douglas Fir Tensile Strength!Document28 pagesDouglas Fir Tensile Strength!mattyzf321No ratings yet

- Innovation in Newspaper WAN IFRA 2015Document116 pagesInnovation in Newspaper WAN IFRA 2015Asociación Nacional de la Prensa - Chile100% (1)

- Safe Work in Confined Spaces: Confined Spaces Regulations 1997 Approved Code of Practice, Regulations and GuidanceDocument44 pagesSafe Work in Confined Spaces: Confined Spaces Regulations 1997 Approved Code of Practice, Regulations and GuidanceantonpeleleNo ratings yet

- Shilpa PPT FinalDocument51 pagesShilpa PPT FinalDrakeNo ratings yet

- 9 St. Catherine Class ScheduleDocument1 page9 St. Catherine Class ScheduleAleah TungbabanNo ratings yet

- Cell Phone Dete-WPS OfficeDocument9 pagesCell Phone Dete-WPS OfficekrishnaNo ratings yet

- S5-1-2 - Typical Steel Beam DetailsDocument1 pageS5-1-2 - Typical Steel Beam DetailsTony PedaNo ratings yet

Recommended Torque Value Chart - Sanger Metal

Recommended Torque Value Chart - Sanger Metal

Uploaded by

Musab ShabbirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recommended Torque Value Chart - Sanger Metal

Recommended Torque Value Chart - Sanger Metal

Uploaded by

Musab ShabbirCopyright:

Available Formats

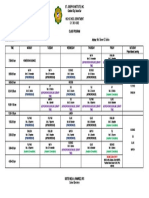

3/14/2017 RECOMMENDEDTORQUEVALUECHARTSANGERMETAL

MainPage>Products>HiForceHydraulictools>THEINFORMATIONPAGES>RECOMMENDEDTORQUEVALUECHART

RECOMMENDEDTORQUEVALUECHART

Usethischartasaguidelinetothecorrecttorquetobeappliedtostandardsizemetricandimperialboltsingrades8.8(metric)andASTMA193gradeB7(imperial)or

similar.Thetorquefiguresarecalculatedinbothmetric(Nm]andimperial(lbf.ft)valuesusingachoiceofthreecommonlyusedboltthreadlubricants.Alwaysconsider

thecoefficientoffrictionapplicableforthechosenboltlubricant.Forgrade10.9boltsadd40%andgrade12.9boltsadd70%tothefiguredetailedagainsttherelevant

8.8grademetricstudboltsize.

Rememberthesetorquevaluesareforguidancepurposesonly!Alwayschecktheequipment/boltmanufacturerfortheactualtorquerequiredandspecifiedforbolted

componentswithintheparticularequipmentdesign.

Bolt Torqueforspecifiedlubricant

NutAFsize Bolttension

dimeter Nm(lbfft.)

(seenote2) (seenote3)

(seenote1) (seenote4)

Moly Cooper MachineOil

mm ins mm ins kN (lds.force)

(friction=0.06) (friction=0.10) (friction=0.15)

16 24 60 (15,760) 102 (75) 155 (114) 184 (136)

5/8 1.1/16 67 (15,218) 99 (73) 150 (110) 179 (131)

3/4 1.1/4 96 (21,652) 175 (129) 263 (194) 314 (231)

20 30 99 (24,730) 202 (148) 305 (224) 363 (267)

7/8 1.7/16 134 (30,135) 277 (204) 423 (311) 501 (368)

24 36 159 (35,634) 346 (254) 526 (387) 621 (457)

1 1.5/8 199 (44,981) 416 (307) 631 (464) 746 (549)

27 41 210 (47,153) 505 (372) 774 (569) 913 (672)

1.1/8 1.13/16 261 (58,622) 629 (463) 965 (709) 1,081 (795)

30 46 255 (57,302) 687 (505) 1,051 (773) 1,177 (866)

1.1/4 2 329 (74,068) 872 (642) 1,348 (991) 1,505 (1,107)

33 50 319 (71,695) 928 (682) 1,428 (1,050) 1,592 (1,171)

1.3/8 2.3/16 407 (91,316) 1,169 (860) 1,820 (1,338) 2,026 (1,490)

36 55 374 (84,088) 1.198 (881) 1,837 (1,351) 2,067 (1,520)

1.1/2 2.3/8 492 (110,369) 1,526 (1,122) 2,352 (1,729) 2,654 (1,951)

39 60 451 (101,353) 1,546 (1,364) 2.384 (1,753) 2,646 (1,946)

1.5/8 2.9/16 584 (131,226) 1,949 (1,433) 2,388 (1,756) 2,650 (1,949)

42 65 517 (116,220) 1,967 (1,446) 3,037 (2,233) 3,386 (2,490)

1.3/4 2.3/4 684 (153,888) 2,444 (1,797) 3,856 (2,835) 4,301 (3,163)

45 70 606 (136,153) 2,388 (1,756) 3,690 (2,714) 4,096 (3,012)

1.7/8 2.15/16 793 (178,353) 3,021 (2,221) 4,781 (3,515) 5,317 (3.910)

48 75 680 (153,016) 2,881 (2,119) 4,444 (3,267) 4,933 (3,627)

2 3.1/8 910 (204,621) 3,676 (2,703) 5,835 (4,291) 6,482 (4,766)

52 80 819 (184,051) 3,690 (2,713) 5,718 (4,204) 6,347 (4,667)

56 85 944 (212,237) 4,578 (3,366) 7,081 (5,207) 7,860 (5,779)

2.1/4 3.1/2 1,168 (262,571) 5,250 (3,860) 8,372 (6,156) 9,297 (6,836)

60 90 1,105 (258,590) 5,707 (4,196) 8,838 (6,499) 9,810 (7,213)

2.1/2 3.7/8 1,458 (327,737) 7,223 (5,311) 11,561 (8,501) 12,827 (9,432)

64 95 1,250 (281,106) 6,835 (5,026) 10,595 (7,791) 11,760 (8,647)

68 100 1,435 (322,736) 8,328 (6,123) 12,961 (9,530) 14,387 (10,578)

2.3/4 4.1/4 1,611 (362,012) 8,735 (6,423) 14,031 (10,317) 15,519 (11,411)

72 105 1,633 (367,081) 9,820 (7,220) 15,326 (11,269) 16,935 (12,452)

3 4.5/8 1,931 (434,028) 11,343 (8,340) 18,273 (13,436) 20,226 (14,872)

80 115 1,870 (420,273) 12,264 (9,018) 19,251 (14,155) 21,272 (15,641)

3.1/4 5 2,280 (512,574) 14,451 (10,626) 23,335 (17,158) 25,796 (18,968)

3.1/2 5.3/8 2,659 (597,647) 18,081 (13,295) 29,257 (21,513) 32,311 (23,758)

90 130 2,424 (545,035) 27,654 (12,981) 27,881 (20,501) 30,809 (22,653)

3.3/4 5.3/4 3,066 (689,249) 22,252 (16,362) 36,075 (26,526) 39,834 (29,290)

100 145 3,050 (685,695) 24,410 (17,949) 38,742 (54,239) 42,810 (31,478)

4 6.1/8 3,503 (787,381) 27,024 (19,871) 43,883 (32,267) 48,444 (35,621)

4.1/4 6.1/2 3,133 (704,242) 25,605 (18,830) 41,647 (30,633) 45,956 (33,791)

4.1/2 6.7/8 4,146 (932,023) 30,423 (22,370) 49,538 (36,425) 54,641 (40,177)

Notes:1=BoltMaterialGrades8.8(Metric)andASTMA193/BS4882GradeB7(Imperial)orsimilar

2=AFsizebasedonheavyseriesnuts

3=Bolttensionequatestoaboltstressof70%oftheminimumyieldstrength

4=Torquefiguresdetailedarebasedon70%oftheminimumyieldstrengthftheminimumboltyieldstress

www.sangermetal.com Projektirealizacja,hosting:Stopklatka.pl

http://www.sangermetal.com/products/hiforce_hydraulic_tools/the_information_pages/recommended_torque_value_chart0727.html?sscid=26714&ssbid=3369 1/1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lesson Plan in SwotDocument7 pagesLesson Plan in SwotFlorentina Visto100% (2)

- Galaxy at War - Star Wars SagaDocument225 pagesGalaxy at War - Star Wars SagaSebastián Rigoni100% (7)

- SDV, BDV, Esdv ChecklistDocument2 pagesSDV, BDV, Esdv ChecklistMusab Shabbir67% (3)

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 ForkliftsinghajitbNo ratings yet

- InstrManual SCO1-1Document29 pagesInstrManual SCO1-1Juan Felipe AlvarezNo ratings yet

- Expats HmoDocument2 pagesExpats HmoMusab ShabbirNo ratings yet

- Barton 202e 202n 242e J8a Tech DataDocument4 pagesBarton 202e 202n 242e J8a Tech DataMusab Shabbir100% (1)

- Gambat South Gas Processing Facility (Gpf-Iii) : Client ContractorDocument1 pageGambat South Gas Processing Facility (Gpf-Iii) : Client ContractorMusab ShabbirNo ratings yet

- Package Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Document1 pagePackage Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Musab ShabbirNo ratings yet

- E-014B Rev C2 Protection Relay CircuitDocument3 pagesE-014B Rev C2 Protection Relay CircuitMusab ShabbirNo ratings yet

- E019 MV Breaker Function TestDocument10 pagesE019 MV Breaker Function TestMusab ShabbirNo ratings yet

- Package Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Document1 pagePackage Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Musab ShabbirNo ratings yet

- Calibration StickersDocument1 pageCalibration StickersMusab ShabbirNo ratings yet

- IAL Biology SB2 Answers 7CDocument7 pagesIAL Biology SB2 Answers 7CsalmaNo ratings yet

- A Description of Dzә (Jenjo) Nouns and Noun PhrasesDocument15 pagesA Description of Dzә (Jenjo) Nouns and Noun PhrasesSamuel EkpoNo ratings yet

- Emotional IntelligenceDocument15 pagesEmotional IntelligenceMandar Raut100% (1)

- Project 4Document6 pagesProject 4Trai TranNo ratings yet

- Political FactorsDocument4 pagesPolitical FactorsThùyy DunggNo ratings yet

- The Ecology of DragonsDocument2 pagesThe Ecology of DragonsMarti LelisNo ratings yet

- Z:/windchill/codebase Z:/windchill/codebaseDocument3 pagesZ:/windchill/codebase Z:/windchill/codebaseamalNo ratings yet

- Social Anthropology Group AssignmentDocument6 pagesSocial Anthropology Group AssignmentKidus SeleshiNo ratings yet

- Rise of Health and Medical Tourism by John ConnellDocument19 pagesRise of Health and Medical Tourism by John ConnellEren Osman KurnazNo ratings yet

- ExergyDocument27 pagesExergyniralnaikNo ratings yet

- Progress TestDocument9 pagesProgress TestvhtproNo ratings yet

- BD F118S en WW - LDocument12 pagesBD F118S en WW - LyusufNo ratings yet

- FS SSIV ActuatorDocument11 pagesFS SSIV Actuatorscribd_thakurNo ratings yet

- Corona Rotate Lec MachDocument2 pagesCorona Rotate Lec Machr_chulinNo ratings yet

- Construct A Context Data-Flow Diagram, Illustrating The Customer Tracking System's ScopeDocument7 pagesConstruct A Context Data-Flow Diagram, Illustrating The Customer Tracking System's ScopeChristine Corpuz GuzmanNo ratings yet

- Assignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Document1 pageAssignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Krishna Pratap MallNo ratings yet

- Guide Card: Casa Del Niño Montessori School Guinatan, City of Ilagan, IsabelaDocument5 pagesGuide Card: Casa Del Niño Montessori School Guinatan, City of Ilagan, IsabelaManAsseh EustaceNo ratings yet

- Pola Seismic Code CommentaryDocument15 pagesPola Seismic Code Commentary_ARCUL_100% (1)

- Achievement Report PDFDocument4 pagesAchievement Report PDFAnonymous IpBC61ZNo ratings yet

- Douglas Fir Tensile Strength!Document28 pagesDouglas Fir Tensile Strength!mattyzf321No ratings yet

- Innovation in Newspaper WAN IFRA 2015Document116 pagesInnovation in Newspaper WAN IFRA 2015Asociación Nacional de la Prensa - Chile100% (1)

- Safe Work in Confined Spaces: Confined Spaces Regulations 1997 Approved Code of Practice, Regulations and GuidanceDocument44 pagesSafe Work in Confined Spaces: Confined Spaces Regulations 1997 Approved Code of Practice, Regulations and GuidanceantonpeleleNo ratings yet

- Shilpa PPT FinalDocument51 pagesShilpa PPT FinalDrakeNo ratings yet

- 9 St. Catherine Class ScheduleDocument1 page9 St. Catherine Class ScheduleAleah TungbabanNo ratings yet

- Cell Phone Dete-WPS OfficeDocument9 pagesCell Phone Dete-WPS OfficekrishnaNo ratings yet

- S5-1-2 - Typical Steel Beam DetailsDocument1 pageS5-1-2 - Typical Steel Beam DetailsTony PedaNo ratings yet