Professional Documents

Culture Documents

065

065

Uploaded by

Aan aribdeuCopyright:

Available Formats

You might also like

- Newton S Laws Ex1Document3 pagesNewton S Laws Ex1Ahmed ZakiNo ratings yet

- Ketone Ethylene Ester Based Sheet Roofing: Standard Specification ForDocument4 pagesKetone Ethylene Ester Based Sheet Roofing: Standard Specification ForMohammad YaseenNo ratings yet

- End BlockDocument9 pagesEnd BlockChrisYapNo ratings yet

- GFRP Laminates 2020-1-5Document5 pagesGFRP Laminates 2020-1-5oussNo ratings yet

- Comparative Study of Commercial Glass Fiber‑Reinforced Polyester Composite Beams: Thermal Behavior and Durability to QUV ExposureDocument10 pagesComparative Study of Commercial Glass Fiber‑Reinforced Polyester Composite Beams: Thermal Behavior and Durability to QUV ExposureRetno WulandariNo ratings yet

- Tensile Strength Analysis of Polymer Composite Materials Fiber Reinforced in The Fiber Boat ApplicationDocument7 pagesTensile Strength Analysis of Polymer Composite Materials Fiber Reinforced in The Fiber Boat ApplicationMehvish TaqiNo ratings yet

- C 582 - 95 - Qzu4mi05nqDocument7 pagesC 582 - 95 - Qzu4mi05nqKhoai Sai GonNo ratings yet

- Effect of Twist Level On Tire Cord Performance PDFDocument5 pagesEffect of Twist Level On Tire Cord Performance PDFMarcus NguyễnNo ratings yet

- Experimental Determining The Mechanical and Stiffness Properties 2020 PolymDocument13 pagesExperimental Determining The Mechanical and Stiffness Properties 2020 PolymClaudia UngureanuNo ratings yet

- Testing Erosion For FRPDocument6 pagesTesting Erosion For FRPocta aldyNo ratings yet

- Strengthening of Beams Using Glass Fiber Reinforced Polymer (GFRP) LaminateDocument9 pagesStrengthening of Beams Using Glass Fiber Reinforced Polymer (GFRP) LaminateRatnakarVarunNo ratings yet

- Effect of Twist Level On Tyre Cord PerformanceDocument6 pagesEffect of Twist Level On Tyre Cord Performanceayserinkskc_22375979No ratings yet

- Impact Strength Analysis of Polymer Composite MateDocument9 pagesImpact Strength Analysis of Polymer Composite MaterajesaravindNo ratings yet

- An Investigation Into The Effects of Fibre Volume Fraction On GFRP Plate 1Document7 pagesAn Investigation Into The Effects of Fibre Volume Fraction On GFRP Plate 1Abdul jeleelNo ratings yet

- 11.glassfiber Reinforcedpolymercomposite Areview OriginalDocument20 pages11.glassfiber Reinforcedpolymercomposite Areview OriginalŜṟéẻ Ṛąṁ ChowdaryNo ratings yet

- Journal of Reinforced Plastics and CompositesDocument19 pagesJournal of Reinforced Plastics and Compositeshue558110No ratings yet

- Glass Fiber-Reinforced Polymer Composite - A Review - OriginalDocument20 pagesGlass Fiber-Reinforced Polymer Composite - A Review - OriginalAvinash Singh100% (1)

- Experimental Study On Retrofitted RC T-BEAM Using FRPDocument5 pagesExperimental Study On Retrofitted RC T-BEAM Using FRPInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Song 2016Document8 pagesSong 2016AnkushNo ratings yet

- Sample Paper 1 PDFDocument9 pagesSample Paper 1 PDFAnni MataqeiNo ratings yet

- Experimental Study On Behaviour of RC T-Beam StrenDocument6 pagesExperimental Study On Behaviour of RC T-Beam Strenshaik saifulla lNo ratings yet

- Fabrication and Testing of Fibre Reinforced Polymer Composites MaterialDocument8 pagesFabrication and Testing of Fibre Reinforced Polymer Composites Materialyadagani nirmalNo ratings yet

- Flexural and Shear Performance of HFRC BeamsDocument5 pagesFlexural and Shear Performance of HFRC BeamsStephenNo ratings yet

- Mechanical Characterization of Carbon - EpoxyDocument4 pagesMechanical Characterization of Carbon - EpoxyDanielNo ratings yet

- Design and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With IsopolymerDocument30 pagesDesign and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With Isopolymershakeel100% (1)

- Publication 13Document7 pagesPublication 13Vishnu KalyanNo ratings yet

- Mechanical Testing and Microstructure Characterization of Glass Fiber Reinforced Isophthalic Polyester CompositesDocument10 pagesMechanical Testing and Microstructure Characterization of Glass Fiber Reinforced Isophthalic Polyester Compositespinkan25No ratings yet

- JETIR2105363Document10 pagesJETIR2105363ivs yeswanthNo ratings yet

- Material Today ProcDocument10 pagesMaterial Today ProcVikasKhatkarNo ratings yet

- Investigation of The Effect of Glass Fiber Content On The Mechanical Properties of Cast PolyamideDocument8 pagesInvestigation of The Effect of Glass Fiber Content On The Mechanical Properties of Cast PolyamideIndra JayaNo ratings yet

- C1666C1666MDocument3 pagesC1666C1666MKingNo ratings yet

- Mechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositeDocument4 pagesMechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositesriyajambukarNo ratings yet

- STRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS IeeeDocument3 pagesSTRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS Ieeettk qsNo ratings yet

- Conference PaperDocument5 pagesConference Paperaravind029No ratings yet

- Literature ReviewDocument10 pagesLiterature ReviewsithananthansithuNo ratings yet

- Retrofittng of Reinforced Concrete Beams Using GFRP OverlaysDocument17 pagesRetrofittng of Reinforced Concrete Beams Using GFRP OverlaysIAEME PublicationNo ratings yet

- Thermoplastic Composites - Best Practice GuideDocument49 pagesThermoplastic Composites - Best Practice GuidemanikandapriyaNo ratings yet

- Mechanical, Physical, and Wear Properties of Polypropylene Reinforced Short Carbon Fiber Composites With Different Fiber LengthDocument11 pagesMechanical, Physical, and Wear Properties of Polypropylene Reinforced Short Carbon Fiber Composites With Different Fiber LengthHarriJunaediNo ratings yet

- Use of Polymer in Bridge RehabilitationDocument13 pagesUse of Polymer in Bridge RehabilitationIJRASETPublicationsNo ratings yet

- Corbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016Document12 pagesCorbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016adonaies19No ratings yet

- Mechanical Properties of Glass Fibre Reinforced Polymer Based On Resin From Recycled PlasticDocument9 pagesMechanical Properties of Glass Fibre Reinforced Polymer Based On Resin From Recycled PlasticHernando ZambranoNo ratings yet

- Development of Glass/Banana Fibers Reinforced Epoxy CompositeDocument6 pagesDevelopment of Glass/Banana Fibers Reinforced Epoxy CompositeNeymarNo ratings yet

- Comparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesDocument7 pagesComparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesAndrew NallayanNo ratings yet

- Prediction of Mechanical Behavior of GFRP With Elastomer Under Impact and Tensile LoadingDocument4 pagesPrediction of Mechanical Behavior of GFRP With Elastomer Under Impact and Tensile LoadingRaguvaranNo ratings yet

- Study of The Mechanical Properties of Nonwoven Fibre Mat Reinforced Photopolumers Used in Rapid Photo TypingDocument6 pagesStudy of The Mechanical Properties of Nonwoven Fibre Mat Reinforced Photopolumers Used in Rapid Photo TypingJasminVasquezNo ratings yet

- Strength Analysis of E-Glass and Jute Fiber Reinforced Polyester CompositesDocument10 pagesStrength Analysis of E-Glass and Jute Fiber Reinforced Polyester CompositesTJPRC PublicationsNo ratings yet

- Developmental E Glass FiberDocument8 pagesDevelopmental E Glass FiberWidya Puspita SariNo ratings yet

- 10.2478 - Cee 2023 0036Document8 pages10.2478 - Cee 2023 0036ajayyadav24127No ratings yet

- Ballistic Performance of Thermoplastic CDocument8 pagesBallistic Performance of Thermoplastic CPedro ThiagoNo ratings yet

- Mechanical Properties of Polymer Matrix Composites: Effect of HybridizationDocument3 pagesMechanical Properties of Polymer Matrix Composites: Effect of HybridizationNagaraj K CNo ratings yet

- Composites Part B: K. Naresh, K. Shankar, R. VelmuruganDocument16 pagesComposites Part B: K. Naresh, K. Shankar, R. VelmuruganPavan Kumar ArigiNo ratings yet

- Investigation of Bending Properties On Carbon Fiber Reinforced Polymer Matrix Composites Used For Micro Wind Turbine BladesDocument7 pagesInvestigation of Bending Properties On Carbon Fiber Reinforced Polymer Matrix Composites Used For Micro Wind Turbine BladesAhmed ismailNo ratings yet

- Herzog Glass Transitiontempvinyleesterresin JPAS2005app.21868Document10 pagesHerzog Glass Transitiontempvinyleesterresin JPAS2005app.21868Kiplgat ChelelgoNo ratings yet

- Contact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentDocument8 pagesContact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentQUALITY MAYURNo ratings yet

- Astm C 582Document7 pagesAstm C 582ISIES SENAINo ratings yet

- 20ijmperdjun201920 PDFDocument8 pages20ijmperdjun201920 PDFTJPRC PublicationsNo ratings yet

- D 4389 - 99 - RdqzodkDocument5 pagesD 4389 - 99 - Rdqzodkmyusuf123No ratings yet

- Effect of Siwak and Bamboo Fibers On Tensile Properties of Self-Cure Acrylic Resin Used For Denture ApplicationsDocument6 pagesEffect of Siwak and Bamboo Fibers On Tensile Properties of Self-Cure Acrylic Resin Used For Denture ApplicationsJawad K. OleiwiNo ratings yet

- Composites: Part B: Antonio Greco, Alfonso Maffezzoli, Giovanni Casciaro, Flavio CarettoDocument6 pagesComposites: Part B: Antonio Greco, Alfonso Maffezzoli, Giovanni Casciaro, Flavio CarettoabhishekNo ratings yet

- Mechanical Properties of A Hybrid Nanocomposite Under Room Temperature and Hot-Wet EnvironmentsDocument8 pagesMechanical Properties of A Hybrid Nanocomposite Under Room Temperature and Hot-Wet EnvironmentsJoão BarrigóNo ratings yet

- Handbook of Composites from Renewable Materials, Design and ManufacturingFrom EverandHandbook of Composites from Renewable Materials, Design and ManufacturingNo ratings yet

- Simulation of Texture Development in A Deep Drawing ProcessDocument11 pagesSimulation of Texture Development in A Deep Drawing ProcessAnya CooperNo ratings yet

- General Pre Stress and ElasticDocument28 pagesGeneral Pre Stress and ElasticJorge Nickolai NavalesNo ratings yet

- Stochastic Processes 2Document11 pagesStochastic Processes 2Seham RaheelNo ratings yet

- Introductory Thermal Physics Worksheets and SolutionsDocument30 pagesIntroductory Thermal Physics Worksheets and SolutionsLetmiDwiridalNo ratings yet

- Working Monitors: Recent Valves, Actuators & Regulators DiscussionsDocument13 pagesWorking Monitors: Recent Valves, Actuators & Regulators DiscussionsraulNo ratings yet

- Alan - Macdonald 2012 A.survey - Of.geometric - Algebra.and - Geometric.calculusDocument33 pagesAlan - Macdonald 2012 A.survey - Of.geometric - Algebra.and - Geometric.calculusgiantgeorgeNo ratings yet

- Full Text 01Document90 pagesFull Text 01Walid NASRINo ratings yet

- BROSUR Solmax Waste English Rev0514Document28 pagesBROSUR Solmax Waste English Rev0514Naufal IhsanNo ratings yet

- Thoshiba Power TransformerDocument28 pagesThoshiba Power TransformerSERGIO_MANNo ratings yet

- Belden Optical Fiber Cable Catalog EMEA - Original - 54507Document94 pagesBelden Optical Fiber Cable Catalog EMEA - Original - 54507Agus YulfizarNo ratings yet

- Efficient Implementation of Superquadric Particles in DiscreteDocument18 pagesEfficient Implementation of Superquadric Particles in DiscretedavidusachNo ratings yet

- Microwave Coaxial Connector Technology: A Continuing EvolutionDocument21 pagesMicrowave Coaxial Connector Technology: A Continuing EvolutionTHBFLNo ratings yet

- Electrical Machines - I: Electric Circuit TheoryDocument22 pagesElectrical Machines - I: Electric Circuit TheoryPradeep SinglaNo ratings yet

- Pidicrete CF 121 (m1)Document1 pagePidicrete CF 121 (m1)nickdash09No ratings yet

- Beilstein Journal of NanotechnologyDocument11 pagesBeilstein Journal of NanotechnologydeepshaNo ratings yet

- Angle of Twist: Torsion II: 1Document4 pagesAngle of Twist: Torsion II: 1Anjana ENo ratings yet

- LaserDocument20 pagesLasertsrockon28No ratings yet

- MATH-6103-2013T (UGRD) Calculus 2: Prelim ExamDocument18 pagesMATH-6103-2013T (UGRD) Calculus 2: Prelim ExamJitlee PapaNo ratings yet

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghNo ratings yet

- The Acoustics HutcinsDocument43 pagesThe Acoustics Hutcinsarmadillo27No ratings yet

- CFD Analysis of Centrifugal Pump ImpelleDocument9 pagesCFD Analysis of Centrifugal Pump Impelleبلال بن عميرهNo ratings yet

- 3.2 Mass Ma 4 KG Rests On Top of Mass MB 5kg That Rests On A FricDocument7 pages3.2 Mass Ma 4 KG Rests On Top of Mass MB 5kg That Rests On A Fricsoumengoswami10No ratings yet

- Bolted Tension Flanges Joining Square Hollow Section MembersDocument15 pagesBolted Tension Flanges Joining Square Hollow Section MembersGhitzaaaNo ratings yet

- Objective (MCQ) Chemical Engineering SampleDocument25 pagesObjective (MCQ) Chemical Engineering SampleKapilSahu50% (2)

- CoreLok ManualDocument41 pagesCoreLok ManualRafa Bernal Padilla100% (1)

- DescriptionDocument111 pagesDescriptionKaaliNo ratings yet

- Mokon: Central Chillers and Pump TanksDocument4 pagesMokon: Central Chillers and Pump Tanksbird99No ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument4 pagesCambridge International Advanced Subsidiary and Advanced LevelParveen AkhtarNo ratings yet

065

065

Uploaded by

Aan aribdeuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

065

065

Uploaded by

Aan aribdeuCopyright:

Available Formats

Available online at http://www.journalijcst.

com

International Journal of Current Science and Technology

Vol.3, Issue, 10, pp. 104-106, October, 2015

ISSN: 2320-8090

RESEARCH ARTICLE

CHARACTERIZATION OF FRP COMPOSITE MATERIALS

Veera Sudarsana Reddy R*

Narayana Engineering College Gudur, SPSR Nellore (Dt) Andhra Pradesh, India

ARTICLE INFO ABSTRACT

Article History: Fiber Reinforced Polymer (FRP) composites are gaining acceptance for use in different fields of

Received 10th September, 2015 engineering due to its light weight, strong corrosion resistance and better mechanical properties

Received in revised form 12th September, compared to conventional materials. The selection of matrix and reinforcement for fabrication of

2015 any FRP composite product mainly depends on the properties of matrix and reinforcement.

Accepted 15th October, 2015 Two types of thermoset resin systems namely Isophthalic polyester and Vinylester were collected

Published online 28th October, 2015 from three manufacturers and tested for the mechanical properties of both liquid and cast resin

properties. Two types of glass fiber reinforcement product forms such as WRM 610 gsm and UDC

880 gsm, were used for making laminates. The tensile properties of glass fibers were obtained

Key words: by conducting standard tests. Tests were conducted to find the flexural, tensile and shear properties

xxx of GFRP composite laminates that had been made with WRM 610 gsm and UDC 880 gsm with

vinylester and isophthalic resin systems. The results were presented and suggestions for the

selection of resin and reinforcement for making a fiber reinforced polymer composite product

were given based on the test results.

Copyright 2015 Veera Sudarsana Reddy R., This is an open access article distributed under the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

laminates. The viscosity, relative density and gel time for

INTRODUCTION liquid resin were determined as per IS: 6746-1994 and peak

exotherm was determined as per BS: 2782-Method 111D.

Fiber reinforced polymer composite material contains a matrix

The ultimate tensile strength and the tensile modulus,

system with reinforcing fibers. In most engineering

ultimate flexural strength and flexural modulus and

applications, these materials are used in the form of

water absorption were obtained for cast resin by testing the

laminates, which consist of layers of various lamina. The

standard test specimens, as per BS: 2782-Method 320C, ISO:

increasing use of composite materials in structural

178-1975(E), BS: 2782- Method 121A and ISO: 62-1980(E)

applications lead to a corresponding increase in the need

respectively. The tensile properties of glass fibers were

for experimental data and test methodology of composite

obtained by casting and testing five standard test specimens

materials has received considerable attention in recent years.

using the INSTRON testing machine as per ASTM: D 2343-

The complex nature of data required for the design of FRP

67. The flexural strength and modulus of GFRP composite

components need to critically evaluate the composite test

laminates were determined by casting and testing five standard

methods. The aim of this present investigation is to determine

test specimens as per ISO: 178-1975(E). The tensile strength

the properties of matrix, reinforcement and GFRP composite

and modulus of GFRP composite laminate were calculated

and also to study the influence of type of resin (Isophthalic

by casting and testing five standard test coupons as per ISO:

polyester/vinylester) and reinforcement (WRM 610 gsm/UDC

3268-1978(E). The shear modulus of GFRP composite

880 gsm) on the mechanical properties of composite laminate.

laminate was obtained by casting and testing five standard test

specimens as per 450 coupon test. Electrical resistance strain

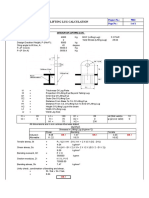

Test Specimens and Test Details gauges were used for determining the strains and Poissons

ratio of GFRP laminate. The fabricated specimens and test

Thermoset resins such as Isophthalic polyester and

set-up for determining the tensile properties and shear

Vinylesters were collected from three manufacturers and

modulus were shown in Figs.1 and 2 respectively.

tested for liquid and cast resin properties. The accelerator,

catalyst and promoter used in the study were cobalt

naphthanate, Methyl Ethyl Ketone Peroxide (MEKP) and RESULTS AND DISCUSSIONS

dimethyl amine respectively. Two types of ECR glass fiber

reinforcements namely WRM 610 gsm and UDC 880 gsm The liquid resin properties of both Isophthalic polyester and

were used as reinforcement for making GFRP composite vinylester resin were shown in Table 1. Tensile properties

of glass fibers were shown in Table 2. Tensile and flexural

*Corresponding author: Veera Sudarsana Reddy R Narayana properties of cast resin were shown in Tables 3 and 4

Engineering College Gudur, SPSR Nellore (Dt) Andhra Pradesh, respectively. The percentage of water absorption of cast

India resin and GFRP composite specimens were shown in Table 5.

International Journal of Current Science and Technology Vol.3, Issue, 10, pp.104-106, October, 2015

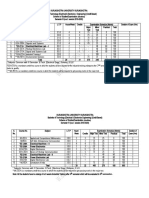

The flexural and tensile properties of GFRP composite Table 6 Flexural Properties of GFRP Laminate

laminate with WRM 610gsm as reinforcement were shown in

Tables 6 and 7 respectively. Tensile properties and shear Isophthalic Polyester Resin Vinylester Resin

Parameter

M-1 M-2 M-3 M-1 M-2 M-3

modulus of GFRP composite laminate made by vinylester Bending Strength

resin and WRM 610 gsm/UDC 880 gsm were shown in Table 280 297 273 334 384 273

( MPa)

8. Graphs were plotted between stress and strain for GFRP Flexural Modulus

14052 12397 12135 17380 20452 14113

composite, cast resin and glass fiber reinforcement for tension (MPa)

test specimens and were shown in Figs 3, 4 and 5 respectively.

Table 1 Properties of Liquid Resin

Manufacturer-1 Manufacturer-2 Manufacturer-3

(M-1) (M-2) (M-3)

Property

Iso Iso Iso

Vinylester Vinylester Vinylester

phthalic phthalic phthalic

Viscosity

380 315 564 276 492 254

(CP)

Relative

1.092 1.053 1.112 1.058 1.105 1.08

Density

Gel Time

18 19 46 19 16 7

(Minutes)

Peak

Exotherm 148 118 145 129 148 168

( 0C)

Figure 3 Stress Vs Strain for GFRP Laminate in Tension Test

Table 7 Tensile Properties of GFRP Laminate

Isophthalic Polyester Resin Vinylester Resin

Parameter

M-1 M-2 M-3 M-1 M-2 M-3

Ultimate Tensile

255 229 209 333 238 195

Strength ( MPa)

Poissons Ratio 0.20 0.12 0.18 0.24 0.16 0.15

Tensile Modulus

(MPa) 18067 16115 13918 27618 20287 18104

Table 8 Properties of GFRP Laminate

Reinforcement

Sl.No. Property

WRM610 gsm UDC 880 gsm

Figure 1 GFRP Tension Test Figure 2 Tension Test Ultimate Tensile Strength in 1-

Specimen Setup 1 Direction (MPa) 333 407

Ultimate Tensile Strength in 2-

Table 2 Tensile Properties of Glass Fibers 2 Direction (MPa) 368 34

Gauge Load at Failure Youngs 3 Poissons Ratio 0.24 0.24

Percentage Failure

Sl.No. Length Failure Stress Modulus

Elongation Strain 4 Youngs Modulus, E1 (MPa) 27618 27039

(mm) (kN) (MPa) (GPa)

1 255 3.044 2.8 1808 0.0256 70.636 5 Youngs Modulus, E2 (MPa) 22959 12793

2 255 3.277 2.9 1946 0.0275 70.651 6 Shear Modulus, G12 (MPa) 2631 2464

3 255 2.895 2.8 1719 0.0252 68.129 Weight density ( N/mm3)(X10-5)

7 1.55 1.67

4 255 3.048 2.8 1810 0.0256 70.596

5 255 2.858 2.6 1697 0.0240 70.652

Table 3 Tensile Properties of Cast Resin

Isophthalic Polyester Resin Vinylester Resin

Parameter

M-1 M-2 M-3 M-1 M-2 M-3

Ultimate Tensile

44 44 50 41 29 35

Strength (MPa)

Tensile Modulus

1621 1605 1969 1235 1214 1387

(MPa)

Table 4 Flexural Properties of Cast Resin

Isophthalic Polyester Resin Vinylester Resin

Parameter

M-1 M-2 M-3 M-1 M-2 M-3

Bending Stress

65 48 59 68 15 58

( MPa)

Flexural Modulus

2127 2022 2521 2543 1439 2679

(MPa)

Figure 4 Stress Vs Strain for Cast Resin in Tension Test

Table 5 Water Absorption of Cast Resin and GFRP The relative density and peak exotherm of vinylester

Composite Specimens resin from manufacturer-1 (M-1) were less compared to

% Water Absorption vinylester resin supplied by manufacturers. The relative

Type of Resin Cast Resin GFRP Composite density and peak exotherm of isophthalic polyester resin

M-1 M-2 M-3 M-1 M-2 M-3 supplied by all the three manufacturers were more than the

Isophthalic

Polyester

0.13 0.13 0.12 1.77 2.45 0.07 Vinylester resin. The percentage of water absorption of cast

Vinylester 0.08 0.09 0.15 0.05 0.06 0.09 vinylester (M-1) resin specimens was 0.01-0.07 percentage

less compared to isophthalic resin and vinylester resin from

105

Characterization Of Frp Composite Materials

other manufacturers. CONCLUSIONS

Based on the test results it was found that the GFRP laminate

made using vinylester resin from manufacturer-1 and ECR

glass WRM 610 gsm showed better mechanical properties,

good water resistant capabilities and light in weight. Based

on the test results it is suggested to use the vinylester

resin with WRM 610 gsm for making lightweight GFRP

composite product with desired tensile, flexural, shear and

water resistant properties.

References

1. James M Whitney, Issac M. Daniel and R.Byron Pipes,

Figure 5 Stress Vs Strain for Res in, Reinforcement and FRP

Experimental Mechanics of Fiber Reinforced Composite

Composite Materials, 1 st ed. The Society for Experimental Stress

Tensile strength and modulus of cast vinylester resin from Analysis, Brookfield Center, Connecticut, p 185

M-1 were high, and also the flexural strength and modulus 2. Indian Standard, Unsaturated Polyester Resin Systems-

of cast vinylester (M-1) resin well comparable with Specification , IS6746: 1994 Bureau of Indian

isophthalic resin and vinylester resin from other two Standards, New Delhi

manufacturers. The tensile strength and modulus, and flexural 3. Methods of Testing Plastics, BS 2782:1970, British

strength and modulus, of GFRP composite laminate made Standards Institution Gr13, London, WIA

using vinylester resin from M-1and WRM 610 gsm were high 4. International Standard, Plastics-Determination of

and well comparable with the corresponding properties of Flexural Properties of Rigid Plastics, ISO 178-1975 (E)

composite laminate made using vinylester/Isophthalic resin 5. International Standard, Plastics-Glass Reinforced

from other manufacturers and WRM 610 gsm as a Materials-Determination of Tensile Properties, ISO

reinforcement. For the same vinylester resin the weight 3268-1978 (E)

density of GFRP composite laminate made of WRM 610 gsm 6. Standard Test Method for Tensile Properties of Glass

was less compared to laminate made using UDC 880 gsm. Fiber Strands, Yarns, And Rovings Used in Reinforced

Also tensile strength , youngs modulus, and shear modulus in Plastics, ANSI/ASTM D 2343 67

1 and 2 direction of GFRP laminate made using vinylester 7. British Standard Method of Testing Plastics Part-10,

resin and WRM 610 gsm were greater than those laminates Glass Reinforced Plastics, Method 1003, Determination

made using same vinylester resin and UDC 880 gsm. of Tensile Properties

8. International Standard, Plastics- Determination of Water

Absorption, ISO 62-1980(E).

fffffff

106

You might also like

- Newton S Laws Ex1Document3 pagesNewton S Laws Ex1Ahmed ZakiNo ratings yet

- Ketone Ethylene Ester Based Sheet Roofing: Standard Specification ForDocument4 pagesKetone Ethylene Ester Based Sheet Roofing: Standard Specification ForMohammad YaseenNo ratings yet

- End BlockDocument9 pagesEnd BlockChrisYapNo ratings yet

- GFRP Laminates 2020-1-5Document5 pagesGFRP Laminates 2020-1-5oussNo ratings yet

- Comparative Study of Commercial Glass Fiber‑Reinforced Polyester Composite Beams: Thermal Behavior and Durability to QUV ExposureDocument10 pagesComparative Study of Commercial Glass Fiber‑Reinforced Polyester Composite Beams: Thermal Behavior and Durability to QUV ExposureRetno WulandariNo ratings yet

- Tensile Strength Analysis of Polymer Composite Materials Fiber Reinforced in The Fiber Boat ApplicationDocument7 pagesTensile Strength Analysis of Polymer Composite Materials Fiber Reinforced in The Fiber Boat ApplicationMehvish TaqiNo ratings yet

- C 582 - 95 - Qzu4mi05nqDocument7 pagesC 582 - 95 - Qzu4mi05nqKhoai Sai GonNo ratings yet

- Effect of Twist Level On Tire Cord Performance PDFDocument5 pagesEffect of Twist Level On Tire Cord Performance PDFMarcus NguyễnNo ratings yet

- Experimental Determining The Mechanical and Stiffness Properties 2020 PolymDocument13 pagesExperimental Determining The Mechanical and Stiffness Properties 2020 PolymClaudia UngureanuNo ratings yet

- Testing Erosion For FRPDocument6 pagesTesting Erosion For FRPocta aldyNo ratings yet

- Strengthening of Beams Using Glass Fiber Reinforced Polymer (GFRP) LaminateDocument9 pagesStrengthening of Beams Using Glass Fiber Reinforced Polymer (GFRP) LaminateRatnakarVarunNo ratings yet

- Effect of Twist Level On Tyre Cord PerformanceDocument6 pagesEffect of Twist Level On Tyre Cord Performanceayserinkskc_22375979No ratings yet

- Impact Strength Analysis of Polymer Composite MateDocument9 pagesImpact Strength Analysis of Polymer Composite MaterajesaravindNo ratings yet

- An Investigation Into The Effects of Fibre Volume Fraction On GFRP Plate 1Document7 pagesAn Investigation Into The Effects of Fibre Volume Fraction On GFRP Plate 1Abdul jeleelNo ratings yet

- 11.glassfiber Reinforcedpolymercomposite Areview OriginalDocument20 pages11.glassfiber Reinforcedpolymercomposite Areview OriginalŜṟéẻ Ṛąṁ ChowdaryNo ratings yet

- Journal of Reinforced Plastics and CompositesDocument19 pagesJournal of Reinforced Plastics and Compositeshue558110No ratings yet

- Glass Fiber-Reinforced Polymer Composite - A Review - OriginalDocument20 pagesGlass Fiber-Reinforced Polymer Composite - A Review - OriginalAvinash Singh100% (1)

- Experimental Study On Retrofitted RC T-BEAM Using FRPDocument5 pagesExperimental Study On Retrofitted RC T-BEAM Using FRPInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Song 2016Document8 pagesSong 2016AnkushNo ratings yet

- Sample Paper 1 PDFDocument9 pagesSample Paper 1 PDFAnni MataqeiNo ratings yet

- Experimental Study On Behaviour of RC T-Beam StrenDocument6 pagesExperimental Study On Behaviour of RC T-Beam Strenshaik saifulla lNo ratings yet

- Fabrication and Testing of Fibre Reinforced Polymer Composites MaterialDocument8 pagesFabrication and Testing of Fibre Reinforced Polymer Composites Materialyadagani nirmalNo ratings yet

- Flexural and Shear Performance of HFRC BeamsDocument5 pagesFlexural and Shear Performance of HFRC BeamsStephenNo ratings yet

- Mechanical Characterization of Carbon - EpoxyDocument4 pagesMechanical Characterization of Carbon - EpoxyDanielNo ratings yet

- Design and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With IsopolymerDocument30 pagesDesign and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With Isopolymershakeel100% (1)

- Publication 13Document7 pagesPublication 13Vishnu KalyanNo ratings yet

- Mechanical Testing and Microstructure Characterization of Glass Fiber Reinforced Isophthalic Polyester CompositesDocument10 pagesMechanical Testing and Microstructure Characterization of Glass Fiber Reinforced Isophthalic Polyester Compositespinkan25No ratings yet

- JETIR2105363Document10 pagesJETIR2105363ivs yeswanthNo ratings yet

- Material Today ProcDocument10 pagesMaterial Today ProcVikasKhatkarNo ratings yet

- Investigation of The Effect of Glass Fiber Content On The Mechanical Properties of Cast PolyamideDocument8 pagesInvestigation of The Effect of Glass Fiber Content On The Mechanical Properties of Cast PolyamideIndra JayaNo ratings yet

- C1666C1666MDocument3 pagesC1666C1666MKingNo ratings yet

- Mechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositeDocument4 pagesMechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositesriyajambukarNo ratings yet

- STRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS IeeeDocument3 pagesSTRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS Ieeettk qsNo ratings yet

- Conference PaperDocument5 pagesConference Paperaravind029No ratings yet

- Literature ReviewDocument10 pagesLiterature ReviewsithananthansithuNo ratings yet

- Retrofittng of Reinforced Concrete Beams Using GFRP OverlaysDocument17 pagesRetrofittng of Reinforced Concrete Beams Using GFRP OverlaysIAEME PublicationNo ratings yet

- Thermoplastic Composites - Best Practice GuideDocument49 pagesThermoplastic Composites - Best Practice GuidemanikandapriyaNo ratings yet

- Mechanical, Physical, and Wear Properties of Polypropylene Reinforced Short Carbon Fiber Composites With Different Fiber LengthDocument11 pagesMechanical, Physical, and Wear Properties of Polypropylene Reinforced Short Carbon Fiber Composites With Different Fiber LengthHarriJunaediNo ratings yet

- Use of Polymer in Bridge RehabilitationDocument13 pagesUse of Polymer in Bridge RehabilitationIJRASETPublicationsNo ratings yet

- Corbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016Document12 pagesCorbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016adonaies19No ratings yet

- Mechanical Properties of Glass Fibre Reinforced Polymer Based On Resin From Recycled PlasticDocument9 pagesMechanical Properties of Glass Fibre Reinforced Polymer Based On Resin From Recycled PlasticHernando ZambranoNo ratings yet

- Development of Glass/Banana Fibers Reinforced Epoxy CompositeDocument6 pagesDevelopment of Glass/Banana Fibers Reinforced Epoxy CompositeNeymarNo ratings yet

- Comparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesDocument7 pagesComparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesAndrew NallayanNo ratings yet

- Prediction of Mechanical Behavior of GFRP With Elastomer Under Impact and Tensile LoadingDocument4 pagesPrediction of Mechanical Behavior of GFRP With Elastomer Under Impact and Tensile LoadingRaguvaranNo ratings yet

- Study of The Mechanical Properties of Nonwoven Fibre Mat Reinforced Photopolumers Used in Rapid Photo TypingDocument6 pagesStudy of The Mechanical Properties of Nonwoven Fibre Mat Reinforced Photopolumers Used in Rapid Photo TypingJasminVasquezNo ratings yet

- Strength Analysis of E-Glass and Jute Fiber Reinforced Polyester CompositesDocument10 pagesStrength Analysis of E-Glass and Jute Fiber Reinforced Polyester CompositesTJPRC PublicationsNo ratings yet

- Developmental E Glass FiberDocument8 pagesDevelopmental E Glass FiberWidya Puspita SariNo ratings yet

- 10.2478 - Cee 2023 0036Document8 pages10.2478 - Cee 2023 0036ajayyadav24127No ratings yet

- Ballistic Performance of Thermoplastic CDocument8 pagesBallistic Performance of Thermoplastic CPedro ThiagoNo ratings yet

- Mechanical Properties of Polymer Matrix Composites: Effect of HybridizationDocument3 pagesMechanical Properties of Polymer Matrix Composites: Effect of HybridizationNagaraj K CNo ratings yet

- Composites Part B: K. Naresh, K. Shankar, R. VelmuruganDocument16 pagesComposites Part B: K. Naresh, K. Shankar, R. VelmuruganPavan Kumar ArigiNo ratings yet

- Investigation of Bending Properties On Carbon Fiber Reinforced Polymer Matrix Composites Used For Micro Wind Turbine BladesDocument7 pagesInvestigation of Bending Properties On Carbon Fiber Reinforced Polymer Matrix Composites Used For Micro Wind Turbine BladesAhmed ismailNo ratings yet

- Herzog Glass Transitiontempvinyleesterresin JPAS2005app.21868Document10 pagesHerzog Glass Transitiontempvinyleesterresin JPAS2005app.21868Kiplgat ChelelgoNo ratings yet

- Contact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentDocument8 pagesContact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentQUALITY MAYURNo ratings yet

- Astm C 582Document7 pagesAstm C 582ISIES SENAINo ratings yet

- 20ijmperdjun201920 PDFDocument8 pages20ijmperdjun201920 PDFTJPRC PublicationsNo ratings yet

- D 4389 - 99 - RdqzodkDocument5 pagesD 4389 - 99 - Rdqzodkmyusuf123No ratings yet

- Effect of Siwak and Bamboo Fibers On Tensile Properties of Self-Cure Acrylic Resin Used For Denture ApplicationsDocument6 pagesEffect of Siwak and Bamboo Fibers On Tensile Properties of Self-Cure Acrylic Resin Used For Denture ApplicationsJawad K. OleiwiNo ratings yet

- Composites: Part B: Antonio Greco, Alfonso Maffezzoli, Giovanni Casciaro, Flavio CarettoDocument6 pagesComposites: Part B: Antonio Greco, Alfonso Maffezzoli, Giovanni Casciaro, Flavio CarettoabhishekNo ratings yet

- Mechanical Properties of A Hybrid Nanocomposite Under Room Temperature and Hot-Wet EnvironmentsDocument8 pagesMechanical Properties of A Hybrid Nanocomposite Under Room Temperature and Hot-Wet EnvironmentsJoão BarrigóNo ratings yet

- Handbook of Composites from Renewable Materials, Design and ManufacturingFrom EverandHandbook of Composites from Renewable Materials, Design and ManufacturingNo ratings yet

- Simulation of Texture Development in A Deep Drawing ProcessDocument11 pagesSimulation of Texture Development in A Deep Drawing ProcessAnya CooperNo ratings yet

- General Pre Stress and ElasticDocument28 pagesGeneral Pre Stress and ElasticJorge Nickolai NavalesNo ratings yet

- Stochastic Processes 2Document11 pagesStochastic Processes 2Seham RaheelNo ratings yet

- Introductory Thermal Physics Worksheets and SolutionsDocument30 pagesIntroductory Thermal Physics Worksheets and SolutionsLetmiDwiridalNo ratings yet

- Working Monitors: Recent Valves, Actuators & Regulators DiscussionsDocument13 pagesWorking Monitors: Recent Valves, Actuators & Regulators DiscussionsraulNo ratings yet

- Alan - Macdonald 2012 A.survey - Of.geometric - Algebra.and - Geometric.calculusDocument33 pagesAlan - Macdonald 2012 A.survey - Of.geometric - Algebra.and - Geometric.calculusgiantgeorgeNo ratings yet

- Full Text 01Document90 pagesFull Text 01Walid NASRINo ratings yet

- BROSUR Solmax Waste English Rev0514Document28 pagesBROSUR Solmax Waste English Rev0514Naufal IhsanNo ratings yet

- Thoshiba Power TransformerDocument28 pagesThoshiba Power TransformerSERGIO_MANNo ratings yet

- Belden Optical Fiber Cable Catalog EMEA - Original - 54507Document94 pagesBelden Optical Fiber Cable Catalog EMEA - Original - 54507Agus YulfizarNo ratings yet

- Efficient Implementation of Superquadric Particles in DiscreteDocument18 pagesEfficient Implementation of Superquadric Particles in DiscretedavidusachNo ratings yet

- Microwave Coaxial Connector Technology: A Continuing EvolutionDocument21 pagesMicrowave Coaxial Connector Technology: A Continuing EvolutionTHBFLNo ratings yet

- Electrical Machines - I: Electric Circuit TheoryDocument22 pagesElectrical Machines - I: Electric Circuit TheoryPradeep SinglaNo ratings yet

- Pidicrete CF 121 (m1)Document1 pagePidicrete CF 121 (m1)nickdash09No ratings yet

- Beilstein Journal of NanotechnologyDocument11 pagesBeilstein Journal of NanotechnologydeepshaNo ratings yet

- Angle of Twist: Torsion II: 1Document4 pagesAngle of Twist: Torsion II: 1Anjana ENo ratings yet

- LaserDocument20 pagesLasertsrockon28No ratings yet

- MATH-6103-2013T (UGRD) Calculus 2: Prelim ExamDocument18 pagesMATH-6103-2013T (UGRD) Calculus 2: Prelim ExamJitlee PapaNo ratings yet

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghNo ratings yet

- The Acoustics HutcinsDocument43 pagesThe Acoustics Hutcinsarmadillo27No ratings yet

- CFD Analysis of Centrifugal Pump ImpelleDocument9 pagesCFD Analysis of Centrifugal Pump Impelleبلال بن عميرهNo ratings yet

- 3.2 Mass Ma 4 KG Rests On Top of Mass MB 5kg That Rests On A FricDocument7 pages3.2 Mass Ma 4 KG Rests On Top of Mass MB 5kg That Rests On A Fricsoumengoswami10No ratings yet

- Bolted Tension Flanges Joining Square Hollow Section MembersDocument15 pagesBolted Tension Flanges Joining Square Hollow Section MembersGhitzaaaNo ratings yet

- Objective (MCQ) Chemical Engineering SampleDocument25 pagesObjective (MCQ) Chemical Engineering SampleKapilSahu50% (2)

- CoreLok ManualDocument41 pagesCoreLok ManualRafa Bernal Padilla100% (1)

- DescriptionDocument111 pagesDescriptionKaaliNo ratings yet

- Mokon: Central Chillers and Pump TanksDocument4 pagesMokon: Central Chillers and Pump Tanksbird99No ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument4 pagesCambridge International Advanced Subsidiary and Advanced LevelParveen AkhtarNo ratings yet