Professional Documents

Culture Documents

Test 2

Test 2

Uploaded by

Prashant SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test 2

Test 2

Uploaded by

Prashant SharmaCopyright:

Available Formats

Birla Institute of Technology and Science Pilani, Hyderabad Campus

Second Semester 2015-2016

MF F341 DESIGN OF MACHINE TOOLS

Open Book

Test 2 09.04.2016

60 minutes 20%weightage

Answers should be crisp and to the point, Vague or incomplete answers will not get ANY credit

Q1. What are the different types of thick film and thin film lubrication methods used in the machine

tools? [4]

Q2. Design a guide way for a heavy duty lathe machine, considering following specifications and

conditions:

Maximum cutting forces Px= 120 kgf, Py= 130kgf, Pz= 300 kgf

Weight of the carriage, tool post, and tool with other assembly parts = 16 Kgf

Select the maximum permissible value of pressure [pmax] for heavy duty machine tool

operating at low sliding velocity. For the average [pav] to maximum [pmax] pressure relation,

assume that the tool post is mounted on the carriage such that the reactional forces are exactly

acting at the center of the carriage. Hence, xA/L=0.

The horizontal distance from the tip of the tool to the center of the nearest guideway is 30 cm.

The center to center distance of the guide ways is 100 cm. The axis of workpiece supposed to

locate at 60 cm height (vertical) from the centers of guideways.

The length of the carriage cannot be more than 20 cm because of other dimensional

constraints.

Determine the face lengths (a, b, c) for the guide ways. Determine the pulling force (Q) for the

carriage, if the coefficient of friction between the guideway and carriage is 0.2. Also make a

schematic diagram of the guide way with tool and work piece, mentioning all dimensions and

forces/reactions acting. [9+4+3]

Q3. Compute average pressure, maximum shearing stress and pitch error for a lead screw of lathe

machine. The lead screw is double start ACME thread. The various parameters are, Minor

diameter=44mm, major diameter=46mm, Pitch=8 mm, Effective diameter=45 mm, Length of

nut=120 mm, Px=50 kgf, Py=60 kgf, Pz=120kgf, coefficient of friction between the thread and the

nut=0.1, coefficient of friction between the guide and carriage=0.2, weight of carriage = 40 kgf.

[For steel E=2105 kgf/cm2, G=1.6105 kgf/cm2] [10]

Q4. For a lathe machine, the maximum permissible error in diameter during the turning operation is

0.12mm. It is desired to find out the effect of only spindle on the dimensional errors. The

minimum allowed stiffness values of the headstock and tailstock is 4000 kgf/mm, and 2500

kgf/mm respectively. Compute the maximum permissible cutting force in radial direction (Py)

subject to the dimensional accuracy stated earlier. What will be the minimum dimensional error

in diameter corresponding to this cutting force component? [10]

***END***

You might also like

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- Kaptronics Private Limited PDFDocument9 pagesKaptronics Private Limited PDFkaptronicsNo ratings yet

- Design and Fabrication of Trenching Machine: Amal.M.S, Vimal Cherian Joseph Jose, Texo JoseDocument4 pagesDesign and Fabrication of Trenching Machine: Amal.M.S, Vimal Cherian Joseph Jose, Texo JoseSarath Philip Mathew VenkadathNo ratings yet

- Design and Fabrication of 4 - Way Hacksaw Machine: Department of Mechanical Engineering 2018Document28 pagesDesign and Fabrication of 4 - Way Hacksaw Machine: Department of Mechanical Engineering 2018Shailendra VermaNo ratings yet

- Practice Exam 6: Plant Engineering: FactoriesDocument8 pagesPractice Exam 6: Plant Engineering: Factoriestapera_mangeziNo ratings yet

- Question 3Document4 pagesQuestion 3Ramesh ShresthaNo ratings yet

- 3455 PDF PDFDocument6 pages3455 PDF PDFrezNo ratings yet

- DME MiniProjectDocument17 pagesDME MiniProjectJinmay KalitaNo ratings yet

- Design and Fabrication of Hydraulic Lift Cover Hlccomponent Tilting MachineDocument4 pagesDesign and Fabrication of Hydraulic Lift Cover Hlccomponent Tilting Machineahmed jemalNo ratings yet

- Design and Fabrication PDFDocument3 pagesDesign and Fabrication PDFSuresh IndiaNo ratings yet

- Final Year Project ReportDocument90 pagesFinal Year Project ReportSunil AdhikariNo ratings yet

- 6450 Board Diploma Examination, (C-16) : WWW - Manaresults.co - inDocument2 pages6450 Board Diploma Examination, (C-16) : WWW - Manaresults.co - inGod deva123No ratings yet

- Design & Development of Multipurpose Machine: Prof. S.S.Lande, Shrishiel Desai, Chetan JadhavDocument7 pagesDesign & Development of Multipurpose Machine: Prof. S.S.Lande, Shrishiel Desai, Chetan JadhavAung Khin ZawNo ratings yet

- Cad by BiomedicalDocument20 pagesCad by BiomedicalAshish RajNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- Design of Machine ElementsDocument4 pagesDesign of Machine ElementsniteshNo ratings yet

- Report FEADocument15 pagesReport FEAamuNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- 07rr310305 Design of Machine Members IDocument8 pages07rr310305 Design of Machine Members IandhracollegesNo ratings yet

- 3rdi A QP Faculty DME-2Document3 pages3rdi A QP Faculty DME-2vaijanath patilNo ratings yet

- Cad 1 Project FinalDocument19 pagesCad 1 Project FinalBill 007No ratings yet

- WWW - Manaresults.co - In: Design of Machine Members - IiDocument8 pagesWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNo ratings yet

- Grace Merryline - MidDocument10 pagesGrace Merryline - MidGrace BornengNo ratings yet

- Pont Dalle en Ba Groupe Gci ADocument20 pagesPont Dalle en Ba Groupe Gci Aken koemhongNo ratings yet

- FP FINAL-converted (2) - Merged-Pages-DeletedDocument18 pagesFP FINAL-converted (2) - Merged-Pages-DeletedAbdullah Raghib SiddiquiNo ratings yet

- Welding Tools and EquipmentsDocument9 pagesWelding Tools and EquipmentsMarko futeNo ratings yet

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of GearboxChandrakiran AlapatiNo ratings yet

- PDF ArghyaDocument75 pagesPDF Arghyaaghosh704No ratings yet

- Automated Feed Handling System For Stamping Process: Chanvim Engineering Industries Pvt. LTDDocument28 pagesAutomated Feed Handling System For Stamping Process: Chanvim Engineering Industries Pvt. LTDmayank soniNo ratings yet

- Swapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTDocument5 pagesSwapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTGogyNo ratings yet

- Hammer Mill 1 PDFDocument8 pagesHammer Mill 1 PDFsaadatnailuNo ratings yet

- Quiz1 PDFDocument5 pagesQuiz1 PDFratgauriNo ratings yet

- MSDMD ManualDocument20 pagesMSDMD ManualBhupesh GoyalNo ratings yet

- Prasad 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012058Document7 pagesPrasad 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012058ajiejohn56No ratings yet

- Star Wire FilesDocument32 pagesStar Wire FilesMehtaMilanNo ratings yet

- Dme Question Paper PDFDocument34 pagesDme Question Paper PDFVenkatesh ChellaboinaNo ratings yet

- Shang2018 Article ModellingOfCuttingForcesAndResDocument12 pagesShang2018 Article ModellingOfCuttingForcesAndResJosé Veríssimo ToledoNo ratings yet

- Gearless TransmissionDocument37 pagesGearless TransmissionTanvi KhuranaNo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- Me-302 Id (Ao819) PDFDocument2 pagesMe-302 Id (Ao819) PDFVikasNo ratings yet

- SM CT-3Document2 pagesSM CT-3gowrisankar32No ratings yet

- IJCRT2305283Document6 pagesIJCRT2305283rrpatil1221No ratings yet

- Analytical Models For High Performance Milling. Part II: Process Dynamics and StabilityDocument11 pagesAnalytical Models For High Performance Milling. Part II: Process Dynamics and StabilityAditya Pujasakti YuswiNo ratings yet

- Design of Machine Elements Oct 2017Document3 pagesDesign of Machine Elements Oct 2017Kalpesh JadhavNo ratings yet

- Assignments Machine Tool DesignDocument7 pagesAssignments Machine Tool Designabdullah 3mar abou reashaNo ratings yet

- Roll Number: Tiet, Engineering Auxiliary Exam, 21 February 2018 Course: Machine Design (UME 408/504/508) Max Marks: 100 Time: 03 HoursDocument2 pagesRoll Number: Tiet, Engineering Auxiliary Exam, 21 February 2018 Course: Machine Design (UME 408/504/508) Max Marks: 100 Time: 03 Hoursvasu jamwalNo ratings yet

- Reliability Analysis of Broaching MachineDocument34 pagesReliability Analysis of Broaching MachineSangram Kharade IINo ratings yet

- Colombo International Nautical & Engineering College: ME1324-Workshop Practice Class Test-2, (Batch - 4)Document1 pageColombo International Nautical & Engineering College: ME1324-Workshop Practice Class Test-2, (Batch - 4)Nipun BandaraNo ratings yet

- ME1324 Class Test 2Document1 pageME1324 Class Test 2Nipun BandaraNo ratings yet

- 2018 ICEM FSCW KPI Draft1 checkOKDocument8 pages2018 ICEM FSCW KPI Draft1 checkOKMaycon MaranNo ratings yet

- "HMS, HWS, Ma-1 & LPS" AT Diesel Locomotive Works, Varanasi: Alok GuptaDocument31 pages"HMS, HWS, Ma-1 & LPS" AT Diesel Locomotive Works, Varanasi: Alok GuptaAlok GuptaNo ratings yet

- Pdf&rendition 1Document24 pagesPdf&rendition 1pavanrp997No ratings yet

- Design of Machine Members-IDocument8 pagesDesign of Machine Members-IMahesh Babu TalupulaNo ratings yet

- Engineering Project-Paper Cutting & Rewinding MachineDocument94 pagesEngineering Project-Paper Cutting & Rewinding MachineMechanical Prasad82% (11)

- Prediction of Tool Wear Using Regression and ANN ModelsDocument14 pagesPrediction of Tool Wear Using Regression and ANN ModelsAtsis PapadopoulosNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- WWW - Manaresults.Co - In: (Common To ME, AME)Document3 pagesWWW - Manaresults.Co - In: (Common To ME, AME)Your ChoiceNo ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- FP Metal Enclosed Switchgear BrochureDocument24 pagesFP Metal Enclosed Switchgear BrochureAlex Jr ApuyaNo ratings yet

- BS en Iso 9445 (2006)Document26 pagesBS en Iso 9445 (2006)Syerifaizal Hj. MustaphaNo ratings yet

- KeraplastDocument6 pagesKeraplastpotexNo ratings yet

- Adf LabDocument80 pagesAdf LabSurendra BabuNo ratings yet

- Cisco Switch Configuration Template For Aastra Phones: Advanced Technical Assistance Center (ATAC)Document7 pagesCisco Switch Configuration Template For Aastra Phones: Advanced Technical Assistance Center (ATAC)ausmitchNo ratings yet

- QoS SOLO TEST VELOCIDADDocument2 pagesQoS SOLO TEST VELOCIDADArnulfo MartinezNo ratings yet

- DNS PresentationDocument29 pagesDNS PresentationJeng Dev100% (1)

- MGI Supplier Quality Statement of Requirement 21.06.19Document8 pagesMGI Supplier Quality Statement of Requirement 21.06.19Uday SharmaNo ratings yet

- SCSI 3 Reservation ExplainedDocument4 pagesSCSI 3 Reservation ExplainedShanmuga AnandNo ratings yet

- Ms CustomuiDocument551 pagesMs CustomuiDamner Davila TacuchiNo ratings yet

- Review XXX ACS Guide 2014Document2 pagesReview XXX ACS Guide 2014Vinod ManjuNo ratings yet

- Igus CF211Document2 pagesIgus CF211James ValenzuelaNo ratings yet

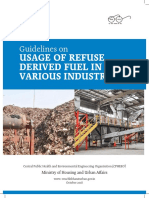

- Guidelines On Usage of RDF in Various IndustriesDocument104 pagesGuidelines On Usage of RDF in Various Industriessaravanan gNo ratings yet

- Psdemux LogDocument47 pagesPsdemux Logvaishnavi hulsureNo ratings yet

- Zero Based Budgeting - Incremental BudgetingDocument2 pagesZero Based Budgeting - Incremental Budgeting9nishitNo ratings yet

- Furuno Felcom 12 SoftwareDocument9 pagesFuruno Felcom 12 SoftwaredhmaidyNo ratings yet

- PD Cen TR 13930-2009 (2010)Document32 pagesPD Cen TR 13930-2009 (2010)Sadek SadNo ratings yet

- 14250A ch19Document19 pages14250A ch19jcarlos7411No ratings yet

- 802d SL E01Document25 pages802d SL E01Raghavendran Babuji100% (1)

- ASME B1.30 (2002) Screw Threads Standard Practice For Calculating & Rounding DimensionsDocument36 pagesASME B1.30 (2002) Screw Threads Standard Practice For Calculating & Rounding Dimensionsbobuncle03No ratings yet

- Soft Shell Clothing From Niton 08-Issue-14Document12 pagesSoft Shell Clothing From Niton 08-Issue-14RomiNo ratings yet

- Ensayo Sobre La Cultura Nativa AmericanaDocument5 pagesEnsayo Sobre La Cultura Nativa Americanaafefhijqi100% (2)

- Pipe Flow Expert BrochureDocument2 pagesPipe Flow Expert BrochureklganandNo ratings yet

- 05 Refrigeration Compressors A Trane Air Conditioning ClinicDocument11 pages05 Refrigeration Compressors A Trane Air Conditioning Clinicmaddy_sggsNo ratings yet

- React Developer - ZahraDocument4 pagesReact Developer - ZahraAnonymous pow3LFSNo ratings yet

- LineTroll 111K DescriptionDocument4 pagesLineTroll 111K DescriptionsivasankarNo ratings yet

- Basic Concepts For Explosion Protection - ExDocument41 pagesBasic Concepts For Explosion Protection - ExRadu Babau100% (1)

- 6th Sem Lesson Plan EVEN 2020-1 PDFDocument32 pages6th Sem Lesson Plan EVEN 2020-1 PDFyourMomNo ratings yet

- Web Security (Transport-Level Security)Document16 pagesWeb Security (Transport-Level Security)Vasantha KumariNo ratings yet