Professional Documents

Culture Documents

What's HDI Circuit Board - News - Heros Electronics

What's HDI Circuit Board - News - Heros Electronics

Uploaded by

Heros ElectronicsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What's HDI Circuit Board - News - Heros Electronics

What's HDI Circuit Board - News - Heros Electronics

Uploaded by

Heros ElectronicsCopyright:

Available Formats

2017328 What'sHDICircuitBoard?

NewsHerosElectronics

+867552749 5167 Ext. 806 sales@heroselectronics.com

Home Capacities Products News Contact Request A Quote

Home / News

What'sHDICircuitBoard?

The authorPageviews148Release time20160514 10:47:57

20layer HDI Circuit Boad Stackup

HDI is the abbreviation for High Density Interconnect. HDI circuit board is defined as a PCB with a higher wiring density per unit area than conventional PCB. They have finer lines

and spaces, smaller vias and capture pads and higher connection pad density than employed in conventional PCB technology. HDI PCB is used to reduce size and weight, as

well as to enhance electrical performance of the device. HDI PCB is made through Microvia and buried vias and sequential lamination with insulation materials and conductor

wiring for higher density of routing. HDI PCB is the best alternative to high layercountand expensive standard laminate or sequentially laminated boards.

Concerning the electrical requirements for highspeed signal, the PCB must possess some AC characteristics, such as impedance control, highfrequency transmission capability

and reduce unnecessary radiation. Multilayered design is necessary for the structure of Stripline and Microstrip. In order to lesson the quality issues of signal transmission, the

insulating material with low dielectric factor and low attenuation ratio is applied. Duo to the miniaturization and arrays of the electronic components, the PCB must be improved

in the density. Along with the outcome of the assembling methods of Ball Grid Array, Chip Scale Package and Direct Chip Attachment, the PCB is featured with unprecedented

highdensity. The hole with a diameter less than 150um is known as Microvia. It can improve the effectiveness of assembly and space utilization and so on. Its also necessary for

the miniaturization of electronic products.

There were a lot of different names for the PCB with such structures. For example, it was called SBU (Sequence Build up the Process) in European and American industry as the

program production is in the constructive mode of sequence. It was called MVP (Microvia Process) in Japanese industry because the hole of such products is much smaller than

the previous one. It was also called BUM (Build up Multilayer Board) because the traditional multilayer is known as MLB (Multilayer Board).In order to avoid confusion, IPC Printed

Circuit Association proposed to call it HDI (High Density Interconnection Technology) as the common name, but it can not reflect the characteristics of the circuit board. So the

majority in the PCB industry define such products as HDI PCB.

There are a lot of advantages with HDI Circuit Board, such as small size pcb, high speed pcb and high frequency pcb. It is the main components of personal computers, portable

computers, mobile phones and personal digital assistants. At present, except mobile phones, HDI PCB is also widely used in a variety of other consumer products, such as game

consoles and industrial controller, etc. In addition, the applying of HDI PCB in notebook computer is expected trend since 2006 is in the industry.

Pre Blind & Buried Via Technology in HDI PCB

Next Why High Layer PCB Board Used So Widely?

Contact Our Features News Click to send mail

Tel: PCB Assembly Capacities Introduction of PCB Materials Get PCB and PCBA quick quote!

+867552749 5167 Ext. 806

Rigid PCB Capacities DFM From Gerber files to PCB Production

Email: Data Send Email

sales@heroselectronics.com File Package Information

Skype: Blind & Buried Via Technology in HDI PCB

130Layer FR4 PCB

alan@heroselectronics.com

Aluminum PCB Controlled Impedance Printed Circuit

Address: Board

3F, A4 Building, Junfeng Industrial Car Devices

Park, Chongqing Road, Fuyong Computer

Street, Bao'an District, Shenzhen

518103, China.

http://heroselectronics.com/en/News/95.html 1/1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Servo Amplifier - Troubleshooting GuideDocument5 pagesServo Amplifier - Troubleshooting GuideOmar Leon0% (1)

- Order Management SystemDocument7 pagesOrder Management SystemAther Uddin100% (1)

- Shengyi FR4 S7136 High Frequency PCB For Communication Antenna - High Frequency PCB - Heros ElectronicsDocument3 pagesShengyi FR4 S7136 High Frequency PCB For Communication Antenna - High Frequency PCB - Heros ElectronicsHeros ElectronicsNo ratings yet

- RoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsDocument3 pagesRoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsHeros ElectronicsNo ratings yet

- 2 Layer Cheap RO3003 PCB Rogers High Frequency PCB Fabrication - High Frequency PCB - Heros Electronics PDFDocument3 pages2 Layer Cheap RO3003 PCB Rogers High Frequency PCB Fabrication - High Frequency PCB - Heros Electronics PDFHeros ElectronicsNo ratings yet

- 2 Layer Next Day PCB Prototype Shenzhen - PCB Prototype Board - Heros Electronics PDFDocument3 pages2 Layer Next Day PCB Prototype Shenzhen - PCB Prototype Board - Heros Electronics PDFHeros ElectronicsNo ratings yet

- 2L High Frequency Circuit Board Arlon AD1000 PCB With Immersion Silver - High Frequency PCB - Heros ElectronicsDocument3 pages2L High Frequency Circuit Board Arlon AD1000 PCB With Immersion Silver - High Frequency PCB - Heros ElectronicsHeros ElectronicsNo ratings yet

- 1W/mK Aluminium PCB Fabrication - Aluminum PCB - Heros ElectronicsDocument4 pages1W/mK Aluminium PCB Fabrication - Aluminum PCB - Heros ElectronicsHeros ElectronicsNo ratings yet

- SMT & DIP PCB Prototype Assembly - Consumer Electronics - Heros ElectronicsDocument3 pagesSMT & DIP PCB Prototype Assembly - Consumer Electronics - Heros ElectronicsHeros ElectronicsNo ratings yet

- Aeon7200A-Service Manual - v0 (1) .7Document67 pagesAeon7200A-Service Manual - v0 (1) .7Carlito Sales100% (7)

- Hydraulic Thrust DeviceDocument2 pagesHydraulic Thrust DeviceAlbar Budiman100% (6)

- Siemens Fluorospot X-Ray Image System - User Manual PDFDocument237 pagesSiemens Fluorospot X-Ray Image System - User Manual PDFEdinson Ocampo CastilloNo ratings yet

- Project No 11Document83 pagesProject No 11fpttmm100% (1)

- 4 - Wrench (Plane Stress Problem - Bicycle Wrench) : Right Click (Starts Up Design Modeler)Document4 pages4 - Wrench (Plane Stress Problem - Bicycle Wrench) : Right Click (Starts Up Design Modeler)msi appleNo ratings yet

- 12steme 9 Group7Document30 pages12steme 9 Group7Jaderick BucaoNo ratings yet

- Skiip 30 Nab 12 Miniskiip 3 Semikron Integrated Intelligent Power Skiip 30 Nab 12 3-Phase Bridge Rectifier + Braking Chopper + 3-Phase Bridge InverterDocument4 pagesSkiip 30 Nab 12 Miniskiip 3 Semikron Integrated Intelligent Power Skiip 30 Nab 12 3-Phase Bridge Rectifier + Braking Chopper + 3-Phase Bridge InverterjonathanNo ratings yet

- Landownership in The Philippines Under SpainDocument27 pagesLandownership in The Philippines Under SpainSheena De La CruzNo ratings yet

- Towards High Potential Engineers and Future ManagersDocument17 pagesTowards High Potential Engineers and Future ManagersMuhammad SiddNo ratings yet

- ECE-C201 Programming For Engineers Programming Assignment 2 Run-Length Encoding & Decoding 1 BackgroundDocument5 pagesECE-C201 Programming For Engineers Programming Assignment 2 Run-Length Encoding & Decoding 1 BackgroundAbdul MunamNo ratings yet

- Installation Guide: Technical Support For This Product Is Available by Calling Tyco Helpdesk On 0870 123 8787Document20 pagesInstallation Guide: Technical Support For This Product Is Available by Calling Tyco Helpdesk On 0870 123 8787rodrigoaranhaNo ratings yet

- Navitron Systems LTD: Analogue & Digital Heading RepeatersDocument7 pagesNavitron Systems LTD: Analogue & Digital Heading RepeatersABDOULAYE DIAGNENo ratings yet

- Com 5501 SoftDocument11 pagesCom 5501 SoftComBlockNo ratings yet

- MAR - KL-GM186 5th Annual Plantation Management 4.0 (Brochure) 2Document5 pagesMAR - KL-GM186 5th Annual Plantation Management 4.0 (Brochure) 2Amrafael sitompulNo ratings yet

- IT IS - CNS - Data Network - Cisco PDFDocument7 pagesIT IS - CNS - Data Network - Cisco PDFkrunalNo ratings yet

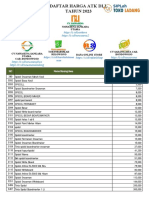

- Daftar Harga Atk DLL Update BondowosoDocument14 pagesDaftar Harga Atk DLL Update BondowosoFoppsi TamananNo ratings yet

- Mac Operating SystemDocument12 pagesMac Operating SystemMaham100% (1)

- Rci-4000is Function CodeDocument3 pagesRci-4000is Function CodeEpuAmerNo ratings yet

- Chapter 11: Marketing of Small BusinessDocument3 pagesChapter 11: Marketing of Small BusinessJM MiraNo ratings yet

- Stand Alone PV SystemsDocument244 pagesStand Alone PV SystemsKits KittuNo ratings yet

- Foundations of Information Systems in BusinessDocument50 pagesFoundations of Information Systems in BusinessRaghuram BhandariNo ratings yet

- Vehicle Detection Using Morphological Image Processing TechniqueDocument5 pagesVehicle Detection Using Morphological Image Processing TechniquevijayNo ratings yet

- CS6711 Security Lab Manual PDFDocument82 pagesCS6711 Security Lab Manual PDFAathi LinNo ratings yet

- Manufacturing Resource PlanningDocument4 pagesManufacturing Resource PlanningMiguel HernándezNo ratings yet

- MCOM 402 - Online Journalism: The Digital Journalist's Handbook, 2012, by Mark S. Luckie. ISBN-13: 978-1450565608Document5 pagesMCOM 402 - Online Journalism: The Digital Journalist's Handbook, 2012, by Mark S. Luckie. ISBN-13: 978-1450565608Stan DielNo ratings yet

- 3GPP TS 23.038Document56 pages3GPP TS 23.038Eddie CarpenterNo ratings yet