Professional Documents

Culture Documents

Reg - No:: B.E. Degree Examination, Internal-I (2016 - 2017)

Reg - No:: B.E. Degree Examination, Internal-I (2016 - 2017)

Uploaded by

muthuraja0 ratings0% found this document useful (0 votes)

14 views1 pageThis document appears to be an exam question paper for a mechanical engineering course on transmission system design. It contains two parts - Part A with 9 short answer questions worth 2 marks each, and Part B with 2 long answer questions worth 16 marks each requiring students to design belt drives and gear drives based on given specifications and constraints. The questions cover topics like the use of idler pulleys, velocity ratio calculations, belt materials, gear tooth profiles, and factors to consider when designing transmission components like expected loads, speeds, life, and materials.

Original Description:

gdjp

Original Title

Gdjp Internal 1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document appears to be an exam question paper for a mechanical engineering course on transmission system design. It contains two parts - Part A with 9 short answer questions worth 2 marks each, and Part B with 2 long answer questions worth 16 marks each requiring students to design belt drives and gear drives based on given specifications and constraints. The questions cover topics like the use of idler pulleys, velocity ratio calculations, belt materials, gear tooth profiles, and factors to consider when designing transmission components like expected loads, speeds, life, and materials.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

14 views1 pageReg - No:: B.E. Degree Examination, Internal-I (2016 - 2017)

Reg - No:: B.E. Degree Examination, Internal-I (2016 - 2017)

Uploaded by

muthurajaThis document appears to be an exam question paper for a mechanical engineering course on transmission system design. It contains two parts - Part A with 9 short answer questions worth 2 marks each, and Part B with 2 long answer questions worth 16 marks each requiring students to design belt drives and gear drives based on given specifications and constraints. The questions cover topics like the use of idler pulleys, velocity ratio calculations, belt materials, gear tooth profiles, and factors to consider when designing transmission components like expected loads, speeds, life, and materials.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

Reg.

No:

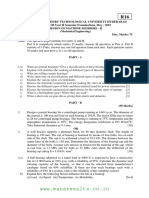

Question Paper Code: VCEME61

B.E. DEGREE EXAMINATION, INTERNAL-I [2016 - 2017]

Sixth Semester

Mechanical Engineering

ME 6601 DESIGN OF TRANSMISSION SYSTEM

(Regulation 2013)

(Use of PSG Data book is permitted)

Time: One hour Thirty Minutes Maximum: 50 marks

Answer ALL questions Date: 13 .02 .2017

PART A (9X 2 = 18 marks)

1. Why are idler pulleys used in a belt drive?

2. Define velocity ratio of a belt drive?

3. State the law of belting?

4. What is meant by ply in a flat belt?

5. State reasons for V-belt drive being preferred to flat belt drive?

6. What are the different cross sections of a V-belt?

7. Back lash for spur gears depends on which two factors?

8. Define module.

9. What are the common forms of gear tooth profile?

PART B (5X16 = 80marks)

10. (a) Design a flat belt drive to transmit 20 KW at 900 rpm. The diameter of driving

pulley 200 mm and that of driven pulley is 600 rpm. The center distance between pulley is

1.8m. the drive is subjected to miner shock load is expected to work for 8 hrs/day. Take

coefficient of friction between belt an pulley as 0.28. (16)

(Or)

(b) Design a V- belt to transmit 2KW for a grinding machine. The driving motor runs

at 1440 rpm with a speed reduction of 4. The diameter of driving shaft pulley is 100 mm . the

center distance should be at least 1m. (16)

11. (a) Design a spur gear drive to transmit 10KW at 1200 rpm. The required speed ratio is

3. The pinion and wheel material are C-45 steel and cast iron grade 30 respectively (the drive is

expected to work for 12 hours/day 300 days for a year and for 4 years) (16)

(Or)

(b) Design a helical gear to transmit 8 KW at 960 rpm. The required speed ratio is 5.6.

the helix angle is 150 expected life of drive is 4000hrs. the material of pinion and wheel are CI

grade 35 and C-45 steel. (16)

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

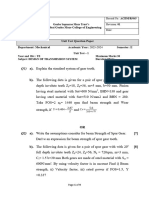

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)PradeepNo ratings yet

- Jeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Document3 pagesJeppiaar Institute of Technology: Kunnam, Sunguvarchatram, Sriperumbudur, Chennai - 631 604Balu phoenixNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)PradeepNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.kr_padmavathiNo ratings yet

- Apollo Priyadarshanam Institute of Technology Department of Mechanical Engineering Cycle Test - Ii Subject Code/Name: Me6601/Dts Date: Year/Sem: Iii/Vi Max - Marks: 50 Part-A (5x2 10MARKS)Document3 pagesApollo Priyadarshanam Institute of Technology Department of Mechanical Engineering Cycle Test - Ii Subject Code/Name: Me6601/Dts Date: Year/Sem: Iii/Vi Max - Marks: 50 Part-A (5x2 10MARKS)Ramar Madasamy100% (1)

- Design of Transmission SystemsDocument3 pagesDesign of Transmission SystemsSaravanan KumarNo ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- DTS 2Document2 pagesDTS 2Soundaryan PraveenNo ratings yet

- Dts Model Que Type B 2018-19Document2 pagesDts Model Que Type B 2018-19rammit2007No ratings yet

- Dme - II Mid - I QP Set-1,2 (16bt50301)Document2 pagesDme - II Mid - I QP Set-1,2 (16bt50301)Gangaraju MoopuriNo ratings yet

- Cme 389 DTS Iat 1 2024Document3 pagesCme 389 DTS Iat 1 2024meganathanNo ratings yet

- Design of Machine Elements Oct 2017Document3 pagesDesign of Machine Elements Oct 2017Kalpesh JadhavNo ratings yet

- DTS Prelim 2022-23Document4 pagesDTS Prelim 2022-23Prathamesh RaneNo ratings yet

- Unit3 Premodel1Document2 pagesUnit3 Premodel1T.V.B.BabuNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- DMD PDFDocument14 pagesDMD PDFAstik ThombareNo ratings yet

- Date: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinDocument2 pagesDate: 29.09.2021 Marks: 50 Year/Sem: III/V Sub: ME8594 Dynamics of Machines Duration: 90 MinsathishskymechNo ratings yet

- DTS Iat-1Document2 pagesDTS Iat-1Ajay KumarNo ratings yet

- Me0405 7 SemDocument2 pagesMe0405 7 SemSurya BalamuruganNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- ACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDocument3 pagesACFrOgA5tUgRDZJXHXmL8 Tw5dcxYJxiOIwOU5Eo4HonpVpoFZFJo3FpR3jkEpxVlzSr4SlTPfwEhXU2oUrUpctlLPK5aDrEIjX Z49543n2D8VZdCWCJYobCVtHeuFv-2Hje7s8XnE4FiVLAx-HDept of MechanicalNo ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- 2 2440 - GUG-S-16-6620 - Year - B.E. (With Credits) - Regular-Semester 2012-Mechanical Engineering Sem VII Subject - ME - Design of Mechanical DrivesDocument2 pages2 2440 - GUG-S-16-6620 - Year - B.E. (With Credits) - Regular-Semester 2012-Mechanical Engineering Sem VII Subject - ME - Design of Mechanical DrivesKunal MohurleNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- Sathyabama University: Register NumberDocument3 pagesSathyabama University: Register NumberSecret SecretNo ratings yet

- Machine Design Ii Nme602 1Document3 pagesMachine Design Ii Nme602 1himanshujaiswal04596No ratings yet

- Ilovepdf - Merged - 2024-02-25T160140.090Document10 pagesIlovepdf - Merged - 2024-02-25T160140.090Aman SharmaNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Design of Mechanical Drives: B.E. (Mechanical Engineering / Power Engineering) Seventh Semester (CBS)Document3 pagesDesign of Mechanical Drives: B.E. (Mechanical Engineering / Power Engineering) Seventh Semester (CBS)Komal HingeNo ratings yet

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 pagesB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PNo ratings yet

- Me 2352 - DTS Q BankDocument5 pagesMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- MDDocument2 pagesMDAbhijeet PramanikNo ratings yet

- ME2352 Design of Transmission Question BankDocument4 pagesME2352 Design of Transmission Question BankKarthik SubramaniNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- Me-302 Id (Ao819) PDFDocument2 pagesMe-302 Id (Ao819) PDFVikasNo ratings yet

- Eighth Semester B.Tech. Degree Examination, November 2008 (2003 Scheme) Branch: Production 03.804: Machine Tool Design (P)Document3 pagesEighth Semester B.Tech. Degree Examination, November 2008 (2003 Scheme) Branch: Production 03.804: Machine Tool Design (P)Jithesh VNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- 14 ACAD-R-45 - Unit Test QPDocument9 pages14 ACAD-R-45 - Unit Test QPsomnath swamiNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Design of Transmission ElementDocument42 pagesDesign of Transmission ElementVenkatesh MohanNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityrajushamla9927No ratings yet

- Dmm2 Mar2006Document8 pagesDmm2 Mar2006Abdul Saleem MohammedNo ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNo ratings yet

- r05320305 Design of Machine Members IIDocument9 pagesr05320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- Me 1352Document6 pagesMe 1352arunramakrishnanNo ratings yet

- R8 Nov-Dec-2015Document3 pagesR8 Nov-Dec-2015Hari VenkitNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- Dts Important Ques 2 16 MarksDocument5 pagesDts Important Ques 2 16 MarksBas RamuNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- UPTU 2013-14 Machine Design - II EME 602Document4 pagesUPTU 2013-14 Machine Design - II EME 602nitin_johriNo ratings yet

- Design of Mechanical Drives w17Document4 pagesDesign of Mechanical Drives w17aniket ingle100% (1)

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- ME 7601 DTS Assessment IIDocument2 pagesME 7601 DTS Assessment IIraghulNo ratings yet

- Gujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70Document3 pagesGujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70NILESH SUTHARNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet