Professional Documents

Culture Documents

Fd4.25f Alegria Maintance Checklist 3 2012-01

Fd4.25f Alegria Maintance Checklist 3 2012-01

Uploaded by

Mosab Babikir0 ratings0% found this document useful (0 votes)

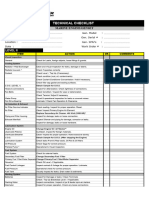

86 views1 pageThis document is a maintenance checklist for a medical device. It lists various functions and components to check, such as cables, displays, fluid systems, filters, motors, dispensing needles, and temperature controls. For each item, it indicates whether the part should be inspected, cleaned, adjusted, repaired, or replaced based on the results. The checklist is to be completed during routine maintenance with the date, model, and serial number recorded.

Original Description:

Alegria analyser

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a maintenance checklist for a medical device. It lists various functions and components to check, such as cables, displays, fluid systems, filters, motors, dispensing needles, and temperature controls. For each item, it indicates whether the part should be inspected, cleaned, adjusted, repaired, or replaced based on the results. The checklist is to be completed during routine maintenance with the date, model, and serial number recorded.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

86 views1 pageFd4.25f Alegria Maintance Checklist 3 2012-01

Fd4.25f Alegria Maintance Checklist 3 2012-01

Uploaded by

Mosab BabikirThis document is a maintenance checklist for a medical device. It lists various functions and components to check, such as cables, displays, fluid systems, filters, motors, dispensing needles, and temperature controls. For each item, it indicates whether the part should be inspected, cleaned, adjusted, repaired, or replaced based on the results. The checklist is to be completed during routine maintenance with the date, model, and serial number recorded.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Maintenance Checklist

Institution: Model: Serial number:

Date:

Function Procedure Result

Cables Inspect the power cable and the other cables (cord and plug) for cuts,

wear or breaks and replace if needed.

Date and time Check for date and time.

Change the battery on the mother board every 3 years.

TFT display Check touch screen and calibrate if needed. Check for visual

abnormalities. If damages larger than 1 x 1 cm, please replace.

Fluid system Check tubing and connections for leakage, obstruction and cracks, if

leakage or cracks then replace. Check bottom of device for fluid, if

found verify from where and if there is a leak.

Check all tubes and valves for contamination. Clean and wash.

Replace both pump heads of waste pump once a year.

Bottom filter Check the filter in the fluid containers, if found saturated replace

(minimum once a year).

Waste tube Replace the whole waste tube. Beginning from the pump head to the

waste container. But keep the Y-connection.

Air filters Clean instrument with vacuum cleaner for dust. Check the rear

ventilation filter for dust and obstruction. Replace the filter once a

year.

Accessories Check all accessories for proper fit and function.

Barcode scanner Clean barcode scanner and window.

Motors Check motor mounting screws for tightness, oil spindles.

Check dispense and Check drive belts for correct tension and wear. If signs of

turning plate drive deformation/wear then replace.

belt Frequency dispense belt 50 80 Hz (Target 65 Hz)

Frequency motor belt 138 179 Hz (Target 158.5 Hz)

Rotation plate Calibrate the rotation plate of the Alegria.

Analyse module Check for contamination, clean, and check OD with ORG 3OD.

and climate Results: Strip 1 Strip 2 Strip 3 Strip 4

chamber

Check washing Verify that washing of reaction wells and washing of needles

function function properly. Also check dispensing and suction motors,

dispensing and turning plate motor. Check the liquid level in cavities

after washing. Inspect the needles for wear, if broken or has low

performance then replace.

Replace dispense Check the dispensing (volume 100 l) of both dispensing needles.

needle Inspect for wear, if broken or has low performance then replace

(standard needle once a year; conjugate needle every 3 years).

Temperature Double check the internal temperature inside the climate chamber

against a calibrated external thermometer.

Performance test / Perform a run with Positive Control (ORG 310) and optional

QC test Negative Control (ORG 311) test devices.

Date:

Maintenance performed by:

OK Inspected/checked/tested ok RA Repaired

NOK Inspected/checked/tested Not ok RL Replaced

C Cleaned NA Not applicable

A Adjusted

ORGENTEC Diagnostika GmbH Postfach 100352 D-55134 Mainz / Germany

FD4.25F Maintenance Checklist; Version 3 valid from 2012-01-02

Page 1/1

You might also like

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Maintenance & Troubleshoot AHUDocument11 pagesMaintenance & Troubleshoot AHUEva Sulistiany100% (2)

- Quarterly Extruder Performance Checklist: Control Panel Barrel HeatersDocument1 pageQuarterly Extruder Performance Checklist: Control Panel Barrel HeatersAntonius Prakosa100% (2)

- Zexel Dieselmasteraru Dieselmasterarufr44109144 3062pdfpdfDocument6 pagesZexel Dieselmasteraru Dieselmasterarufr44109144 3062pdfpdfAntonio Gaspar100% (1)

- Service Manual: 19990220-99800 Hamamatsu, JapanDocument51 pagesService Manual: 19990220-99800 Hamamatsu, JapanSantiago JacoboNo ratings yet

- Sot Sc70 OcapDocument63 pagesSot Sc70 OcapPBlurnz005100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Callister 7th Edition Solution Manual PDFDocument2 pagesCallister 7th Edition Solution Manual PDFFarhaan MahmoodNo ratings yet

- Maint IPENDocument13 pagesMaint IPENosmaidaNo ratings yet

- Maintenance Schedule For SubstationDocument21 pagesMaintenance Schedule For SubstationSajid Shaikh100% (1)

- Classic E.O.S. From SN #BE7Document4 pagesClassic E.O.S. From SN #BE7Foued MbarkiNo ratings yet

- Laptop/Software/Firmware: Concerns With Updates. Customer Permission Is Required To Perform UpdatesDocument3 pagesLaptop/Software/Firmware: Concerns With Updates. Customer Permission Is Required To Perform UpdatesMuhammad RezaNo ratings yet

- Maintenance Check List of HydraulicDocument7 pagesMaintenance Check List of HydraulicShubham SinghNo ratings yet

- Major Works To Be DoneDocument6 pagesMajor Works To Be DoneAustin UdofiaNo ratings yet

- Preventive Maintenance ChecklistDocument3 pagesPreventive Maintenance ChecklistjjmemeNo ratings yet

- Air Handling Units GuidelineDocument5 pagesAir Handling Units GuidelineImam MansyurNo ratings yet

- 2.4 Urgency Handling: 3.1 Brief IntroductionDocument46 pages2.4 Urgency Handling: 3.1 Brief IntroductionClip nhungcaunoihayNo ratings yet

- Micromass GCT PM ProtocolDocument12 pagesMicromass GCT PM ProtocolOliver MüllerNo ratings yet

- Maintenanace Proposal NAF Officers Mess & Suites AC PDFDocument9 pagesMaintenanace Proposal NAF Officers Mess & Suites AC PDFM.Y AbdulrahimNo ratings yet

- Generators Expected ServicesDocument3 pagesGenerators Expected Servicesmoaz zahidNo ratings yet

- Comprehensive Electrical System Maintenance ChecklistsDocument12 pagesComprehensive Electrical System Maintenance ChecklistsFarrukh Nadeem100% (1)

- JXFM325 132e 05SDocument4 pagesJXFM325 132e 05SgiahaoNo ratings yet

- Picture 1Document1 pagePicture 1bashar3324No ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Introduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownDocument51 pagesIntroduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownKenneth John BrownNo ratings yet

- stc12017q0002 - Post Provided Generator Checklist PDFDocument13 pagesstc12017q0002 - Post Provided Generator Checklist PDFAnand KrishnanNo ratings yet

- For RFQ - Scope of Works PM of AHU, FCU and PumpsDocument8 pagesFor RFQ - Scope of Works PM of AHU, FCU and PumpsJay MarkNo ratings yet

- Maintenance Manual of TransformerDocument19 pagesMaintenance Manual of TransformerSidhartha MallickNo ratings yet

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- Sop On Maintenance of Air Handling Unit - Pharmaceutical GuidanceDocument3 pagesSop On Maintenance of Air Handling Unit - Pharmaceutical Guidanceruhy690100% (1)

- ChecksheetDocument2 pagesChecksheetSándor SopronyiNo ratings yet

- Milton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceDocument2 pagesMilton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceEdwin AlexNo ratings yet

- Fcu OjtDocument3 pagesFcu OjtHuzairi SulaimanNo ratings yet

- AHU FAHU - AnnuallyDocument3 pagesAHU FAHU - AnnuallyDreamliner100% (1)

- 2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTDocument4 pages2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTOsscar HerreraNo ratings yet

- ChecklistDocument1 pageChecklistGóes71No ratings yet

- Checklist PPM AircondDocument6 pagesChecklist PPM AircondsyahirahafiqahNo ratings yet

- SLPG Gtg-2yDocument5 pagesSLPG Gtg-2yAshraf MohammedNo ratings yet

- Donaldson Self-Cleaning Filter System For Turbo M Achinery: 6 Golden Rules To Maintain The Highest Performance of YourDocument33 pagesDonaldson Self-Cleaning Filter System For Turbo M Achinery: 6 Golden Rules To Maintain The Highest Performance of YourKamal ArabNo ratings yet

- SLPG - HT Motor-4yDocument4 pagesSLPG - HT Motor-4yAshraf MohammedNo ratings yet

- Sysmex CA-1500 - PMI - ProDocument2 pagesSysmex CA-1500 - PMI - ProBakhrom KasimovNo ratings yet

- IEEE STD C57 - MaintenanceDocument5 pagesIEEE STD C57 - MaintenanceGILI RELIABILITYNo ratings yet

- Engstrom CarestationDocument24 pagesEngstrom CarestationmaruthaiNo ratings yet

- ABB Substation Condition Monitoring ScheduleDocument16 pagesABB Substation Condition Monitoring ScheduleRey Arthur100% (1)

- Motor Life Evaluation of An Upright Vacuum Cleaner: Standard Test Method ForDocument7 pagesMotor Life Evaluation of An Upright Vacuum Cleaner: Standard Test Method ForDylkanWingsNo ratings yet

- Safety Safety Safety Safety Guide Guide Guide GuideDocument12 pagesSafety Safety Safety Safety Guide Guide Guide GuideMecanica SeguraNo ratings yet

- Maintenance of Motor PDFDocument4 pagesMaintenance of Motor PDFBilal AslamNo ratings yet

- Air Filter CleaningDocument13 pagesAir Filter CleaningMIDHUN MOHAN.M.PNo ratings yet

- Soft TROUBLE SHOOTING & PMPDocument10 pagesSoft TROUBLE SHOOTING & PMPLaur IriNo ratings yet

- Assignment Fluid Dynamics& Mass Tranfer Lab MaintenanceDocument8 pagesAssignment Fluid Dynamics& Mass Tranfer Lab MaintenanceAbdul Mannan KhanNo ratings yet

- Filters For Compressed AirDocument11 pagesFilters For Compressed AirNiaz MalikNo ratings yet

- HPLC Preventative Maintenance Check-ListDocument7 pagesHPLC Preventative Maintenance Check-ListMubarak PatelNo ratings yet

- Checklist For Erection Power TransformerDocument6 pagesChecklist For Erection Power Transformersasikumar67% (3)

- Operations and Maintenance ChecklistDocument1 pageOperations and Maintenance ChecklistBarep Apriadi100% (1)

- Handling Manual - NEWDocument106 pagesHandling Manual - NEWAseem Vivek MasihNo ratings yet

- Rohit Dave: Wednesday, February 17, 2010Document78 pagesRohit Dave: Wednesday, February 17, 2010Ryan JohnNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Eurus Swivel Chair: DimensionsDocument2 pagesEurus Swivel Chair: DimensionsMosab BabikirNo ratings yet

- 2019 KrafitDocument40 pages2019 KrafitMosab BabikirNo ratings yet

- You Will Love It.: Kavo Estetica E30Document7 pagesYou Will Love It.: Kavo Estetica E30Mosab BabikirNo ratings yet

- Clima Plus RX Clima RX: Istruzioni - Instructions - Einstellanleitungen Instructions - InstruccionesDocument44 pagesClima Plus RX Clima RX: Istruzioni - Instructions - Einstellanleitungen Instructions - InstruccionesMosab BabikirNo ratings yet

- Mocom Futura Classic Brochure - Australian VersionDocument20 pagesMocom Futura Classic Brochure - Australian VersionMosab BabikirNo ratings yet

- Kratko Uputstvo Za Upotrebu E30 EngDocument31 pagesKratko Uputstvo Za Upotrebu E30 EngMosab BabikirNo ratings yet

- Ajax Catalog 2015Document36 pagesAjax Catalog 2015Mosab BabikirNo ratings yet

- X Radius Trio Plus: Every Diagnostic DimensionDocument10 pagesX Radius Trio Plus: Every Diagnostic DimensionMosab BabikirNo ratings yet

- Kavo E30 Short IFUDocument32 pagesKavo E30 Short IFUMosab BabikirNo ratings yet

- Recommended Stock of Spare Parts For BC-3200Document1 pageRecommended Stock of Spare Parts For BC-3200Mosab Babikir100% (1)

- EJMCM Volume 7 Issue 3 Pages 2086-2092Document7 pagesEJMCM Volume 7 Issue 3 Pages 2086-2092Mosab BabikirNo ratings yet

- Moxa Mgate mb3180 mb3280 mb3480 Series Manual v11.2Document97 pagesMoxa Mgate mb3180 mb3280 mb3480 Series Manual v11.2Eugene BondarenkoNo ratings yet

- STS 10 PDFDocument4 pagesSTS 10 PDFJuan Glicerio C. ManlapazNo ratings yet

- MSC Thesis S.A. FrankeDocument111 pagesMSC Thesis S.A. Frankemohamed faisalNo ratings yet

- Intelimax M2M HSPA 3G Modems - MaxonDocument62 pagesIntelimax M2M HSPA 3G Modems - MaxonAdvanced Telemetry Product ManufacturersNo ratings yet

- A20 LIME2 GPIOs PDFDocument2 pagesA20 LIME2 GPIOs PDFIlja LebedevNo ratings yet

- SAMSUNG 43" N5300 Series 5 Flat Full HD TV PDFDocument4 pagesSAMSUNG 43" N5300 Series 5 Flat Full HD TV PDFLongin NkundimanaNo ratings yet

- Introduction To Data Communication: Dept. of Computer Engineering Faculty of EngineeringDocument29 pagesIntroduction To Data Communication: Dept. of Computer Engineering Faculty of Engineeringআসিফ রেজাNo ratings yet

- 1MRK505371-UEN G en Technical Manual Busbar Protection REB670 Version 2.2 IECDocument1,018 pages1MRK505371-UEN G en Technical Manual Busbar Protection REB670 Version 2.2 IECDimitar GeorgievNo ratings yet

- Online Shopping Cart: SynopsisDocument8 pagesOnline Shopping Cart: SynopsisRushi BageNo ratings yet

- Log Analysis 2018Document35 pagesLog Analysis 2018Ricardo MeloNo ratings yet

- P8Z77-M ProDocument170 pagesP8Z77-M ProEnglish Training Studio -ETSNo ratings yet

- 121cpug Oracle Collaborative Planning Implementation and User's GuideDocument482 pages121cpug Oracle Collaborative Planning Implementation and User's Guidesayedi1No ratings yet

- C701, CEHv11-CEH 12 Study Guide Flashcards QuizletDocument62 pagesC701, CEHv11-CEH 12 Study Guide Flashcards QuizletIwanNo ratings yet

- ADSPDocument2 pagesADSPanand787No ratings yet

- Hyundai IONIQ 5 BrochureDocument44 pagesHyundai IONIQ 5 BrochureKeith LeeNo ratings yet

- Company Specification: Basic Forms For Project and Internal Normalization DocumentationDocument43 pagesCompany Specification: Basic Forms For Project and Internal Normalization Documentationjana zongerNo ratings yet

- A Learning Report On Short Circuit Studies From IEEE-399Document8 pagesA Learning Report On Short Circuit Studies From IEEE-399Walter MenesesNo ratings yet

- 345K-E-Series-High-Power-Transmitter-Manuale EcresoDocument186 pages345K-E-Series-High-Power-Transmitter-Manuale EcresoCarlos QuiveNo ratings yet

- Module 7 Lecture Notes: 635.482: Website DevelopmentDocument5 pagesModule 7 Lecture Notes: 635.482: Website DevelopmentAlfred JengoNo ratings yet

- Index IttcDocument8 pagesIndex Ittc18847No ratings yet

- Kerri Carbone ResumeDocument2 pagesKerri Carbone Resumeapi-283383906No ratings yet

- Distributed Smart PV Solution Brochure - APAC (20190517)Document25 pagesDistributed Smart PV Solution Brochure - APAC (20190517)Rhey NaturalNo ratings yet

- WCCI14 Poster Template IJCNNDocument2 pagesWCCI14 Poster Template IJCNNRenee WhiteNo ratings yet

- Report JammerDocument20 pagesReport JammerDr-Ahmed Abdulridha0% (1)

- 2 Air Transportation Engineering and Assignment 1Document3 pages2 Air Transportation Engineering and Assignment 1Angelo John R. JavinezNo ratings yet

- BS 2562 Cable Boxes For Transformers and ReactorsDocument70 pagesBS 2562 Cable Boxes For Transformers and ReactorsMohamed987100% (1)

- Presentation - Java - Basics - and Thread (Session 1 and Session 2)Document112 pagesPresentation - Java - Basics - and Thread (Session 1 and Session 2)hari chandanNo ratings yet