Professional Documents

Culture Documents

Basic Rigging & Slinging Course PDF

Basic Rigging & Slinging Course PDF

Uploaded by

Brunoro Dantas60%(5)60% found this document useful (5 votes)

3K views82 pagesOriginal Title

basic rigging & slinging course.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

60%(5)60% found this document useful (5 votes)

3K views82 pagesBasic Rigging & Slinging Course PDF

Basic Rigging & Slinging Course PDF

Uploaded by

Brunoro DantasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 82

BASIC |

_ RIGGING |

| & |

_SLINGING |

_ COURSE

|

TUV

“SUDDEUTSCHLAND

1. LEGISLATION

Wherever you are working, you will find there is legislation regarding Health and Safety which

Puts the onus on the employer to provide a safe place of work. This duty includes the provision of

all Recessary instruction, training and supervision. Equally important, you will Find thet as an

employee, you will also have a responsibilty to take reasonable care for your own health and

safely and that of other people who may be affected by your conduct at work. "This includes

complying with any safety requirements imposed by either your employer or the owner/operator of

the work site.

Should you be operating a crane, local regulations will dictate that Crane Operators shoud have

received adequate training or al least have the relevant practical experience to enable them to

demonstrate their competence.

If you are involved with using lifting gear and equipment, you will be aware that as part of the

certfication criteria, it must be inspected at regular intervals. Local standards will indicate a

maximum time span between these examinations but, outwith this, alitems of liting gear must be

sxamined by VOU prior to each use to ensure so far as is practical they are in a good state of

repair and fit for purpose to carry out the intended task safely.

{you are dealing with dangerous goods, there are Intemational regulations describing how they

should be segregated if necessary, packaged safely and marked up with hazard labels as

appropriate.

2. RESPONSIBILITIES OF RIGGER

To Qualify 2s a Stinger/Banskman, the person should:

¥ Be medically anc physically it (have a good eye sight, hearing)

Y _ Have been trained in the safe use of iting equipment.

Abily to select and use the lifting tackles as per load configuration,

To be able to provide necessary signals for crane operators as per standard signals

attached in this training material.

To locate load in away, to ensure safety of load and working personnel

To understand his companies’ rules and regulation, colour coding and certification

of lifting tackle. :

v

To be able to communicate with radio where the crane operator is out of image.

STEEL WIRE ROPE SLING

What is a Wire Rope?

A wire rope consists of steel wires in groups of between 6 and 60 or more twisted together into

strands. The strands (numbering between 3 to 8 in simple constructions) are in tum twisted

together around the core.

The steel wire is drawn from rod of diameters between Core 6

and 10mm to wire of the exact diameter found to give the best

performance in the rope to be made. Most specifications for

wire ropes stipulate outside diameter tolerance of +4% and -

0%, so with upwards of 100 wires per rope the tolerance on

each wire is in effect very small

As the wire diameter is reduced by drawing through

progressively smaller tungsten carbide dies, the tensile

strength is raised by cold working, so that by varying the

number and sizes of dies, a wire can be produced with the

correct diameter, with a tensile strength ranging from

1420N/sq mm to upwards of 2150N/sq mm, and with the

required characteristics of hardness and flexibility. The wires

can be galvanized or left ungalvanized (or bright).

This account is, of course, very much simplified. In

practice, many variables are introduced and the

number, size and arrangement of wires in the strand

and strands in the rope (ie. the “construction” of the

rope) carries according to the rope specification to give

varying degrees of strength, flexibility, resistance to

abrasion, crushing and shock loading. Some further

explanation of these factors will be found in the

following pages.

Every time a wire rope bends each wire moves slightly in relation to its neighbours, therefore the

sizes and dispositions of the wires are very important to the performance and life of the rope. One

distinction can clearly be drawn here between two different types of strand construction, Equal

Lay and Cross Lay.

TUV

‘SUDDEUTSCHLAND

Equal Lay - all layers of wire are in spirals of the same pitch, so that each wire

Supports or is supported by its length. These constructions are more compact,

therefore have a higher density of steel than a cross lay, so the strand is nol easily

crushed out of shape and the wires do not have points of relatively high contact

Pressure, Examples of equal lay ropes are 6 x 19 Sale, 6 x 19 Filler and 6 x 36

Warrington Seale, which are shown in cross sections below:

6x36 Wartington

Seale Construction

$x19 Ordinary, 8x 19 Ordinary, 6 x.19. Seale IWRC 8 x 19 Ordinary,

Fibre Core Fibre Core Fibre Core

er netennteneensnnnnee Ne COPE

‘Warrington Construction Filler Construction

6x LD Werrington, 8x19 Warrington, 6 x 21 Filler, Fibre. Sx 19 Filler, IWRC

Fibre Core Fibre Core. Core

ret OE

Basic 19 Wire Strand-Constructian

19 Wire Warring Strand

6 x 19 Seale IWRC Details of 19 Wire $x19 Warrington, Details af 19 Wire

Rope Seale Strand Fibre Core Rope Warrington Strand

25 Wire Filler Strand

6x25 Filler, IWRC Rope Details of 25 Wire Filler Strand _

“SiopEvTscHLAND

| “OBS Ct

| GRID@PA)FC © 6x19 (0N) «6x 19 (ANGHEHN) -6 wIOACIOVEHER/I)

| (6x 198) IWRC. FC (6x I6F) TWRE

6x 2610/5 & S/5/1) 6 N26 (1O/S and 6 x31 (12/6+6/G/N) 6 x 31 (12/6+6/6/1)

FC x 26 WS) 5/5/1) TWRCE FC (6 x 16WS) IWRC

(8) 6x19 group

6 «36 (14/7 eund 1/71) FC

(6.x 36 WS

6x41 (1G and 8/81)" 6 x 46 Warrington Seale. 6x49 Warrington Seale

IWRC . (16/8 and 8/8/8/1) FC {16/8 and 8/8/8/1) IWRC.

() 6x36 gréup-

6x 19 and 6 x 36 construction groups

SOBDEUTSCHLAND

‘one with F.C.

4 rope with an I.W.R.C. is also superior in very het working conkitions, such as steel making plant

where the F.G. will soon dry out and cease to support the outer strands, In general a rope with

an IW.R.C. has a breaking strength 8% higher than a similar rope with F.C.

Wire rope lay

This term is applied in various ways:

Te describe the direction of rotation of wires and strands:

'n an Ordinary Lay (Regular Lay) rope, the wires are laid in one direction and the strands in the

other, so that the visible wires appear to run parallel, to the rope axis. In this construction a rope

under tension may rotate as the strands ‘unwind’, but at the same time the wires is the strands

are being twisted more tightly, and a balance is achieved between the two opposing rotational

forces. On reskaxation of the tension on the rope it wil return toils normal state. ‘This construction

has more resistance than Langs Lay to drum crushing when multi-layered.

ina Langs Lay rope, the wires and strands are laid in the same direction, so that the visible wires

fun at an angle of about 30° to the rope axis. In this way a longer length of each wire is presented

1 cana Surface to spread abrasion more evenly, so this construction offers a high resistance

iP Sbtasion, e.g. in earthmoving equipment or conveyor systems. Langs Lay rope does not have

ins same built-in resistance to unlaying and therefore SHOULD NOT BE USED WHERE one

END OF THE ROPE IS FREE TO ROTATE.

the direction or lay or rotation of the strands is normally right hand, but some machinery needs

(et hand lay ropes to achieve a balance of torques. A rope may be desetibed ae Right Hand

Ordinary Lay, Right Hand Lang's Lay, Left Hand ordinary Lay or Left Hand Lang's Lay (see

illustrations).

‘Right Hand Lay Rope

TOV

‘SODDEUTSCHLAND

Right Lay REGULAR LAY ». Left. Lay REGULAR LAY

Lay length is the length of the rope in which one strand makes one helical revolution around the

core. This may be expressed as X mm (or inches) or as Xx rope diameter. A short lay rope has

more elasticity than a long lay rope, and the lay length is dictated by the application for which the

rope is intencled

How the anéi-Rotetional Characteristic is Built into a Non-Rotating Rope

‘When the outer and inner The tendency of ower

jayers aré laid in oppasite layer to xotate to the

directions. right is balsneed by

inner layer tending to

sotate

‘When ends are not properly seized the care can slip and either

4 on the other end or through the outer layer

TUV

“SUDDEUTSCHLAND

tis possible for core slippage.to-obenr ifthe.

thinible is too small or ifthe rope end-is not tightly seized

ing

To protect the rope from corrosion, a coating of zinc can be applied to the individual

wires. Bridon Ropes apply this zinc coating by the Hot Dip process where the wires are

passed through a bath of molten zinc.

Two levels of coating are available:

‘2 type" where the wires are galvanized and the wire is then drawn to its finished size,

achieving a higher tensile but lower zinc coal weight.

“A Wype" where the wires are galvanized after final wire drawing. This achieves a thicker coating

of zinc but with some loss in the physical properties of the wire.

Engineering ropes normally have the drawn galvanized *Z type" coating,

Strength and Flexibility

Strength depends on rope size, construction and wire tensile strength. The standard

‘enslle strength for engineering wire rope is 1770N/sq mm but wire ropes are made in a

Tange of tensiles from 1420N/sq mm to 2150N/sq mm.

Fibre cores (F.C.) can be of natural fibre (Sisal, Manila or Jute) or of man-made fibre

(polypropylene) and may initially give an impression of greater flexibility but can be a

problem in difficult service conditions due to core deterioration.

SODDEUISCHLAND

Independent Wire Rope Cores (|.W.R.C.) give better support to the load bearing outer

strands of the rope leading to better fatigue life. The resistance to crushing of an

I.W.R.C. means that it retains its lubricant better than a fibre core.

The greater the number of wires in the outer strands, the greater the flexibility. However,

corrosion will affect small wires more quickly than larger wires. ts effect can be reduced

by galvanizing.

The fewer the number of wires in the outer strands, the better the resistance to abrasion

and corrosion but flexibility is reduced, A Lang's Lay construction in six and eight strand

topes can be used to further improve wear characteristics but can only be used where

both ends of the rope are fixed or the load is guided (i.e. not free. to rotate).

Multi-strand ropes are more liable to intemal deterioration and are poor in bending

fatigue, but are essential in some applications where limited rotation is needed. Whereas

six strand rope has 6% of its breaking load in the core, a multi-strand has 50% of its

breaking load in the core making internal inspection essential.

Dyform® or compacted ropes have strands with a smooth appearance. The compacted

strand increases the breaking load due to the greater volume of steel in the cross section

A Dyform® rope can replace a conventional rope but not vice versa.

Important Note

tis a legal requirement to be in possession of a test certificate before ropes are put into

service. This will also identify the rope state the breaking and safe working loads and

facilitate re-orclering

‘SUDDEUTSCHLAND

WIRE ROPE MANUFACTURING

Performance

14 preformed rope is unlaid (i.e. the strands and wires are separated) it will be seen that the

slements all have their set helical forms and the rope can be easily laid up again. A preformed

rope has the following advantages:

1) The rope is dead and is therefore more easily handled

2) When the rope is cut, the cut ends do not automatically unlay (Le. spring open)

The process of preforming is carried out by a preforming head, through which the strands pase

immediately before the closing head, in which they are formed into the wire rope.

A Preforming Head

Cores

The central core of a steel wire rope maintains the circular section of the rope by supporting the

Strands around it. The core may be of two classes:

Fibre Cores - composed of vegetable fibre (e.g. Manilla, Jule or more commonly Sisal) or man-

made fibre (such.as Polypropylene), which has the advantage of being more resistant to

deterioration. Fibre cores are often referred to as F.C, or F.F.C. and are impregnated with a

suitable preservative lubricant.

Steel Cores ~ may be a Wire Strand Core - W.S.C, (usually in ropes of a diameter less than 8mm)

oF @ complete rope in itself, an independent Wis Rope Core - LWIR.C. (usually of 7 x 7

construction - 6 strands of 7 wires around 1 strand of 7 wires).

ACCIDENTAL DAMAGE

Any accident to your rope, for instance jumping a sheave; or being struck. by falling rock

or other objects being run over, or any of the many things that may happen to a ropecalls

for particularly careful inspection and constant checking, as it is impossible to determine

the strength remaining in the rope, If there is possibility of personal Injury, it is good

practice to replace the rope immediately

if you have any question at any time regarding your wire rope installation, do not hesitate

to call your Yellow Strand distributor. He will be glad to inspect your ropes and your

equipment, make recommendations as to grade and construction of rope and give you

suggestions for prolonging rope life.

HOW TO MEASURE WIRE ROPE

CORRECT INCORRECT

METHOD METHOD

‘diy Jou |W pue pssuejeg s| peoj

8uy Jey} yOsys UeYy ‘punoyzH ay} Jo sea/o

ysnf peo) ayy Bury) Aynops Aq apew

8q Pinoys s}yij fel4} UeUy pexysew Ajueajo

jou aie peo] oy} jo sjurod BuiBuyjs ey} yy

‘aN

GVOT HL JO FONV TIVE AO INIOd SHL

yo

LHOISM

SLIA@ GVOT AHL 40 FYLNZD FAL

28] SUUa}

ojduis ul peo e Jo AAeID Jo a1jU9D su

éqgvol Vv 40

ALIAVES JO SHIN3S SHL SI LVHM

"WUO paysew suey ¢

8S0y} SAey Op Jey} SusEH! 404 J] aBUEYD

11 3sn. LON Oa

V UO pexysew

SW € 8S9y3 BAeY JOU Saop } 4]

SPog snGJoOD "¢

‘ON UOHeIARUEP] “Z

“TMS “L

UO PSyseu

suie} € Sey pue UOBIPUOD poos ul

S! juewdinbe Guns anoA pepinoid

Pen eq Ajeyes ues jeyy peoj

ey) SI! (TMS) peoy Bupopy ayes

é( TM's) avoi ONIMYOM S34VS 4O ONINVSIN SHL SI LYHM

peouejeg sj peoy oy

oe

HET IER A

ew

uogisod siu3

oyu) Buys 1131

“peourjeq

you Si peo] ayL

1

cle Buowm

Zo | ‘pasuejequy,

*B'9 J8A0 pa quay \I/ | ‘papuedsns

TOV

SODDEUTSCHLAND

WIRE ROPE TOLERANCES

DIAMETER OF WIRE ROPE

The components of a wire rope each has a small but definite size tolerance. Therefore, the

fope itself must have a diameter at least equal to the nominal, or catalog, size never smaller,

Standard ropes may exceed the nominal-diameter by the amounts shown below.

Nominal Diameter of rope In Undorsize Inches ‘Oversize inches

Inches

f 0-% oO 41132 ut

1 aie-1 18 oO 3/64

1 3ne—1% 0 16

1 o6- 2% oO 3/32

2 8/16 and larger 0 18

These tolerances do not apply to elevator ropes. Consult our Engineering Dept. on

elevator applications,

> Establishing wire rope safe working load.

> The Safe Working Load of wire rope can be calculated by the following formula

SWL = M.BLL.

SF.

Where :

M.B.L. = Wire Rope Minimum Braking Load

S.F. = Safety Factor

S.W.L. = Wire rope

Remarks: The Safety Factor for the wire rope is 5:1.

Example:

> Asample of 1" dia steel wire rope has @ M.B.L. of 40Tonnes. Determine the S.W.L,

Answer: Since the S.F. for the wire rope is 5:1 then

SWL= _40_ = 8Tons

5

SWL= 8Tons

> The wire S.W.L. can be achieved using common table produced by the wire rope

mig. a sample of such table is shown hereunder:

‘SODDEUTSCHLAND

TWO HOOK TURNING

Two-hook turning is used for turning loads freely in air while supported. Turn loads in air

only when absolutely necessary, It is the most difficult type of rigging operation and

should be done only after careful preparation and caution have been executed. One sling

on the Main hoist supports the load and acts as the pivot around which the turn is made.

A second sling on an auxiliary hook is employed to provide control, Note: It is necessary

to disconnect the Auxiliary sling prior to turning in air, and then to reconnect after the tum

has been made.

Aux MAIN AUX MAIN AUX RIK

[|

s foal F |e

CONDITIONS TO CONSIDER FOR PROPER RIGGING

ABRASION - A basket hitch made with a choker sling having both loops in one crane

hook should not be used for tuming loads because of the inevitable movement of the load

against a small portion of the sling. This movement causes abrasion of the individual

wires in the rope and possible actual failure of the sling. Where two crane hooks are

available, @ pair of two-legger bridle slings can be used — one placed to unwrap while the

opposite sling wraps around the load. Slings should not be attached to the ends of a

rolling load if either slippage or rubbing of the load against the sling will occur.

DESIGN FACTOR = FIVETO ONE

DESIGN FAGTOR = This isthe number of times the récommended lifting” capacity is

multiplied to equal the ultimate or breaking strength of the sling. Wire rope slings are

recommended for use at a design factor of five or more. This design factor is designated

to take care of any overload that cannot be foresees, such as shock loads, incorrect use

or other unusual conditions, Catalog ratings are based on new slings. Load ratings on

wom slings should be reduced. Never use a sling with a design factor less than three.

“SODDEUTECHTAND

SLING ANGLES — Sling angles are

shown in different ways in various

catalogs. Regardless of how the sling

angle is stated, or the method used to

figure the stress in a sling leg, the load

rating should be the same.

The following description applies to the

included angle measured between ‘one sling

and a plumb line suspended from the hook

A lot of misunderstanding results from the change in carrying capacity of a sling when the

leg angle is changed. Actually, there is no change in the tensile strength of the sling leg,

[that happens: is that the operator is picking the load straight up or vertically, but the sling

{eg is pulling at a disadvantage. For quick figuring in the shop, a 30° included leg angle

causes a loss in lifting capacity of 15%., . .45°leg angle — 30% .... 60° leg angle —50%

It's not 100% accurate, but easy to remember and slightly on the safe side.

SLING ANGLES

I's always good practice, within limits, to keep the sling leg angle as small as possible.

However, the length and width of the load, the sing leg length or the available headroom

sometimes determine the sling leg angle.

ie itt ett

‘SUODEUTECHLAND

WIRE ROPE SLING CAPACITY CHART

BS i290

DIA

1Omm(3/

13mm(1/2") 2.2T 3.0T 22T 46T 4.6T | 3.3T

16mm(5/8") 33T 4.6T aat | 6.9T 6.9T 4.6T

19mm(3/4") 4.7T 6.5T 4.1T 9.8T 98T 7.0T

22mm(7/8") 6.3T 8.8T 63T 13.2T 13.2T 94T |

25mm(1") 8.8T 12.3T 88T 18.4T 18.4T 13.37

28mm(1.V/8") | 10.SF-]. 14.77 | 10.57

32mm(1.14")

3Smm(1.3/8"")e

38mm(1.1/2").

44mm(1.3/4")

TOV

ete

It is neither economical nor good practice to exceed a 60° sling leg angle. Angles

greater than 60° not only build up tension in the sling legs out of all proportion to

the weight of the load; they also create a much greater “in-pull’ on the ends of the

load. This Produces eccentrically loaded column effect. Long, slender objects

have a tendency to buckle.

Inclided angles greater than 60° indicate some thought should be given to the use of a lifting

beam in connection with the lift.

Lifting capacities on slings are misleading unless the sling angle is stated. A sling that will handle

10 Tons al 15° ircluded leg angle will only handle 5 Tons if the angle is increased to 60°.

Sling Angle Stresses per

with Vertical | Sling Leg

Per-i.000 Lbs

Tetal-Load

> Types of wire rope sling

> The wire rope sling has been manufactured in a variety of shapes to suit different load

configuration lift @ single, two leg, three leg and four leg wire rope sling is shown in here

under:

© Basket hitch

Diar,90° RieLA

(@ Basket hitch,

araltel 142.0

(1) Straight putt

Asi

@) Choke bitch

Meg.

(5) Two-leggcil sting’

MeL

©) Four-legied! sling

M20

(a) Single strop

(Q) Straight pull

Ma2.0

(Q) Choke hitch

DM8.6

(3) Basket bitch

Max$0° Ma2.8

(4) Basket hte

parallel M=0

(b) Endless sting

> As shown in the above sketch the sling angle and configuration has direct affect

on the sling S.W.L. The factor M in each configuration can be applied in the

formula to determine the exact S.W.L. of sling during the lifting operation.

TOV

“SODDEUTSCHLAND

> The following are other types of common used wire rope slings.

Effective length

TOV

‘SODDEUTSCHLAND

Figure 1. BASKET HITCH

NOTE 1: The total load that may be lifted when the included angle does not exceed 90° is

1.4 x that marked on the sling.

NOTE 2: A basket hitch should only be used when the sling is passed through part of the

load and the load is balanced on the sling.

‘SODDEUTSCHLAND

Figure 2. SIMPLE CHOKE HITCH

NOTE: The total load that may be lifted is Qu2 x ka FRIED of WE Stns.

‘SUDDEUTECHLAND

Figure 3. DOUBLE AND CHOKED

NOTE: The total load that may be lifted {+(o x that marked on the sling.

“SODDEUTSCHANO

Figure 4. CHOKE HITCH DOUBLE WRAPPED eee

NOTE: The total load that may be lifted is O, 2X MAGQLGO ead HE SLinle.

“Boj ey} 0} a]qeesesy pue Guys yey} 0} enbjun Buleq

yequinu Buys ayy yp sGupyew uoReoynuep! enbiun

seunjoejnueu 34} esN JO sBuryew uor

anblun umo sj} ajeasa yeys jusujedeq “ypeq

“sBurs y9e} 0} Asee 3! Buyyeu osojosoy} pue

Ho pajyepdn ue Huyureyuyew ul Siesn jsisse siuL

ubOO

Now, se pedweys aq pinos yun euel9 Asouyoy ‘ot

-soyoadsu| Bug edoy asi payeubisep sjyuowyedeg

4easp ayy Aq ajnuey sBuys yj} uo pedweys A\se9|9

JO payweA eg pinoys JequNN uoReoyRUEpP! eYL

dweis IMS

‘ON ‘Gl

"ASNLON OG “T'M'S ON

“younjoeynueul Aq padwieys si “TM's Gulls

ONS AdOY SeIM

(o# Buimeip ejdwexe

38s) (Guipues}siepup) “spueng ued (g)

“(z# Buimeup ajduiexe ses) ‘BuiBeopuig (7)

‘(L# Bummeup ajdiuexe aas) ‘sau paxuny (¢)

“(1 Bumesp ejdwexe eas) ‘seu peysnig (Z)

*0]AIS WOdJ PAAOWAal

eq LSNIN Buijs ayy ‘asn Jo uosedsul

JO eWR 72 SjqISIA JoU-sI “TMS 8 Hi

“HOLOSdSNI GSZINDO93Y

Vv A@ GSLITIdNOD SI SIHL ‘SONIIS OLNO

“TMS G3LVe SHL divLs LNAIWLYVdad

YASNYANMO SHL TIVHS SWIL ON LY

uoneoyloeds sjaunjoesnuew Jed

se Buljs uo paysew Aueajo Ty's pewey (1)

“SMOTIOS SV G3LSIT SNOLLIGNOD

B1avld390VNN =SHL 3O ANY UOd

G3LOSdSNI 3A TIWHS SONIIS 3d0uY SelM

‘ans

“BIRDCAGING IN WIRE ROPES”

Example Drawing #2

|

iy

i

ia

Ha

\

\

“298}INS aJ1M ay} UO UOHIaS

JBAIIS 40 Aus & 105 YOO7

(4W3M BAISSIOXS) LV Ts

*pouinos0

>1UP{ 94) eroym eose

oun uy peusyEY

°g Wom ‘peysnio

eae sodou asoy gSyNm

L# Bumeig ajdwiexy

(sBuys

Jo esnsiw Aq pesnes Ajyensn si si)

«SAd0¥Y GIN 2 GALLId

“‘GANSLLV14 ‘NYOM ‘GSHSNYO,

SOVINVG 3d0u YIM

"SallM UByOug [esAal UAaYo |jIM ado4 e Hulxe]4

+ = =

jedosduuy Aq

pesneo yupj =

ayesapoul sapun uado uy

pue ezis sadoid

| ayy jo seneaus sen0

| Bulpueg payeaday

daye onBges jo ynsea

Se SouM UaxONg

Bulpuess yoy

“Bulpeo] yooys Woy Buyynses QYyMI JO UoIsnjolg

“Bulpeo] yD0ys Jo yNseu e se UOISNAO1d B109

og Buimwig ejdwex3

«ONIGNVYLS HOIH 2 NOISNYLOYd 3YOD AdOw SIM.

‘0s’

nT

adoy pafewepuy jeu0N

SESE EEE EEE Ge Ee eae ee

aSadOud JuIM N3MON"” 2 GSHOLaeLs:,

“sjeuBis uejnGe. asn

way ‘peay uo ys dey

“LSIOH NIVW 3SN

*SBjD41D [ERUOZLOY

{Jews uy puey aaow ‘umop

Bunuiod saGuyss0 ‘paemumop

“9/24}9 Je}UOZ}JoOY jjews uy puey

eaow ‘dn Sunuiod sabuyasoy

“JEONNOA WIeS40} UIA “LSTOH

Amo

puey

(siduses se umoys

IS 3510} “JeuBIs UoROW |4yy Bue

JO yu0dj3 u! ssojuoRow puey

4eyjo eoejd pue jeuGjs woo Aue

eni6

03 pueYy UO BSN “AIMOTS 3AOW

“Apog $0 quo. u! spuey

dsei9 "SNIHLAYZAR 50a

“Ajpequozisoy

403 pue ypeq

we 2Aow! ‘umop ujed

‘popueixe wy ‘dois.

"AR ad BNA oN

- Rie

MG. Kt

(Ajuo sauess 42;mes> 405) Apog so

pasor pue 346i Aypidea uous ut Ajjeonj49A payero. 354 49430 JO Jonesy Jo UOROU! SulYsNd BUPjeUL

SUE 2405 BAOW /UMOP YOHJOU! JeIND4ID Aq peze21pu!l UORIEP — ‘pasjes AMYBI[S pue usdo puey

sued ‘papus}xe Su sul 921]. aYIsOddo janes} ‘Js1y poster ‘paensos papucyxo uuy *(syeaL,

= Aq poesipu apis uo es} 34} P07 YjOg euedD JeIMe4D) “TEAVEL

*(Qj9e4, BU SURAD 421;MeID) “TEAVEL

Tai

bibl etch betas uonpesp ul uoRoW Bulysnd

eee Apog jo juo4s ur SIsly YO" ayew ‘pasies ApyBIs

¢ @ Buy HL. +(suroog Buidoasaja4) pue uédo puey ‘paemuoy

wood Lovulad "WOO GN3LXa pepuspe way “GAVEL

SNOILVYAdO ANVYO ONITIOULNOS YOs STVNOIS GNVH

“peaisep Ss} JuaWoAOW

“peuisap si juaueaow

ee peo} se Guoj se yno pue

pep] se Guo] se Jno pue ws

susbuy xey ‘umop Buuiod hats suGuy xey ‘dn Gunujod “wooq

quinuy pepueyxe ue Ya quant "Pepuerxe Wie WM 40 Buims yo uoRaa4ip

*dvO13HL 3SIvu “GVO SHL YaMO1 uy se6uy ym quiod

NV WOOS 3HL w3M0T 3HL ONW WOOd 3HL 3SIVY ‘pepuayxe way “DNIMS

“paemumop BuRuiod ‘paemdn Bunuiod quinyy “sjeuBis sejn5es

quinuy ‘pasoj suBuyy ‘pesoj> susBuyy ‘popuszxe SN way fpueY au UM Moga deL

papusy~e Way "WOOs Y3MO7T wy ‘WOOd 3STVa “(CASIO AMVITIXNV) SNTIdIHM JsN

Ey

ANTE 'SNTUNUad ao ON A iM os rn nae

* SYNTHETIC WEB SLINGS

Web sling are available in two materials — nylon and polyester (Dacron), Nylon is

resistant to many alkalis whereas polyester is resistant to many acids. Consult the

manufacturer before using web

slings in a Chemical environment. Nylon slings are more common but polyester slings are

often recommended where headroom is limited since they stretch only half as much as

nylon slings.

Synthetic web slings offer a number of advantages for rigging purposes

> Their relative softness and width create much less tendency to mar or scratch

finely machined, highly polished or painted surfaces and less tendency to crush

fragile objects than fibre rope, wire rope or chain, slings.

SYNTHETIC WEB SLINGS DO NOT DAMAGE

OR CRUSH LOADS

> Because of their flexibility, they tend to mold themselves to the shape of the load.

WEB SLINGS MOLD THEMSELVES TO THE LOAD

Synthetic web slings are not affected by moisture and certain chemicals.

They do not rust and thus will not stait omamental précast concrete or stone.

They are non-sparking and can be used safety in explosive atmospheres.

They minimize twisting and spinning during lifting.

Their light weight permits ease’ of rigging, their sbftness precludes hand cuts, and

the: danger of harm from a frée-swinging sling is minimal. =

They are. elastic and stretch under load more tharv-either wire rope or chain and

can thus absorb heavy shocks and cushion loads, in cases where sling stretching

must be minimized, a sling of larger load capacity or a polyester sling should be

used,

» Synthetic web slings are available in a number of configurations useful in

construction.

vyevvy

v

Sato bloging 2 Saphir Course :

{ TYPE OF WEB SLINGS

I

Choker End Fittings

Telangle End Fittings

METAL END FITTINGS

Sefataeing 8 Stagine Coursa

Page 24 of 49

TOV

“SuDDENTECHLAND

Endless or Grommet Slings -both ends of one piece of webbing lapped and

sewn to forms a continuous piece. They can be used as vertical hitches,

bridle hitches, in choker arrangements or as basket hitches. Because load

contact points can be shifted with every lift, wear is evenly distributed and

sling life extended.

ENDLESS OR GROMMET SLINGS

Standard Eye-and-Eye—webbing assembled and sewn to form a flat body sling with an

eye at each end and eye openings in the same plane as the sling body. The eyes may be

either full web width or tapered by being folded and sewn narrower than the webbing

width

STANDARD EYE-AND-EYE SLINGS

Twisted Eye—an eye-and-eye with twisted terminations at both ends. The eye openings

are at 9090 the plane of the sling body. This configuration is available with either full:

width or tapered eyes,

|

|

|

|

SeroMiguing 8 Staghag bourse Page 25 of 49

Seto Gleging.s Staing Conse

‘SIDSEUTSCHLAD

The rated capacity of synthetic web slings is based on the tensile strength

of the webbing, a factor of safety of #7and the fabrication efficiency.

Fabrication efficiency accounts for loss of strength, in the webbing after it is

stitched and otherwise modified during’ manufacture. Fabrication

efficiency is typically 80 to 85% for single-pBy slings but will be lower for

multi-ply slings and very wide slings.

Although manufacturers provide, tables for bridle and. basket configurations, these should

be used with extreme caution. At low sling angles on edge of the web will be overloaded

and the sling will tend to tear.

Ifthe sling angle is too low

the web can tear here

EFFECT OF LOW SLING ANGLE ON WEBBING |

Slings with aluminum fittings should never be used in acid or alkali environments. Nylon

and polyester slings must not be used at temperatures above 194°F (90°C)

Inspect synthetic web slings regularly. Damage is usually easy to detect. Cuts, holes,

tears, frays, broken stitching, worn eyes and wom or distorted fittings, and bums from

acid, caustics or heat are immediately evident and signal the rieed for replacement. Do

not attempt repairs yourself

Marking (Sting Identification). Each sling shall be permanently marked to show:

(a) Name or trademark of manufacturer

(b) Manufacturer's code or stock number

(c) Rated loads (rated capacities) for the types of hitches used

(d) Type of synthetic web material

i

i

|

|

|

|

Page 27 of 49

hoisting rough-surfaced loads.

stretch in the same ratio as the sling body.

REGU LAR—This is Ce npe that is cen on

to grvs fixed procccnon at expected wear

pois. They. can be senn anywhere on the

slime ot any leteth ox one tide or on boll

sides

SUDBEUTSCHTANG

Despite their inherent toughness, synthetic web slings can be cut by

repeated use around sharp-cornered objects and abraded by continually

Protective devices offered by most sling manufacturers can minimize these effects.

> Buffer strips of leather, nylon, or other materials sewn on the body of the sling protect

against wear Leather pads are most resistant to wear and cutting, but are subject to

weathering and differ from these of webbing. On the other hand, nylon web wear

pads are more resistant to weathering, oils, grease and, most alkalis. Moreover they

> Edge guards consist of strips of webbing or leather sewn around each edge of the

sling. This is necessary whenever sling edges are subject to damage.

> Sleeve or sliding tube wear pads are available for slings used to handle material with

sharp edges. The pads are positioned on the sling where required, will not move

when the sling stretches, adjust to the load and cover both sides of the sling.

EDGEGUARD—A sity of webbing or

leather is sewn around each edge of the

sing This necessary for ceetsin

applicatrons where the sling edues ore

suiect ta danae

SLEEVE-Somietimes called sliding sleeve of tube pe wear

fds, these pads are ideal for handling merial with sharp

edges bscause the sleeve doesn’t move when the sling stetchics

‘nid adjusts to the load, Sleeves cover both sides ofthe sling id

‘an be shifted to pains of expected ssinruin wear.

WEB SLING

>! Reinforcing strips: sewn intorthe:sling eyes double or-triple. the eye thickness and

greatly increase sling life and saféty.

> Coatings provide added resistance to abrasion and chemicals as well as @ better grip

on slippery loads, Coatings can be brightly coloured for safety or load rating.

> Cotton-faced nylon webbing affords protection for hoisting granite and other rough

surfaceci material.

Sata going 8 Stagingr Bourse

|

I

‘S@oDEUTECH AND

EXAMINATION AND REMOVAL CRITERIA

A sling shall be removed from service if damage such as the following is visible

and shall only be returned to service when approved by a designated person.

(a) acid or caustic bums

(b) _renelting or charring of any part ofthe sling

(c)_ Faoles, tears, cuts, orsnags +

(4) tproken or wom stitching in load bearing splices

(€) excessive abrasive wear

() Knots in any part of the sting

(9) excessive pitting or corrosion, or cracked, distorled, or broken fittings

(h) other visible damage that causes doubt as to the strength of the sling

Sttohicaty 8 Staving Gomes Page 280140

39

KNOTS

ILLIGIBLE TAG

sevaanavomnaipercncrnewn tran

G

=

a

=

tears

-

‘tures,

punc

snags.

a

iy

ey,

snags,

damaged yarn

42

RE

_ACID EXPOSU

id exposure

ack

43

waome

a

TYPICAL WEB AND ROUND SLINGS

WITH SWL AND MODE MARKINGS

THE S.WL. ARE IN TONNES

SINGLE LEG a ss

SLING 7

BASKET

ASSEMBLY MODE | STRAIGHT | CHOKE PARALLEL BASKET 90°

ENDLESS WEB

_ SLING &

ROUND SLING

| MODE FACTOR i 08 2 14

WLLL. [COLOUR] SWI. -. MODE OF ASSEMBLY ~ SW, |

10 VIOLET 1 08 2 T 14

2.0 | GREEN 2.0 16 46 2.8

30 | YELLOW 30 | 24 60 42

J | GREY 4.0 32 aeRO ol 5.6

5.0 [RED 5.0 4.0 10.0 2.0 ry

(“so sRown | 60 48 [ao 8.4

50 BLUE 8.0 6.4 16.0 12

| 100 “[ORANGE| 16.0 80) 20.6 14.0

120 [ORANGE 12.0 9.6 24.0 16.8

A Safe Working E.oad and Mode of Czpreity label is sewn into the sting, the capacity cal also be

designated by cotour coding the entire fabric of the sting.

45

CHAIN SLINGS MADE FROM STEEL

Modem chains are made from steel. A number of grades of chain are

manufactured which is dependant on the properties of the steel itself

and the heat treatment during manufacture.

Each grade of steel has its own strength and shock absorbing

properties and it follows that chain slings manufactured from different

steels have differing SAFE WORKING LOADS.

All chain sling fittings, such as hooks, rings etc. are assembled with a

similar type of steel to that of the chain to which they are attached.

Do not therefore interchange chain sling fittings.

‘lis Very important to check the SAFE WORKING LOAD marked ona

ng before use as chains of the same diameter do not always have the

m2 SAFE WORKING LOAD.

The following grades of steel are in common use, where it may easily be

seen the need to double check the SAFE WORKING LOAD marked

on alll items of lifting tackle. The safe working loads listed are alll for

12.7 mmm diameter chain.

Grade M or Grade 40 higher tensile steel

Amedium carbon steel which produces good general purpose chains,

hooks and shackles with a SAFE WORKING LOAD of 2.0 tons.

Grade S or Grade 60 alloy steel

An alloy steel giving lighter slings and fittings, having high shock

absorbing properties and resistance to weaf with a SAFE WORKING

LOAD of 3.0 tons,

Grade T or Grade 80 alloy steel

A high alfoy steel, riuch harder than the lower grades giving a greater

resistance. to wear at.the same time retaining ample shook absorbing

properties and allowing a lighter sling with a SAFE WORKING LOAD of

5.0 tons.

46

CHAIN SLINGS |

Chain

Try to avoid using chain when it is possible

to use wire rope. The failure of a single link

of a chain results in the complete failure of

the chain, whereas the wire rope is made up

of many Wires and strands and they must all

fail before the rope breaks, Chain usually

gives no warning when It is about to break,

Other than obvious visible signs, whereas a

wire rope breaks through a progression of

snapping wires and strands which can usu-

ally be clearly heard.

Chain is not suitable for impact loading as

there is no elasticity. A wire rope should nat

be shock loaded either, but it does allow

limited flexibility.

Chains are better suited than wire rope for

-ertain jobs as they will withistand rougher

handling and will not kink. Chains are much

more. resistant to abrasion and corrosion

then wire rope and well suited as slings in

industrial plants for lifting loads such as

heavy castings

Rasen © oe

FIG. 6 CHAI

“ster nk

Lower sag fetings

Chain Grade Identification

Chain should have an identitying mark

stamped regularly on the link, a3 indicated

in illustration #76. Chain quality identifica-

tion is confusing as every manufacturer uses

a different system of marking, although some

of the more common markings for alloy

hoisting chain are "A", "T", ora version of

the number "8", such as "80" or "800"

ASTER Une

cua ures |

2 a)

Mustration #76 ~ Chain Isentiticstion

Siagit Leg Stings

‘Coupting tink

|

|

chain

Coyating tine

Coupling fink

LING MAJOR COMPONENTS

Lower end fing

TYPICAL CHAIN SLINGS WITH SWL MARKINGS

As an alternative to‘the stamp markings on rings ete. permanent metal tabs can be

fitted skrowing the SWL and identity number

48

GRADE 80 ALLOY STEEL CHAIN SLING CAPACITIES

Mate &} jo°-90°

You will note from the capacity ratings that for both 3 leg and 4 leg the

Safe Working Loads are the same.

In practice most of the load is taken up on only 3 legs of the sling.

49

SAFE USE OF SHACKLES.

Beis important ia the case of shackles fitted with »

bolt, nyt and split eotter pia (type L, figure 7) that the

ny

Accembiy lng ee lan portion of dhe bt uch tat te ma

: will jam on the inner end-of the thread and not on the

‘Shackles shauld be inspected before use to ensure eves of the shackle, thus leaving the bolt free torotate,

thee tnd thatthe nut and Bolt re cross dilled fora slit eoteer

{0} the body of the shackle and the pin are both pin when inthis position,

identifiable as being of the some quatity rade:

() all soathcieigs sta eadable, Usha

fc} the pins favo the cortect fyPE: Sledt te GOrvtch type of shickle for aparticotar

cee agpliestion from the information gizen

(0) the threéack of the pin and the body are undsmesed;

(2) the shack andpin are not distorted; j

‘ Shackles shouldbe fitted to the foad in @ manner

(0) we shazkteand pin are not undsly worm; |. ag thous the shackle body to-takt the loadin # tue tine

(6) the shactefé andpin are free from nicks, gouges, along its tenteeline; and not in such @ way that bending

cracks and comtotion, oats are induced, ather than those for which the shackle

Enuure, whete appropriate, thatthe pin it cocrecsly is dorignied, See figure 8.

screwed into the sharkle eye, i. Gghies Tingéetghs, then

tock using a sonatt tominiy bar oF suitable foo! so that the

blac of the pin ie fully ested on the shackle eye. Ensure

that the pin is of the eorréct length so-that it pénetsates the

full depth of the screwed eye and allows the collar of the

pin to bed on the wisfoce of the gilled eve.

Incorrect seating of thé’ pin lay be due to a bent

pin, too tight #ieting theead oF misalignment of pin holes,

Dont use the sfackle under these circumstances, but

refer the matter to.acompetent person,

Never replace a shackle pin with 2 bolt, other then

one detigned for he porpose, Sit may not be saab or ieorret

the loads impened See gure 8

Neve repince »

shockle pin oid

‘ot

(eevee!

‘The foad weit

bend the Bote

Figure 8. treeoreet replacement of shackle pin

Figure 9, Correct ond incorrect uve of shucks

SHACKLE INFORMATION

MANUFACTURERS LOGO

Designating angle of

Diameter of

Normally marked

as W.L.L. (Weight

Load Limit)

When pin sc:

here

Plain hole must be true

with tapped hole

51

Ba] a[Buls 10) pasn sepjoeys Sep 9/4 ‘SBuys BjdiyjNU Joy pesn sepjoeys Mog <

“SOM Jo}2M UO JO UOS@ULOS

jo pouad peo} Jo) pesn aye sepyeYs 490} Ajayes yy anu pue yor <

SpPOeys JOySUy

apjoeys Urey punoy

adh, Mayes

apiseys wleyd apjoeys ureyd

ulg punoy Ulg Mel9g

epjoeys Joyouy epjaeys soyouy

ulg punoy Ud Mas

52

uolsueunp

yoaai09

40} ojgey

appeysyseyg | | *

feu!

$0 %CE

53

VATS LON.

dVLS TMS

speauy,

pebeweg

sa]4eYS U! 1Nd90 UeD Jey} saBeweg Jo sajdwexy

9# Guimesg ajdwexg

Incorrect — Shackle pin

bearing an running line

can work loose.

Correct Correct ~ Shackle

pin cannot turn,

Figure 10, U se of loose spacers on shackle pin

Figure 11. Use of shackles co avoid

ppin unscrewing : exemple

55

ACCORDING TO U.S, FEDERAL SPECIFICATION

RR-C-2718

eo oT oo eo)

laside: ‘Approx. weight

with | par ica POS

of fe

Bow | "screw | Safety

pia | pin

am | tgs | kos

165 | 225 -

20 s -

a 115 -

26 14 -

29 19 -

32 a | 38

43 63 70

54 96 | 100

se | 185 | 170

85 95 8.50 68 230 260

90 108 9.50 7s | 324 | 380

ey 94 115 12 83 440 | 480

a ee

i

i i 11s | 133 | 13.50 92 | 600 | 700

127 146 Ww 99 750 850

149 17a | 25 126 | 1400 | 1600

{pj —|

5 i741 197 35 yas} 1992.|. 2100

SHACKLE at -

en er te 105 203 284 55 ras | 3718 | 4200

ee sy 127 230 0 85 190 - | 6300

. at | af | tas | 267 | 301 | 120 | ae [| - |rz000

\ | ee

MINIMUM BREAKING STRENGTH =6 TIMES 56

aie SAFE WORKING LOAD.

EYE BOLTS AND EYE NUTS

There are two basic types of eye bolt:-.with and without a collar,

The collar eyebo It is designed for side loading up to an angle of 45 degrees from the

vertical. eee Sas ani |

‘The eyeboit With no collar Is calied a dynamo eyebolt, it Is only suitable for vertical

lifts, no side loading whatsoever.

Ifa plece of equi pment Is installed that needs to be lifted is installed with two

dynamo eyebolts a spreader beam should be used to apply a vertical lift to both

eyebolts.

When fitting a eyebolt to a machine for lifting make sure the threads match and that

the thread is of the correct length.

Do not force thre eyebolt or eye nut, but make sure the shoulder of the eye bolt or nut _

is sectiré Against the face of the machiné before attempting the lift.

For lifting of a vertically mounted electric motor or pump from side mounted

syebolts extreme care must be taken as a right angled load is being applied to the

eyebolt. You must ensure that the eyebolts so fitted are the ones designed for that

particular purporse, not alternatives.

It follows that it is not good working practice to remove an eye bolt or nut from a

machine once installed.

57

WT100 wiann SVU

Stee ibe i AA

Tr CS 5 |

yan GaaWvIS aT Y

‘ROTI 40 TAAL STWILLTT ee

“C1 INV1d SI UATWON

“MINLIVANNYW 40 UVIA

58

“OmuAWAL F GAHONIND

THE COLLAR EYE BOLT AND NUT

SUITAESLE FOR SIDE LOADING UP TO 45 DEGREES FROMTHE VERTICAL

THE DYNAMO EYEBOLT

ONLY SUITABLE FORA VERTICAL LIFTING

59

speaiyy padeus

pue pedding

uowoysig eZ — +

syjoqeA3 ul! unos0 ued Jey} saBeweg Jo sejdwexy

eos

60

Bucs,

peo} eg

PEO? opis

SMOOH TSuuva: BAg 3SusaAaa GNNOY SMOOH dvNS

= eae

yoqe7] Bupjao7 eagisog uAh

YMOOH ONILYOS OOH ONS YO Odd OOH YSWOHS ONIGMS: OOH 3A3 907— YNHS

ONIGWaedS LOU!

syova

3Aq YOoH

ug AeoN|

@alssa0x3|

HOLWT ONISSIIN

62

low HLIM 3as4dYSLNI NV dOO7

‘goae JUSIaIp Ul peyIuued si poyyaw

yoly noqe Aouedasosip epim e s] o18yy yuouuedep

VHSOISHDO eIqeoydde oy; YM 498UD t SLON

ab

“ssovds pauytios uj suoposfosd

uo sBeus 11 ynsai e se pur ‘Big 003 sj dooj arg Jeu you

af] 0} anp pasn aq jouues saupowos yng ‘suogeinBas

Aayes Auew ul s} yor poygow & st 9 UORENSNI|)

“puo peep 617 0} paddya st adou yo qrys poys y

ueindod ysow! s] yoiym poze ou) si g UORERSNII]

“aul] peo} ayy eGewep 0} yBnous 1489 eq

JOU pinoys dijo op pue sul] peo] ayy Uo paseld si ajppes

dijo auy YoR]s apy e eAeY Pinoys pus peap oy ‘sul

PeO| et 03 peddijo sj pue peep etg “y UORERSNII Ul

“O'a'y # UopeRSNI uy UMoYs ase edos eum a4 Jo

pus peep ey Buynoes Jo spowjeu! easy, quoWYoERE

pue peap atp Guyussouos Area suogeinBe: Gees

yewoos otp ye

JEM Ss] e189 UBYM AjfeoIPoLed 40 3nd eq 0} pus oY

smoqe Siu, “Auessoou UsYy Jaquny YGnoJUg pus peep

op ind yo}008 eBpom & 0} edos euym e Busyoene UeyAg?

“paulquiod AjUOUIUIOD Sie Aeuy Jenamoy Sjoyoos

abpam unm esn Jo} pepuawuosal jou si ados

Bupeos-uoy “urd ey wos eur 3yBjens e uy Gund

THE TURNBUCKLE

‘The turnbuckle consists of a barrel with opposite threads at each end, into which

may be screwed 2 number of end fittings, such ast- eyes, hooks and a shackle type of

fitting. 7 eee eee

‘The opposing (clockwise and anti-clockwise threads) allow rotation of thé barrel to ~

tighten or loosen the end fittings and attached slings.

This is a very valuable and often under used item of lifting tackle. It is very useful

for making adjustments to the rigging on odd shaped loads that require unequal

sling lengths for a balanced lift.

As with all items of lifting tackle, this should be marked with its Safe Working

Load.

SECURING OF TURNBUCKLE END FITTINGS

(hams

End Fittings must be secured.

=a ¢ ‘

ICH Tm kVA KOO

“peelyy ay} UO peo}

2U} 0} ppe Ay) “wey; yy paddinbs awoo jou

OP YOIYM Sepjonquiny Uo s}nu Wel asn jou og

“Bun pue ay} Jo Swed 843

490] 0} jueLoduy s} y1 Queseud S! UOHeIGIA yy

SUNW AYP ash 2oNOe

fincas sunt puz eponquiny— voRegsnii)

poonpey

sey yoo amg. mee

‘UOHeSAIyI

Ul Peyeo|puy eve suemYoeye apjonquiny snowe,

000'8e wb

oos's oor'tz Ke

o00's ooz'‘st %”L

00's ooo‘os v

o00'y o's BIL

00's o0z‘s %

‘osz'z oos‘e Big

oos‘t ooze %

00", o0z'h are

oz 008 Sus

oo oos %

{spunog)

(spunog) sBunyy pug (seyouy)

Sums ‘ang Jepouelq

Uy YooH ‘oka ‘mer __ 19g

PeO7 Bupyoyy eseg sapyonquin L

e198

U! PeleoIpu! e4e Sepjonquan3 Jo speo] Bupyom

8488 84) “uoHJod papesiuy ayy so sajewerp

843 UO spuedep peo; Bupjom ayes ayy

“Papjam aq jou pynoys

Pue jes Aye Jo |q pinoys seponquiny

65

No general description is needed of a

chain hoist. for any rigger worthy of the

title is well acquainted with it, There are,

however, ‘four types of chain -hoists,

namely,’ the spur-geared, the screw:

geared, differential, and the pull-lift types.

he first thiree types are used for hoisting,

while the last type is used primarily for

pulling a horizontal direction.

For frequent use and where a minimum of

labour is awailable to operate it, the spur-

eared hoist (Figs) recommended

though the cost of this hoist is the

highest, it ‘will prove most economical to

operate. Where the hoist is to be used

infrequently, Such as in a public garage,

and where: ‘the first cost is a consideration,

the screw-geared hoist is commonly used.

For very frequent use, such as in 4 private

garage ancl where light weight and low

cost are important, the differential hoist

finds its ptace

In the screw-geared hoist (Fig.2) about 85

per cent of the eneray the operator exerts,

is concerted into useful work fifting the

load; the other 15 per cent is wasted in

overcoming the ‘friction in the gears,

bearing, chains, etc. The screw-geared

hoist transforms from one-third of the

energy input. Some hoist manufacturers

roduce @ special ball-bearing differential

ist, which has a higher efficiency.

The screw—geared and differential hoists

have sufficient internal friction to prevent

the load from running on the lowering

motion. Such’ is not the case with the

Spur-geared hoist, so a load brake is

incorporate d with it

All chain fioists are designed with their

hooks as the weakest parts, the two

hooks not being interchangeable. In other

words, if the hoist is overloaded it is first

indicaled b the spreading or opening up of

the lower: hook." As designed, the inner

contour of the hook is an are of a circle,

and any deviation from a circle is

evidence of overloading. If sufficiently

overloaded, the hook” will gradually

straighten Sut until it finally releases the

load, and yet no damage should have

beer done ‘to other load-bearing parts of

‘Safe igolay a Stiagtagr bourse

66

the hoist

SOoDEUTSCHAND

CHAIN HOISTS

As shown in this illustration, a distorted

hook de prana-tede evidence of not a minor

overload but rather of overloading of great

magnitude. All the hooks shown are rated at

ton capacity (2,000 Ib). Even an overload

of 2,000 Ib does not cause noticeable

distortion. An overload of 3,800 Ib on a

2.000 Ib boom causes very little spreading

Yet it is not uncommon to see chain hoists

in. use-with the hook opened up and this

required an-overioad of 4,800 Ib. Of course,

there is no excuse whatsoever for

overloading any chain hoist to this extend.

Fig.1 Typical efur-

Fig. 2 Typical screw-

geared chein hols. geared chain hoist.

(Yee 8 Toms Wa Co) | (Yale @ Towne Ma

Vinge a hook has been severety oveticades. it

anould ber replaced by 9 new buck, Never

‘sitempl to Forge & spresc hook back into

Shape. A mew hook Ig toa chaap 19 waciant

taking any chiarces with an overtoad naok,

W there Is ewHence of severe overloading,

have the chain hoisl sent fo ihe maintenance

shop for @ complete Inlmat examination 2nd

overhaut. Pay particular attention la ine wear

‘on the brake caused by excessive toad.

Occasional la a manufacturing plant a chains

heist Is used for towering material inte cil

balns of for holding material while il is sprayee

wath cit In elther case tha foad chsln may be

coated with an excensive amount of ei, and

when Ine neiis! is oparates Ihe all iz transtered

{o the sprocket and may eventualy in its way

in the fowd Drake. thus redusing its holding

power, For service such as mis the sorex-

eared er differentia! helet shoud be weed,

Only forgect steel should be used for holt

parts that are subject to sivoss, such as tne

hooks, swivels, chain, sprackel, gears, an

similat parts. yet some koisls are mace by

Figura 4 typeal citerantist

‘epulabte manufacturers wath same such

made of cast iron or malleable in,

laingpesting 2 chain noiat iis not only

necessary 12 examine the boeks anc the

‘yenefal appearance of the chain eatetully. Det

4 more thorough examination i vary

important. Figure (4) shows a hook of & chain

hola! Rint was used In w Inclustisl plast for

continuous service on thvee shitis. A safety

Inspector observed that ina nook wes badly

‘wom, and he-ordered i-eaplacad by 2 new

hook. However, he tai (o inspect the chaia,

(herouphly. Much to the surprise of ait

eacerned, when the hook was removes, |

vas discovered thal the chain wat in even

‘worte consition thaa the: hook, as indicalen by

‘ne ore fink remaining ailached to the hock

For puting horizontally, (Fig. §) such Bs wien

removing tee alumes, baller Wbes, ar

vehicles stuck tn the mud, 2 screw-geared

loas hook if the load being lovered shou'd foul

‘an cbttruetion, It ts good practice to lasts ox

the hook 2 rugged safety laich. IN such ws no:

roxily obtainable, make a mousing ol several

\veags of manila rope yara or mwin on the hock,

one

hain hott (Yale & Towns Mig Co

Figare 4: “his hook wns condemned by the Sotery

| toapeetor. Unen removal lar enain ness the worn

Tak was dssoovered

Figure 5. Lever Operated Daxice for puting

‘8ME f0p0 vertically or tarizontaly (Geahaist, Inc}

Sale Rlgalag 8 Stgtag Course _

67

Tv

SLINGING PROCEDURE

PREPARATION

4. Assessing the weight of the load.

Before starting any lifting always know the weight of the load to be

lifted, usually is marked on the packing case, it not use a weighting

device (S.L.I) or check the manifest or loading list.

2. Checking the route or path.

Always check the path that the load will be traveling through, look out

for overhead obstructions or personnel working in the vicinity. Make

sure that they are aware of the lift that is going on, and always ensure

that wooden bearers or similar are available and in position to land the

lift.

3. Select your lifting material.

Select your lifting equipment, ensuring that it has the 3 items on it, ie

colour code, S.W.L. & L.D. markings, if it does not do not use it, |

change it for lifting equipment that does have these 3 items on it.

4, Inspection of your lifting equipment.

Now that you have selected your lifting equipment, check it for wires

broken, nicks or gouges in your shackles, and generally badly worn

equipment.

6. Centre of gravity.

The centre of gravity of any lift can usually be found already marked on

its lifting case, however, if it is not, a trial lift should be carried out with

caution.

6. Controlling the load.

“In any ‘lifting operation it “is essential that Control of the load is.

maintained at all times. To ensure this the use of a tagline is most

important, as a rigger it is your esponsibalty to make sure that all lifting

operations do have at least | No. Tagline attached.

Sate aging 8 Stators bourse

68

Tv

LIFTING GPERATION

7. Positioning the hook of the crane.

Using the correct crane signal the appointed banksman will center the

hook over the centre of the gravity, ensuring that the crane operator is:

able to see him at all times during the lift.

8. Taking the weight.

The appointed banksmen will again check the path of the lift ensuring

that it is clear, when he is satisfied it is safe to continue, he will take

the weight of the lift and “float” the lift, checks will be made to make

sure that the load will not slip, when the banksman is sure everything

is secure, he will instruct the crane operator to move the load ‘using

the correct crane signals.

9. Safety Awareness.

When carrying out any lifting operation, aways expect trouble, if you

are aware that something could go wrong, then you will be able to

react that much quicker.

10. Travelling the load.

Now that you have started moving the load you must ensure that the

| crane operator can see you at all times. On completion of the traveling

of the load, always ensure that the wooden blocks or anything that will

enable you remove your slings safely are positioned correctly.

11. Lancding the load.

| On completion of traveling the load, instruct the crane operator to

“stop” the load movement, Position the load above the wooden blocks,

then instruct the crane operator to lower the loads “slowly” until the

| load has been landed safely. Once the load has been landed you can

~ ~safely remove the. slings, coil or roll them up and stow them safely

away until then next time.

Sale tgalag a Staging Course .

69

10,

4

12.

13.

14.

15.

16.

SAFE IRKING PROCEDURES FOR BANKSMEN

Everything possible should be done to ensure the complete safety of the crane

and all personnel

Ensuire crane operator and banksman are familiar with signals to be used.

Be aware of obstructions within crane outreach and working area.

Be aware of wind speed (pressure).

Know the weight of the load and become familiar with single line maximum loads.

When lifting personnel, ensure safety catch if fitted to the hook and is in good

working order.

Stand in a position where the crane operator can clearly see you. if your

instructions are not being followed, i.e. the crane stops, it may well be that the

crane operator has lost sight of your signals.

Check that lifting gear being used is slung correctly to the load.

When lifting, stop load just clear of deck 10 check balance and security of load

before carrying on.

Always use clear and distinct signals to control lifting operations and in poor light

conditions exaggerate all crane signals.

Warn other personnel in the area of the movement of the load.

Ens.ure all hands are free from the lifing gear and stand clear before the crane

takes the load.

Do not stand between the load being lifted/lowered and any obstruction

Make it clear to the crane operator when load has to be moved and placed if

possible precede each load to its destination.

Never stand beneath a suspended load or allow other persons to do so.

Keep a check on other activities within the cranes operating area to avoid

development of unforeseen hazards.

{f anything out of the ordinary occurs STOP-CHECK.

‘Sule Rigging a Stinging Louren

70

Tuy

if the crane stops and your instructions are not being followed, it may be that the

crane operator has been given a signal to stop by someone who has seen a

situation developing which you have missed,

When banking use extreme caution when the crane is approaching its minimum

radius,

Become familiar with maximum boom angles.

Do not slew or drag loads over the deck as this imposes severe side stresses onto

the crane boom,

Ensure the crane operator never leaves the crane unattended with @ load on the

hook.

Never instruct cranes to slew outboard when divers are in the vicinity

Ensure crane is manned at all times wien supply boats are tied up in case a quick

cast offis required

Ensure helicopter landing officers are consulted before working in vicinity of

helicopter.

When working with supply boats the ultimate decision is with the supply boat

captain, although consultation must take place with the OlM/crane operator!

captain,

When preparing a load for lifting, keep the crane hook well clear of personnel.

Do not ride on @ hook or a load and do not allow anybody to do so.

Suteflgaing & Stiagiees Course E

71

SIDDENTSEHLAND

SAFETY PROCEDURES: CRANES OFFSHORE

Personnel and equipment transfer to and from supply boat.

1 When using the personnel transfer basket always make sure that the following

procedures are followed.

A) When landing the personnel transfer basket on the moving deck of the

supply boat, always lower enough slack in the crane wire to stop the

Personnel transfer basket lifting clear of the supply boat deck, during rough

sea conditions causing injury to transfer personnel.

B) When carrying out personnel transfer from the ship to the supply boat,

always remember that it is easier and safer for you, the crane operator, to

adjust your personnel transfer baskets to the supply boat's position than for

the supply boat captain to, try and adjust- his supply boat's position to your

crane. Especially if passengers- are on the personnel transfer basket.

2. When landing equipment on the deck-of the supply boat, always lower enough slack

in the crane wire immediately the load has landed ‘on the supply boat deck,

otherwise in rough sea conditions the supply boat will fall away during wave

movement, causing the load to retum ‘to the crane wire giving “shock loading” both

to the crane wire and the crane boom. This is to be avoided as either wire rope

failure or crane boom collapse could occur.

3, Any crane operation involving the offloading or back loading of materials to/from a

supply boat then the operator must observe the following instructions.

A) Ensure that all supply boat personnel are standing clear of the load being

lowered or lifted,

B) Ensure that the load is fitted with a tagline.

©) When lowering the load to the supply boat the operator must make sure that

the load is lifted clear of personnel on deck of the platform i.e. do not travel

the load over peoples heads, and when over the side of the platform the load

must be sited aver the water (sea) and never above the supply boat's deck

or accommodation.

D) Likewise when hoisting a load from the supply boat fo the platform the load

must be sited over the water (sea) as soon as the load can safely clear the

supply boats side/gunwale. While this operation is ongoing all supply boat

personnel must retire to a place of safety.

When the load is clear of the supply boats side, the operator must keep the

load over the water and not above the suppiy boat. When the load is al the

required height for transfer to the platform the operator must check that the

personnel both on the supply boat end the platform are clear of the load untit

its landed on the platform.

Sate Rlgoing ¢ Staging Course 7

72

Factors that Mer the

Cranes Rated Capacity

SMoseurEchCAND

CONFIG! wil NI E

‘The capacities in the load chart depend on the crane’s base (how it is set up) as follows:

Carrier-Mounted Cranes (including lattice boom, and rough terrain units)

The base will be either:

“

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lifting & Rigging ProceduresDocument32 pagesLifting & Rigging ProceduresBrunoro DantasNo ratings yet

- Craning and Rigging Handbook PDFDocument240 pagesCraning and Rigging Handbook PDFBrunoro DantasNo ratings yet

- 3 - 4 - Red T-MoldingDocument2 pages3 - 4 - Red T-MoldingBrunoro DantasNo ratings yet

- Hagun Engineering: Installing Vessel 1100 TDocument2 pagesHagun Engineering: Installing Vessel 1100 TBrunoro DantasNo ratings yet

- 06 HG Rigging TooLsDocument9 pages06 HG Rigging TooLsBrunoro DantasNo ratings yet

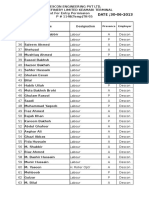

- Rigging Gloves Issuance RecordDocument318 pagesRigging Gloves Issuance RecordBrunoro DantasNo ratings yet

- Heisco: HSE Training at BS-180 Hyundai Tank Project (Site Office) Crane & Rigging (21/10/2012)Document1 pageHeisco: HSE Training at BS-180 Hyundai Tank Project (Site Office) Crane & Rigging (21/10/2012)Brunoro DantasNo ratings yet

- Rigger Training AND AssessmentDocument60 pagesRigger Training AND AssessmentBrunoro DantasNo ratings yet

- Q Rigging Manual 1.2ENDocument18 pagesQ Rigging Manual 1.2ENBrunoro Dantas100% (1)

- RP Rigging LoadsDocument1 pageRP Rigging LoadsBrunoro DantasNo ratings yet

- Lifting & Rigging ProceduresDocument27 pagesLifting & Rigging ProceduresBrunoro DantasNo ratings yet