Professional Documents

Culture Documents

GM Delphi Uses Vissim To Reduce Brake Control System Prototyping Time

GM Delphi Uses Vissim To Reduce Brake Control System Prototyping Time

Uploaded by

Tijana MrdakovicCopyright:

Available Formats

You might also like

- Everest Group Life Annuity Insurance AssessmentDocument14 pagesEverest Group Life Annuity Insurance AssessmentKoyel RoyNo ratings yet

- SicmaDocument8 pagesSicmaCarli BraunNo ratings yet

- ITSM Reference Architecture - ITSM - Whitepaper PDFDocument21 pagesITSM Reference Architecture - ITSM - Whitepaper PDFBensito CastilloNo ratings yet

- Touchless Vehicle Identification - AudiDocument2 pagesTouchless Vehicle Identification - AudiUmesh SNo ratings yet

- 41620simocode Case StudyDocument4 pages41620simocode Case StudyMeshackMukakaNo ratings yet

- DS90UB901, DS90UB902, DS90UB903, DS90UB904: Driving High-Speed Data Against The TrafficDocument8 pagesDS90UB901, DS90UB902, DS90UB903, DS90UB904: Driving High-Speed Data Against The TrafficLungu CristianNo ratings yet

- Integrating Low Cost With High Fault Coverage For Advanced Technology BoardsDocument4 pagesIntegrating Low Cost With High Fault Coverage For Advanced Technology BoardspvvsczNo ratings yet

- AMC-servo Drive OverviewDocument28 pagesAMC-servo Drive OverviewjoonimNo ratings yet

- ZK SAMpDocument2 pagesZK SAMpEddy FungNo ratings yet

- IOT in AutomationDocument5 pagesIOT in AutomationyourssunNo ratings yet

- World's First Truly Integrated Safety Controller: Safe, Reliable and Available Control Without CompromiseDocument6 pagesWorld's First Truly Integrated Safety Controller: Safe, Reliable and Available Control Without CompromiseDinesh JadavNo ratings yet

- Komax News 2019 ENDocument6 pagesKomax News 2019 ENsamir abdellaouiNo ratings yet

- 06 USBDAQ Smart Factory EngDocument2 pages06 USBDAQ Smart Factory EngJoséNo ratings yet

- Xillinx-Zynq-based Development Plarform For ADASDocument8 pagesXillinx-Zynq-based Development Plarform For ADASSatishNo ratings yet

- CEMAT - Process Control For The Cement Industry. Answers For Industry.Document20 pagesCEMAT - Process Control For The Cement Industry. Answers For Industry.ylebongoNo ratings yet

- Modern SCADA Technologies Offer Choices That Satisfy Functionality and Security Requirements While Improving Performance For Remote UsersDocument5 pagesModern SCADA Technologies Offer Choices That Satisfy Functionality and Security Requirements While Improving Performance For Remote UsersAdrian BalbuenaNo ratings yet

- SIMOTICS MotorsDocument26 pagesSIMOTICS MotorsJeimy Rafael Zacarias RodriguezNo ratings yet

- Pilot FleetDocument2 pagesPilot Fleettrxopti9No ratings yet

- Providing Fleet Visibility ... Since 1970Document21 pagesProviding Fleet Visibility ... Since 1970roberd_leeNo ratings yet

- JDSU Acterna DSAM Series Digital Services Analysis Meter Data Sheet PDFDocument16 pagesJDSU Acterna DSAM Series Digital Services Analysis Meter Data Sheet PDFVíctor MayaNo ratings yet

- Liquidtool Manager: "Digital First" - Including in SalesDocument10 pagesLiquidtool Manager: "Digital First" - Including in SalesJitu InduNo ratings yet

- Power Plant AutomationDocument3 pagesPower Plant AutomationAbdelRhman Elfky0% (1)

- A Fpga Based Solution To LCD Digital Automobile DashDocument5 pagesA Fpga Based Solution To LCD Digital Automobile DashsrikanthshenoyNo ratings yet

- Digipostpro Tech Sheet WebDocument2 pagesDigipostpro Tech Sheet Webphil_turboNo ratings yet

- 3D Construction CatalogueDocument32 pages3D Construction CatalogueBhuvnesh KhajuriaNo ratings yet

- SIMNET ServicesDocument18 pagesSIMNET Servicesvamp eeNo ratings yet

- 5 - HyperLynx E1Document45 pages5 - HyperLynx E1Nguyễn Tiến100% (1)

- QEI TDMS System SCADADocument2 pagesQEI TDMS System SCADALee PearceNo ratings yet

- Ami ManDocument78 pagesAmi ManGuillermo RamirezNo ratings yet

- 3bse007295r0201 - en Advant Ocs - Open Control System Solution With Advasoft For Windows Advant Controller 110 and AdDocument12 pages3bse007295r0201 - en Advant Ocs - Open Control System Solution With Advasoft For Windows Advant Controller 110 and Adamitpatra009No ratings yet

- SICAM Navigator - ProfileDocument2 pagesSICAM Navigator - ProfileAldo Bona HasudunganNo ratings yet

- Pilot Walktour Pack-BrochureDocument4 pagesPilot Walktour Pack-BrochureSantosh KumarNo ratings yet

- Simatic: Technical SlidesDocument22 pagesSimatic: Technical SlidesArmand MutebNo ratings yet

- 8D Case StudyDocument5 pages8D Case StudyBooksyBNo ratings yet

- White Paper Video and Image Processing Design Using Fpgas: Table 1. Resolutions by End Equipment TypesDocument6 pagesWhite Paper Video and Image Processing Design Using Fpgas: Table 1. Resolutions by End Equipment TypesmorexyzNo ratings yet

- Sicam PASDocument16 pagesSicam PASRami El Naqa100% (1)

- Affinity BrochureDocument14 pagesAffinity BrochureSERVITECKNo ratings yet

- SYSTIMAX Structured Cabling SolutionsDocument8 pagesSYSTIMAX Structured Cabling SolutionsdanknoopNo ratings yet

- ETG3000 BrochureDocument9 pagesETG3000 BrochureMayolo MartinezNo ratings yet

- Sivicam: Reliable Video Detection at Intersections, Without Pavement CutsDocument4 pagesSivicam: Reliable Video Detection at Intersections, Without Pavement CutsAna Maria Orozco IdroboNo ratings yet

- Sppa T3000Document6 pagesSppa T3000Dipti Bhanja100% (1)

- Simatic St80 STPC Chap03 English 2016Document164 pagesSimatic St80 STPC Chap03 English 2016voltus88No ratings yet

- 2016 - SA-G+ 3G Novatel WirelessDocument2 pages2016 - SA-G+ 3G Novatel WirelessDario Gabriel Coz RojasNo ratings yet

- CaseStudy CliftonDocument2 pagesCaseStudy CliftonHECTORNo ratings yet

- PB RecordersandControllers-EN BDocument12 pagesPB RecordersandControllers-EN BSimarelecNo ratings yet

- DCP DasDocument2 pagesDCP DasSony ZebuaNo ratings yet

- Canviewer® Canviewer® SystemDocument3 pagesCanviewer® Canviewer® Systemgraceenggint8799No ratings yet

- Asigra Cloud Backup and Recovery SoftwareDocument5 pagesAsigra Cloud Backup and Recovery SoftwaremathewkylescribdNo ratings yet

- Airlinkravenxehsupadatasheet20100913173317 PDFDocument2 pagesAirlinkravenxehsupadatasheet20100913173317 PDFFabio XavierNo ratings yet

- Airports: Security and Business Solutions ForDocument5 pagesAirports: Security and Business Solutions ForTamerNo ratings yet

- K-Chief: All Control Requirements Fulfilled - in A Uniform SystemDocument16 pagesK-Chief: All Control Requirements Fulfilled - in A Uniform Systemdnse90900No ratings yet

- SIPROTEC 7VK87 ProfileDocument3 pagesSIPROTEC 7VK87 Profile01666754614100% (1)

- Control Systems For Mobile Vehicles Catalogue 2016/2017Document123 pagesControl Systems For Mobile Vehicles Catalogue 2016/2017ifm electronic100% (2)

- STAR CD BrochureDocument2 pagesSTAR CD BrochureUday RajNo ratings yet

- Creating A Global, Zero-Downtime Network Environment: ChallengesDocument3 pagesCreating A Global, Zero-Downtime Network Environment: ChallengesVijay BhargavNo ratings yet

- Nano DiagDocument8 pagesNano DiagkallatisNo ratings yet

- The Sammi Application Development KitDocument2 pagesThe Sammi Application Development KitRolando DíazNo ratings yet

- TC52 and TC57 Series Touch Computer: The Ultimate in Enterprise-Class Touch ComputingDocument4 pagesTC52 and TC57 Series Touch Computer: The Ultimate in Enterprise-Class Touch ComputingHisham AhmedNo ratings yet

- Idrac Spec SheetDocument6 pagesIdrac Spec SheetrdridsNo ratings yet

- SCADAVision OverviewDocument4 pagesSCADAVision Overviewrealdeal01No ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie589Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie589ali alilouNo ratings yet

- 1 s2.0 S187770581101705X Main - MainnnDocument7 pages1 s2.0 S187770581101705X Main - MainnnTijana MrdakovicNo ratings yet

- 1 s2.0 S187770581101705X Main - MainnnDocument7 pages1 s2.0 S187770581101705X Main - MainnnTijana MrdakovicNo ratings yet

- Mechatronics: Wonhee Kim, Daehee Won, Donghoon Shin, Chung Choo ChungDocument3 pagesMechatronics: Wonhee Kim, Daehee Won, Donghoon Shin, Chung Choo ChungTijana MrdakovicNo ratings yet

- 147 2 PDFDocument11 pages147 2 PDFTijana MrdakovicNo ratings yet

- Honeywell PDFDocument1 pageHoneywell PDFTijana MrdakovicNo ratings yet

- Analyze UGv3 PDFDocument65 pagesAnalyze UGv3 PDFTijana MrdakovicNo ratings yet

- Air Force Uses Vissim For Weapons System Design: Dynamic Simulation of A 6-Dof Munitions SystemDocument1 pageAir Force Uses Vissim For Weapons System Design: Dynamic Simulation of A 6-Dof Munitions SystemTijana MrdakovicNo ratings yet

- Analyze UGv3Document65 pagesAnalyze UGv3Tijana MrdakovicNo ratings yet

- CCode UGv3Document42 pagesCCode UGv3Tijana MrdakovicNo ratings yet

- 40 Inventive Principles With Applications in ServiDocument16 pages40 Inventive Principles With Applications in Servisina yadegariNo ratings yet

- Estimation Engineer Fa Cult AteDocument2 pagesEstimation Engineer Fa Cult AteLaurentiu TanaseNo ratings yet

- 01 Swink - MOAS - 4e - Ch01 - PPTDocument35 pages01 Swink - MOAS - 4e - Ch01 - PPTisfi23001No ratings yet

- Start - Up (1) - 250 MW PDFDocument2 pagesStart - Up (1) - 250 MW PDFPrabhat KiskuNo ratings yet

- Topic Name: Smart Dhaka City: Group Name-Philosophers StoneDocument35 pagesTopic Name: Smart Dhaka City: Group Name-Philosophers StoneNavila FarhanaNo ratings yet

- 06-Srk-t-050 Technical Manual SRK ZD Ze R410aDocument297 pages06-Srk-t-050 Technical Manual SRK ZD Ze R410adfountoukidis100% (2)

- Farrel Mixing Presentation 051110Document73 pagesFarrel Mixing Presentation 051110rossifam777100% (1)

- Equipment Sizing & Installation: Michael D. Haughey, P.EDocument36 pagesEquipment Sizing & Installation: Michael D. Haughey, P.EDemetrios GkikasNo ratings yet

- Lab Manual Industrial AutomationDocument48 pagesLab Manual Industrial Automationrashmi patilNo ratings yet

- 2.4.1 ADWEA Approved Vendor List.Document274 pages2.4.1 ADWEA Approved Vendor List.Ahmed AlnagarNo ratings yet

- WMS, TMS, CRM. Information SystemsDocument18 pagesWMS, TMS, CRM. Information SystemsValentina MartínezNo ratings yet

- Bank Mandiri The Digital Era of Banking Industry PDFDocument28 pagesBank Mandiri The Digital Era of Banking Industry PDFHendy LismanNo ratings yet

- Vapour Compression Refrigeration Cycle-ProblemsDocument17 pagesVapour Compression Refrigeration Cycle-ProblemsRuturaj BadalNo ratings yet

- en - Ditec Civik BrochureDocument3 pagesen - Ditec Civik BrochureRosemeire MarinelliNo ratings yet

- 30 Artificial Intelligence Terms You Need To KnowDocument5 pages30 Artificial Intelligence Terms You Need To KnowRolazski123No ratings yet

- Cad MCQ Unit 5Document3 pagesCad MCQ Unit 5ddeepak123No ratings yet

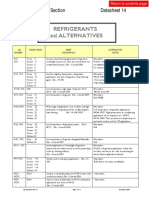

- Datasheet 14 - Master Gas ListDocument4 pagesDatasheet 14 - Master Gas ListMahmoud MohamedNo ratings yet

- Enterprise Architecture - Enterprise Service CatalogDocument27 pagesEnterprise Architecture - Enterprise Service CatalogFrancis100% (1)

- Selection Sheet - 30XA452 Screw ChillerDocument1 pageSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478No ratings yet

- Personal Reflection - f5Document24 pagesPersonal Reflection - f5andrew_yardy2623No ratings yet

- Electrical and Electronics Engineering: Prof. RESHMA.V.P, Assistant ProfessorDocument10 pagesElectrical and Electronics Engineering: Prof. RESHMA.V.P, Assistant ProfessorHigelNo ratings yet

- RTWD Rlc-Prc029-En 2007 09Document77 pagesRTWD Rlc-Prc029-En 2007 09Success Sinh ViênNo ratings yet

- 24 Daewoo FR540N PDFDocument47 pages24 Daewoo FR540N PDFLutionnnNo ratings yet

- Ufc-85 Motors ListDocument5 pagesUfc-85 Motors ListNguyễn Văn HưngNo ratings yet

- ASHRAE Journal - CO2-Based DCV Using 62.1Document7 pagesASHRAE Journal - CO2-Based DCV Using 62.1Gustavo ChavesNo ratings yet

- Controlling of AC Lamp Dimmer Through Mobile Phone: FeaturesDocument2 pagesControlling of AC Lamp Dimmer Through Mobile Phone: FeaturesHari KishorNo ratings yet

- Rentokil Initial Optimizes Credit & Collection Management With OnguardDocument5 pagesRentokil Initial Optimizes Credit & Collection Management With OnguardKirito AgcoproxNo ratings yet

- Artificial IntelligenceDocument2 pagesArtificial IntelligenceChi Keung Langit ChanNo ratings yet

GM Delphi Uses Vissim To Reduce Brake Control System Prototyping Time

GM Delphi Uses Vissim To Reduce Brake Control System Prototyping Time

Uploaded by

Tijana MrdakovicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GM Delphi Uses Vissim To Reduce Brake Control System Prototyping Time

GM Delphi Uses Vissim To Reduce Brake Control System Prototyping Time

Uploaded by

Tijana MrdakovicCopyright:

Available Formats

GM Delphi Uses VisSim to Reduce Brake

Control System Prototyping Time

Gary Fulks, senior design engineer at GM Delphi

describes his use of VisSim and VisSim/Real-Time to

Peter Darnell, president of Visual Solution

In the past, it took up to two months of special machine shop work, circuit design, hand-coded

software development and in-car testing to determine whether a design was feasible for

production. Now, with the combination of fast and powerful block diagram-based modeling and

simulation software from Visual Solutions and highly reliable, noise-immune data acquisition

cards from National Instruments, such testing can be done in two days or less.

GM Delphi configured a system of VisSim running on a lap top with two PCMCIA DAC Card

1200s, 16analog inputs, 4 analog outputs and16 digital I/Os. With their complex control system,

they achieved closed-loop sampling rates of over 200 Hz running a 100 MHz Pentium laptop.

VisSim/Real-Time is capable of closed-loop sampling rates of up to 5000 Hz depending upon the

complexity of the closed-loop system and the CPU speed.

A typical use of this setup is to test out electronic braking assist equipment. Both the closed-loop

control as well as data logging can easily be developed and configured with VisSim. Once the

sensors and equipment under test are installed in the vehicle, it is a simple matter to mount the

laptop in the passengers seat, secured with a standard 2" nylon web tie-down, then plug in the

ribbon cables to the DAQ Card 1200s, and turn on the laptop. Because it is difficult to view the

laptop display during daylight driving, an LED display panel, driven by the digital I/O of the DAQ

Card, is used for critical function monitoring. Five-minute runs with strip charts tracking user

inputs, pedal pressures, accelerations, controller outputs are typical.

In over a year of use, VisSim has never failed during a real-time run. The system has proven robust

under the harsh demands of vigorous brake testing, lack of good electrical ground, wide

temperature and humidity variations common to Ohio, and general garage lab treatment.

We also use VisSim in lab bench situations such as automated performance testing of hydraulic

valves. Using map blocks, it is easy to create time-based test sequences and correlate sensor

outputs with command inputs. The wide array of plotting capability and data export makes it easy

for data analysis. We feel that VisSim has been an important addition to the set of tools we use in

automotive design and test.

Visual Solutions

I N C O R P O R A T E D

Modeling The Future

487 Groton Road

Westford, MA 01886

Tel: 1-978-392-0100

1-800-VISSIM-1

Fax: 1-978-692-3102

info@vissol.com Application: Automotive

www.vissim.com

You might also like

- Everest Group Life Annuity Insurance AssessmentDocument14 pagesEverest Group Life Annuity Insurance AssessmentKoyel RoyNo ratings yet

- SicmaDocument8 pagesSicmaCarli BraunNo ratings yet

- ITSM Reference Architecture - ITSM - Whitepaper PDFDocument21 pagesITSM Reference Architecture - ITSM - Whitepaper PDFBensito CastilloNo ratings yet

- Touchless Vehicle Identification - AudiDocument2 pagesTouchless Vehicle Identification - AudiUmesh SNo ratings yet

- 41620simocode Case StudyDocument4 pages41620simocode Case StudyMeshackMukakaNo ratings yet

- DS90UB901, DS90UB902, DS90UB903, DS90UB904: Driving High-Speed Data Against The TrafficDocument8 pagesDS90UB901, DS90UB902, DS90UB903, DS90UB904: Driving High-Speed Data Against The TrafficLungu CristianNo ratings yet

- Integrating Low Cost With High Fault Coverage For Advanced Technology BoardsDocument4 pagesIntegrating Low Cost With High Fault Coverage For Advanced Technology BoardspvvsczNo ratings yet

- AMC-servo Drive OverviewDocument28 pagesAMC-servo Drive OverviewjoonimNo ratings yet

- ZK SAMpDocument2 pagesZK SAMpEddy FungNo ratings yet

- IOT in AutomationDocument5 pagesIOT in AutomationyourssunNo ratings yet

- World's First Truly Integrated Safety Controller: Safe, Reliable and Available Control Without CompromiseDocument6 pagesWorld's First Truly Integrated Safety Controller: Safe, Reliable and Available Control Without CompromiseDinesh JadavNo ratings yet

- Komax News 2019 ENDocument6 pagesKomax News 2019 ENsamir abdellaouiNo ratings yet

- 06 USBDAQ Smart Factory EngDocument2 pages06 USBDAQ Smart Factory EngJoséNo ratings yet

- Xillinx-Zynq-based Development Plarform For ADASDocument8 pagesXillinx-Zynq-based Development Plarform For ADASSatishNo ratings yet

- CEMAT - Process Control For The Cement Industry. Answers For Industry.Document20 pagesCEMAT - Process Control For The Cement Industry. Answers For Industry.ylebongoNo ratings yet

- Modern SCADA Technologies Offer Choices That Satisfy Functionality and Security Requirements While Improving Performance For Remote UsersDocument5 pagesModern SCADA Technologies Offer Choices That Satisfy Functionality and Security Requirements While Improving Performance For Remote UsersAdrian BalbuenaNo ratings yet

- SIMOTICS MotorsDocument26 pagesSIMOTICS MotorsJeimy Rafael Zacarias RodriguezNo ratings yet

- Pilot FleetDocument2 pagesPilot Fleettrxopti9No ratings yet

- Providing Fleet Visibility ... Since 1970Document21 pagesProviding Fleet Visibility ... Since 1970roberd_leeNo ratings yet

- JDSU Acterna DSAM Series Digital Services Analysis Meter Data Sheet PDFDocument16 pagesJDSU Acterna DSAM Series Digital Services Analysis Meter Data Sheet PDFVíctor MayaNo ratings yet

- Liquidtool Manager: "Digital First" - Including in SalesDocument10 pagesLiquidtool Manager: "Digital First" - Including in SalesJitu InduNo ratings yet

- Power Plant AutomationDocument3 pagesPower Plant AutomationAbdelRhman Elfky0% (1)

- A Fpga Based Solution To LCD Digital Automobile DashDocument5 pagesA Fpga Based Solution To LCD Digital Automobile DashsrikanthshenoyNo ratings yet

- Digipostpro Tech Sheet WebDocument2 pagesDigipostpro Tech Sheet Webphil_turboNo ratings yet

- 3D Construction CatalogueDocument32 pages3D Construction CatalogueBhuvnesh KhajuriaNo ratings yet

- SIMNET ServicesDocument18 pagesSIMNET Servicesvamp eeNo ratings yet

- 5 - HyperLynx E1Document45 pages5 - HyperLynx E1Nguyễn Tiến100% (1)

- QEI TDMS System SCADADocument2 pagesQEI TDMS System SCADALee PearceNo ratings yet

- Ami ManDocument78 pagesAmi ManGuillermo RamirezNo ratings yet

- 3bse007295r0201 - en Advant Ocs - Open Control System Solution With Advasoft For Windows Advant Controller 110 and AdDocument12 pages3bse007295r0201 - en Advant Ocs - Open Control System Solution With Advasoft For Windows Advant Controller 110 and Adamitpatra009No ratings yet

- SICAM Navigator - ProfileDocument2 pagesSICAM Navigator - ProfileAldo Bona HasudunganNo ratings yet

- Pilot Walktour Pack-BrochureDocument4 pagesPilot Walktour Pack-BrochureSantosh KumarNo ratings yet

- Simatic: Technical SlidesDocument22 pagesSimatic: Technical SlidesArmand MutebNo ratings yet

- 8D Case StudyDocument5 pages8D Case StudyBooksyBNo ratings yet

- White Paper Video and Image Processing Design Using Fpgas: Table 1. Resolutions by End Equipment TypesDocument6 pagesWhite Paper Video and Image Processing Design Using Fpgas: Table 1. Resolutions by End Equipment TypesmorexyzNo ratings yet

- Sicam PASDocument16 pagesSicam PASRami El Naqa100% (1)

- Affinity BrochureDocument14 pagesAffinity BrochureSERVITECKNo ratings yet

- SYSTIMAX Structured Cabling SolutionsDocument8 pagesSYSTIMAX Structured Cabling SolutionsdanknoopNo ratings yet

- ETG3000 BrochureDocument9 pagesETG3000 BrochureMayolo MartinezNo ratings yet

- Sivicam: Reliable Video Detection at Intersections, Without Pavement CutsDocument4 pagesSivicam: Reliable Video Detection at Intersections, Without Pavement CutsAna Maria Orozco IdroboNo ratings yet

- Sppa T3000Document6 pagesSppa T3000Dipti Bhanja100% (1)

- Simatic St80 STPC Chap03 English 2016Document164 pagesSimatic St80 STPC Chap03 English 2016voltus88No ratings yet

- 2016 - SA-G+ 3G Novatel WirelessDocument2 pages2016 - SA-G+ 3G Novatel WirelessDario Gabriel Coz RojasNo ratings yet

- CaseStudy CliftonDocument2 pagesCaseStudy CliftonHECTORNo ratings yet

- PB RecordersandControllers-EN BDocument12 pagesPB RecordersandControllers-EN BSimarelecNo ratings yet

- DCP DasDocument2 pagesDCP DasSony ZebuaNo ratings yet

- Canviewer® Canviewer® SystemDocument3 pagesCanviewer® Canviewer® Systemgraceenggint8799No ratings yet

- Asigra Cloud Backup and Recovery SoftwareDocument5 pagesAsigra Cloud Backup and Recovery SoftwaremathewkylescribdNo ratings yet

- Airlinkravenxehsupadatasheet20100913173317 PDFDocument2 pagesAirlinkravenxehsupadatasheet20100913173317 PDFFabio XavierNo ratings yet

- Airports: Security and Business Solutions ForDocument5 pagesAirports: Security and Business Solutions ForTamerNo ratings yet

- K-Chief: All Control Requirements Fulfilled - in A Uniform SystemDocument16 pagesK-Chief: All Control Requirements Fulfilled - in A Uniform Systemdnse90900No ratings yet

- SIPROTEC 7VK87 ProfileDocument3 pagesSIPROTEC 7VK87 Profile01666754614100% (1)

- Control Systems For Mobile Vehicles Catalogue 2016/2017Document123 pagesControl Systems For Mobile Vehicles Catalogue 2016/2017ifm electronic100% (2)

- STAR CD BrochureDocument2 pagesSTAR CD BrochureUday RajNo ratings yet

- Creating A Global, Zero-Downtime Network Environment: ChallengesDocument3 pagesCreating A Global, Zero-Downtime Network Environment: ChallengesVijay BhargavNo ratings yet

- Nano DiagDocument8 pagesNano DiagkallatisNo ratings yet

- The Sammi Application Development KitDocument2 pagesThe Sammi Application Development KitRolando DíazNo ratings yet

- TC52 and TC57 Series Touch Computer: The Ultimate in Enterprise-Class Touch ComputingDocument4 pagesTC52 and TC57 Series Touch Computer: The Ultimate in Enterprise-Class Touch ComputingHisham AhmedNo ratings yet

- Idrac Spec SheetDocument6 pagesIdrac Spec SheetrdridsNo ratings yet

- SCADAVision OverviewDocument4 pagesSCADAVision Overviewrealdeal01No ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie589Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie589ali alilouNo ratings yet

- 1 s2.0 S187770581101705X Main - MainnnDocument7 pages1 s2.0 S187770581101705X Main - MainnnTijana MrdakovicNo ratings yet

- 1 s2.0 S187770581101705X Main - MainnnDocument7 pages1 s2.0 S187770581101705X Main - MainnnTijana MrdakovicNo ratings yet

- Mechatronics: Wonhee Kim, Daehee Won, Donghoon Shin, Chung Choo ChungDocument3 pagesMechatronics: Wonhee Kim, Daehee Won, Donghoon Shin, Chung Choo ChungTijana MrdakovicNo ratings yet

- 147 2 PDFDocument11 pages147 2 PDFTijana MrdakovicNo ratings yet

- Honeywell PDFDocument1 pageHoneywell PDFTijana MrdakovicNo ratings yet

- Analyze UGv3 PDFDocument65 pagesAnalyze UGv3 PDFTijana MrdakovicNo ratings yet

- Air Force Uses Vissim For Weapons System Design: Dynamic Simulation of A 6-Dof Munitions SystemDocument1 pageAir Force Uses Vissim For Weapons System Design: Dynamic Simulation of A 6-Dof Munitions SystemTijana MrdakovicNo ratings yet

- Analyze UGv3Document65 pagesAnalyze UGv3Tijana MrdakovicNo ratings yet

- CCode UGv3Document42 pagesCCode UGv3Tijana MrdakovicNo ratings yet

- 40 Inventive Principles With Applications in ServiDocument16 pages40 Inventive Principles With Applications in Servisina yadegariNo ratings yet

- Estimation Engineer Fa Cult AteDocument2 pagesEstimation Engineer Fa Cult AteLaurentiu TanaseNo ratings yet

- 01 Swink - MOAS - 4e - Ch01 - PPTDocument35 pages01 Swink - MOAS - 4e - Ch01 - PPTisfi23001No ratings yet

- Start - Up (1) - 250 MW PDFDocument2 pagesStart - Up (1) - 250 MW PDFPrabhat KiskuNo ratings yet

- Topic Name: Smart Dhaka City: Group Name-Philosophers StoneDocument35 pagesTopic Name: Smart Dhaka City: Group Name-Philosophers StoneNavila FarhanaNo ratings yet

- 06-Srk-t-050 Technical Manual SRK ZD Ze R410aDocument297 pages06-Srk-t-050 Technical Manual SRK ZD Ze R410adfountoukidis100% (2)

- Farrel Mixing Presentation 051110Document73 pagesFarrel Mixing Presentation 051110rossifam777100% (1)

- Equipment Sizing & Installation: Michael D. Haughey, P.EDocument36 pagesEquipment Sizing & Installation: Michael D. Haughey, P.EDemetrios GkikasNo ratings yet

- Lab Manual Industrial AutomationDocument48 pagesLab Manual Industrial Automationrashmi patilNo ratings yet

- 2.4.1 ADWEA Approved Vendor List.Document274 pages2.4.1 ADWEA Approved Vendor List.Ahmed AlnagarNo ratings yet

- WMS, TMS, CRM. Information SystemsDocument18 pagesWMS, TMS, CRM. Information SystemsValentina MartínezNo ratings yet

- Bank Mandiri The Digital Era of Banking Industry PDFDocument28 pagesBank Mandiri The Digital Era of Banking Industry PDFHendy LismanNo ratings yet

- Vapour Compression Refrigeration Cycle-ProblemsDocument17 pagesVapour Compression Refrigeration Cycle-ProblemsRuturaj BadalNo ratings yet

- en - Ditec Civik BrochureDocument3 pagesen - Ditec Civik BrochureRosemeire MarinelliNo ratings yet

- 30 Artificial Intelligence Terms You Need To KnowDocument5 pages30 Artificial Intelligence Terms You Need To KnowRolazski123No ratings yet

- Cad MCQ Unit 5Document3 pagesCad MCQ Unit 5ddeepak123No ratings yet

- Datasheet 14 - Master Gas ListDocument4 pagesDatasheet 14 - Master Gas ListMahmoud MohamedNo ratings yet

- Enterprise Architecture - Enterprise Service CatalogDocument27 pagesEnterprise Architecture - Enterprise Service CatalogFrancis100% (1)

- Selection Sheet - 30XA452 Screw ChillerDocument1 pageSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478No ratings yet

- Personal Reflection - f5Document24 pagesPersonal Reflection - f5andrew_yardy2623No ratings yet

- Electrical and Electronics Engineering: Prof. RESHMA.V.P, Assistant ProfessorDocument10 pagesElectrical and Electronics Engineering: Prof. RESHMA.V.P, Assistant ProfessorHigelNo ratings yet

- RTWD Rlc-Prc029-En 2007 09Document77 pagesRTWD Rlc-Prc029-En 2007 09Success Sinh ViênNo ratings yet

- 24 Daewoo FR540N PDFDocument47 pages24 Daewoo FR540N PDFLutionnnNo ratings yet

- Ufc-85 Motors ListDocument5 pagesUfc-85 Motors ListNguyễn Văn HưngNo ratings yet

- ASHRAE Journal - CO2-Based DCV Using 62.1Document7 pagesASHRAE Journal - CO2-Based DCV Using 62.1Gustavo ChavesNo ratings yet

- Controlling of AC Lamp Dimmer Through Mobile Phone: FeaturesDocument2 pagesControlling of AC Lamp Dimmer Through Mobile Phone: FeaturesHari KishorNo ratings yet

- Rentokil Initial Optimizes Credit & Collection Management With OnguardDocument5 pagesRentokil Initial Optimizes Credit & Collection Management With OnguardKirito AgcoproxNo ratings yet

- Artificial IntelligenceDocument2 pagesArtificial IntelligenceChi Keung Langit ChanNo ratings yet