Professional Documents

Culture Documents

High Resilient Bearings

High Resilient Bearings

Uploaded by

Hung NguyentheCopyright:

Available Formats

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Arduino VDI ExperimentsDocument7 pagesArduino VDI ExperimentsJuanCarlosCaballeroNo ratings yet

- Automatic Electronic Drain Valve Atlas Copco Ewd 330 enDocument1 pageAutomatic Electronic Drain Valve Atlas Copco Ewd 330 enamerican_guy1050% (4)

- Duromax Xp10000e Generator Owners ManualDocument28 pagesDuromax Xp10000e Generator Owners Manualduromax0% (1)

- LASTO®HDRB International EN (Eversion)Document4 pagesLASTO®HDRB International EN (Eversion)SanjaNo ratings yet

- Brochure Vibration Solutions For Building Services Equipment ENDocument20 pagesBrochure Vibration Solutions For Building Services Equipment ENKevin LowNo ratings yet

- Study of Various Types of Dampers Used For Civil StructuresDocument3 pagesStudy of Various Types of Dampers Used For Civil StructuresjayeshNo ratings yet

- 790 19.design and Analysis of Structural Precast Interlocking Blocks For Retaining WallDocument10 pages790 19.design and Analysis of Structural Precast Interlocking Blocks For Retaining WallM SNo ratings yet

- Lysaght W-Dek - User GuideDocument6 pagesLysaght W-Dek - User Guidemr_chowNo ratings yet

- Standing Tall: Taylor Solutions For High-Rise StructuresDocument6 pagesStanding Tall: Taylor Solutions For High-Rise StructuresKhagesh AkreNo ratings yet

- PDR BearingDocument11 pagesPDR BearingcristinelbNo ratings yet

- PRS Neoloy BrochureDocument12 pagesPRS Neoloy BrochureMulsa KTGNo ratings yet

- Annotating - 24 - Ria SilaenDocument3 pagesAnnotating - 24 - Ria SilaenriaasilaennNo ratings yet

- Designing Tall Buildings Structure As Architecture-103-134Document32 pagesDesigning Tall Buildings Structure As Architecture-103-134Milka VincentiyaNo ratings yet

- Name: Indra Sudrajat NIM: 2122201026 MATA KULIAH: Bahasa InggrisDocument9 pagesName: Indra Sudrajat NIM: 2122201026 MATA KULIAH: Bahasa InggrisAlex Maulana SaputraNo ratings yet

- Wellington StadiumDocument9 pagesWellington StadiumRavinesh SinghNo ratings yet

- Comparative Analysis of A Multistorey Building With and Without DamperDocument4 pagesComparative Analysis of A Multistorey Building With and Without Damperfharak patelNo ratings yet

- Bosch Rexroth Gearbox Product LineDocument10 pagesBosch Rexroth Gearbox Product Linexxsh100% (1)

- Editorial Smart Passive Damper Design For BuildingDocument3 pagesEditorial Smart Passive Damper Design For BuildingcherifdjNo ratings yet

- UniplanxDocument12 pagesUniplanxbiik0076153No ratings yet

- NexSys Bloc Brochure EnglishDocument4 pagesNexSys Bloc Brochure EnglishAdriana Marcela adrianitamenesesNo ratings yet

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemQ8123No ratings yet

- Seismic Response of Building Base Isolated With Filled Rubber Bearings Under Earthquakes of Different CharacteristicsDocument2 pagesSeismic Response of Building Base Isolated With Filled Rubber Bearings Under Earthquakes of Different CharacteristicsSahda HardiningtyasNo ratings yet

- Secondary Impact CrushersDocument8 pagesSecondary Impact CrushersKevin David Guao Bolano100% (1)

- 4A High Strength Concrete HandoutDocument2 pages4A High Strength Concrete HandoutNathanniel Pogado GonzalesNo ratings yet

- IBC EXAD - Flyer - EnglischDocument4 pagesIBC EXAD - Flyer - EnglischEdwin RodríguezNo ratings yet

- Precast Concrete Slabs On Load Bearing Masonry Walls: Good Practice GuideDocument8 pagesPrecast Concrete Slabs On Load Bearing Masonry Walls: Good Practice Guidepierre_oosthuizenNo ratings yet

- Reston Pendulum BearingsDocument4 pagesReston Pendulum BearingsTamaduianu IoanNo ratings yet

- SG Gyproc Ireland Plasterboard - Selector - GuideDocument2 pagesSG Gyproc Ireland Plasterboard - Selector - GuideOlivia SaferNo ratings yet

- ZL50GN: XCMG For Your SuccessDocument6 pagesZL50GN: XCMG For Your SuccessELILTANo ratings yet

- Fact Sheet Extended Mass-Spring System For Use in Standing Water enDocument4 pagesFact Sheet Extended Mass-Spring System For Use in Standing Water ensorinarseneNo ratings yet

- DFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDocument10 pagesDFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDaniel MarínNo ratings yet

- Wind Loads: Structural Provisions and LoadingDocument5 pagesWind Loads: Structural Provisions and LoadingShubham BeraNo ratings yet

- Ductile PilesDocument8 pagesDuctile PilesRazvanNo ratings yet

- On The Rise: Popularity of Multi-Storey Steel Frame BuildingsDocument2 pagesOn The Rise: Popularity of Multi-Storey Steel Frame BuildingsJaleel Claasen100% (1)

- Ground .: Innovating SupportDocument12 pagesGround .: Innovating SupportAntonio BocanegraNo ratings yet

- PROSPECT RESTON PENDULUM CH enDocument4 pagesPROSPECT RESTON PENDULUM CH enDaniel Zamudio LopezNo ratings yet

- Ever008 May09 PDFDocument41 pagesEver008 May09 PDFMilan PavlovicNo ratings yet

- Helifix Dixie Micro-Piles Product DatasheetDocument2 pagesHelifix Dixie Micro-Piles Product Datasheetanele_amisNo ratings yet

- CBRIDocument15 pagesCBRIsonakshiNo ratings yet

- MPH122Document8 pagesMPH122Hasan BasriNo ratings yet

- KGN BrochureDocument8 pagesKGN BrochureBijaya RaulaNo ratings yet

- BT415 Gumallaoi Judelle v. RSW MT No.1Document18 pagesBT415 Gumallaoi Judelle v. RSW MT No.1Judelle GumallaoiNo ratings yet

- Plant Layout AssignmentDocument8 pagesPlant Layout AssignmentAnmol JainNo ratings yet

- The Reliable Solution For Automated Conveying Systems: Inverted-Tooth Chains From RexrothDocument24 pagesThe Reliable Solution For Automated Conveying Systems: Inverted-Tooth Chains From RexrothLuis Eduardo Albarracin RugelesNo ratings yet

- Slipform International BrochureDocument16 pagesSlipform International BrochureBipin AgarwalNo ratings yet

- Introduction To Advanced R.C.C Roofing.: Group - 1Document15 pagesIntroduction To Advanced R.C.C Roofing.: Group - 1Nidhi MehtaNo ratings yet

- Horizons-Rapidwall Brochure 2018Document16 pagesHorizons-Rapidwall Brochure 2018ridminjNo ratings yet

- Portal FramesDocument10 pagesPortal FramesManal KhatibNo ratings yet

- GeoGauge H-4140 LiteratureDocument2 pagesGeoGauge H-4140 LiteratureWayjantha Sunethra Bandara JayawardhanaNo ratings yet

- Brochure Vibration Protection For Pumps ENDocument4 pagesBrochure Vibration Protection For Pumps ENAkshay KadiaNo ratings yet

- Advantages of Steel Fibre Reinforced Con PDFDocument5 pagesAdvantages of Steel Fibre Reinforced Con PDFAce NovoNo ratings yet

- NASA Facts: Creating A Turbomachinery RevolutionDocument4 pagesNASA Facts: Creating A Turbomachinery RevolutionPrathyusha RamadurgamNo ratings yet

- Base IsolationDocument25 pagesBase IsolationApoorv Kalal100% (1)

- Additional Precast Flooring SystemDocument36 pagesAdditional Precast Flooring SystemAbdullah Ramzi100% (1)

- Brochure Increasing Value Through Elastic Shielding of Building EN US DNODocument16 pagesBrochure Increasing Value Through Elastic Shielding of Building EN US DNOdnoscribdNo ratings yet

- Mac Gregor Sealing DevicesDocument8 pagesMac Gregor Sealing DevicesFernando Raúl LADINONo ratings yet

- BI - New DesignNDMA Course Feb-March2013Document65 pagesBI - New DesignNDMA Course Feb-March2013Abhijit BhattacharjeeNo ratings yet

- Dts-Pt-Gen-001 r2 Tensa Slab Post Tensioning SystemDocument38 pagesDts-Pt-Gen-001 r2 Tensa Slab Post Tensioning Systemimde2No ratings yet

- Assignment 1 CAST IN PLACE AND PRECASTDocument6 pagesAssignment 1 CAST IN PLACE AND PRECASTMica Tagalog DaubaNo ratings yet

- Coltman Technical SpecificationDocument10 pagesColtman Technical SpecificationltslloydNo ratings yet

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

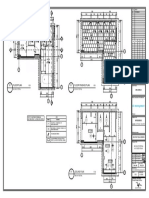

- Floor Plan 01 Section 1-1 03: Detail 01Document1 pageFloor Plan 01 Section 1-1 03: Detail 01Hung NguyentheNo ratings yet

- CANOPY - DETAILS-ModelDocument1 pageCANOPY - DETAILS-ModelHung NguyentheNo ratings yet

- A 2020 PDFDocument1 pageA 2020 PDFHung NguyentheNo ratings yet

- Floor Plan 01 Section 1-1 03: Detail 01Document1 pageFloor Plan 01 Section 1-1 03: Detail 01Hung NguyentheNo ratings yet

- Aic Management: Perspective 3 01Document1 pageAic Management: Perspective 3 01Hung NguyentheNo ratings yet

- Detail 04 01: Aic ManagementDocument1 pageDetail 04 01: Aic ManagementHung NguyentheNo ratings yet

- Aic Management: Left View 01Document1 pageAic Management: Left View 01Hung NguyentheNo ratings yet

- Aic Management: 1St Floor Finishes Plan 01Document1 pageAic Management: 1St Floor Finishes Plan 01Hung NguyentheNo ratings yet

- Aic Management: MR & MRS.MDocument1 pageAic Management: MR & MRS.MHung NguyentheNo ratings yet

- Floor Finishes Plan 01 Floor Plan 01: Aic ManagementDocument1 pageFloor Finishes Plan 01 Floor Plan 01: Aic ManagementHung NguyentheNo ratings yet

- Aic Management: Ground Floor Finishes Plan 01Document1 pageAic Management: Ground Floor Finishes Plan 01Hung NguyentheNo ratings yet

- Aic Management: Right View 01Document1 pageAic Management: Right View 01Hung NguyentheNo ratings yet

- Aic Management: Left View 01Document1 pageAic Management: Left View 01Hung NguyentheNo ratings yet

- Key Plan: Aic ManagementDocument2 pagesKey Plan: Aic ManagementHung NguyentheNo ratings yet

- Aic Management: WC 05 WC 08 Balcony 03Document1 pageAic Management: WC 05 WC 08 Balcony 03Hung Nguyenthe100% (1)

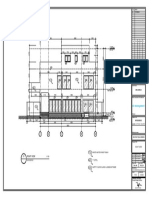

- Aic Management: Front View 01Document1 pageAic Management: Front View 01Hung NguyentheNo ratings yet

- Dry Area Dry Area: Aic ManagementDocument1 pageDry Area Dry Area: Aic ManagementHung NguyentheNo ratings yet

- Design Cost of Remaining Tender Package Follow Decree 79Document1 pageDesign Cost of Remaining Tender Package Follow Decree 79Hung NguyentheNo ratings yet

- Aic Management: Ground Floor Furniture Plan 01Document1 pageAic Management: Ground Floor Furniture Plan 01Hung NguyentheNo ratings yet

- Modeling of Ribbed Slabs For Footfall Vibration Analysis: Baris Erkus, 15 May 2009Document5 pagesModeling of Ribbed Slabs For Footfall Vibration Analysis: Baris Erkus, 15 May 2009Hung NguyentheNo ratings yet

- Request InformationDocument1 pageRequest InformationHung NguyentheNo ratings yet

- Excel 2007 Lesson 6 QuizDocument5 pagesExcel 2007 Lesson 6 Quizdeep72No ratings yet

- QA Sample Resume 2Document7 pagesQA Sample Resume 2Md shadabNo ratings yet

- Optical Braille Recognition Using Object Detection CNN: Ilya G. OvodovDocument6 pagesOptical Braille Recognition Using Object Detection CNN: Ilya G. Ovodovzelalem tamrieNo ratings yet

- RBT Task List 1Document3 pagesRBT Task List 1AbuzarNo ratings yet

- Kmea Engineering College: EdathalaDocument10 pagesKmea Engineering College: EdathalaAfnas VLthNo ratings yet

- Deleting Old History Files On The As 400Document2 pagesDeleting Old History Files On The As 400rachmat99No ratings yet

- Is Iso 2631 2 2003 PDFDocument17 pagesIs Iso 2631 2 2003 PDFCarl VegaNo ratings yet

- Numerical Descriptive Techniques (6 Hours)Document89 pagesNumerical Descriptive Techniques (6 Hours)Kato AkikoNo ratings yet

- Soalan Assignment emDocument9 pagesSoalan Assignment emafieqafariha1904No ratings yet

- Tradeoff Analysis ExampleDocument2 pagesTradeoff Analysis ExampleAdrián PérezNo ratings yet

- Rhetorical AnalysisDocument7 pagesRhetorical AnalysisrarthurcNo ratings yet

- Eztrieve PresentationDocument60 pagesEztrieve Presentationswetha_8888No ratings yet

- IMI Herion Valve CatalogDocument12 pagesIMI Herion Valve CatalogjbkimNo ratings yet

- Datasheet Eaton 93 STS - Static Transfer SwitchDocument2 pagesDatasheet Eaton 93 STS - Static Transfer SwitchWilliam QuintelaNo ratings yet

- CHE 217 Lab 4Document10 pagesCHE 217 Lab 4igor_silva02No ratings yet

- International Economics 4th Edition Feenstra Test Bank 1Document48 pagesInternational Economics 4th Edition Feenstra Test Bank 1steven100% (42)

- Journactl LogDocument10 pagesJournactl LogDavid BlaževićNo ratings yet

- APA Citation GuideDocument7 pagesAPA Citation Guidesilly lizzyNo ratings yet

- Basic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseDocument121 pagesBasic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseMarian VasileNo ratings yet

- Workshop 1 - StartupsDocument22 pagesWorkshop 1 - StartupsHernan MonteroNo ratings yet

- Reading Comprehension Sheet-IiDocument4 pagesReading Comprehension Sheet-IiStella GomesNo ratings yet

- Rotochambers: DescriptionDocument4 pagesRotochambers: DescriptionPABLONo ratings yet

- 2003 IMO Training Camp: Contributors: Sayan, Magical, Omid HatamiDocument2 pages2003 IMO Training Camp: Contributors: Sayan, Magical, Omid HatamiHariPrasad PoilathNo ratings yet

- Thesis Ni Mam JesselDocument15 pagesThesis Ni Mam JesselNylram Sentoymontomo AiromlavNo ratings yet

- Project Proposal For NagaDocument3 pagesProject Proposal For NagaRamil AlcalaNo ratings yet

- Brochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTDocument8 pagesBrochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTArturo lopez abucharNo ratings yet

- Criminal 2016 XixDocument3 pagesCriminal 2016 XixTenshi FukuiNo ratings yet

High Resilient Bearings

High Resilient Bearings

Uploaded by

Hung NguyentheCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Resilient Bearings

High Resilient Bearings

Uploaded by

Hung NguyentheCopyright:

Available Formats

High-Resilient Bearings

Efficient vibration insulation

in minimal space

Applications and advantages

of high-resilient bearings

Efficient supporting

of heavy weights

Getzner Werkstoffe has developed a The high-resilient bearings from

new product to simplify elastic sup- Getzner offer high performance,

porting of heavy loads in situations particularly with small support sur- Product advantages

with design constraints. faces.

High load decoupling with

T he high-resilient bearings isolate

vibrations and concussions in

structures extremely efficiently, even

A small bearing point is sufficient

to efficiently support very high

loads on the material. This allows an

bearings in minimal space

No expensive structural

alterations required

while taking up minimal space. elastic bearing to provide optimal Simple handling and

performance even under limited processing

M any buildings, such as high-rises,

must be supported on elastic

bearings in order to efficiently protect

space conditions. Point as well as strip

bearings are possible. This flexibility

eliminates the need for expensive

Minimized total costs

them from vibrations and concus- structural alterations, simplifying re-

sions. High-resilient elastic bearings alization of the building and positively altered on the construction site with-

are also required for structures in impacting the total costs. Even during out difficulty and also impress with

which high loads meet very small are- a renovation or subsequent work, maximum efficiency and quality as

as, such as for crane installations, optimal results can be achieved with well as uncomplicated handling.

steel structures and heavy machinery. the installation of high-resilient bear-

However, high loads typically also

require large bearing surfaces over

which the weight can be evenly distri-

ings. The easy handling of these bear-

ings is particularly evident on the con-

struction site. They are relatively

T he high dynamic efficiency of the

material guarantees outstanding

vibration insulation. These elastic

buted. In many cases, such large sur- light, can be positioned without effort bearings also have low heights and

faces are not available due to design and even readjusted later. The high- are easy to work with.

constraints. load bearings from Getzner can be

A high-resilient bearing from Getzner

Werkstoffe can support a comparable

load of roughly 600 tons on an area of

one square meter.

Complete vibration insulation

from a single source

Comprehensive service,

engineering know-how

C ombining Getzner standard mate-

rials with high-resilient bearings

produces an optimal project-specific

solution, depending on the structural

requirements. Customers profit from

the comprehensive Getzner service

and the proven quality of the materi-

als. Many reference installations con-

firm that the solutions for shock-

proofing and vibration insulation

stand the test in practice.

Individually tailored

services

G etzner works closely with cus-

tomers to solve vibration-related

problems, always focusing on the spe-

cific project requirements. The prelim-

inary calculation of the deflection,

natural frequency and degree of isola- Product properties

tion form the basis for the material

selection consulting. These compo- High dynamic efficiency

nents are critical for the success of High load capacity: Up to 6 N/mm2

the project. Getzner manufactures Long service life

the materials to specification, if re- Best long-term creep resistance

quired, to ensure that they can be Low amplitude dependence

installed quickly and easily. If desired, Low frequency dependence

the company will also take over local Relatively low weight

construction site management, or- Low flammability

ganization of the installation work Resistant to chemicals and oils

and creation of individual installation High mechanical strength (tensile strength, elongation at break)

plans. Specially selected stiffness values for various load

requirements

Usable as point or strip bearing

Successful projects

speak for themselves

O ver 40 years of experience with vibration insulation resulted in the devel-

opment of the Getzner high-resilient bearings. Getzner Werkstoffe offers

builders, architects and other construction professionals a mature product

that is ready to handle the challenges of real-world constructions.

Getzner develops elastic solutions for vibration insulation for railway, con-

struction and industrial applications. The PUR materials are the result of

in-house research and development. The companys competence is founded

on years of experience and expertise. Many complex and successfully imple-

mented projects have made Getzner a leading provider of vibration reduction

solutions in the construction industry.

Information required to use References

the high-load bearings

Beisheim Centre Ritz-Carlton, Berlin

Drawings Biogen Institute, Boston

(horizontal projection, cross- National Training Centre, Tokyo

sections, details, etc.) Lufthansa Headquarters, Frankfurt TB HRB en Copyright by Getzner Werkstoffe GmbH | 11-2010

Dead load, live load Kirloskar Oil Engines, Kagal

(people) EADS, Manching site

Bearing position Kahoku Shimpo, Sendai

Bearing dimensions Theatro National de Catalunya, Barcelona

(length, width, height) The National Opera, Oslo

Excitation frequency Drachen-Centre, Basel

Target natural frequency Skyline, Vienna

Maximum deflection amount The Rushmore Building, NYC

Music Centre, Helsinki

www.getzner.com

AustriaBrs germanyBerlinMunich JordanAmman JapanTokyo INDIAPune CHINABeijing

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Arduino VDI ExperimentsDocument7 pagesArduino VDI ExperimentsJuanCarlosCaballeroNo ratings yet

- Automatic Electronic Drain Valve Atlas Copco Ewd 330 enDocument1 pageAutomatic Electronic Drain Valve Atlas Copco Ewd 330 enamerican_guy1050% (4)

- Duromax Xp10000e Generator Owners ManualDocument28 pagesDuromax Xp10000e Generator Owners Manualduromax0% (1)

- LASTO®HDRB International EN (Eversion)Document4 pagesLASTO®HDRB International EN (Eversion)SanjaNo ratings yet

- Brochure Vibration Solutions For Building Services Equipment ENDocument20 pagesBrochure Vibration Solutions For Building Services Equipment ENKevin LowNo ratings yet

- Study of Various Types of Dampers Used For Civil StructuresDocument3 pagesStudy of Various Types of Dampers Used For Civil StructuresjayeshNo ratings yet

- 790 19.design and Analysis of Structural Precast Interlocking Blocks For Retaining WallDocument10 pages790 19.design and Analysis of Structural Precast Interlocking Blocks For Retaining WallM SNo ratings yet

- Lysaght W-Dek - User GuideDocument6 pagesLysaght W-Dek - User Guidemr_chowNo ratings yet

- Standing Tall: Taylor Solutions For High-Rise StructuresDocument6 pagesStanding Tall: Taylor Solutions For High-Rise StructuresKhagesh AkreNo ratings yet

- PDR BearingDocument11 pagesPDR BearingcristinelbNo ratings yet

- PRS Neoloy BrochureDocument12 pagesPRS Neoloy BrochureMulsa KTGNo ratings yet

- Annotating - 24 - Ria SilaenDocument3 pagesAnnotating - 24 - Ria SilaenriaasilaennNo ratings yet

- Designing Tall Buildings Structure As Architecture-103-134Document32 pagesDesigning Tall Buildings Structure As Architecture-103-134Milka VincentiyaNo ratings yet

- Name: Indra Sudrajat NIM: 2122201026 MATA KULIAH: Bahasa InggrisDocument9 pagesName: Indra Sudrajat NIM: 2122201026 MATA KULIAH: Bahasa InggrisAlex Maulana SaputraNo ratings yet

- Wellington StadiumDocument9 pagesWellington StadiumRavinesh SinghNo ratings yet

- Comparative Analysis of A Multistorey Building With and Without DamperDocument4 pagesComparative Analysis of A Multistorey Building With and Without Damperfharak patelNo ratings yet

- Bosch Rexroth Gearbox Product LineDocument10 pagesBosch Rexroth Gearbox Product Linexxsh100% (1)

- Editorial Smart Passive Damper Design For BuildingDocument3 pagesEditorial Smart Passive Damper Design For BuildingcherifdjNo ratings yet

- UniplanxDocument12 pagesUniplanxbiik0076153No ratings yet

- NexSys Bloc Brochure EnglishDocument4 pagesNexSys Bloc Brochure EnglishAdriana Marcela adrianitamenesesNo ratings yet

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemQ8123No ratings yet

- Seismic Response of Building Base Isolated With Filled Rubber Bearings Under Earthquakes of Different CharacteristicsDocument2 pagesSeismic Response of Building Base Isolated With Filled Rubber Bearings Under Earthquakes of Different CharacteristicsSahda HardiningtyasNo ratings yet

- Secondary Impact CrushersDocument8 pagesSecondary Impact CrushersKevin David Guao Bolano100% (1)

- 4A High Strength Concrete HandoutDocument2 pages4A High Strength Concrete HandoutNathanniel Pogado GonzalesNo ratings yet

- IBC EXAD - Flyer - EnglischDocument4 pagesIBC EXAD - Flyer - EnglischEdwin RodríguezNo ratings yet

- Precast Concrete Slabs On Load Bearing Masonry Walls: Good Practice GuideDocument8 pagesPrecast Concrete Slabs On Load Bearing Masonry Walls: Good Practice Guidepierre_oosthuizenNo ratings yet

- Reston Pendulum BearingsDocument4 pagesReston Pendulum BearingsTamaduianu IoanNo ratings yet

- SG Gyproc Ireland Plasterboard - Selector - GuideDocument2 pagesSG Gyproc Ireland Plasterboard - Selector - GuideOlivia SaferNo ratings yet

- ZL50GN: XCMG For Your SuccessDocument6 pagesZL50GN: XCMG For Your SuccessELILTANo ratings yet

- Fact Sheet Extended Mass-Spring System For Use in Standing Water enDocument4 pagesFact Sheet Extended Mass-Spring System For Use in Standing Water ensorinarseneNo ratings yet

- DFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDocument10 pagesDFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDaniel MarínNo ratings yet

- Wind Loads: Structural Provisions and LoadingDocument5 pagesWind Loads: Structural Provisions and LoadingShubham BeraNo ratings yet

- Ductile PilesDocument8 pagesDuctile PilesRazvanNo ratings yet

- On The Rise: Popularity of Multi-Storey Steel Frame BuildingsDocument2 pagesOn The Rise: Popularity of Multi-Storey Steel Frame BuildingsJaleel Claasen100% (1)

- Ground .: Innovating SupportDocument12 pagesGround .: Innovating SupportAntonio BocanegraNo ratings yet

- PROSPECT RESTON PENDULUM CH enDocument4 pagesPROSPECT RESTON PENDULUM CH enDaniel Zamudio LopezNo ratings yet

- Ever008 May09 PDFDocument41 pagesEver008 May09 PDFMilan PavlovicNo ratings yet

- Helifix Dixie Micro-Piles Product DatasheetDocument2 pagesHelifix Dixie Micro-Piles Product Datasheetanele_amisNo ratings yet

- CBRIDocument15 pagesCBRIsonakshiNo ratings yet

- MPH122Document8 pagesMPH122Hasan BasriNo ratings yet

- KGN BrochureDocument8 pagesKGN BrochureBijaya RaulaNo ratings yet

- BT415 Gumallaoi Judelle v. RSW MT No.1Document18 pagesBT415 Gumallaoi Judelle v. RSW MT No.1Judelle GumallaoiNo ratings yet

- Plant Layout AssignmentDocument8 pagesPlant Layout AssignmentAnmol JainNo ratings yet

- The Reliable Solution For Automated Conveying Systems: Inverted-Tooth Chains From RexrothDocument24 pagesThe Reliable Solution For Automated Conveying Systems: Inverted-Tooth Chains From RexrothLuis Eduardo Albarracin RugelesNo ratings yet

- Slipform International BrochureDocument16 pagesSlipform International BrochureBipin AgarwalNo ratings yet

- Introduction To Advanced R.C.C Roofing.: Group - 1Document15 pagesIntroduction To Advanced R.C.C Roofing.: Group - 1Nidhi MehtaNo ratings yet

- Horizons-Rapidwall Brochure 2018Document16 pagesHorizons-Rapidwall Brochure 2018ridminjNo ratings yet

- Portal FramesDocument10 pagesPortal FramesManal KhatibNo ratings yet

- GeoGauge H-4140 LiteratureDocument2 pagesGeoGauge H-4140 LiteratureWayjantha Sunethra Bandara JayawardhanaNo ratings yet

- Brochure Vibration Protection For Pumps ENDocument4 pagesBrochure Vibration Protection For Pumps ENAkshay KadiaNo ratings yet

- Advantages of Steel Fibre Reinforced Con PDFDocument5 pagesAdvantages of Steel Fibre Reinforced Con PDFAce NovoNo ratings yet

- NASA Facts: Creating A Turbomachinery RevolutionDocument4 pagesNASA Facts: Creating A Turbomachinery RevolutionPrathyusha RamadurgamNo ratings yet

- Base IsolationDocument25 pagesBase IsolationApoorv Kalal100% (1)

- Additional Precast Flooring SystemDocument36 pagesAdditional Precast Flooring SystemAbdullah Ramzi100% (1)

- Brochure Increasing Value Through Elastic Shielding of Building EN US DNODocument16 pagesBrochure Increasing Value Through Elastic Shielding of Building EN US DNOdnoscribdNo ratings yet

- Mac Gregor Sealing DevicesDocument8 pagesMac Gregor Sealing DevicesFernando Raúl LADINONo ratings yet

- BI - New DesignNDMA Course Feb-March2013Document65 pagesBI - New DesignNDMA Course Feb-March2013Abhijit BhattacharjeeNo ratings yet

- Dts-Pt-Gen-001 r2 Tensa Slab Post Tensioning SystemDocument38 pagesDts-Pt-Gen-001 r2 Tensa Slab Post Tensioning Systemimde2No ratings yet

- Assignment 1 CAST IN PLACE AND PRECASTDocument6 pagesAssignment 1 CAST IN PLACE AND PRECASTMica Tagalog DaubaNo ratings yet

- Coltman Technical SpecificationDocument10 pagesColtman Technical SpecificationltslloydNo ratings yet

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

- Floor Plan 01 Section 1-1 03: Detail 01Document1 pageFloor Plan 01 Section 1-1 03: Detail 01Hung NguyentheNo ratings yet

- CANOPY - DETAILS-ModelDocument1 pageCANOPY - DETAILS-ModelHung NguyentheNo ratings yet

- A 2020 PDFDocument1 pageA 2020 PDFHung NguyentheNo ratings yet

- Floor Plan 01 Section 1-1 03: Detail 01Document1 pageFloor Plan 01 Section 1-1 03: Detail 01Hung NguyentheNo ratings yet

- Aic Management: Perspective 3 01Document1 pageAic Management: Perspective 3 01Hung NguyentheNo ratings yet

- Detail 04 01: Aic ManagementDocument1 pageDetail 04 01: Aic ManagementHung NguyentheNo ratings yet

- Aic Management: Left View 01Document1 pageAic Management: Left View 01Hung NguyentheNo ratings yet

- Aic Management: 1St Floor Finishes Plan 01Document1 pageAic Management: 1St Floor Finishes Plan 01Hung NguyentheNo ratings yet

- Aic Management: MR & MRS.MDocument1 pageAic Management: MR & MRS.MHung NguyentheNo ratings yet

- Floor Finishes Plan 01 Floor Plan 01: Aic ManagementDocument1 pageFloor Finishes Plan 01 Floor Plan 01: Aic ManagementHung NguyentheNo ratings yet

- Aic Management: Ground Floor Finishes Plan 01Document1 pageAic Management: Ground Floor Finishes Plan 01Hung NguyentheNo ratings yet

- Aic Management: Right View 01Document1 pageAic Management: Right View 01Hung NguyentheNo ratings yet

- Aic Management: Left View 01Document1 pageAic Management: Left View 01Hung NguyentheNo ratings yet

- Key Plan: Aic ManagementDocument2 pagesKey Plan: Aic ManagementHung NguyentheNo ratings yet

- Aic Management: WC 05 WC 08 Balcony 03Document1 pageAic Management: WC 05 WC 08 Balcony 03Hung Nguyenthe100% (1)

- Aic Management: Front View 01Document1 pageAic Management: Front View 01Hung NguyentheNo ratings yet

- Dry Area Dry Area: Aic ManagementDocument1 pageDry Area Dry Area: Aic ManagementHung NguyentheNo ratings yet

- Design Cost of Remaining Tender Package Follow Decree 79Document1 pageDesign Cost of Remaining Tender Package Follow Decree 79Hung NguyentheNo ratings yet

- Aic Management: Ground Floor Furniture Plan 01Document1 pageAic Management: Ground Floor Furniture Plan 01Hung NguyentheNo ratings yet

- Modeling of Ribbed Slabs For Footfall Vibration Analysis: Baris Erkus, 15 May 2009Document5 pagesModeling of Ribbed Slabs For Footfall Vibration Analysis: Baris Erkus, 15 May 2009Hung NguyentheNo ratings yet

- Request InformationDocument1 pageRequest InformationHung NguyentheNo ratings yet

- Excel 2007 Lesson 6 QuizDocument5 pagesExcel 2007 Lesson 6 Quizdeep72No ratings yet

- QA Sample Resume 2Document7 pagesQA Sample Resume 2Md shadabNo ratings yet

- Optical Braille Recognition Using Object Detection CNN: Ilya G. OvodovDocument6 pagesOptical Braille Recognition Using Object Detection CNN: Ilya G. Ovodovzelalem tamrieNo ratings yet

- RBT Task List 1Document3 pagesRBT Task List 1AbuzarNo ratings yet

- Kmea Engineering College: EdathalaDocument10 pagesKmea Engineering College: EdathalaAfnas VLthNo ratings yet

- Deleting Old History Files On The As 400Document2 pagesDeleting Old History Files On The As 400rachmat99No ratings yet

- Is Iso 2631 2 2003 PDFDocument17 pagesIs Iso 2631 2 2003 PDFCarl VegaNo ratings yet

- Numerical Descriptive Techniques (6 Hours)Document89 pagesNumerical Descriptive Techniques (6 Hours)Kato AkikoNo ratings yet

- Soalan Assignment emDocument9 pagesSoalan Assignment emafieqafariha1904No ratings yet

- Tradeoff Analysis ExampleDocument2 pagesTradeoff Analysis ExampleAdrián PérezNo ratings yet

- Rhetorical AnalysisDocument7 pagesRhetorical AnalysisrarthurcNo ratings yet

- Eztrieve PresentationDocument60 pagesEztrieve Presentationswetha_8888No ratings yet

- IMI Herion Valve CatalogDocument12 pagesIMI Herion Valve CatalogjbkimNo ratings yet

- Datasheet Eaton 93 STS - Static Transfer SwitchDocument2 pagesDatasheet Eaton 93 STS - Static Transfer SwitchWilliam QuintelaNo ratings yet

- CHE 217 Lab 4Document10 pagesCHE 217 Lab 4igor_silva02No ratings yet

- International Economics 4th Edition Feenstra Test Bank 1Document48 pagesInternational Economics 4th Edition Feenstra Test Bank 1steven100% (42)

- Journactl LogDocument10 pagesJournactl LogDavid BlaževićNo ratings yet

- APA Citation GuideDocument7 pagesAPA Citation Guidesilly lizzyNo ratings yet

- Basic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseDocument121 pagesBasic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseMarian VasileNo ratings yet

- Workshop 1 - StartupsDocument22 pagesWorkshop 1 - StartupsHernan MonteroNo ratings yet

- Reading Comprehension Sheet-IiDocument4 pagesReading Comprehension Sheet-IiStella GomesNo ratings yet

- Rotochambers: DescriptionDocument4 pagesRotochambers: DescriptionPABLONo ratings yet

- 2003 IMO Training Camp: Contributors: Sayan, Magical, Omid HatamiDocument2 pages2003 IMO Training Camp: Contributors: Sayan, Magical, Omid HatamiHariPrasad PoilathNo ratings yet

- Thesis Ni Mam JesselDocument15 pagesThesis Ni Mam JesselNylram Sentoymontomo AiromlavNo ratings yet

- Project Proposal For NagaDocument3 pagesProject Proposal For NagaRamil AlcalaNo ratings yet

- Brochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTDocument8 pagesBrochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTArturo lopez abucharNo ratings yet

- Criminal 2016 XixDocument3 pagesCriminal 2016 XixTenshi FukuiNo ratings yet