Professional Documents

Culture Documents

Nowadays, Most Countries Are Looking Forward at Reducing Pollution One

Nowadays, Most Countries Are Looking Forward at Reducing Pollution One

Uploaded by

Rusel Zahraw0 ratings0% found this document useful (0 votes)

10 views2 pagesThis document summarizes a study on using date palm waste materials to enhance concrete characteristics. Date palm fibers, seed, and leaf stem ash were tested as partial replacements for materials in concrete mixes. The date palm fibers improved flexural, splitting tensile strength, and impact resistance when added at 0.4-1.2% by volume, but decreased compressive strength. Date seed decreased compressive strength when replacing sand at 3-15% by weight. 10% leaf stem ash as a partial cement replacement improved compressive strength. The study demonstrated date palm waste materials can provide benefits to concrete properties when used as replacements or additions in appropriate amounts.

Original Description:

تتث

Original Title

Abstract

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes a study on using date palm waste materials to enhance concrete characteristics. Date palm fibers, seed, and leaf stem ash were tested as partial replacements for materials in concrete mixes. The date palm fibers improved flexural, splitting tensile strength, and impact resistance when added at 0.4-1.2% by volume, but decreased compressive strength. Date seed decreased compressive strength when replacing sand at 3-15% by weight. 10% leaf stem ash as a partial cement replacement improved compressive strength. The study demonstrated date palm waste materials can provide benefits to concrete properties when used as replacements or additions in appropriate amounts.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

10 views2 pagesNowadays, Most Countries Are Looking Forward at Reducing Pollution One

Nowadays, Most Countries Are Looking Forward at Reducing Pollution One

Uploaded by

Rusel ZahrawThis document summarizes a study on using date palm waste materials to enhance concrete characteristics. Date palm fibers, seed, and leaf stem ash were tested as partial replacements for materials in concrete mixes. The date palm fibers improved flexural, splitting tensile strength, and impact resistance when added at 0.4-1.2% by volume, but decreased compressive strength. Date seed decreased compressive strength when replacing sand at 3-15% by weight. 10% leaf stem ash as a partial cement replacement improved compressive strength. The study demonstrated date palm waste materials can provide benefits to concrete properties when used as replacements or additions in appropriate amounts.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Abstract

Nowadays, most countries are looking forward at reducing Pollution; one

of the best solutions is using waste products as recycled materials. This not

only can develop sustainable environmental management, but also presenting

new materials for general use. The search for green or

environmentally friendly materials in the building industry

involves the development of new materials, but might also

lead to the reconsideration of traditional ones. The date palm

(Phoenix dactylifera) wastes are one of the common wastes abundantly

available in the Middle East countries.

A study has been conducted to look into the performance of date palm

wastes for enhancing concrete characteristics. The date palm wastes included

date palm fibers: leaf (L) and leaf stem (LS) fiber, date palm seed and leaf

stem ash. Leaf stem fibers were added to concrete mix by (0.4, 0.8 and 1.2)

% by volume, while leaf fibers were added by (0.4, 0.8 and 1) % by volume.

The date palm fibers were used untreated and treated with 1% NaOH

solution, then the untreated date palm fiber-concrete (ULS & UL) was

compared with treated date palm fiber-concrete (TLS & TL).

Date seed was used as partial replacement of sand at (3, 5, 7.5, 10 and 15)

% by weight and tested for compressive strength at the ages of 7, 28 and 90

days, date seed decreased compressive strength at all percentages.

10% Leaf stem ash (LSA) was used as partial replacement of cement and

tested for compressive strength for the ages of 7, 28 and 60 days.

Date palm fiber-concrete have been tested for the compressive, flexural and

splitting tensile strength, impact resistance, thermal conductivity and

ultrasonic pulse velocity.

Leaf stem fibers decreased compressive strength by 24.13% for ULS1.2

and 6.35% for TLS1.2, at age 120 days. However, it improved flexural,

splitting tensile strength and impact resistance by 6.86 % and 10.23% for

ULS0.4 and TLS0.4, by 7.62 % and 3.59% for ULS0.4 and TLS0.4, by

42.1% and 57.89% for ULS0.8 and TLS0.8, respectively at age 120 days.

Thermal conductivity of concrete was reduced by the addition of treated and

untreated leaf stem fiber; best fiber content was 0.8% for untreated and1.2%

for treated.

Leaf fibers improved compressive, flexural strength and impact resistance

by 9.37% and13.65% for UL1.0 and TL0.8, by 3.37% and 7% for UL1.0 and

TL1.0, and by to 94.74% and 131.58% for UL0.4 and TL1.0, respectively.

2

Abstract

However, it decreased splitting tensile strength by 9.87% and 8.3 % for

UL1.0 and TL1.0, respectively at the age of 120 days. Thermal conductivity

of concrete was reduced by the addition of treated and untreated leaf fiber;

best fiber content was 0.8 % for untreated and 1% for treated.

The present study demonstrated that the pozzolanic activity of leaf stem

ash (LSA) at curing ages of 7 and 28 days was 96.7% and 90.37%,

respectively. 10% LSA as partial replacement of cement improved the

compressive strength of concrete at curing ages 28 and 60 days.

You might also like

- Ebook Ebook PDF Introductory Econometrics For Finance 4Th Edition All Chapter PDF Docx KindleDocument41 pagesEbook Ebook PDF Introductory Econometrics For Finance 4Th Edition All Chapter PDF Docx Kindlevicki.lusk103100% (32)

- Breakwater and Dredging Works BOQ - ExampleDocument8 pagesBreakwater and Dredging Works BOQ - ExampleAthanasius Kurniawan Prasetyo Adi100% (1)

- V25N04 PDFDocument16 pagesV25N04 PDFandualemNo ratings yet

- NBOK Guide 2016Document264 pagesNBOK Guide 2016Sam50% (2)

- Var WWW HTML CCT HTML Authors 0 186 186 2015-06-09 3 1433845455 PDFDocument8 pagesVar WWW HTML CCT HTML Authors 0 186 186 2015-06-09 3 1433845455 PDFAhmad Farid EhsanNo ratings yet

- Ishii 2006Document9 pagesIshii 2006martina.cirronis96No ratings yet

- Wood Ash 15Document11 pagesWood Ash 15r;rNo ratings yet

- Recycled Plastic and Cork Waste For Structural Lightweight Concrete ProductionDocument15 pagesRecycled Plastic and Cork Waste For Structural Lightweight Concrete Productiondjumbirko1No ratings yet

- Wood Ash 4Document12 pagesWood Ash 4r;rNo ratings yet

- Crystallinity Cellulose FormulaDocument7 pagesCrystallinity Cellulose Formulaetnomuz2003No ratings yet

- Preparation and Properties of Cellulose Nanocrystals: Rods, Spheres, and NetworkDocument8 pagesPreparation and Properties of Cellulose Nanocrystals: Rods, Spheres, and NetworkEndarto YudoNo ratings yet

- BioRes 11 4 10201 Yu TWZZM Eval Dimensional Stability Leaching-Perform ACQ Wax Southern PineDocument12 pagesBioRes 11 4 10201 Yu TWZZM Eval Dimensional Stability Leaching-Perform ACQ Wax Southern PineyonNo ratings yet

- PDP Example 3Document11 pagesPDP Example 3squiro89No ratings yet

- "Experimental Studies On Effect of Date Seed Ash (DSA) On Strength Properties of Cement Sand Mortar"., G I Gunarani and S P Chakkravarthy., (2017)Document4 pages"Experimental Studies On Effect of Date Seed Ash (DSA) On Strength Properties of Cement Sand Mortar"., G I Gunarani and S P Chakkravarthy., (2017)AnniesonNo ratings yet

- Effect of Treated Coconut Shell and Fiber On The R PDFDocument8 pagesEffect of Treated Coconut Shell and Fiber On The R PDFfiqri asrulNo ratings yet

- Nbnfi Fe201902276409Document25 pagesNbnfi Fe201902276409Ambreen KalsoomNo ratings yet

- Artificial Aggregate Made From Waste Stone Sludge and Waste Silt PDFDocument6 pagesArtificial Aggregate Made From Waste Stone Sludge and Waste Silt PDFAhmed AliNo ratings yet

- CH 1 and 2Document41 pagesCH 1 and 2jega okoNo ratings yet

- Microporous and Mesoporous Materials: SciencedirectDocument7 pagesMicroporous and Mesoporous Materials: SciencedirectSepransiska WNo ratings yet

- Optimizing sulfonation process of polystyrene waste for hardness andDocument7 pagesOptimizing sulfonation process of polystyrene waste for hardness andEzgi GeyikNo ratings yet

- Shrinkage of Endodontic SealersDocument2 pagesShrinkage of Endodontic Sealersdr.samiNo ratings yet

- 2006.effects of Sample Disturbance and Consolidation - Lunne-Et-Al-2006-TestingDocument25 pages2006.effects of Sample Disturbance and Consolidation - Lunne-Et-Al-2006-Testing202111120014No ratings yet

- Structural Strength Characteristics of Cement-Cassava Peel Ash Blended ConcreteDocument11 pagesStructural Strength Characteristics of Cement-Cassava Peel Ash Blended ConcreteMUSTAPHA SHEHU ABUBAKARNo ratings yet

- Ramos Et. Al Draft3Document21 pagesRamos Et. Al Draft3Crystal Gyle MontesNo ratings yet

- Aging Mechanisms in RTV Polysiloxane Foams: LA-UR-15-23317 (Accepted Manuscript)Document24 pagesAging Mechanisms in RTV Polysiloxane Foams: LA-UR-15-23317 (Accepted Manuscript)dewi nurhasanahNo ratings yet

- 1 s2.0 S0921344923000198 MainDocument7 pages1 s2.0 S0921344923000198 MainWill BNo ratings yet

- Inglês - A 20, Leggate, Anatomia, Permeabilidade, ResinaDocument23 pagesInglês - A 20, Leggate, Anatomia, Permeabilidade, ResinaVinicius Sousa LimaNo ratings yet

- Kuo 2015Document6 pagesKuo 2015Nguyen Thanh CuongNo ratings yet

- Engineering Properties of Asphalt Concrete Made With Recycled GlassDocument16 pagesEngineering Properties of Asphalt Concrete Made With Recycled Glassهوا عجلون-المهندسNo ratings yet

- Treatment of Date Palm Bres Mesh: in Uence On The Rheological and Mechanical Properties of Bre-Cement CompositesDocument13 pagesTreatment of Date Palm Bres Mesh: in Uence On The Rheological and Mechanical Properties of Bre-Cement CompositesMalek GolNo ratings yet

- Guntekin and SahinDocument9 pagesGuntekin and SahinYuri KomissarovNo ratings yet

- Original ResearchDocument9 pagesOriginal ResearchDilleswararao ChintalaNo ratings yet

- Chandra 1998Document11 pagesChandra 1998CamilaBurgosNo ratings yet

- The Effect of Fines On Critical State and Liquefaction Resistance Characteristics of Non-Plastic Silty Sands Anthi Papadopoulou & Theodora TikaDocument38 pagesThe Effect of Fines On Critical State and Liquefaction Resistance Characteristics of Non-Plastic Silty Sands Anthi Papadopoulou & Theodora Tikagucsonfeie100% (6)

- Effects of Wood Ash On Properties of ConcreteDocument15 pagesEffects of Wood Ash On Properties of Concretekeerthupanda18No ratings yet

- Review of Concrete With and Without Glass Powder and Plastic As IngredientsDocument11 pagesReview of Concrete With and Without Glass Powder and Plastic As IngredientsRohit KumarNo ratings yet

- Swelling Behaviour of Pine Apple Leaf Fiber Reinforced Polymer Composites in Different Working FluidsDocument6 pagesSwelling Behaviour of Pine Apple Leaf Fiber Reinforced Polymer Composites in Different Working Fluidsrakshith sNo ratings yet

- JBR 04 (4) 343-352Document11 pagesJBR 04 (4) 343-352pwishnutama9No ratings yet

- Effect of Particle Size On Alkali-Silica Reaction in Recycled Glass Mortars PDFDocument11 pagesEffect of Particle Size On Alkali-Silica Reaction in Recycled Glass Mortars PDFEduardo K SbardelottoNo ratings yet

- Marine Pollution Bulletin: Yu-Ling Wei, Chang-Yuan Lin, Kuan-Wei Ko, H. Paul WangDocument6 pagesMarine Pollution Bulletin: Yu-Ling Wei, Chang-Yuan Lin, Kuan-Wei Ko, H. Paul WangFernando Volpatto RamosNo ratings yet

- The Effect of Fines On Critical State and Liquefaction Resistance Characteristics of Non-Plastic Silty Sands Anthi Papadopoulou & Theodora TikaDocument36 pagesThe Effect of Fines On Critical State and Liquefaction Resistance Characteristics of Non-Plastic Silty Sands Anthi Papadopoulou & Theodora Tikakaren.wynne813100% (7)

- Lightweight Aggregate Made From Sewage Sludge and Incinerated AshDocument9 pagesLightweight Aggregate Made From Sewage Sludge and Incinerated AshMaria Renee OlivaNo ratings yet

- Lab Assignment 1 GuideDocument2 pagesLab Assignment 1 Guideحسمان الفهيميNo ratings yet

- Dickhout 2017Document16 pagesDickhout 2017VishnuShantanNo ratings yet

- Autoclaved Bamboo Pulp Fibre Reinforced Cement: R. S. P. CouttsDocument8 pagesAutoclaved Bamboo Pulp Fibre Reinforced Cement: R. S. P. Couttsakash kumarNo ratings yet

- Glass Transition and Crystallization of Amorphous Trehalose Sucrose MixturesDocument17 pagesGlass Transition and Crystallization of Amorphous Trehalose Sucrose MixturesPedro TorresNo ratings yet

- Evaluation of Basalt Fibre Composites For Marine ApplicationsDocument10 pagesEvaluation of Basalt Fibre Composites For Marine Applicationsภัทรพล ธีรพงศ์ภักดีNo ratings yet

- Effect of Specimen Thickness To Grain Size Ratio On Tensile Behavior of The MaterialDocument7 pagesEffect of Specimen Thickness To Grain Size Ratio On Tensile Behavior of The Materialfnl drjNo ratings yet

- Strength-Enhancing Effect of Cationic STDocument7 pagesStrength-Enhancing Effect of Cationic STarjunanpnNo ratings yet

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeDocument4 pagesTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaNo ratings yet

- Umma Sankar, Meenaloshini Satgunam, Mahdi Amiriyan, Ramesh Singh and W. D. TengDocument9 pagesUmma Sankar, Meenaloshini Satgunam, Mahdi Amiriyan, Ramesh Singh and W. D. Tengmeenaloshini SatgunamNo ratings yet

- Development of Wood Crete From Treated S - 2014 - Construction and Building MateDocument8 pagesDevelopment of Wood Crete From Treated S - 2014 - Construction and Building MateArlen GutierrezNo ratings yet

- Chemical Engineering Journal: Contents Lists Available atDocument9 pagesChemical Engineering Journal: Contents Lists Available atermiasNo ratings yet

- Efektivitas Penggunaan Biji Kelor Moringa Oleifera PDFDocument14 pagesEfektivitas Penggunaan Biji Kelor Moringa Oleifera PDFMasniNo ratings yet

- 1 s2.0 S0950061821031974 MainDocument11 pages1 s2.0 S0950061821031974 MainInácio RibeiroNo ratings yet

- 2021 JournalofEnvironmentalQuality ReclamationDocument12 pages2021 JournalofEnvironmentalQuality ReclamationELIUD DANIEL VELEZ LOPEZNo ratings yet

- A Comparative Study of Selected Physical Properties of Five Root-Canal SealersDocument7 pagesA Comparative Study of Selected Physical Properties of Five Root-Canal SealersAmelia RahmayantiNo ratings yet

- Ageing Phenomena of CelluloseDocument9 pagesAgeing Phenomena of CellulosedchyNo ratings yet

- Need of Experimental Studies On Variation of Additives On Basalt Fiber Fly Ash ConcreteDocument3 pagesNeed of Experimental Studies On Variation of Additives On Basalt Fiber Fly Ash ConcreteSatyen RamaniNo ratings yet

- Tosyl CelluloseDocument11 pagesTosyl CelluloseAyesha WasimNo ratings yet

- X rayFluorescenceSpectrometryCDocument9 pagesX rayFluorescenceSpectrometryCUdrescu Andreea-IrinaNo ratings yet

- Evaluation of Fluid Storage Characteristics at Nanoscopic Scale For Some Natural ZeolitesDocument14 pagesEvaluation of Fluid Storage Characteristics at Nanoscopic Scale For Some Natural ZeolitesGözde BayazitNo ratings yet

- Application of Membranes in Rendering Plant WastewaterDocument7 pagesApplication of Membranes in Rendering Plant Wastewatersusana velasquezNo ratings yet

- Pulp Friction in Tasmania: A Review of the Environmental Assessment of Gunns' Proposed Pulp MillFrom EverandPulp Friction in Tasmania: A Review of the Environmental Assessment of Gunns' Proposed Pulp MillNo ratings yet

- اسئلهDocument7 pagesاسئلهRusel ZahrawNo ratings yet

- Applied Mathematics For The Managerial Life and Social Sciences Fifth ..Document3 pagesApplied Mathematics For The Managerial Life and Social Sciences Fifth ..Rusel ZahrawNo ratings yet

- Salinity: Salinity in Inland WatersDocument3 pagesSalinity: Salinity in Inland WatersRusel ZahrawNo ratings yet

- k2pdf OptionDocument1 pagek2pdf OptionRusel ZahrawNo ratings yet

- Chapter 2 FinalDocument32 pagesChapter 2 FinalRusel ZahrawNo ratings yet

- Recycled Plastic Used in Concrete Paver Block PDFDocument3 pagesRecycled Plastic Used in Concrete Paver Block PDFRusel ZahrawNo ratings yet

- الأذكياء # اليك كتابي PDFDocument159 pagesالأذكياء # اليك كتابي PDFmohNo ratings yet

- SheetDocument6 pagesSheetMohamed Tag EldeenNo ratings yet

- English C2 Activity 3Document5 pagesEnglish C2 Activity 3sofia irina arriagadaNo ratings yet

- Technology Needs AssessmentDocument34 pagesTechnology Needs AssessmentVincs KongNo ratings yet

- English Mission For SSC and HSCDocument5 pagesEnglish Mission For SSC and HSCPrachi DamleNo ratings yet

- Types: Abrasive Blasting, More Commonly Known As Sandblasting, Is The Operation of Forcibly Propelling ADocument4 pagesTypes: Abrasive Blasting, More Commonly Known As Sandblasting, Is The Operation of Forcibly Propelling AMarvin BerrensteinNo ratings yet

- 22 Chapter22 DobbinsandDundonDocument20 pages22 Chapter22 DobbinsandDundonHuyn LeeNo ratings yet

- Experimental Characterisation of Polyethylene Terephthalate (PET) Bottle Eco-BricksDocument30 pagesExperimental Characterisation of Polyethylene Terephthalate (PET) Bottle Eco-BricksJake ManzanoNo ratings yet

- Design Heuristic WorkshopDocument22 pagesDesign Heuristic WorkshopMaryel LaraNo ratings yet

- Assertive SkillsDocument11 pagesAssertive SkillsRahul Dodiya0% (1)

- Chap 2Document12 pagesChap 2Muhammad UsmanNo ratings yet

- Po No PO Text Doc No Vendor CodeDocument2 pagesPo No PO Text Doc No Vendor CodeAshish MishraNo ratings yet

- 1.instruction Handbook - Order Picker - EP - EnG OM20GBOR1AQ0Document134 pages1.instruction Handbook - Order Picker - EP - EnG OM20GBOR1AQ0Juan Ismael Grave LolNo ratings yet

- Uniqueness in The Forensic Identification Sciences - Fact or FictionDocument7 pagesUniqueness in The Forensic Identification Sciences - Fact or FictionNik sNo ratings yet

- Research PaperDocument8 pagesResearch PaperAshish MangalNo ratings yet

- Chap 1-Data and Information Assignment1 With AnswerDocument2 pagesChap 1-Data and Information Assignment1 With AnswerPoornima CNNo ratings yet

- Template SiteSupervision PlanDocument106 pagesTemplate SiteSupervision PlanThaung Myint OoNo ratings yet

- Experiment - 1: Aim: To Determine The Nature of Roots of A Quadratic Equation, Its Input Is Triple of PositiveDocument22 pagesExperiment - 1: Aim: To Determine The Nature of Roots of A Quadratic Equation, Its Input Is Triple of PositivenvsroxNo ratings yet

- Army Technical GuideDocument27 pagesArmy Technical GuideOlaniran Habib OlajideNo ratings yet

- MU320 Presentation 10Document4 pagesMU320 Presentation 10William JeremyNo ratings yet

- Assessment of Aleatory and Model Uncertainties For Non-LinearDocument131 pagesAssessment of Aleatory and Model Uncertainties For Non-LinearGenNo ratings yet

- Chapter 01 - CtsDocument56 pagesChapter 01 - CtssengthaiNo ratings yet

- Koenigsegg AgeraRS Specification PDFDocument1 pageKoenigsegg AgeraRS Specification PDFVian ToroNo ratings yet

- Aksesor GU PDFDocument271 pagesAksesor GU PDFAdmir MatoshiNo ratings yet

- 7 Secrets Guidebook FINALVERSIONDocument26 pages7 Secrets Guidebook FINALVERSIONnetzonetechnical managerNo ratings yet

- Liew Huay Ling, Lim Siew Yee and Helmer Aslaksen Department of Mathematics, National University of Singapore Semester 2, 2000/2001Document4 pagesLiew Huay Ling, Lim Siew Yee and Helmer Aslaksen Department of Mathematics, National University of Singapore Semester 2, 2000/20011940LaSalleNo ratings yet

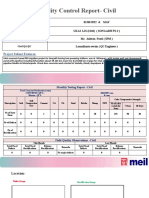

- MRM (Civil) REPORT MAY 2022 MonthDocument4 pagesMRM (Civil) REPORT MAY 2022 MonthLaxmikanta swainNo ratings yet