Professional Documents

Culture Documents

Armaturen: Order Information Nameplate Data

Armaturen: Order Information Nameplate Data

Uploaded by

Nguyen HaiCopyright:

Available Formats

You might also like

- HPTO12: Installation & MaintenanceDocument29 pagesHPTO12: Installation & Maintenancewilmer fernando lopez galeano100% (1)

- WoodwardDocument104 pagesWoodwardwachuwachuNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- Lube Oil Flushing ProcedureDocument18 pagesLube Oil Flushing ProcedureKevin Chen100% (2)

- API 6A Spec Flange Bolt+ Ring Chart PDFDocument1 pageAPI 6A Spec Flange Bolt+ Ring Chart PDFAlan JuanNo ratings yet

- List of AttachementsDocument1 pageList of AttachementsgauravNo ratings yet

- 44043-0015 Rev 3 Foundation Loads PlanDocument1 page44043-0015 Rev 3 Foundation Loads PlanRidip DuttaNo ratings yet

- Corr1 Part-3 CPI9725P19 PDFDocument119 pagesCorr1 Part-3 CPI9725P19 PDFkaustavNo ratings yet

- 2324MTC037 11359Document1 page2324MTC037 11359Shrikrushna DalviNo ratings yet

- Check ValvesDocument12 pagesCheck Valveshaniif mkNo ratings yet

- Datasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)Document2 pagesDatasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)usama666No ratings yet

- Shaft Sleeve CWP Pump 180mm RevisiDocument1 pageShaft Sleeve CWP Pump 180mm Revisiwawan dweeNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- SL 910Document4 pagesSL 910Yarisa VangeNo ratings yet

- 1.a11a PMSDocument5 pages1.a11a PMSS.selvakumarNo ratings yet

- D11200ADocument4 pagesD11200AmahendrandsNo ratings yet

- 2324MTC037 11361Document1 page2324MTC037 11361Shrikrushna DalviNo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Shaft Sleeve CWP Pump 170mm Revisi PDFDocument1 pageShaft Sleeve CWP Pump 170mm Revisi PDFwawan dweeNo ratings yet

- Auto On Off Ball Valve Suresales - Commented - QAP - REV-01Document1 pageAuto On Off Ball Valve Suresales - Commented - QAP - REV-01Deepak UpadhyayNo ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- PROCEDURE MANUALS - (Materials and Process Specifications Manual) - (07-01)Document15 pagesPROCEDURE MANUALS - (Materials and Process Specifications Manual) - (07-01)RickyNo ratings yet

- Pt. SMC Pneumatic Indonesia: Revision RecordDocument1 pagePt. SMC Pneumatic Indonesia: Revision RecordArifin MuliaNo ratings yet

- Job Card: Process Inspection ReportDocument10 pagesJob Card: Process Inspection ReportAbhi YadavNo ratings yet

- Weld MapDocument3 pagesWeld Mapeffiezool mohdNo ratings yet

- R3572-4002-B HPU Column Reel DriveDocument1 pageR3572-4002-B HPU Column Reel DriveKarikalan JayNo ratings yet

- Ds - Control ValvesDocument15 pagesDs - Control ValvesNawfel ArafathNo ratings yet

- Taper Frame 1Document4 pagesTaper Frame 1VKL QualityNo ratings yet

- MOV DatasheetDocument98 pagesMOV Datasheetsrik11No ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- m24.30 DenisonDocument80 pagesm24.30 Denison黃重銘No ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- PreviewDocument20 pagesPreviewFarhatNo ratings yet

- Taper BlockDocument2 pagesTaper BlockVKL QualityNo ratings yet

- Certificate 82337983.10 Z100435 Elp-M20-8 Eye Lifting Point PDFDocument1 pageCertificate 82337983.10 Z100435 Elp-M20-8 Eye Lifting Point PDFAngela GracielaNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- TQ-3 (Della Foglia) CompleteDocument2 pagesTQ-3 (Della Foglia) CompleteABDUL KADHARNo ratings yet

- Self Acting Pressure Control ValveDocument7 pagesSelf Acting Pressure Control ValveSreejesh Sundaresan100% (1)

- Hojas de Datos Orificios de Restricción: Ingenieria de Detalle Siar 18.5KbwpdDocument3 pagesHojas de Datos Orificios de Restricción: Ingenieria de Detalle Siar 18.5Kbwpdlaura velazquesNo ratings yet

- Datasheet Level GaugeDocument9 pagesDatasheet Level GaugemmtdarxNo ratings yet

- Extracted Pages From G.V DSDocument4 pagesExtracted Pages From G.V DSkoraina2015No ratings yet

- A325M - M24x70Document3 pagesA325M - M24x70nam nguyengiangNo ratings yet

- Ramy Abou El SoaadDocument10 pagesRamy Abou El SoaadAhmed Ayman AhmedNo ratings yet

- Benzyna 4 T Max v2Document1 pageBenzyna 4 T Max v2iflix iflixNo ratings yet

- PSV 2404Document1 pagePSV 2404Tomás MercadoNo ratings yet

- BN551-MSRF-1164 - Piping Spool Material For PRV InstallationDocument2 pagesBN551-MSRF-1164 - Piping Spool Material For PRV InstallationMohammed AbdallaNo ratings yet

- 9700 SERIES: Manitou North America, IncDocument16 pages9700 SERIES: Manitou North America, IncRazvan MitruNo ratings yet

- 9700 SERIES: Manitou North America, IncDocument16 pages9700 SERIES: Manitou North America, IncRazvan MitruNo ratings yet

- AR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFDocument6 pagesAR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFYaakoubi FethiNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- A18 PDFDocument5 pagesA18 PDFBalakrishnan KrishnanNo ratings yet

- BSM80C-150AA Customer Information PacketDocument7 pagesBSM80C-150AA Customer Information PacketPedro ReyesNo ratings yet

- A Polyhydron Group Company: DescriptionDocument2 pagesA Polyhydron Group Company: DescriptionRenjithSivaNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- PSV-2404Document1 pagePSV-2404Tomás MercadoNo ratings yet

- 2 - Focus II C-307 DC Motor Sigma - IngDocument127 pages2 - Focus II C-307 DC Motor Sigma - IngMatias BruschiniNo ratings yet

- FMEDA计算书 菲锐西1Document15 pagesFMEDA计算书 菲锐西1ajinkya.patilNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Juchan PQDocument46 pagesJuchan PQNguyen HaiNo ratings yet

- Asme b16 48 2005 Juntas Ciegas PDFDocument50 pagesAsme b16 48 2005 Juntas Ciegas PDFNguyen HaiNo ratings yet

- A451 PDFDocument4 pagesA451 PDFNguyen HaiNo ratings yet

- Tubacex Catalogue 2015Document28 pagesTubacex Catalogue 2015Nguyen HaiNo ratings yet

- Basis2 Steel enDocument107 pagesBasis2 Steel enNguyen HaiNo ratings yet

- Basis1 Steel en PDFDocument90 pagesBasis1 Steel en PDFNguyen HaiNo ratings yet

Armaturen: Order Information Nameplate Data

Armaturen: Order Information Nameplate Data

Uploaded by

Nguyen HaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Armaturen: Order Information Nameplate Data

Armaturen: Order Information Nameplate Data

Uploaded by

Nguyen HaiCopyright:

Available Formats

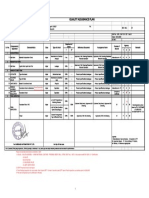

Final Test Report

ARMATUREN For ASME B&PV Code Section VIII Div. 1

(UV) Safety Relief Valves

_

---_._ ... .... __ .__ ._----------_ ..__ ._--_ ........ _ .._- ........ _ ..._._----_ _ _ ........... __ ._-

... ... ... -------_ .._.__._ ........... _ ...._ .._---_ __ ..._._ .......In

... _-_ ....Accordance with EN 10204-3.1

__ .__ ........ ------------

Order Information Nameplate Data

Sales Order Number 216347 Model R-50JS4280B1087 Stamp

Purchase Order Number 504759 Serial No. 216347-01 I Size 3J4

Customer Company

Yes

ARI Armaturen Malaysia Project No. 01-2015/PVSD-ARI

Customer Contact KEN WONG Kd 0.724 I Date 9/17/2015

Location VIETNAM Set Press. 1087 psig 74.9 bar Temp 136 OF

Valve Information Back Press. 0- 65 psig 0-4.5 bar Temp 58 C

Model Number R-50JS4280 B1087

---

I Service Liquid

-------_._---

CDTP

----_.

1087 psig 74.9 bar

-.------

Over

Tag Number 04PSVl728

I Serial Number 216347-01 Capacity 1358GPM 10%

Press.

Project No. 01-2015/PVSD-ARI Area 1.427 in2 I Orif. Dia. 1.348 in Lift 0.41 in

Spring Number N72S

I Spring Range 957 -1078 psig Tag No. 04PSVl728

Heat Number Assignment Hydrostatic Pressure Test

The applicable pressure containing parts of the valve have been hydrostatically tested"

Part Name Part Number Heat Number at a minimum of 1.5 times the design pressure of the parts in accordancewith ASME

Body 007-301-0749 KS526 code requirement UG-136 (d)(2) and ARI-Armaturen USA,LP'sEngineeringStandard EN-

P-001 (as applicable).

Bonnet 002-301-0403 K4048

Cap 001-301-0203 111205-5

Disc 005-301-0361 U1735

Valves are in Compliance with the Following

Nozzle 009-301-0134 DNG02 ASMESec.VIII UG-136(d)(3)

ASMESec.VIII UG-136(d)(4)

Base Not applicable Not applicable

EN-T-001 Revision 2

Inlet Stub End Not applicable Not applicable API 527, UG-136(d)(5)

OSHA29CFRPart 1910.119 (4)(iv)

Outlet Stub End Not applicable Not applicable

PED97/23/EC

Inlet Flange Not applicable Not applicable ENIS041261

Outlet Flange Not applicable Not applicable

Test Information

Valvecomplieswith the requirementsof ASMESec.VIIIUG136(d)(3),

ASMESec.VIIIUG136(d)(4),

ENTOO1

Revision2,APIS27,UG136(d)(S),

OSHA29CFRPart1910.119(4)(iv)

Tests Required: ~Set Point ~ Back Pressure ~ Seat Tightness D Customer Inspector

Set Pressure Test Back Pressure Test Seat Tightness Test

Req. Set Press. Range 1087 -1120 psig Min. Required Test 65 psig Min. Required Test 978 psig

Actual Set Pressure 1096 psig Actual Test 65 psig Actual Test 978 psig

Nozzle Ring Setting 2

--

Test Stand and Gauge Information Assembled By: U. Date: 12/22/2015

Test Stand ID Number Test 1 Tested By: A.Y. ~. 12/22/2015

Gauge Serial Number 025246 Customer Inspector: A-'::

,~ .Uat~~

7,

Gauge Calibration Date 9/24/2016 Final Inspection: V.H. ... Da~e: r '-2/22/2015

ARI-Armaturen USA,LPcertifies that data supplied in this report is correct and that all detallsfor design, material, constructiorl and workmanshipOf'the, J>ressurerelief valve

herein conform with the requirements of Section Vllf, Division 1 of the ASME Boiler and Pressu

~ Q 110 ~

~~

-~""

OF ~

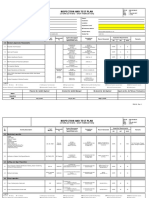

Final Test Report

ARMATUREN For ASME B&PV Code Section VIII Div. 1

(UV) Safety Relief Valves

ARI-Armaturen USA, LP

In Accordance with EN 10204-3.1

Order Information Nameplate Data

-------_._-----_._-_._-----_ _

.. _ _._- -_ _-_._ _ _._.__ ._---

.. .. .. ----------_. __ ._ _._ _-_ _--- ---_.-

.. .. ..

Sales Order Number 216347 Model RB50QS4280B0599 Stamp

Purchase Order Number 504759 Serial No.

;~~~~;-~~2"l~;~~'"~~.;

r-------- Yes

Customer Company ARI Armaturen Malaysia Project No. 01-2015/PVSD-ARI

Customer Contact KEN WONG

...~~ _.._... . __ O.724 ._._ L~~~.~........_

_~!~!L~O~~._.__.__ __ _.

Location VIETNAM

_-_

Set Press.

..__ .. ..__ .._

599

_ __ _ _ _._ __

psig

.._._.-

41.3 bar Temp

-.._ _._ _._. __ ._._.- ---_.

122 of

_ __ _-_ _. ..

Valve Information Back Press. 65 psig 4.5 bar Temp 50C

--------------------~------~

Model Number RB50QS4280B0599 Service Liquid CDTP 599 psig 41.3 bar

_ _ ._. .. _ L__ "'~

..--..-- ..- ..- -.-- ..--

Over

Tag Number 23PSV1052A Serial Number 216347-02 Capacity 8161 GPM 10%

..- -.--- ..--- --.- -..-- -.- - --.- ----r--- - - -.. .........

Press e ,

Project No. 01-2015/PVSD-ARI Area 12.24 in2 Orif. Dia. 3.948 in Lift 1.2 in

- - ~ -"

Spring Number S76J Spring Range 560 - 628 psig Tag No. 23PSV1052A

- -- - ---- -

- -

Part Name

Heat Number Assignment

- -~--- ..-.- ...

Part Number

- _ .... _ ... .. _--

Heat

- --

Number

Hydrostatic Pressure Test

The applicable pressure containing parts of the valve have been hydrostatically tested

J

- .- -- - - at a minimum of 1.5 times the design pressure of the parts in accordance with AsK"E

Body 007-301-0753 AG314 code requirement UG-136 (d)(2) and ARI-Armaturen USA, LP's Engineering Standard EN-

P-001 (as applicable).

Bonnet 002-301-0410 A0818

Cap 001-301-0204 A0566 Result: No Visible Leakage

Disc 005-301-0367 U1668

Valves are in Compliance with the Following

Nozzle 009-301-0146 DWR08 ASME Sec. VIII UG-136(d)(3)

ASME Sec.VIII UG-136(d)(4)

Base Not applicable Not applicable

EN-T-001 Revision 2

Inlet Stub End Not applicable Not applicable API 527, UG-136(d)(s)

OSHA 29CFRPart 1910.119 (4)(iv)

Outlet Stub End Not applicable Not applicable

PED97/23/EC

Inlet Flange Not applicable Not applicable ENIS04126-1

Outlet Flange Not applicable Not applicable

- .- -

Test Information

Valve complies with the requirements of ASME Sec. VIII UG-136(d)(3), AS~E Sec. VIII UG-136(d)(4), EN-T-001 Revision 2, API 527, UG-136(d)(5), OSHA29CFRPart 1910.119 (4)(iv)

Tests Required: ~Set Point ~ Back Pressure ~ Seat Tightness o Customer Inspector

Set Pressure Test

T Back Pressure Test Seat Tightness Test

Req. Set Press. Range 599 - 617 psig Min. Required Test 65 psig Min. Required Test 539 psig

- I . I

Actual Set Pressure 600 psig Actual Tes.t 65 psig Actual Test 540 psig

!

Nozzle Ring Setting 2

Test Stand and Gauge Information Assembled By: J.F. Date: 10/22/2015

Test Stand ID Number TEST-1 Tested By: A.Y. Date:. 10/22/2015

Gauge Serial Number 025246 Customer Inspector: .At~fe\t",

Gauge Calibration Date 9/24/2016 Finallnspectiori: V.H. Il~

CE!lti'/}91~:o~~\ 10/23/2015

ARI-Armaturen USA, LPcertifies that data supplied in this report is correct and that all details for design, material, constructlc[ a~1fi8tiost1l9cP.f m} pressure relief valve

herein conform with the requirements of Section VIII, Division 1 of the ASME Boiler and PressLie veliBI Code. .:

d'", 1260110 0

-:1~ OF ,~i-:\>'

Final Test Report

ARMATUREN For ASME B&PV Code Section VIII Div. 1

(UV) Safety Relief Valves

ARI-Armaturen USA, LP

In Accordance with EN 10204-3.1

Order Information Nameplate Data

-------------------------------------- ----------------------------------------"

-------------------------------

---------------------------------------------------,------1

Sales Order Number 216347 Model RB50Qs4280 B0599 Stamp

Purchase Order Number 504759 Serial No. 2 ~~~-~;~~~--r~;;~--- 6 Q8

Customer Company ARI Armaturen Malaysia Project No. 01-2015/PVsD-ARI

Yes

-------------

Customer Contact KEN WONG ~~____________________________9.~!~~___ L~~~~_______ __~!~!(~ a.~~_ _ _

Location VIETNAM Set Press. 599 psig 41.3 bar Temp 122 of

----------------------------- f--------------------------------- -----------------------------------------------------

-----------------------------

Valve Information Back Press. 65 psig 4.5 bar Temp 50C

RB50Qs4280B0599_ I Service

_______________________________________

1 _.---------------------_

Model Number Liquid CDTP 599 psig

_._ _-- .. .. _-_ 41.3 bar

.._--.-_._---------- -- __ ._-_ _----_ _-

Tag Number 23PsV1052B Serial Number 216347-03 Capacity 8161 GPM 10% Over

Project No. 01-2015/PVsD-ARI

--~;~-~----------

---------------~;-:;~----~~~---T~~;;~-~-;~-.--3-:;~~--;~-----

-~;~~----~-:;---- Press.

in

Spring Number s76J Spring Range 560 - 628 psig Tag No. 23PsV1052B

- -- --- -- --

Heat Number Assignment

- ------ ._.- --- -

Hydrostatic Pressure Test

The applicable pressure containing parts of the valve have been hydrostatically tes;ed

l

Part Name Part Number Heat Number at a minimum of 1.5 times the design pressure of the parts in accordance with ASME

-

Body 007 -301-0753 code requirement UG-136 (d}(2) and ARI-Armaturen USA, LP's Engineering Standard EN-

A0314

P-001 (as applicable).

Bonnet 002-301-0410 A0818

Cap 001-301-0204 A0566 Result: No Visible Leakage

Disc 005-301-0367 U1668

Valves are in Compliance with the Following

Nozzle 009-301-0146 DWR11 ASME Sec. VIII UG-136(d}(3}

ASME Sec. VIII UG-136(d}(4}

Base Not applicable Not applicable

EN-T-001 Revision 2

Inlet Stub End Not applicable Not applicable API 527, UG-136(d}(5}

OSHA 29CFRPart 1910.119 (4}(iv)

Outlet Stub End Not applicable Not applicable

PED97/23/EC

Inlet Flange Not applicable Not applicable ENIS04126-1

Outlet Flange Not applicable Not applicable

-

Test Information

Valve complies with the requirements of ASME Sec. VIII UG-136(d)(3), ASfI1E See. VIII UG-136(d)(4), EN-T-001 Revision 2, API 527, UG-136(d)(S), OSHA 29CFR Part 1910.119 (4)(iv)

Tests Required: ~set Point ~ Back Pressure ~ Seat Tightness o Customer Inspector

Set Pressure Test Back Pressure Test Seat Tightness Test

Req. Set Press. Range 599 - 617 psig Min. Required Test 539

,--------------+1--------- - p~~~

Actual Set Pressure 602 psig Actual Test 65 psig Actual Test 539 psig

-------------- --I

Nozzle Ring Setting 2

Test Stand and Gauge Information Assembled By: J.F. Date: 11/2/2015

Test Stand 10 Number test-I Tested By: A.Y. Date: 11/2/2015

Gauge Serial Number 255110 Customer Inspector:

Gauge Calibration Date 5/5/2016 Final mspectlori. V.H.

ssure relief valve

Final Test Report

ARMATUREN For ASME B&PV Code Section VIII Div. 1

(UV) Safety Relief Valves

ARI-Armaturen USA, LP

In Accordance with EN 10204-3.1

Order Information Nameplate Data

._-_._-_ _ .._ _ _ __ ..__ .._ _

_-_ __ _ .._--_ .. .._ .._ .._._ _ _ .. -_ __ .-._--,---

Sales Order Number 216347 Model R-11GS424CKB0189 Stamp

---_ _-----_ _----------_ __ ._.- _-- ------ ..-..-----..-------r- ..--..---- ..------

Purchase Order Number 504759 Serial No. 216347-04 Size 1.5 G 3

Customer Company ARI Armaturen Malaysia Project No. 01-2015/PVSD-ARI

Yes

Customer Contact KEN WONG f-K_d

__ . ._0._.8

__6 ,I_D_a_t_e 9/__

1_7_/_2~_15 ._.__

Location VIETNAM Set Press. 189 psig 13 bar Temp 547 of

Valve Information Back Press. o psig o bar Temp 286C

I - ------.-.-.--------------.----- ----_ .. _ ..-.

Model Number

_________ .__.

R-11GS424CKB0189

. .__. ._.

Service

L_~._._ ...

Vapor

._.__ -_ ..-._-._----_._-- __

CDTP 195 psig

._._- _._----_._-

13.4 bar

-_ __ ._._ ..__ _-_ ..

Tag Number 54PSV1001A Serial Number 216347-04 Capacity 1958 SCFM 21% Over

1

f--------- --- - ..- - -..--r- --..-.. -- - ---- ..- .._- ..-i------ ..

- -.Press.

Project No. 01-2015/PVSD-ARI Area 0.558 in2 Orif. Dia. 0.843 in Lift 0.26 in

Spring Number F54F Spring Range 188 - 239 psig Tag No . 54PSV1001A

..._- - ._ --

J

.. --- -

Heat Number Assignment .__ Hy~rost~tic ~ress~re Test_

- - -- -- - - - --- -

The applicable pressure containing parts of the valve have been hydrostatically te~ed

Part Name _ .. Part Number Heat Number at a minimum of 1.S times the design pressure of the parts in accordance with ASME

- -- -

Body 007-301-0771 code requirement UG-136 (d)(2) and ARI-Armaturen USA, LP's Engineering Standard EN-

K5526

P-001 (as applicable).

Bonnet 002-301-0396 K5530

Cap 001-301-0202 152 Result: No Visible Leakage

Disc 005-301-0359 U1677

Valves are in Compliance with the Following

-

Nozzle 009-301-0126 HX02 ASME Sec. VIII UG-136(d)(3)

ASME Sec. VIII UG-136(d)(4)

Base Not applicable Not applicable

EN- T -001 Revision 2

Inlet Stub End Not applicable Not applicable API S27, UG-136(d)(S)

OSHA 29CFR Part 1910.119 (4)(iv)

Outlet Stub End Not applicable Not applicable

PED97/23/EC

Inlet Flange Not applicable Not applicable ENIS04126-1

Outlet Flange Not applicable Not applicable

- -

Test Information

Valve complies with the requirements of ASME Sec. VIII UG-136(d)(3), ASI'4E Sec. VIII UG-136(d)(4). EN-T-001 Revision 2, API 527, UG-136(d)(5). OSHA 29CFR Part 1910.119 (4)(iv)

Tests Required: ~Set Point ~ Back Pressure ~ Seat Tightness o Customer Inspector

Set Pressure Test Back Pressure Test Seat Tightness Test

Req. Set Press. Range 195 - 201 psig Min. Required Test 35 psig Min. Required Test 176 psig

Actual Set Pressure 195 psig Actual Test 35 psig Actual Test 176 psig

Nozzle Ring Setting 9

Test Stand and Gauge Information Assembled By:c........ .=.cJ.c....F.c........ Date: __ ....:.1"'0'1...:/1""9'L/.o:.20:::..:1::=5:

__ 1

Test Stand 10 Number TEST-l Tested By:.....: ....:..A..::..Y.:...:. ~\;i\1 10/19/2015

Gauge Serial Number 255110 Customer Inspector:'---:- ..p.r,::--_

Gauge Calibration Date 5/5/2016 Final lnspectionj V.H.

ARI-Armaturen USA, LP certifies that data supplied in this report is correct and that all details for design, material, construction, ressure relief valve

herein conform with the requirements of Section VIII, Division 1 of the ASME Boiler and Pressure

Final Test Report

ARMATUREN For ASME B&PV Code Section VIII Div. 1

(UV) Safety Relief Valves

ARI-Armaturen USA, LP

In Accordance with EN 10204-3.1

Order Information Nameplate Data

..- ..-...

------.- ...-.-- ..---- ....

-.----- ....- ....

- ..- ..

_- ...

-----1

Sales Order Number 216347 Model R-11GS424CKB0189 Stamp

Purchase Order Number 504759 Serial ~~:-;16347.05r~;~~ 1.5 G 3

Customer Company ARI Armaturen Malaysia Project No. 012015/PVSD-ARI

Yes

Customer Contact KEN WONG Kd

0.86......L~~~~..._... .....

~!.~.?(~~~5 ..._ ..._....__

Location VIETNAM Set Press.

.... _._. __ ._-_ _

189

_.

... __ _

.. .. _-_ .................. _

_psig 13

_ _ bar

_-_ Temp

_547_._ _OF_-

.. ..

Valve Information Back Press. o psig 0 bar Temp 286C

bar

_Model Numbe~._. .~~~GS~~~.~~~~l.~?._ .. _[~=r~i~.= .... _.. ... CDTP

~.~?.~~._ 195 psig 13.4

Tag Number 54PSV1001B Serial Number 21634705 C it 1958 SCFM 210{, Over

f _apa._

..c I y.._ __ _ _ __ -l- _

-r-..................................................................... /._' Press.

Project No. 012015/PVSDARI Area 0.558 in2 lorif. Dia. 0.843 in Lift 0.26 in

Spring Number F54F Spring Range 188 . 239 psig Tag No. 54PSV1001B

. . - - _. - - _. - - - l

Heat Number Assignment Hydrostatic Pressure Test ~

Part Name

-- - Part

- --

Number

''---

Heat

----

Number

- -

The applicable pressure containing parts of the valve have been hydrostatically te~~ed

- - - - at a minimum of 1.5 times the design pressure of the parts in accordance with ASME

Body 0073010771 K5526 code requirement UG-136 (d)(2) and ARI-Armaturen USA, LP's Engineering Standard EN-

P-001 (as applicable).

Bonnet 0023010396 K5530

Cap 0013010202 152 Result: No Visible Leakage

Disc 0053010359 U1677

Valves are in Compliance with the Following

Nozzle 0093010126 HX02 ASME Sec. VIII UG136(d)(3)

ASME Sec. VIII UG136(d)(4)

Base Not applicable Not applicable

ENT001 Revision 2

Inlet Stub End Not applicable Not applicable API 527, UG-136(d)(5)

OSHA 29CFRPart 1910.119 (4)(iv)

Outlet Stub End Not applicable Not applicable

PED97/23/EC

Inlet Flange Not applicable Not applicable ENIS04126-1

Outlet Flange Not applicable Not applicable

Test Information

Valvecomplieswith the requirementsof ASMESec.VIII UG-136(d)(3),AS~ESec.VIII UG136(d)(4),ENT-001Revision2,API527,UG136(d)(5),OSHA29CFRPart1910.119(4)(iv)

Tests Required: ~Set Point ~ Back Pressure ~ Seat Tightness o Customer Inspector

Set Pressure Test

1 Back Pressure Test Seat Tightness Test

I

Req. Set Press. Range 195 - 201 psig Min. Required Test 35 psig Min. Required Test 176 psig

-------- .._..__.....

_-+--------._._._ .......

_---_._-_ ..... ------_.

__..

__

....

j

Actual Set Pressure 195 psig Actual Test 35 psig Actual Test 176 psig

Nozzle Ring Setting 9

Test Stand and Gauge Information Assembled By: J.F. Date: 10/19/2015

-

Test Stand ID Number

Gauge Serial Number

TEST-1

255110

--

Customer

Tested By:

Inspector:

A.Y.

s:

':f

,

~\

CertiD&!~

(/9\

of Y

r-

10/19/2015 I

I

Gauge Calibration Date 5/5/2016 Hnal Inspectiori' V.H. RegistDatel No. -o hO/19/2015

ARI-Armaturen USA, LPcertifies that data supplied in this report is correct and that all details for design, material, construction, nd ~~1!18m~of th pressure relief valve

herein conform with the requirements of Section VIII, Division 1 of the ASME Boiler and Pressure el Code. ':+,i?

)-~ OF "i:.

-

You might also like

- HPTO12: Installation & MaintenanceDocument29 pagesHPTO12: Installation & Maintenancewilmer fernando lopez galeano100% (1)

- WoodwardDocument104 pagesWoodwardwachuwachuNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- Lube Oil Flushing ProcedureDocument18 pagesLube Oil Flushing ProcedureKevin Chen100% (2)

- API 6A Spec Flange Bolt+ Ring Chart PDFDocument1 pageAPI 6A Spec Flange Bolt+ Ring Chart PDFAlan JuanNo ratings yet

- List of AttachementsDocument1 pageList of AttachementsgauravNo ratings yet

- 44043-0015 Rev 3 Foundation Loads PlanDocument1 page44043-0015 Rev 3 Foundation Loads PlanRidip DuttaNo ratings yet

- Corr1 Part-3 CPI9725P19 PDFDocument119 pagesCorr1 Part-3 CPI9725P19 PDFkaustavNo ratings yet

- 2324MTC037 11359Document1 page2324MTC037 11359Shrikrushna DalviNo ratings yet

- Check ValvesDocument12 pagesCheck Valveshaniif mkNo ratings yet

- Datasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)Document2 pagesDatasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)usama666No ratings yet

- Shaft Sleeve CWP Pump 180mm RevisiDocument1 pageShaft Sleeve CWP Pump 180mm Revisiwawan dweeNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- SL 910Document4 pagesSL 910Yarisa VangeNo ratings yet

- 1.a11a PMSDocument5 pages1.a11a PMSS.selvakumarNo ratings yet

- D11200ADocument4 pagesD11200AmahendrandsNo ratings yet

- 2324MTC037 11361Document1 page2324MTC037 11361Shrikrushna DalviNo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Shaft Sleeve CWP Pump 170mm Revisi PDFDocument1 pageShaft Sleeve CWP Pump 170mm Revisi PDFwawan dweeNo ratings yet

- Auto On Off Ball Valve Suresales - Commented - QAP - REV-01Document1 pageAuto On Off Ball Valve Suresales - Commented - QAP - REV-01Deepak UpadhyayNo ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- PROCEDURE MANUALS - (Materials and Process Specifications Manual) - (07-01)Document15 pagesPROCEDURE MANUALS - (Materials and Process Specifications Manual) - (07-01)RickyNo ratings yet

- Pt. SMC Pneumatic Indonesia: Revision RecordDocument1 pagePt. SMC Pneumatic Indonesia: Revision RecordArifin MuliaNo ratings yet

- Job Card: Process Inspection ReportDocument10 pagesJob Card: Process Inspection ReportAbhi YadavNo ratings yet

- Weld MapDocument3 pagesWeld Mapeffiezool mohdNo ratings yet

- R3572-4002-B HPU Column Reel DriveDocument1 pageR3572-4002-B HPU Column Reel DriveKarikalan JayNo ratings yet

- Ds - Control ValvesDocument15 pagesDs - Control ValvesNawfel ArafathNo ratings yet

- Taper Frame 1Document4 pagesTaper Frame 1VKL QualityNo ratings yet

- MOV DatasheetDocument98 pagesMOV Datasheetsrik11No ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- m24.30 DenisonDocument80 pagesm24.30 Denison黃重銘No ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- PreviewDocument20 pagesPreviewFarhatNo ratings yet

- Taper BlockDocument2 pagesTaper BlockVKL QualityNo ratings yet

- Certificate 82337983.10 Z100435 Elp-M20-8 Eye Lifting Point PDFDocument1 pageCertificate 82337983.10 Z100435 Elp-M20-8 Eye Lifting Point PDFAngela GracielaNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- TQ-3 (Della Foglia) CompleteDocument2 pagesTQ-3 (Della Foglia) CompleteABDUL KADHARNo ratings yet

- Self Acting Pressure Control ValveDocument7 pagesSelf Acting Pressure Control ValveSreejesh Sundaresan100% (1)

- Hojas de Datos Orificios de Restricción: Ingenieria de Detalle Siar 18.5KbwpdDocument3 pagesHojas de Datos Orificios de Restricción: Ingenieria de Detalle Siar 18.5Kbwpdlaura velazquesNo ratings yet

- Datasheet Level GaugeDocument9 pagesDatasheet Level GaugemmtdarxNo ratings yet

- Extracted Pages From G.V DSDocument4 pagesExtracted Pages From G.V DSkoraina2015No ratings yet

- A325M - M24x70Document3 pagesA325M - M24x70nam nguyengiangNo ratings yet

- Ramy Abou El SoaadDocument10 pagesRamy Abou El SoaadAhmed Ayman AhmedNo ratings yet

- Benzyna 4 T Max v2Document1 pageBenzyna 4 T Max v2iflix iflixNo ratings yet

- PSV 2404Document1 pagePSV 2404Tomás MercadoNo ratings yet

- BN551-MSRF-1164 - Piping Spool Material For PRV InstallationDocument2 pagesBN551-MSRF-1164 - Piping Spool Material For PRV InstallationMohammed AbdallaNo ratings yet

- 9700 SERIES: Manitou North America, IncDocument16 pages9700 SERIES: Manitou North America, IncRazvan MitruNo ratings yet

- 9700 SERIES: Manitou North America, IncDocument16 pages9700 SERIES: Manitou North America, IncRazvan MitruNo ratings yet

- AR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFDocument6 pagesAR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFYaakoubi FethiNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- A18 PDFDocument5 pagesA18 PDFBalakrishnan KrishnanNo ratings yet

- BSM80C-150AA Customer Information PacketDocument7 pagesBSM80C-150AA Customer Information PacketPedro ReyesNo ratings yet

- A Polyhydron Group Company: DescriptionDocument2 pagesA Polyhydron Group Company: DescriptionRenjithSivaNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- PSV-2404Document1 pagePSV-2404Tomás MercadoNo ratings yet

- 2 - Focus II C-307 DC Motor Sigma - IngDocument127 pages2 - Focus II C-307 DC Motor Sigma - IngMatias BruschiniNo ratings yet

- FMEDA计算书 菲锐西1Document15 pagesFMEDA计算书 菲锐西1ajinkya.patilNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Juchan PQDocument46 pagesJuchan PQNguyen HaiNo ratings yet

- Asme b16 48 2005 Juntas Ciegas PDFDocument50 pagesAsme b16 48 2005 Juntas Ciegas PDFNguyen HaiNo ratings yet

- A451 PDFDocument4 pagesA451 PDFNguyen HaiNo ratings yet

- Tubacex Catalogue 2015Document28 pagesTubacex Catalogue 2015Nguyen HaiNo ratings yet

- Basis2 Steel enDocument107 pagesBasis2 Steel enNguyen HaiNo ratings yet

- Basis1 Steel en PDFDocument90 pagesBasis1 Steel en PDFNguyen HaiNo ratings yet