Professional Documents

Culture Documents

MBR Process: Membrane Bioreactors MBR Plants

MBR Process: Membrane Bioreactors MBR Plants

Uploaded by

prem_k_sCopyright:

Available Formats

You might also like

- L5 - Physical TreatmentDocument67 pagesL5 - Physical Treatmentrushdi100% (1)

- Brochure CE 705 - Activated Sludge Process ENDocument9 pagesBrochure CE 705 - Activated Sludge Process ENedimaprwNo ratings yet

- Wwi MBR Reuse 2014Document2 pagesWwi MBR Reuse 2014qiaoxin136No ratings yet

- Membrane Bioreactors: State of The Art and Technology ExchangeDocument54 pagesMembrane Bioreactors: State of The Art and Technology ExchangeNermeen ElmelegaeNo ratings yet

- End of PipeDocument4 pagesEnd of PipeIndustria ProyectosNo ratings yet

- Multiflo 2013 EN PDFDocument8 pagesMultiflo 2013 EN PDFEbaid AbdoNo ratings yet

- 04 Canziani MBRDocument27 pages04 Canziani MBRyevgeniyNo ratings yet

- NPTEL Civil Engineering - Water and Waste Water EngineeringDocument2 pagesNPTEL Civil Engineering - Water and Waste Water EngineeringRushan LakdimuthuNo ratings yet

- Micro - and UltrafiltrationDocument16 pagesMicro - and Ultrafiltrationsihan wangNo ratings yet

- MBR Towards Micropollutant RejectionDocument88 pagesMBR Towards Micropollutant RejectionShankara NarayananNo ratings yet

- Flow Diagram Instalasi Pengolahan Air Limbah By: Cv. Bangkit Maju JayaDocument1 pageFlow Diagram Instalasi Pengolahan Air Limbah By: Cv. Bangkit Maju JayaDenti Maressa MNo ratings yet

- Membrane Drinking Water TreatmentDocument16 pagesMembrane Drinking Water TreatmentRamesh SoniNo ratings yet

- Chapter 1Document22 pagesChapter 1Adam AhsanNo ratings yet

- 3.2 17566 Product Leaflet MBR LowresDocument2 pages3.2 17566 Product Leaflet MBR LowresRahul Damodar100% (1)

- Membrane BioDocument5 pagesMembrane BioIan JamillaNo ratings yet

- Cleansewage-Bio Biological Sewage TreatmentDocument3 pagesCleansewage-Bio Biological Sewage Treatmentirshad sonde100% (1)

- Water Treatment EnglishDocument25 pagesWater Treatment EnglishVincent JosephNo ratings yet

- 05 - Case Study of Sewage TreatmentDocument6 pages05 - Case Study of Sewage TreatmentKharisma NataliaNo ratings yet

- Reactores No ConvencionalesDocument28 pagesReactores No Convencionalesbruce callNo ratings yet

- NYWEA MBR Presentation Session-1Document56 pagesNYWEA MBR Presentation Session-1gulfengsolutionsNo ratings yet

- Chapter 1Document22 pagesChapter 1mohid.shakeel.15No ratings yet

- Containerisedmbrsystem EngDocument12 pagesContainerisedmbrsystem EngNermeen ElmelegaeNo ratings yet

- Serenacel Mitsubishi EngDocument6 pagesSerenacel Mitsubishi EngYoo BoyyooNo ratings yet

- Correlation Between Sludge Volume Index (SVI) and Mixed Liquor Suspended Solids (MLSS)Document2 pagesCorrelation Between Sludge Volume Index (SVI) and Mixed Liquor Suspended Solids (MLSS)Antony ThanosNo ratings yet

- MODUL PARKIR - Parkson-Sand-Saver PDFDocument2 pagesMODUL PARKIR - Parkson-Sand-Saver PDFmessy kolloNo ratings yet

- Napier Reid BrochureDocument8 pagesNapier Reid BrochuresandeepNo ratings yet

- STP Technology Options: Moving Bed Bioreactor (MBBR) Membrane Bioreactor (MBR)Document6 pagesSTP Technology Options: Moving Bed Bioreactor (MBBR) Membrane Bioreactor (MBR)amzad aliNo ratings yet

- Flat Plate Membrane Bioreactor (MBR) System TrainingDocument56 pagesFlat Plate Membrane Bioreactor (MBR) System TrainingmarvilouNo ratings yet

- Membrane Bioreactor (MBR) TechnologyDocument4 pagesMembrane Bioreactor (MBR) Technologyshiomara jhamiletNo ratings yet

- Blue Barrel System Manual EnglishDocument12 pagesBlue Barrel System Manual EnglishKennedy NgoseyweNo ratings yet

- IHG Engineering Design Guidelines RevisiDocument5 pagesIHG Engineering Design Guidelines RevisiMohammad Abd Alrahim ShaarNo ratings yet

- MBCR FlyerDocument4 pagesMBCR FlyerunconformistNo ratings yet

- 2000LPD EnglishDocument10 pages2000LPD EnglishKennedy NgoseyweNo ratings yet

- AquaNereda Brochure 1017 WebDocument4 pagesAquaNereda Brochure 1017 WebdmnNo ratings yet

- Sucess Story - Shenzhen China - MSBRDocument2 pagesSucess Story - Shenzhen China - MSBRImran KhanNo ratings yet

- Algas Microfilter BrochureDocument8 pagesAlgas Microfilter BrochureNehal ImtiazNo ratings yet

- Kuliah MBR ITB 14 Nov 2022 - For PrintDocument31 pagesKuliah MBR ITB 14 Nov 2022 - For PrintEni RohkayatiNo ratings yet

- MABR Product Brochure Aug19Document4 pagesMABR Product Brochure Aug19e.mostafa.abdelhadyNo ratings yet

- 09.advanced WWTDocument30 pages09.advanced WWTMuamar DhikriNo ratings yet

- Solitax en Agua ResidualDocument4 pagesSolitax en Agua ResidualMaritza Catalina Melo MartinezNo ratings yet

- Accelator: InfilcoDocument4 pagesAccelator: InfilcoVanessa Cervantes CampoNo ratings yet

- Indore Municipal Corporation: 9.7 Treatment ProcessDocument1 pageIndore Municipal Corporation: 9.7 Treatment ProcessmkdholkiyaNo ratings yet

- K-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South KoreaDocument1 pageK-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South KoreaNguyen AnNo ratings yet

- Akvola Technologies Technology - WebDocument4 pagesAkvola Technologies Technology - WebHardik VavdiyaNo ratings yet

- SBR MMBR RBCDocument30 pagesSBR MMBR RBCbayu sinyoNo ratings yet

- Week 7-CHEM4015-CIVE4140-2023-2024Document21 pagesWeek 7-CHEM4015-CIVE4140-2023-2024Nitin RautNo ratings yet

- Petroleum Engineering Waste Water TreatmentpptDocument15 pagesPetroleum Engineering Waste Water TreatmentpptKunal JainNo ratings yet

- WTC 102 GemsDocument15 pagesWTC 102 GemsAyoub Mohammed AbdullahNo ratings yet

- Enhanced Nutrient Removal - Nitrogen: Description Description Description Description DescriptionDocument8 pagesEnhanced Nutrient Removal - Nitrogen: Description Description Description Description DescriptionGeorges NemerNo ratings yet

- Use Water As A Symbol, A Network, A Energie Storage Through A Better Consideration of Water As A Life Space..Document2 pagesUse Water As A Symbol, A Network, A Energie Storage Through A Better Consideration of Water As A Life Space..ed bookerNo ratings yet

- Introduction To Wastewater Treatment: Color Odor Solids TemperatureDocument12 pagesIntroduction To Wastewater Treatment: Color Odor Solids TemperatureAaronNo ratings yet

- Aqua AerobicMBRbrochDocument4 pagesAqua AerobicMBRbrochsalcedopozasNo ratings yet

- Industrial WastewaterDocument4 pagesIndustrial WastewaterFaical Sossey AlaouiNo ratings yet

- Industrial Waste Water Treatment by Membrane Bioreactor SystemDocument6 pagesIndustrial Waste Water Treatment by Membrane Bioreactor SystemNikie S. EdilloNo ratings yet

- ActivateSludgeVS Membrane Reactor SLIDEDocument36 pagesActivateSludgeVS Membrane Reactor SLIDEsebascian100% (2)

- Cyclor - P ER 004 EN 1603 - v2Document2 pagesCyclor - P ER 004 EN 1603 - v2Tho HoangNo ratings yet

- Technical Services: RochemDocument16 pagesTechnical Services: RochemNermeen ElmelegaeNo ratings yet

- Membrane Bioreactor Fact Sheet P100il7gDocument9 pagesMembrane Bioreactor Fact Sheet P100il7gGeorge DobreNo ratings yet

- Data Sheet: Allied Trade CentreDocument7 pagesData Sheet: Allied Trade Centreprem_k_sNo ratings yet

- Topics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4Document6 pagesTopics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4prem_k_sNo ratings yet

- Tax Exemption LetterDocument1 pageTax Exemption Letterprem_k_sNo ratings yet

- Topics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4Document6 pagesTopics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4prem_k_sNo ratings yet

- The Quick Way To Learn Microsoft Onenote!Document76 pagesThe Quick Way To Learn Microsoft Onenote!prem_k_sNo ratings yet

- The Quick Way To Learn Microsoft Onenote!Document76 pagesThe Quick Way To Learn Microsoft Onenote!prem_k_sNo ratings yet

- 3103 PDFDocument22 pages3103 PDFprem_k_sNo ratings yet

- Comparison of Overall Performance Between Moving-Bed and Conventional Sequencing Batch ReactorDocument10 pagesComparison of Overall Performance Between Moving-Bed and Conventional Sequencing Batch Reactorprem_k_sNo ratings yet

- Wastewater Treatment Plant Operator Certification Training: Rotating Biological ContactorsDocument52 pagesWastewater Treatment Plant Operator Certification Training: Rotating Biological Contactorsprem_k_sNo ratings yet

- Rotating Biological ContactorsDocument2 pagesRotating Biological Contactorsprem_k_sNo ratings yet

- NoidalofDocument227 pagesNoidalofprem_k_sNo ratings yet

- LNT Form WorkDocument12 pagesLNT Form Workprem_k_sNo ratings yet

- CV - Prem-Rev 1Document3 pagesCV - Prem-Rev 1prem_k_sNo ratings yet

- Permission To Pay Compounded Tax Under Section 8 (A) : Form No. 4DDocument1 pagePermission To Pay Compounded Tax Under Section 8 (A) : Form No. 4Dprem_k_sNo ratings yet

- Sustainable Waste Management Policy in Bangladesh For Reduction Greenhouse GasDocument34 pagesSustainable Waste Management Policy in Bangladesh For Reduction Greenhouse GasFitriSyamsiyahNo ratings yet

- Case Study On Pasig River PhilippinesDocument19 pagesCase Study On Pasig River PhilippinesKatherine Ruth Miranda100% (1)

- Waste Management in Thermal Power PlantDocument10 pagesWaste Management in Thermal Power PlantSahil BrahmaniaNo ratings yet

- Register of Aspect Impact - IMSM 4.3.1 R02Document7 pagesRegister of Aspect Impact - IMSM 4.3.1 R02jrpatel18853100% (2)

- Construction Contracts SpecificallyDocument126 pagesConstruction Contracts SpecificallyOmar HanyNo ratings yet

- Ato-Challange in Textile ProcessingDocument18 pagesAto-Challange in Textile Processinganto_hardianto443No ratings yet

- Campus STP DesignDocument6 pagesCampus STP DesignHarish LakshminarayananNo ratings yet

- Heavy Metals in Agricultural Soil and Their Impacts On Rice Production and Human Health: A ReviewDocument13 pagesHeavy Metals in Agricultural Soil and Their Impacts On Rice Production and Human Health: A ReviewAJAST JournalNo ratings yet

- Mining EngineeringDocument37 pagesMining EngineeringSoumithNo ratings yet

- Waste Management IntroductionDocument49 pagesWaste Management IntroductionAine JeremyNo ratings yet

- Carbios Business Presentation.Document20 pagesCarbios Business Presentation.ommkrishanNo ratings yet

- Cengage Eco Dev Chapter 13 - The Environment and Sustainable Development in AsiaDocument32 pagesCengage Eco Dev Chapter 13 - The Environment and Sustainable Development in AsiaArcy LeeNo ratings yet

- Design of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana StateDocument6 pagesDesign of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana Statedeepak kumarNo ratings yet

- Activated Sludge Calculations With ExcelDocument22 pagesActivated Sludge Calculations With ExcelKaustav Patnaik88% (8)

- Ecw331 Chapter 10 FinalDocument34 pagesEcw331 Chapter 10 FinalNaqib KamarozamanNo ratings yet

- Our Changing Climate: AtmosphereDocument4 pagesOur Changing Climate: AtmosphereNina AzizNo ratings yet

- Rule: Air Quality Implementation Plans Approval and Promulgation Various States: ExclusionsDocument6 pagesRule: Air Quality Implementation Plans Approval and Promulgation Various States: ExclusionsJustia.comNo ratings yet

- Case Study For Fruit IndustryDocument4 pagesCase Study For Fruit IndustryAmruta GoreNo ratings yet

- Synopsis Household Electronic Waste Mana PDFDocument14 pagesSynopsis Household Electronic Waste Mana PDFMabush LamaniNo ratings yet

- Seminar Report Smart Iot Based System For Vehicle Noise and Pollution MonitoringDocument22 pagesSeminar Report Smart Iot Based System For Vehicle Noise and Pollution MonitoringAkshay PatilNo ratings yet

- Refuse, Reduce, Reuse, Recycle and Repair: Before You BeginDocument2 pagesRefuse, Reduce, Reuse, Recycle and Repair: Before You BeginJessabelle PapuaNo ratings yet

- Technical Datasheet: High Capacity MBR Sewage Treatment SystemDocument3 pagesTechnical Datasheet: High Capacity MBR Sewage Treatment Systemkesavaganesan58No ratings yet

- Modified Cluster System Approach To WastDocument10 pagesModified Cluster System Approach To WastGraziella NavacciNo ratings yet

- Table of Provisions and Effluent StandardsDocument12 pagesTable of Provisions and Effluent StandardsNathan A. Campo IINo ratings yet

- Ross&Amter 2000 Poisoned WaterDocument5 pagesRoss&Amter 2000 Poisoned WatergetbooknowNo ratings yet

- ProjectDocument18 pagesProjectqwertyNo ratings yet

- Upcycling Architecture 27-07-22.PDF 2Document6 pagesUpcycling Architecture 27-07-22.PDF 22GI18AT026No ratings yet

- Sustainable Development in South AfricaDocument8 pagesSustainable Development in South AfricaMABUELANo ratings yet

- Poor Air Quality Index in Delhi (Bio)Document11 pagesPoor Air Quality Index in Delhi (Bio)Samriddhi SinhaNo ratings yet

- Waste DisposalDocument18 pagesWaste DisposalYasser Arfat100% (2)

MBR Process: Membrane Bioreactors MBR Plants

MBR Process: Membrane Bioreactors MBR Plants

Uploaded by

prem_k_sOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MBR Process: Membrane Bioreactors MBR Plants

MBR Process: Membrane Bioreactors MBR Plants

Uploaded by

prem_k_sCopyright:

Available Formats

MBR process

Membrane bioreactors MBR plants

Similar, but different An optimum layout

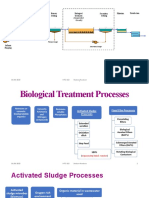

As compared to the conventional activated sludge process, the MBR process has the same phases for aerobic, biological wastewater The position of membrane filtration is of central importance to the design of MBR plants. This is determined by specific plant precondi-

treatment, but of a different scale and design. tions and the process technology requirements relating to the membranes.

Membrane filtration can be integrated into the aeration tank, or used in a separate wet or dry, downstream cell.

Conventional wastewater treatment with disinfection Integrated

Mechanical Pre- Activated sludge tanks Secondary clarification Disinfection Activated sludge Membrane Positioning of the submerged

pre-treatment clarification tanks filtration membrane module in the aerobic

section of the activated sludge

tank

Wastewater Cleaned

wastewater

Waste-

Cleaned

water

wastewater

Membrane bioreactor process (MBR) External

Activated sludge Membrane Positioning of the submerged

Mechanical Activated sludge Membrane tanks filtration membrane module in an external

pre-treatment tanks filtration filtration tank

Cleaned

wastewater Cleaned

Wastewater Wastewater

wastewater

MBR plants use simultaneous aerobic sludge stabilisation, which means that pre-clarification is no longer required. Biomass separation

and extraction from the treated wastewater is accomplished by membrane filtration, which as a rule takes the form of ultra- or microfil- Dry

tration.

External positioning - sidestream

No additional suspended solids, micro-pollutants, COD and germ elimination systems for the further treatment of the wastewater are membrane bioreactor (sMBR)

needed, as in the MBR process these pollutants are retained during the membrane filtration of the activated sludge. Cleaned

Wastewater wastewater

One characteristic of MBR plants is the high concentration of biomass in the activated sludge tanks, whereby the large quantities of

biomass derived from high sludge ages can be handled in relatively small tank volumes. Under these conditions, biological nutrient

removal (phosphorus and nitrogen) can be ideally integrated into the activated sludge process.

Compactness and top quality

By comparison with conventional plants, MBR systems offer an uncomplicated plant structure and compact footprint, as well as the Activated sludge

additional advantage of a marked improvement in the quality of the treated water. tanks

MegamodulTM

4 5

You might also like

- L5 - Physical TreatmentDocument67 pagesL5 - Physical Treatmentrushdi100% (1)

- Brochure CE 705 - Activated Sludge Process ENDocument9 pagesBrochure CE 705 - Activated Sludge Process ENedimaprwNo ratings yet

- Wwi MBR Reuse 2014Document2 pagesWwi MBR Reuse 2014qiaoxin136No ratings yet

- Membrane Bioreactors: State of The Art and Technology ExchangeDocument54 pagesMembrane Bioreactors: State of The Art and Technology ExchangeNermeen ElmelegaeNo ratings yet

- End of PipeDocument4 pagesEnd of PipeIndustria ProyectosNo ratings yet

- Multiflo 2013 EN PDFDocument8 pagesMultiflo 2013 EN PDFEbaid AbdoNo ratings yet

- 04 Canziani MBRDocument27 pages04 Canziani MBRyevgeniyNo ratings yet

- NPTEL Civil Engineering - Water and Waste Water EngineeringDocument2 pagesNPTEL Civil Engineering - Water and Waste Water EngineeringRushan LakdimuthuNo ratings yet

- Micro - and UltrafiltrationDocument16 pagesMicro - and Ultrafiltrationsihan wangNo ratings yet

- MBR Towards Micropollutant RejectionDocument88 pagesMBR Towards Micropollutant RejectionShankara NarayananNo ratings yet

- Flow Diagram Instalasi Pengolahan Air Limbah By: Cv. Bangkit Maju JayaDocument1 pageFlow Diagram Instalasi Pengolahan Air Limbah By: Cv. Bangkit Maju JayaDenti Maressa MNo ratings yet

- Membrane Drinking Water TreatmentDocument16 pagesMembrane Drinking Water TreatmentRamesh SoniNo ratings yet

- Chapter 1Document22 pagesChapter 1Adam AhsanNo ratings yet

- 3.2 17566 Product Leaflet MBR LowresDocument2 pages3.2 17566 Product Leaflet MBR LowresRahul Damodar100% (1)

- Membrane BioDocument5 pagesMembrane BioIan JamillaNo ratings yet

- Cleansewage-Bio Biological Sewage TreatmentDocument3 pagesCleansewage-Bio Biological Sewage Treatmentirshad sonde100% (1)

- Water Treatment EnglishDocument25 pagesWater Treatment EnglishVincent JosephNo ratings yet

- 05 - Case Study of Sewage TreatmentDocument6 pages05 - Case Study of Sewage TreatmentKharisma NataliaNo ratings yet

- Reactores No ConvencionalesDocument28 pagesReactores No Convencionalesbruce callNo ratings yet

- NYWEA MBR Presentation Session-1Document56 pagesNYWEA MBR Presentation Session-1gulfengsolutionsNo ratings yet

- Chapter 1Document22 pagesChapter 1mohid.shakeel.15No ratings yet

- Containerisedmbrsystem EngDocument12 pagesContainerisedmbrsystem EngNermeen ElmelegaeNo ratings yet

- Serenacel Mitsubishi EngDocument6 pagesSerenacel Mitsubishi EngYoo BoyyooNo ratings yet

- Correlation Between Sludge Volume Index (SVI) and Mixed Liquor Suspended Solids (MLSS)Document2 pagesCorrelation Between Sludge Volume Index (SVI) and Mixed Liquor Suspended Solids (MLSS)Antony ThanosNo ratings yet

- MODUL PARKIR - Parkson-Sand-Saver PDFDocument2 pagesMODUL PARKIR - Parkson-Sand-Saver PDFmessy kolloNo ratings yet

- Napier Reid BrochureDocument8 pagesNapier Reid BrochuresandeepNo ratings yet

- STP Technology Options: Moving Bed Bioreactor (MBBR) Membrane Bioreactor (MBR)Document6 pagesSTP Technology Options: Moving Bed Bioreactor (MBBR) Membrane Bioreactor (MBR)amzad aliNo ratings yet

- Flat Plate Membrane Bioreactor (MBR) System TrainingDocument56 pagesFlat Plate Membrane Bioreactor (MBR) System TrainingmarvilouNo ratings yet

- Membrane Bioreactor (MBR) TechnologyDocument4 pagesMembrane Bioreactor (MBR) Technologyshiomara jhamiletNo ratings yet

- Blue Barrel System Manual EnglishDocument12 pagesBlue Barrel System Manual EnglishKennedy NgoseyweNo ratings yet

- IHG Engineering Design Guidelines RevisiDocument5 pagesIHG Engineering Design Guidelines RevisiMohammad Abd Alrahim ShaarNo ratings yet

- MBCR FlyerDocument4 pagesMBCR FlyerunconformistNo ratings yet

- 2000LPD EnglishDocument10 pages2000LPD EnglishKennedy NgoseyweNo ratings yet

- AquaNereda Brochure 1017 WebDocument4 pagesAquaNereda Brochure 1017 WebdmnNo ratings yet

- Sucess Story - Shenzhen China - MSBRDocument2 pagesSucess Story - Shenzhen China - MSBRImran KhanNo ratings yet

- Algas Microfilter BrochureDocument8 pagesAlgas Microfilter BrochureNehal ImtiazNo ratings yet

- Kuliah MBR ITB 14 Nov 2022 - For PrintDocument31 pagesKuliah MBR ITB 14 Nov 2022 - For PrintEni RohkayatiNo ratings yet

- MABR Product Brochure Aug19Document4 pagesMABR Product Brochure Aug19e.mostafa.abdelhadyNo ratings yet

- 09.advanced WWTDocument30 pages09.advanced WWTMuamar DhikriNo ratings yet

- Solitax en Agua ResidualDocument4 pagesSolitax en Agua ResidualMaritza Catalina Melo MartinezNo ratings yet

- Accelator: InfilcoDocument4 pagesAccelator: InfilcoVanessa Cervantes CampoNo ratings yet

- Indore Municipal Corporation: 9.7 Treatment ProcessDocument1 pageIndore Municipal Corporation: 9.7 Treatment ProcessmkdholkiyaNo ratings yet

- K-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South KoreaDocument1 pageK-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South KoreaNguyen AnNo ratings yet

- Akvola Technologies Technology - WebDocument4 pagesAkvola Technologies Technology - WebHardik VavdiyaNo ratings yet

- SBR MMBR RBCDocument30 pagesSBR MMBR RBCbayu sinyoNo ratings yet

- Week 7-CHEM4015-CIVE4140-2023-2024Document21 pagesWeek 7-CHEM4015-CIVE4140-2023-2024Nitin RautNo ratings yet

- Petroleum Engineering Waste Water TreatmentpptDocument15 pagesPetroleum Engineering Waste Water TreatmentpptKunal JainNo ratings yet

- WTC 102 GemsDocument15 pagesWTC 102 GemsAyoub Mohammed AbdullahNo ratings yet

- Enhanced Nutrient Removal - Nitrogen: Description Description Description Description DescriptionDocument8 pagesEnhanced Nutrient Removal - Nitrogen: Description Description Description Description DescriptionGeorges NemerNo ratings yet

- Use Water As A Symbol, A Network, A Energie Storage Through A Better Consideration of Water As A Life Space..Document2 pagesUse Water As A Symbol, A Network, A Energie Storage Through A Better Consideration of Water As A Life Space..ed bookerNo ratings yet

- Introduction To Wastewater Treatment: Color Odor Solids TemperatureDocument12 pagesIntroduction To Wastewater Treatment: Color Odor Solids TemperatureAaronNo ratings yet

- Aqua AerobicMBRbrochDocument4 pagesAqua AerobicMBRbrochsalcedopozasNo ratings yet

- Industrial WastewaterDocument4 pagesIndustrial WastewaterFaical Sossey AlaouiNo ratings yet

- Industrial Waste Water Treatment by Membrane Bioreactor SystemDocument6 pagesIndustrial Waste Water Treatment by Membrane Bioreactor SystemNikie S. EdilloNo ratings yet

- ActivateSludgeVS Membrane Reactor SLIDEDocument36 pagesActivateSludgeVS Membrane Reactor SLIDEsebascian100% (2)

- Cyclor - P ER 004 EN 1603 - v2Document2 pagesCyclor - P ER 004 EN 1603 - v2Tho HoangNo ratings yet

- Technical Services: RochemDocument16 pagesTechnical Services: RochemNermeen ElmelegaeNo ratings yet

- Membrane Bioreactor Fact Sheet P100il7gDocument9 pagesMembrane Bioreactor Fact Sheet P100il7gGeorge DobreNo ratings yet

- Data Sheet: Allied Trade CentreDocument7 pagesData Sheet: Allied Trade Centreprem_k_sNo ratings yet

- Topics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4Document6 pagesTopics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4prem_k_sNo ratings yet

- Tax Exemption LetterDocument1 pageTax Exemption Letterprem_k_sNo ratings yet

- Topics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4Document6 pagesTopics in Finance Part III-Leverage: American Journal of Business Education - April 2010 Volume 3, Number 4prem_k_sNo ratings yet

- The Quick Way To Learn Microsoft Onenote!Document76 pagesThe Quick Way To Learn Microsoft Onenote!prem_k_sNo ratings yet

- The Quick Way To Learn Microsoft Onenote!Document76 pagesThe Quick Way To Learn Microsoft Onenote!prem_k_sNo ratings yet

- 3103 PDFDocument22 pages3103 PDFprem_k_sNo ratings yet

- Comparison of Overall Performance Between Moving-Bed and Conventional Sequencing Batch ReactorDocument10 pagesComparison of Overall Performance Between Moving-Bed and Conventional Sequencing Batch Reactorprem_k_sNo ratings yet

- Wastewater Treatment Plant Operator Certification Training: Rotating Biological ContactorsDocument52 pagesWastewater Treatment Plant Operator Certification Training: Rotating Biological Contactorsprem_k_sNo ratings yet

- Rotating Biological ContactorsDocument2 pagesRotating Biological Contactorsprem_k_sNo ratings yet

- NoidalofDocument227 pagesNoidalofprem_k_sNo ratings yet

- LNT Form WorkDocument12 pagesLNT Form Workprem_k_sNo ratings yet

- CV - Prem-Rev 1Document3 pagesCV - Prem-Rev 1prem_k_sNo ratings yet

- Permission To Pay Compounded Tax Under Section 8 (A) : Form No. 4DDocument1 pagePermission To Pay Compounded Tax Under Section 8 (A) : Form No. 4Dprem_k_sNo ratings yet

- Sustainable Waste Management Policy in Bangladesh For Reduction Greenhouse GasDocument34 pagesSustainable Waste Management Policy in Bangladesh For Reduction Greenhouse GasFitriSyamsiyahNo ratings yet

- Case Study On Pasig River PhilippinesDocument19 pagesCase Study On Pasig River PhilippinesKatherine Ruth Miranda100% (1)

- Waste Management in Thermal Power PlantDocument10 pagesWaste Management in Thermal Power PlantSahil BrahmaniaNo ratings yet

- Register of Aspect Impact - IMSM 4.3.1 R02Document7 pagesRegister of Aspect Impact - IMSM 4.3.1 R02jrpatel18853100% (2)

- Construction Contracts SpecificallyDocument126 pagesConstruction Contracts SpecificallyOmar HanyNo ratings yet

- Ato-Challange in Textile ProcessingDocument18 pagesAto-Challange in Textile Processinganto_hardianto443No ratings yet

- Campus STP DesignDocument6 pagesCampus STP DesignHarish LakshminarayananNo ratings yet

- Heavy Metals in Agricultural Soil and Their Impacts On Rice Production and Human Health: A ReviewDocument13 pagesHeavy Metals in Agricultural Soil and Their Impacts On Rice Production and Human Health: A ReviewAJAST JournalNo ratings yet

- Mining EngineeringDocument37 pagesMining EngineeringSoumithNo ratings yet

- Waste Management IntroductionDocument49 pagesWaste Management IntroductionAine JeremyNo ratings yet

- Carbios Business Presentation.Document20 pagesCarbios Business Presentation.ommkrishanNo ratings yet

- Cengage Eco Dev Chapter 13 - The Environment and Sustainable Development in AsiaDocument32 pagesCengage Eco Dev Chapter 13 - The Environment and Sustainable Development in AsiaArcy LeeNo ratings yet

- Design of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana StateDocument6 pagesDesign of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana Statedeepak kumarNo ratings yet

- Activated Sludge Calculations With ExcelDocument22 pagesActivated Sludge Calculations With ExcelKaustav Patnaik88% (8)

- Ecw331 Chapter 10 FinalDocument34 pagesEcw331 Chapter 10 FinalNaqib KamarozamanNo ratings yet

- Our Changing Climate: AtmosphereDocument4 pagesOur Changing Climate: AtmosphereNina AzizNo ratings yet

- Rule: Air Quality Implementation Plans Approval and Promulgation Various States: ExclusionsDocument6 pagesRule: Air Quality Implementation Plans Approval and Promulgation Various States: ExclusionsJustia.comNo ratings yet

- Case Study For Fruit IndustryDocument4 pagesCase Study For Fruit IndustryAmruta GoreNo ratings yet

- Synopsis Household Electronic Waste Mana PDFDocument14 pagesSynopsis Household Electronic Waste Mana PDFMabush LamaniNo ratings yet

- Seminar Report Smart Iot Based System For Vehicle Noise and Pollution MonitoringDocument22 pagesSeminar Report Smart Iot Based System For Vehicle Noise and Pollution MonitoringAkshay PatilNo ratings yet

- Refuse, Reduce, Reuse, Recycle and Repair: Before You BeginDocument2 pagesRefuse, Reduce, Reuse, Recycle and Repair: Before You BeginJessabelle PapuaNo ratings yet

- Technical Datasheet: High Capacity MBR Sewage Treatment SystemDocument3 pagesTechnical Datasheet: High Capacity MBR Sewage Treatment Systemkesavaganesan58No ratings yet

- Modified Cluster System Approach To WastDocument10 pagesModified Cluster System Approach To WastGraziella NavacciNo ratings yet

- Table of Provisions and Effluent StandardsDocument12 pagesTable of Provisions and Effluent StandardsNathan A. Campo IINo ratings yet

- Ross&Amter 2000 Poisoned WaterDocument5 pagesRoss&Amter 2000 Poisoned WatergetbooknowNo ratings yet

- ProjectDocument18 pagesProjectqwertyNo ratings yet

- Upcycling Architecture 27-07-22.PDF 2Document6 pagesUpcycling Architecture 27-07-22.PDF 22GI18AT026No ratings yet

- Sustainable Development in South AfricaDocument8 pagesSustainable Development in South AfricaMABUELANo ratings yet

- Poor Air Quality Index in Delhi (Bio)Document11 pagesPoor Air Quality Index in Delhi (Bio)Samriddhi SinhaNo ratings yet

- Waste DisposalDocument18 pagesWaste DisposalYasser Arfat100% (2)