Professional Documents

Culture Documents

10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDF

10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDF

Uploaded by

khaireddinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDF

10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDF

Uploaded by

khaireddinCopyright:

Available Formats

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 1 of 10

SPECIFICATIONS

FOR

PRESSURE SAFETY VALVES

Hindustan Petroleum Corporation Ltd Mott MacDonald Consultants (India) Pvt. Ltd.

Visakha Dispatch Station Kothari House, CTS No. 185

VR-ATP Area, Naval Base Post Off Andheri - Kurla Road

Visakhapatnam - 530 014 Andheri (East)

Andhra Pradesh Mumbai 400 059

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 2 of 10

SPECIFICATIONS

FOR

PRESSURE SAFETY VALVES

Client HINDUSTAN PETROLEUM CORPORATION LTD.

MMCI Project No. 254625

Issue and Revision Record:

Rev Date Originator Checked Approved Description

A 18.06.09 HVS AYM RM Issued for Approval

Group Disclaimer

"This document has been prepared for the titled project or named part thereof and should not be relied upon or used

for any other project without an independent check being carried out as to its suitability and prior written authority

of Mott MacDonald being obtained. Mott MacDonald accepts no responsibility or liability for the consequences of

this document being used for a purpose other than the purposes for which it was commissioned. Any person using or

relying on the document for such other purpose agrees, and will by such use or reliance be taken to confirm his

agreement, to indemnify Mott MacDonald for all loss or damage resulting therefrom. Mott MacDonald accepts no

responsibility or liability for this document to any party other than the person by whom it was commissioned.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 3 of 10

List of Contents Page

1 Introduction 4

2 Applicable, Codes, Standards & Specification 4

2.1 General 4

2.2 Codes and Standards 4

2.2.1 International Codes 4

2.2.2 National Codes 5

2.2.3 IBR Certification 5

2.3 Deviations to Specification 5

2.4 Conflicting Requirements 5

2.5 Associated Project Documentation. 5

2.6 Abbreviations & Terminology 6

3 Plant Location 6

4 Scope of Supply 6

5 Construction 6

6. Functional requirements 7

7. Tagging 7

8 Accessories 7

9 Performance 7

10 Test & Test Certificate 8

11 Guarantee 8

12 Documentation 8

12.1 Documentation with offer 8

12.2 Documentation after LOI/PO 9

12.3 Final Documentation 9

13 Spares 9

14 Special Tools 9

15 Transportation and Storage 10

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 4 of 10

1 Introduction

This specification covers the minimum requirements for the design, manufacture, assembly,

inspection, testing, certification, packing and delivery of Pressure Safety Valve for Hindustan

Petroleum Corporation Ltd. (HPCL) for Terminal Automation of Visakh Marketing

Installation Resitement Project Black oil Terminal.

The following definitions shall apply for this specification:

Definitions:

Owner : Hindustan Petroleum Corporation Ltd. (HPCL) Black Oil

Marketing Terminal, Visakh

Consultant : Mott MacDonald Consultants (India) Pvt. Ltd. (MMCI)

Bidder / Manufacturer : Valve supplier

Shall : This is to be understood as a mandatory in relation to the

requirements of this document

Should : This is to be understood as a strong recommendation

2 Applicable, Codes, Standards & Specification

2.1 General

The items shall be designed and supplied in accordance with this specification and the codes

and standards referenced herein.

The design, manufacture, assembly, inspection, testing, certification and delivery of pressure

safety valves shall be in accordance with the latest edition of the codes, specifications and

standards (including standards / specifications mentioned therein) listed in this requisition.

It is assumed that the standards and specifications listed below are in the Bidders possession.

2.2 Codes and Standards

The pressure safety valves shall meet but not be limited to the latest edition or revision of the

following codes and standards.

2.2.1 International Codes

The selection of material and equipment, and the design and construction of the equipment

covered by this specification shall comply with the applicable edition of the references in effect

at the time of the Purchase Order and as noted throughout this specification.

Design and Installation of Pressure Relieving Systems in

API RP 520 2008 Refineries, Part I. Sizing selection and installation of

pressure relieving devices in refineries Part II installation

API STD 521 2007 Guide for pressure relieving & Depressurzing system

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 5 of 10

Flanged Steel Safety Relief Valves for use in Petroleum

API STD 526 2009

Refineries

Commercial Seat Tightness of Safety Valves with Metal to

API STD 527 2002

Metal Seats

ASME Section

2007 Boiler and Pressure Vessel Code

VIII Div I

2.2.2 National Codes

IBR 2008 Indian Boiler Regulations

2.2.3 IBR Certification

For valves described as IBR certification Required, valves shall be in accordance with the

latest IBR regulation. Valves coming under IBR shall each be individually accompanied by

IBR certificate original in Form III-C duly approved by IBR authority / local authority

empowered by Central Boiler Board of India. Photocopy of originals certificate duly attested by

the local boiler inspector where the bidder/manufacturer is located is the minimum requirement

for acceptance.

2.3 Deviations to Specification

2.3.1 The Bidder shall provide an item wise list of any deviations to this specification. These shall be

listed on the compliance sheet with seal & duly signed by authorised signatory & shall be

submitted along with offer.

2.3.2 Where a conflict in standards occurs then the Bidder shall seek a clarification ruling from the

Owner. Where a deviation from the standard is required, then the Bidder shall make a formal

request with full supporting information.

2.3.3 Only those deviations that are agreed between the Owner and the Bidder will be incorporated

into the requisition at the time of order.

2.4 Conflicting Requirements

In case of conflict between documents relating to the enquiry or purchase order, the following

priority of documents shall apply:

First priority : Data Sheets.

Second priority : This specification.

Third priority : International Standards.

Note: Should any conflict arise either before or after order placement the Bidder shall

immediately inform the Owner / Consultant for technical resolution of the conflict.

2.5 Associated Project Documentation.

Specifically applicable codes are found at the beginning of each section of the Project

specifications relevant to Instrumentation and Automation

254625-300-DB-GEN-006 Project Design Basis

254625-300-VL-INT-002 Approved Vendor List

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 6 of 10

254625-300-SP-PIP-002 Piping Specification Index

254625-300-SP-PIP-003 Specifications for Painting

254625-300-SP-PIP-018 Piping Valve specifications

(Globe)

254625-300-DS-INT-027 Data sheet for Pressure Safety Control Valves

2.6 Abbreviations & Terminology

CV Control Valve

LO Lock Open

ISA Instruments Society of America

PCV Pressure Control Valve

PSV Pressure Safety Valve

CCOE Chief Controller Of Explosives

CMRI Central Mining Research Institute

3 Plant Location

For plant location and environment condition refer to Project Design Basis document no.

254625-300-DB-GEN-006.

4 Scope of Supply

This specification covers the minimum requirements for design, manufacture, testing and

supply of pressure safety valves as per this specifications and data sheets. The bidder scope

includes

4.1 Pressure Safety Valve sizing & submission of sizing calculations for approval.

4.2 Valve drawings and calculations, including outline dimensions, weights, section drawings, part

lists and materials for approval.

4.3 Any special tools required for assembly, disassembly and maintenance.

4.4 Manuals for installation, operation, and maintenance, including instructions for any sub-

suppliers.

4.5 List of recommended spare parts.

5 Construction

5.1. Material of Construction shall be as indicated in data sheet.

5.2. Trim shall include the nozzle, the disc holder, stem, guide, blow down ring, ring pin, bushing

and all internal parts, except the body, in contact with the process fluid. The nozzle and disc shall

be forged / bar stock SS 316 with machined stainless steel guide and spindle. The valve spring

design shall permit an adjustment of +/- 5 % of the set pressure as a minimum.

5.3 Spring materials supplied shall be suitable for the relieving temperatures given on the data

sheet. Alloy steel shall be used for temperature below 230C.

5.4 Plain lifting levers shall be provided on all valves for steam service unless specified otherwise

on the data sheet.

5.5 Caps shall be provided over the spring adjusting screws on all valves. The cap and bonnet shall

be provided with a wire seal to prevent unauthorized adjustment.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 7 of 10

5.6 Only safety relief valves incorporating adjustable blow down rings shall be offered for

protecting process equipment.

5.7 Safety / Relief valves shall be painted in accordance with manufacturer standard unless

otherwise specified.

6. Functional requirements

6.1 The safety or relief valve shall be of adequate size to relieve the capacity at the specified

pressure and temperature conditions and fluid physical properties regardless of any preliminary

sizing calculations or orifice designation shown on data sheet.

6.2 Accumulation used in calculating size of relieving devices shall be 10%.

6.3 The valves shall be suitable for continuous operation under the operating conditions indicated

in data sheets.

6.4 For very low capacity applications, if API orifice is offered, vendor shall provide mechanical

stop to prevent lifting. Vendor shall also arrange for witnessing capacity test of such valves.

7. Tagging

A permanently attached (with drive pins or equal) stainless steel tag (s) stamped with the following

information shall be provided on each valve

Tag Number

Manufacturer's Name or Trademark

Model Number

Serial Number and Year of manufacture

Size of Valve with flange rating for inlet and outlet Body Material

Body and Trim Material

Set pressure

Set Pressure Range

Orifice description

Code stamp

8 Accessories

8.1 Lifting lever, Test Gag etc as specified in data sheet shall be supplied.

8.2 Lifting I Bolt shall be provided.

9 Performance

9.1 Each valve shall be factory set and tested in accordance with the appropriate code Procedures.

9.2 When the valve is subjected to the specified set pressure, destructive chattering shall not occur

when raising the pressure to the popping point and then lowering to below the closing pressure.

9.3 Set pressure tolerances shall be as required by the appropriate code.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 8 of 10

9.4 Operational tightness test - the valves shall be bubble tight when tested at 90% of set pressure

in accordance with the appropriate standard.

9.5 Blowdown shall not be less than that specified on the data sheets.

10 Test & Test Certificate

The supplier shall issue with each valve test certificates confirming that it complies with the

relevant codes for:

10.6.1 Hydrostatic pressure test

10.6.2 Seat leakage test

10.6.3 Relieving set pressure

10.6.4 Functional test

10.6.5 Material test certificate for pressure-containing parts.

10.6.6 Unless otherwise specified, owner reserves the right to test and inspect all the item at the

Bidders works.

10.6.7 Bidder shall submit following test certificates and test reports

10.6.7.1 Material test certificates with detailed chemical analysis from the foundry for each

casting Certificate of radiography / X-ray for valve casting.

10.6.7.2 Certificate in form III C for all valves covered under IBR certification

10.6.8 Factory Inspection

The complete valve and actuator assembly shall be inspected by the owner and third party

prior to dispatch unless otherwise advised. Owner/MMCI shall be informed at least 6 weeks in

advance for the inspection and FAT.

11 Guarantee

Any acceptance or release of the completed valve assembly following an inspection or test

activity shall in no way relieve the Bidder of his responsibility to provide guarantees as to the

suitability of the materials, workmanship and performance of the valves in accordance with this

Specification. Bidder shall supply a certificate of compliance with the applicable descriptions,

the data sheet and the test results, for all valves and accessories as per the order.

12 Documentation

12.1 Documentation with offer

The Bidder shall provide the Owner/consultant with the following information as a minimum

along with the tender. These documents shall include, but not be limited to the following:

12.1.1 The Vendor shall complete and submit with the tender the entire information essential to enable

a technical assessment of the bid to be made. All documents shall be submitted in 3 hard copy

sets and a soft copy. Failure to supply the data may cause rejection of the bid. The information

required, as a minimum shall include:

Compliance Sheet

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 9 of 10

Filled up Data Sheet complete with MOC details of valve, manufacturer & model no for

each valve duly signed and stamped.

Sizing calculations

Valve general arrangement Drawing showing main components, main dimensions and

weights.

Any other information considered necessary by the Bidder to show conformity to this

Specification shall be provided.

12.2 Documentation after LOI/PO

Vendor shall provide six (6) sets of the following documents after 2 weeks of LOI / PO

Valve general arrangement Drawing showing main components, main dimensions and

weights.

Sizing of valve

Weight of completely assembled valve.

Catalouges.

Bidders hydrostatic test report for each valve.

Certified Material Test Reports for each valve.

12.3 Final Documentation

Vendor shall provide as a minimum the following documents (8 hard copies + 4 soft copies)

Valve general arrangement Drawing showing main components, main dimensions and

weights.

Technical data / catalogues

Installation requirements

Calibration certificate, hydrostatic pressure test, Seat leakage, Relieving set pressure

Material test certificate for pressure containing parts

All documents mentioned in certification

Inspection clearance certificate (Owner /consultant / Third Party Inspector)

Manuals and drawings

13 Spares

The supply of spares for start-up and commissioning shall be supplied. A list of recommended

spares for two years operation and maintenance shall be attached with offer

14 Special Tools

The Bidder shall supply a set of any special tools, which are required for the installation,

commissioning, operation and maintenance of the PSV being supplied. A list of special tools

shall be supplied along with the offer.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

VISAKH MARKETING INSTALLATION RESITEMENT

PROJECT - BLACK OIL TERMINAL

Doc No:254625-300-SP-INT-027 Rev: A Page 10 of 10

15 Transportation and Storage

15.1 Equipment shall be protected to safeguard against all adverse environment conditions that may

be encountered during shipment, storage and installation.

15.2 All exposed unpainted surfaces shall be coated with preservatives or wrapped.

15.3 Valves that shall be blinded off using bolted metal covers with gaskets and sealed with tape.

Valve internals shall be protected with approved preservatives.

15.4 One complete set of the installation, operation, and maintenance instructions shall be packed in

the boxes or crates with equipment. Packing list with all details shall be pasted on each crate or

box.

P:\Andheri\IndiaProject\254625 HPCL- Black Oil Terminal\05 Control & Automation\Documents\Document\Specifications\Package - II\With

Open Protocol with final change\10_254625-300-SP-INT-027 Specifications for Pressure Safety Valve Rev A.doc

You might also like

- Ansi - Api MPMS Chapter 14.6 2ND Ed (E1)Document66 pagesAnsi - Api MPMS Chapter 14.6 2ND Ed (E1)zidinhoNo ratings yet

- DRS - Operation & Control PhilosophyDocument5 pagesDRS - Operation & Control PhilosophyAnand GNo ratings yet

- ITP For Panel - Rev 1Document4 pagesITP For Panel - Rev 1wawanNo ratings yet

- JGDCL Doc Electronic Odorizer 09-10-2017Document21 pagesJGDCL Doc Electronic Odorizer 09-10-2017bmanojkumar16No ratings yet

- API Valve Trim ChartDocument2 pagesAPI Valve Trim ChartkhaireddinNo ratings yet

- ASME PCC-1 Bolted Flange Joint AssemblyDocument1 pageASME PCC-1 Bolted Flange Joint Assemblykhaireddin75% (4)

- Mts Silentflo 515 Hydraulic Power Units - Compact: Clean Quiet, and Reliable Power GenerationDocument8 pagesMts Silentflo 515 Hydraulic Power Units - Compact: Clean Quiet, and Reliable Power GenerationpeterNo ratings yet

- 2018 - Dlsud - Esd Diagram - Logic Diagram - GRP 5Document1 page2018 - Dlsud - Esd Diagram - Logic Diagram - GRP 5Jake Polo SantiagoNo ratings yet

- Inspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)Document2 pagesInspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)iwan NugrohoNo ratings yet

- 653-Sacrificial Anode Installation For TanksDocument3 pages653-Sacrificial Anode Installation For TanksFolarin AyodejiNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- Job Procedure For Cable TrayDocument5 pagesJob Procedure For Cable TrayNisith SahooNo ratings yet

- SAT Procedure DCI JK5 - Fire Fighting Rev. 2Document14 pagesSAT Procedure DCI JK5 - Fire Fighting Rev. 2Awaludin Angga WNo ratings yet

- ATEXDocument1 pageATEXselvan110663No ratings yet

- SS 4C 1,3Document1 pageSS 4C 1,3عدیل الررحمنNo ratings yet

- WEEKLY MOTOR VIBRATION ChecklistDocument9 pagesWEEKLY MOTOR VIBRATION ChecklistJoyanta Maity100% (1)

- Pressure Switch Mechanical Template SmallDocument1 pagePressure Switch Mechanical Template Smallali AlinezhadNo ratings yet

- 028120-SPT-006 Control Valve and Regulator SpecificationDocument23 pages028120-SPT-006 Control Valve and Regulator SpecificationBang JaliNo ratings yet

- Mov Specification PDFDocument27 pagesMov Specification PDFpl_arunachalam79No ratings yet

- Servo Gauge TI00452G08EN06.14Document41 pagesServo Gauge TI00452G08EN06.14jeduardo2325No ratings yet

- Iooc Idhc BPD Ins Mto 032 03Document9 pagesIooc Idhc BPD Ins Mto 032 03Fatholla SalehiNo ratings yet

- Volume3A Mech PDFDocument321 pagesVolume3A Mech PDFSayee Krishnan100% (1)

- Section-V-technical Specification 20130610 103851Document195 pagesSection-V-technical Specification 20130610 103851Suraj Yedla100% (1)

- Durco Plug Valve Dimensions PDFDocument28 pagesDurco Plug Valve Dimensions PDFjtai1983No ratings yet

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- National Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesDocument13 pagesNational Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesNasim MemarianNo ratings yet

- Certificate / Certificat Zertifikat /: Series 8320 Solenoid Valves Asco, L.P. Florham Park, NJ - USADocument2 pagesCertificate / Certificat Zertifikat /: Series 8320 Solenoid Valves Asco, L.P. Florham Park, NJ - USAandersson benito herreraNo ratings yet

- DBB CatalogueDocument28 pagesDBB CatalogueHeri SetyantoNo ratings yet

- Visio Loop Diagram Cascade Loop2Document1 pageVisio Loop Diagram Cascade Loop2jmnyoungNo ratings yet

- Comment Resolution Sheet 19009 Welding DossierDocument1 pageComment Resolution Sheet 19009 Welding DossierDheeraj E MohananNo ratings yet

- Hes Work Plan.Document126 pagesHes Work Plan.Fl Djoko SulistiyantoNo ratings yet

- (509869149) Leak DetectionDocument12 pages(509869149) Leak Detectionsathish_iyengarNo ratings yet

- Valve InspectionDocument6 pagesValve InspectionMuhammad ZainNo ratings yet

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionDocument1 pageQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoNo ratings yet

- I-Et-3010.00-5140-700-P4x-003 - J - Electrical Requirements For Packages For...Document27 pagesI-Et-3010.00-5140-700-P4x-003 - J - Electrical Requirements For Packages For...everton maldonadoNo ratings yet

- Field Instrument List V1 R1Document12 pagesField Instrument List V1 R1sudhansu8beheraNo ratings yet

- Tas PD 000 Document ListDocument9 pagesTas PD 000 Document ListsswahyudiNo ratings yet

- D A42 1362 0001J 17 Isometric ExtractedDocument3 pagesD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoNo ratings yet

- G GN 210Document32 pagesG GN 210chem job100% (1)

- BE-WI-248-01-F25 Datasheet Solenoid ValveDocument3 pagesBE-WI-248-01-F25 Datasheet Solenoid Valvemika cabelloNo ratings yet

- Indian Oil & GasDocument15 pagesIndian Oil & GasMeena HarryNo ratings yet

- NG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedDocument16 pagesNG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedFolarin AyodejiNo ratings yet

- Major Accident PreventionDocument28 pagesMajor Accident PreventionRoger MooncasterNo ratings yet

- Methodology Tapping Methodology of WaterlineDocument15 pagesMethodology Tapping Methodology of WaterlineBryNo ratings yet

- I3547-6379 - 1.0 (Feed Gas Custody Transfer System)Document19 pagesI3547-6379 - 1.0 (Feed Gas Custody Transfer System)Khaled RemchiNo ratings yet

- KLM PROJECT STANDARDS and SPECIFICATIONS Offshore Elecrical Design Well Platform Rev01Document6 pagesKLM PROJECT STANDARDS and SPECIFICATIONS Offshore Elecrical Design Well Platform Rev01manicheNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- 04931E03Document28 pages04931E03brahim amiraNo ratings yet

- Doha North Sewerage Treatment & Associated WorksDocument67 pagesDoha North Sewerage Treatment & Associated WorksLito MendozaNo ratings yet

- 02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Document38 pages02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Walid BdeirNo ratings yet

- API 2000 5th Vs 6th FinalDocument21 pagesAPI 2000 5th Vs 6th FinalCepopaky CangkrukanNo ratings yet

- VD-LINE-906-MP-4-0004-055 - CAUSE AND EFFECT DIAGRAM - Rev.EDocument18 pagesVD-LINE-906-MP-4-0004-055 - CAUSE AND EFFECT DIAGRAM - Rev.Ehusen123 alhusadaNo ratings yet

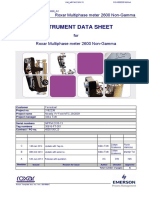

- Instrument Data Sheet: Roxar Multiphase Meter 2600 Non-GammaDocument5 pagesInstrument Data Sheet: Roxar Multiphase Meter 2600 Non-GammaSrewaBenshebilNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- STD Hook-Up Released Copy Aug 2012Document92 pagesSTD Hook-Up Released Copy Aug 2012Stephen Rey CaldeaNo ratings yet

- TechnicalDocument3 pagesTechnicalbmanojkumar16No ratings yet

- Habonim SIL CertificationDocument7 pagesHabonim SIL Certificationjamil vora0% (1)

- FM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetDocument8 pagesFM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetAmr TarekNo ratings yet

- Maximize Your Uptime: InsulgardDocument8 pagesMaximize Your Uptime: InsulgardAODVNo ratings yet

- IPS e El 110Document105 pagesIPS e El 110alinaghibNo ratings yet

- Specification For Control ValveDocument5 pagesSpecification For Control ValveamilasriNo ratings yet

- Components of Aggregate Demand - EconomicsDocument1 pageComponents of Aggregate Demand - EconomicskhaireddinNo ratings yet

- Aggregate Demand Aggregate Supply and InflationDocument28 pagesAggregate Demand Aggregate Supply and InflationkhaireddinNo ratings yet

- Ped Guia FinalDocument4 pagesPed Guia FinalkhaireddinNo ratings yet

- ASTM Specs FittingsDocument10 pagesASTM Specs FittingskhaireddinNo ratings yet

- Universal Robot Case StudyDocument10 pagesUniversal Robot Case StudykhaireddinNo ratings yet

- ASME PCC-1-2013 Table For Pressure Boundary Bolted Flange Joint AssemblyDocument1 pageASME PCC-1-2013 Table For Pressure Boundary Bolted Flange Joint AssemblykhaireddinNo ratings yet

- Material Comparison F316L Vs F321 PDFDocument1 pageMaterial Comparison F316L Vs F321 PDFkhaireddinNo ratings yet

- Bolts Torque ChartDocument13 pagesBolts Torque ChartkhaireddinNo ratings yet

- En 13241-1 - Annexes ZDocument7 pagesEn 13241-1 - Annexes ZkhaireddinNo ratings yet

- Jasna Winter Map 2018Document1 pageJasna Winter Map 2018khaireddinNo ratings yet

- 555 MMN332Document16 pages555 MMN332khaireddinNo ratings yet

- AB-524 Pressure Relief Devices Requirements Specification PDFDocument55 pagesAB-524 Pressure Relief Devices Requirements Specification PDFkhaireddinNo ratings yet

- Axial Bellows Technical DataDocument68 pagesAxial Bellows Technical DatakhaireddinNo ratings yet

- MTU 12V4000M53 Spare Parts Catalog PDFDocument745 pagesMTU 12V4000M53 Spare Parts Catalog PDFkhaireddin100% (2)

- Iso 724-1993Document3 pagesIso 724-1993khaireddinNo ratings yet

- 2D Seismic TutorialDocument264 pages2D Seismic Tutorialjose razoNo ratings yet

- Semiconductor Technology, Design and Test Roadmap: Deliverable D4.4Document13 pagesSemiconductor Technology, Design and Test Roadmap: Deliverable D4.4Anonymous pS4LT2GJUSNo ratings yet

- Summarised Details of ClaimDocument4 pagesSummarised Details of ClaimOm Krish RamNo ratings yet

- Faculty of Engineering: Microelectronic Circuit Analysis and Design EEN 2146 TRIMESTER 2 (2011/2012)Document12 pagesFaculty of Engineering: Microelectronic Circuit Analysis and Design EEN 2146 TRIMESTER 2 (2011/2012)Ah JIng LaLaNo ratings yet

- Special Tools Special Tools: Instruction No Part. No. Instruction No Part. NoDocument47 pagesSpecial Tools Special Tools: Instruction No Part. No. Instruction No Part. NoAlex SibirnayaNo ratings yet

- 85001-0317 - Integrity Re-Entrant Speaker and Speaker-StrobeDocument6 pages85001-0317 - Integrity Re-Entrant Speaker and Speaker-StrobemohammadNo ratings yet

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDocument4 pagesGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- MSC 1581 - SOLAS Cap IIDocument2 pagesMSC 1581 - SOLAS Cap IIMithran DirNo ratings yet

- Mini ProjectDocument6 pagesMini ProjectRachna BhatnagarNo ratings yet

- Stress Analysis andDocument19 pagesStress Analysis andGobinder SinghNo ratings yet

- Tab Cower NTDocument15 pagesTab Cower NTtonoNo ratings yet

- Two Types of FixationDocument7 pagesTwo Types of FixationPOOJANo ratings yet

- Technical Rulebook - SIEP 2022Document29 pagesTechnical Rulebook - SIEP 2022Nithin BVNo ratings yet

- Duct PDFDocument12 pagesDuct PDFroshan jaiswalNo ratings yet

- CarbonFiberHowTo2 PDFDocument20 pagesCarbonFiberHowTo2 PDFSolidWorksNo ratings yet

- GSM-04 08Document630 pagesGSM-04 08Shweta RangeshNo ratings yet

- SPUN PILE WikaDocument3 pagesSPUN PILE WikaCalvin SandiNo ratings yet

- Aerospace Science and Technology: P. Panagiotou, P. Kaparos, C. Salpingidou, K. YakinthosDocument12 pagesAerospace Science and Technology: P. Panagiotou, P. Kaparos, C. Salpingidou, K. YakinthossasasNo ratings yet

- AAAdddd 1Document3 pagesAAAdddd 1Anonymous ufMAGXcskMNo ratings yet

- Physics - Particles and WavesDocument54 pagesPhysics - Particles and WavesGowrisankar RaoNo ratings yet

- Comet GT650RDocument83 pagesComet GT650RBruno SilvaNo ratings yet

- Vista Mast RepairDocument28 pagesVista Mast RepairTan JaiNo ratings yet

- Panel Solar Canadian 325 WPDocument2 pagesPanel Solar Canadian 325 WPEdu Lopez GarciaNo ratings yet

- Fluid FlowDocument15 pagesFluid Flowdekra abdoNo ratings yet

- Old Code OLD R Number New Code NEW R Number Availability Phase Out Phase inDocument7 pagesOld Code OLD R Number New Code NEW R Number Availability Phase Out Phase intecnicomanelNo ratings yet

- Design of Beams 1: Act BCXDocument27 pagesDesign of Beams 1: Act BCXleimrabottNo ratings yet

- Data FTP HMI P5 Software FvDesigneDocument33 pagesData FTP HMI P5 Software FvDesigneQamar Hassan IqbalNo ratings yet

- Week 14 HE Sediment TransportDocument88 pagesWeek 14 HE Sediment TransportRana Asad AliNo ratings yet

- CBISDocument27 pagesCBISSamaria Liaqat100% (1)