Professional Documents

Culture Documents

Enzymes For Second Generation Bioethanol: Basquez, Claire Ann B. May 6, 2017 Bsche - 3 9:30-10:30 Tths

Enzymes For Second Generation Bioethanol: Basquez, Claire Ann B. May 6, 2017 Bsche - 3 9:30-10:30 Tths

Uploaded by

Kyla Arevalo Fermin0 ratings0% found this document useful (0 votes)

12 views2 pagesThe document discusses enzymes for producing second generation bioethanol from lignocellulosic materials. It notes that current ethanol production impacts food supply chains, making ethanol more expensive than fossil fuels. The key to lower-cost second generation bioethanol is efficient enzymatic conversion of structural polysaccharides in plant biomass to fermentable sugars. Various fungi produce enzymes like cellulases and hemicellulases that can break down plant cell walls. Commercial enzyme mixtures typically contain many proteins, but the roles of most are still unclear. Deeper understanding of individual enzymes is needed to develop more efficient enzyme cocktails for lignocellulose degradation and lower-cost bioethanol production.

Original Description:

172849

Original Title

anemal

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses enzymes for producing second generation bioethanol from lignocellulosic materials. It notes that current ethanol production impacts food supply chains, making ethanol more expensive than fossil fuels. The key to lower-cost second generation bioethanol is efficient enzymatic conversion of structural polysaccharides in plant biomass to fermentable sugars. Various fungi produce enzymes like cellulases and hemicellulases that can break down plant cell walls. Commercial enzyme mixtures typically contain many proteins, but the roles of most are still unclear. Deeper understanding of individual enzymes is needed to develop more efficient enzyme cocktails for lignocellulose degradation and lower-cost bioethanol production.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views2 pagesEnzymes For Second Generation Bioethanol: Basquez, Claire Ann B. May 6, 2017 Bsche - 3 9:30-10:30 Tths

Enzymes For Second Generation Bioethanol: Basquez, Claire Ann B. May 6, 2017 Bsche - 3 9:30-10:30 Tths

Uploaded by

Kyla Arevalo FerminThe document discusses enzymes for producing second generation bioethanol from lignocellulosic materials. It notes that current ethanol production impacts food supply chains, making ethanol more expensive than fossil fuels. The key to lower-cost second generation bioethanol is efficient enzymatic conversion of structural polysaccharides in plant biomass to fermentable sugars. Various fungi produce enzymes like cellulases and hemicellulases that can break down plant cell walls. Commercial enzyme mixtures typically contain many proteins, but the roles of most are still unclear. Deeper understanding of individual enzymes is needed to develop more efficient enzyme cocktails for lignocellulose degradation and lower-cost bioethanol production.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

ASSIGNMENT : BIOTECHNOLOGY

BASQUEZ, CLAIRE ANN B. MAY 6, 2017

BSCHE 3 9:30-10:30 TThs

Enzymes for Second Generation Bioethanol

The demand for ethanol has the most significant market where ethanol is either

used as a chemical feedstock or as an octane enhancer or petrol additive. Brazil

produces ethanol from the fermentation of cane juice whereas in the USA corn is

used. The production of ethanol from sugars or starch impacts negatively on the

economics of the process, thus making ethanol more expensive compared with

fossil fuels. Hence the technology development focus for the production of ethanol

has shifted towards the utilisation of residual lignocellulosic materials to lower

production costs.

Enzymatic conversion of structural polysaccharides in plant biomass is a key issue

in the development of second generation (lignocellulosic) bioethanol. The

efficiency of this process depends in part on the ability of enzymes to disrupt

crystalline polysaccharides, thus gaining access to single polymer chains. The

enzymatic alternative, using cellulase and hemicellulase, avoids the use of strong

acids and results in a cleaner stream of sugars for fermentation and fewer by-

products.

Lignocellulolytic enzymes-producing fungi are widespread, and include species

from the ascomycetes (e.g. T. reesei), basidiomycetes including white-rot fungi

(e.g. P. chrysosporium), brown-rot fungi (e.g. Fomitopsis palustris) and finally a few

anaerobic species (e.g. Orpinomyces sp.) which degrade cellulose in

gastrointestinal tracts of ruminant animals. Biomass degradation by these fungi is

performed by complex mixtures of cellulases , hemicellulases and ligninases,

reflecting the complexity of the materials.

Multitude of enzymatic activities are required for the conversion of lignocellulosic

biomass into useful (fermentable) products. Known essential activities to degrade

crystalline cellulose include cellobiohydrolase (CBH), endo-1,4-glucanase (EG),

and -glucosidase (BG). A larger suite of enzymes is necessary to depolymerize

hemicelluloses, including endo-1,4-xylanase (EX), -xylosidase (BX), -

arabinosidase, -glucuronidase, and esterase. Currently available commercial

enzyme preparations for the depolymerization of lignocellulosic materials are

partially defined complex mixtures of the secreted proteins from filamentous fungi

such as Trichoderma Aureobasidium pullulans was presented that have been grown

in the presence of inducers such as sophorose or lactose. Commercial enzyme

cellulase mixtures contain between 80 and 200 protein. Except for a few of the

better-characterized cellulases and hemicellulases, the roles of most of these

proteins in lignocellulose deconstruction are poorly understood. Table 3 presents

an overview of the groups of fungal cellulolytic enzymes and their main features.

The way forward for the development of more efficient lignocellulose-degrading

enzyme cocktails will require deeper and more precise knowledge about the

specific enzymes that are involved in the degradation of lignocellulose. However, it

is not possible to gain this knowledge working only with partially defined complex

mixtures. The precise contribution of an individual enzyme can be established only

by working with it in a purified state in a realistic enzyme cocktail.

Dashtban et al. highlighted that lignocellulolytic microorganisms, especially fungi,

have attracted a great deal of interest as biomass degraders for large-scale

applications due to their ability to produce large amounts of extracellular

ASSIGNMENT : BIOTECHNOLOGY

lignocellulolytic enzymes. Many successful attempts have been made to improve

fungal lignocellulolytic activity including recombinant and non-recombinant

techniques. Process integration has also been considered for the purpose of

decreasing the production cost, which was partly achieved by performing

hydrolysis and fermentation in a single reactor (SSF).

Scaling up the production of lignocellulosic ethanol, requires further reduction of

the production cost. Overall, in order to improve the technology and reduce the

production cost, two major issues have to be addressed: i) improving technologies

to overcome the recalcitrance of cellulosic biomass conversion (pretreatment,

hydrolysis and fermentation) and ii) sustainable production of biomass in very

large amounts.

SOURCE : https://www.omicsonline.org/up-to-date-insight-on-industrial-enzymes-applications-

and-global-market-2155-9821.S4-002.php?aid=3921

You might also like

- Sustainable Liquid Biofuels From Biomass: The Writing's On The WallsDocument13 pagesSustainable Liquid Biofuels From Biomass: The Writing's On The WallsLextito HarnadiNo ratings yet

- Mekanism Antibakteri 3Document15 pagesMekanism Antibakteri 3Sintha HapsariNo ratings yet

- White Biotechnology Final PDFDocument4 pagesWhite Biotechnology Final PDFMayank SharmaNo ratings yet

- Bioproduction of Butanol From Biomass: From Genes To BioreactorsDocument8 pagesBioproduction of Butanol From Biomass: From Genes To BioreactorsOana VasileNo ratings yet

- Molecular Breeding of AdvancedMicroorganisms ForDocument11 pagesMolecular Breeding of AdvancedMicroorganisms ForNesma MamdouhNo ratings yet

- BBB 2142Document15 pagesBBB 2142IslamProNo ratings yet

- Techno-economic analysis of the industrial production of a low-cost enzyme using E. coli: the case of recombinant β-glucosidaseDocument13 pagesTechno-economic analysis of the industrial production of a low-cost enzyme using E. coli: the case of recombinant β-glucosidasekunal.datiwalNo ratings yet

- Tugas B.ing (Nita Andriana)Document2 pagesTugas B.ing (Nita Andriana)nita andrianaNo ratings yet

- Biochemical Characterization and SynergismDocument12 pagesBiochemical Characterization and SynergismJayesh PatidarNo ratings yet

- Mrutunjaya Final TheissDocument45 pagesMrutunjaya Final TheissMrutyunjay DasNo ratings yet

- Fermentation 06 00039 v2Document11 pagesFermentation 06 00039 v2adeeljutt1182No ratings yet

- Gírio, F. M Fonseca, C. Carvalheiro, F. Duarte, L.Marques, S. Bogel-Lukasik, R. (2010) - Hemicelluloses For Fuel Etanol A Review. Bioresource Technology, 101 4775-4800G - MsDocument26 pagesGírio, F. M Fonseca, C. Carvalheiro, F. Duarte, L.Marques, S. Bogel-Lukasik, R. (2010) - Hemicelluloses For Fuel Etanol A Review. Bioresource Technology, 101 4775-4800G - MsanascopelNo ratings yet

- Bioethanol Journal 1Document14 pagesBioethanol Journal 1Muhammad Hafizh HibatullahNo ratings yet

- End-Product Inhibition in Anaerobic Fermentations: Alejandro A. HerreroDocument5 pagesEnd-Product Inhibition in Anaerobic Fermentations: Alejandro A. Herreroalexnorton21No ratings yet

- Biomass Extraction MethodsDocument12 pagesBiomass Extraction MethodsSaid Khalid ShahNo ratings yet

- 10 1016@j Rser 2017 01 151 PDFDocument12 pages10 1016@j Rser 2017 01 151 PDFmochdimaskuNo ratings yet

- Determinacion Por HPLCDocument11 pagesDeterminacion Por HPLCleidyNo ratings yet

- SBTA1502Document119 pagesSBTA1502Vishnupriya MuruganNo ratings yet

- Biofuels ProductionDocument10 pagesBiofuels ProductionLea Camila Morín RambalNo ratings yet

- White Biotechnology: Commentaries & AnalysesDocument5 pagesWhite Biotechnology: Commentaries & Analyseschitralekha pNo ratings yet

- Levaduras OleaginosasDocument3 pagesLevaduras OleaginosasChucho LópezNo ratings yet

- Iofuels: Why Do We Need Biofuels?Document2 pagesIofuels: Why Do We Need Biofuels?rockingtwo07No ratings yet

- Lignocellulosic Ethanol Production: Current Practices and Recent DevelopmentsDocument11 pagesLignocellulosic Ethanol Production: Current Practices and Recent DevelopmentsJesus MoralesNo ratings yet

- Metabolic EngineeringDocument9 pagesMetabolic EngineeringArup ChakrabortyNo ratings yet

- Introduction of LipaseDocument38 pagesIntroduction of LipaseRamneet RanaNo ratings yet

- Cellulolysis Processes Which Consist of Hydrolysis On Pretreated Lignocellulosic Materials, Using EnzymesDocument7 pagesCellulolysis Processes Which Consist of Hydrolysis On Pretreated Lignocellulosic Materials, Using Enzymespacoto livingstoneNo ratings yet

- Fungi and Lignocellulosic BiomassFrom EverandFungi and Lignocellulosic BiomassChristian P KubicekNo ratings yet

- LaccaseDocument3 pagesLaccaseIram AnwarNo ratings yet

- 1 s2.0 S094450132030402X MainDocument16 pages1 s2.0 S094450132030402X Mainbiovijay101No ratings yet

- Begemann 2011Document17 pagesBegemann 2011Rosa LiNo ratings yet

- Lecture-3: Fermentation ProcessesDocument20 pagesLecture-3: Fermentation ProcessesYENUGULA DAVID VENKATNo ratings yet

- Production of Oligosaccharides From AgroDocument27 pagesProduction of Oligosaccharides From AgroMiguelArceMonroyNo ratings yet

- Horn 2012 Cellulases ReviewDocument13 pagesHorn 2012 Cellulases Reviewct239No ratings yet

- Delignification, Bioconversion of Substrates and It's Affecting FactorsDocument32 pagesDelignification, Bioconversion of Substrates and It's Affecting FactorsHarshvardhan ZalaNo ratings yet

- Primary Versus Secondary MetabolitesDocument11 pagesPrimary Versus Secondary MetabolitesJitendra MishraNo ratings yet

- Project On Wheat StrawDocument22 pagesProject On Wheat StrawGlenPalmerNo ratings yet

- A Report On Bio-EthanolDocument13 pagesA Report On Bio-EthanolbukidaNo ratings yet

- The Ford Model T Car of 1908: OncernDocument3 pagesThe Ford Model T Car of 1908: OncernsivsyadavNo ratings yet

- Michelin2019 Article ProductionOfBiomass-DegradingEDocument10 pagesMichelin2019 Article ProductionOfBiomass-DegradingEgriselNo ratings yet

- Bioconversion of Lignocellulosic Biomass To Ethanol Using Different MicroorganismsDocument9 pagesBioconversion of Lignocellulosic Biomass To Ethanol Using Different MicroorganismsIJAR JOURNALNo ratings yet

- Bioresource Technology: ReviewDocument9 pagesBioresource Technology: ReviewRaquel FernandesNo ratings yet

- Biotechnological Potential of Agro-Industrial Residues. I: Sugarcane BagasseDocument12 pagesBiotechnological Potential of Agro-Industrial Residues. I: Sugarcane BagasseAnonymous Wcj4C3jNo ratings yet

- Biofuel Alternatives To Ethanol: Pumping The Microbial WellDocument7 pagesBiofuel Alternatives To Ethanol: Pumping The Microbial WellAshrafNamamuTeratasNo ratings yet

- Bioethanol Production As A Renewable Energy Source From Algal Biomass & Corn StalkDocument6 pagesBioethanol Production As A Renewable Energy Source From Algal Biomass & Corn StalkDilay RıdvanNo ratings yet

- Potential of Agro-Industrial Residues. I Sugarcane BagasseDocument13 pagesPotential of Agro-Industrial Residues. I Sugarcane BagasseAdalbert RinconNo ratings yet

- H 1006025662Document7 pagesH 1006025662IOSRjournalNo ratings yet

- 2G Ethanol ConversionDocument26 pages2G Ethanol Conversionsarim rizviNo ratings yet

- A Novel Cell Factory For Efficient Production of Ethanol From Dairy WasteDocument11 pagesA Novel Cell Factory For Efficient Production of Ethanol From Dairy WasteVitor ArsenioNo ratings yet

- Commentaries & Analyses: AsiabiotechDocument1 pageCommentaries & Analyses: AsiabiotechWaqas MinhasNo ratings yet

- Fungal Cellulase Production and Applications-MinireviewDocument18 pagesFungal Cellulase Production and Applications-MinireviewGlobal Research and Development ServicesNo ratings yet

- FermentationDocument18 pagesFermentationCrissy DionesNo ratings yet

- Redefining Biorefinery: The Search For Unconventional Building Blocks For MaterialsDocument7 pagesRedefining Biorefinery: The Search For Unconventional Building Blocks For Materialsade_lutzaNo ratings yet

- Biomass Size Reduction MachinesDocument23 pagesBiomass Size Reduction MachinesYogesh MethekarNo ratings yet

- 04 GRAAGE Case Study BiofuelDocument6 pages04 GRAAGE Case Study BiofuelBojan VojvodicNo ratings yet

- 10 1016@j Biotechadv 2019 03 013Document23 pages10 1016@j Biotechadv 2019 03 013Komagatae XylinusNo ratings yet

- 1 s2.0 S2589014X21003133 MainDocument13 pages1 s2.0 S2589014X21003133 MainFelipe RojasNo ratings yet

- Economic Power of MicrobeDocument16 pagesEconomic Power of MicrobeAbhishek MuleNo ratings yet

- Metabolic Engineering of Saccharomyces Cerevisiae For Ethanol and Butanol Biofuel ProductionDocument10 pagesMetabolic Engineering of Saccharomyces Cerevisiae For Ethanol and Butanol Biofuel ProductionMamta AgarwalNo ratings yet

- Methods For Pretreatment of Lignocellulosic Biomass For Efficient Hydrolysis and Biofuel ProductionDocument18 pagesMethods For Pretreatment of Lignocellulosic Biomass For Efficient Hydrolysis and Biofuel ProductionFrank O'cengNo ratings yet

- A Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyFrom EverandA Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyNo ratings yet

- Sms CollectionDocument95 pagesSms Collectionsaurabh jainNo ratings yet

- Stat Fax 3300 Chemistry AnalyzerDocument2 pagesStat Fax 3300 Chemistry AnalyzermohamedNo ratings yet

- Chart Patterns: Symmetrical Triangles The Ascending TriangleDocument8 pagesChart Patterns: Symmetrical Triangles The Ascending TriangleGene Stanley100% (1)

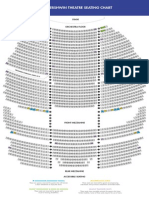

- The Gershwin Theatre Seating Chart: StageDocument1 pageThe Gershwin Theatre Seating Chart: StageCharles DavidsonNo ratings yet

- Make and Grow Money The Right Way (Free Sample)Document12 pagesMake and Grow Money The Right Way (Free Sample)Ankit ChawlaNo ratings yet

- Venture Capital Method.Document4 pagesVenture Capital Method.Vicente MendozaNo ratings yet

- DHS Coast Guard LetterDocument13 pagesDHS Coast Guard LetterThe Hill NewspaperNo ratings yet

- A Project Report On CustomerDocument13 pagesA Project Report On CustomerDrishti BhushanNo ratings yet

- climateChangeStat2015 PDFDocument294 pagesclimateChangeStat2015 PDFPallaviNo ratings yet

- Biops JuliDocument13 pagesBiops Juliklinikutama KayoonNo ratings yet

- Chapter 5 - Object-Oriented Database ModelDocument9 pagesChapter 5 - Object-Oriented Database Modelyoseffisseha12No ratings yet

- BMGT 210 Syllabus Spring 2016 PoliciesDocument8 pagesBMGT 210 Syllabus Spring 2016 PoliciesSamantha KoyNo ratings yet

- Arts 1ST Q Grade 9 ReviewerDocument6 pagesArts 1ST Q Grade 9 Reviewereri zen100% (1)

- Purchase Order NO: 1010849367: VendorDocument2 pagesPurchase Order NO: 1010849367: VendorErian Adhi Nur PersadaNo ratings yet

- Upgrading Oracle GoldengateDocument29 pagesUpgrading Oracle GoldengateDomenico ConteNo ratings yet

- Risk Management in Islamic BankingDocument17 pagesRisk Management in Islamic BankingEdi SusiloNo ratings yet

- Active and Passive VoiceDocument3 pagesActive and Passive VoiceCray CrayNo ratings yet

- nnsm322m PDFDocument22 pagesnnsm322m PDFTLTPSNo ratings yet

- 8 SWOT Analysis Tools For Small Businesses: 1. SmartsheetDocument3 pages8 SWOT Analysis Tools For Small Businesses: 1. SmartsheetSantu BiswaaNo ratings yet

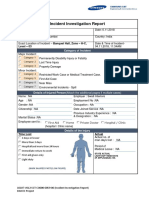

- Incident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsDocument4 pagesIncident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsMobin Thomas AbrahamNo ratings yet

- Encoder Serie Ria-40Document6 pagesEncoder Serie Ria-40Carlos NigmannNo ratings yet

- Tagbino National High SchoolDocument2 pagesTagbino National High SchooldarelleNo ratings yet

- Taylor Lift Trucks Spec Ce8a3eDocument8 pagesTaylor Lift Trucks Spec Ce8a3eIvan ManuelNo ratings yet

- Caspah - Kamunda 1593513704 ADocument42 pagesCaspah - Kamunda 1593513704 Ajoseph wamulumeNo ratings yet

- Bernard Stanley Hoyes: RAG DrawingsDocument29 pagesBernard Stanley Hoyes: RAG Drawingsapi-258238272No ratings yet

- CP3mini Op Inst 2549076Document56 pagesCP3mini Op Inst 2549076Rawnee HoNo ratings yet

- CompassDocument15 pagesCompassozkan toprakNo ratings yet

- English For Academic and Professional Purposes: Learning Module 4: Objectives and Structures of Various Kinds of ReportsDocument6 pagesEnglish For Academic and Professional Purposes: Learning Module 4: Objectives and Structures of Various Kinds of ReportsReymart YagamiNo ratings yet

- Bombay Astrological Society B W UpdatedDocument5 pagesBombay Astrological Society B W UpdatedVishal DhekaleNo ratings yet

- Time Value of Money: Compound InterestDocument28 pagesTime Value of Money: Compound InterestkateNo ratings yet