Professional Documents

Culture Documents

Pulsa 340 Brochure English

Pulsa 340 Brochure English

Uploaded by

ratatrampa25Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pulsa 340 Brochure English

Pulsa 340 Brochure English

Uploaded by

ratatrampa25Copyright:

Available Formats

ENGINEERED PRODUCTS

340 PULSA Series

Our time proven PULSA Series 340 is our smallest,

most economical diaphragm metering pump. It is

engineered with precision, reliability and muscle for tough

jobs. Our unique HYDRAcone head design, along with

a variety of wet end materials, offers a diverse range

of fluid handling solutions. The 340 is ideal for handling

corrosives, non-corrosives, high viscosities, slurries, and

in high-lift applications.

Applications

fertigation, coagulation, slime control,

CPI, pH and odor control

Flow

up to 11.5 gph (43.5 lph)

Pressure

up to 175 psi (12 bar)

Temperature

from 40F (4.4C) to 180F (82C)

API-675 CE ATEX

Hydraulic diaphragm metering delivers more than you expect.

Standard materials of construction Controls HYDRAcone design

Wet end: 316LSS, GF-PPL VFD motor speed The solution for difficult suction lift conditions

Diaphragm: Elastomeric cone Motor Ideal for sheer sensitive and high

Pump body: Aluminum Vertical mount viscosity fluids

Valve ball: 316LSS, Alumina Ceramic Long life bearing design Outstanding hydraulic performance

Valve gaskets: PTFE Footprint Straight flow-through path

Connection type Compact Optional slurry valves

NPT OEM Capable Head: 316LSS, GF-PPL

Elastomeric HYDRAcone

PULSA Series 340

Specifications Flow & Pressure Envelope by Piston Size (inches)

Materials 316LSS, GF-PPL

Flow (lph)

Diaphragm type Cone

0 5 10 15 20 25 30 35 40 45

Motor power up to 0.33 hp (0.25 kW) 200

Motor frame NEMA 42C, 56C 13

Max temp 180F (82C) 175 12

0.5

Min temp 40F (4.4C) 11

Accuracy 1% 150

0.75 10

Standards API-675, CE, ATEX

Pressure (bar)

Pressure (psi)

9

125

8

100 7

6

75 5

Features & Benefits 50

4

3

Stroke length control yields 0-100% linear

2

flow adjustment over a 10:1 turndown range 25

1

Hydraulically balanced diaphragm for long

life and reduced service costs 0 0

0 1 2 3 4 5 6 7 8 9 10 11 12 13

HYDRAcone provides outstanding suction lift

Proven hydraulic management system Flow (gph)

assures consistent performance and rapid

recovery from system upsets

Dimensions

Material options for safety, durability and

chemical compatibility

Sealed drive protects against atmospheric

contamination and assures long service life

Easy maintenance KOPkit (Keep on

Pumping kit) saves time and money 18.5

470

Custom Engineering 11.7 7.75 Inches

297 197 Millimeters

Compatible materials: Alloy C, Alloy 20, PVDF Approximate shipping weight: 35 lb (16 kg)

Custom electronic controls

The dimensions shown may differ depending on pump configuration.

Chemical feed systems

Application consulting

For More Information, Contact Your Authorized

Pulsafeeder Engineered Products Representative

REPRESENTATIVE LOOKUP

VISIT OUR

Pulsafeeder Engineered Products

340spec_Rev0714

2883 Brighton Henrietta Town Line Rd.

Rochester, NY 14623

Phone: +1 (585) 292-8000

Spec Pulsafeeder. pulsa@idexcorp.com pulsa.com

Get more than you expect. Pulsafeeder is an ISO 9001:2008 and 14001:2004 certified company.

Copyright 2014 Pulsafeeder. All rights reserved.

You might also like

- Turbo Expander PDFDocument105 pagesTurbo Expander PDFwqs_1960% (5)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- MSD Axially Split Multistage Pump E00577Document6 pagesMSD Axially Split Multistage Pump E00577chijioke ekekeNo ratings yet

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Sauer-Danfoss Next Generation Hydrostatic Transmission ProductsDocument50 pagesSauer-Danfoss Next Generation Hydrostatic Transmission ProductsJose Manuel Barroso PantojaNo ratings yet

- Transfer Pump GBSD: Technical IndexDocument2 pagesTransfer Pump GBSD: Technical Index李军No ratings yet

- EHYD6 Hydraulic Valves HY14-2502k001Document9 pagesEHYD6 Hydraulic Valves HY14-2502k001Ahmet SaygılıNo ratings yet

- DeltaPValves Product CatalogDocument24 pagesDeltaPValves Product CatalogKyriakos MichalakiNo ratings yet

- LD Brochure LetterDocument6 pagesLD Brochure LetterJackNo ratings yet

- Hilco Hyflow Duplex Filters DatasheetDocument2 pagesHilco Hyflow Duplex Filters DatasheetpicugaNo ratings yet

- Profile Coreless Filter Elements Gas Filtration DatasheetDocument2 pagesProfile Coreless Filter Elements Gas Filtration DatasheethellothisisallenNo ratings yet

- VHP Series Gas Engine: 732 - 1025 BHP (546 - 764 KWB)Document2 pagesVHP Series Gas Engine: 732 - 1025 BHP (546 - 764 KWB)feryNo ratings yet

- Centramate 500 SDocument12 pagesCentramate 500 SArthurNo ratings yet

- Copeland Compressors For Transcritical Co2 Refrigeration en Us 2884908Document2 pagesCopeland Compressors For Transcritical Co2 Refrigeration en Us 2884908JOSE ALVARADO LEYVANo ratings yet

- Verderflex Dura 10 INT English DatasheetDocument4 pagesVerderflex Dura 10 INT English DatasheetWilmerNo ratings yet

- Service Operating - Model 8329 ALEMITEDocument19 pagesService Operating - Model 8329 ALEMITEMorales EduardoNo ratings yet

- Ficha Técnica - Bomba CV Poclain PM10-21Document56 pagesFicha Técnica - Bomba CV Poclain PM10-21carlos miras mondejarNo ratings yet

- Norgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Document4 pagesNorgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Iswar Rauf Aboo 'AqilahNo ratings yet

- Spray Ball Terkait CIPDocument6 pagesSpray Ball Terkait CIPTuti SusilawatiNo ratings yet

- 9bf1l5c0 Bomba Goulds 3656s Bronze FittedDocument3 pages9bf1l5c0 Bomba Goulds 3656s Bronze FittedElmer RafaelNo ratings yet

- Parweld-Plasma - Ultima Pagina Scheme de Conexiuni in Conectorul CPCDocument22 pagesParweld-Plasma - Ultima Pagina Scheme de Conexiuni in Conectorul CPCIonescuTeodoraNo ratings yet

- Technical Manual EVOPICVDocument20 pagesTechnical Manual EVOPICVzoltanNo ratings yet

- Signet 2450 Pressure Sensor: 1. DescriptionDocument4 pagesSignet 2450 Pressure Sensor: 1. Descriptionabbas dehghanNo ratings yet

- Ahlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentDocument28 pagesAhlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentARYAN_FATHONI_AMRINo ratings yet

- Model 8329: Service & Operating ManualDocument19 pagesModel 8329: Service & Operating ManualCesar Marcello Cordova GuerreroNo ratings yet

- Folder LMI C DSD 07-2013Document4 pagesFolder LMI C DSD 07-2013reinpolyNo ratings yet

- X PumpsDocument4 pagesX Pumpspankaj chacholiyaNo ratings yet

- K-45-101 Print ABDocument4 pagesK-45-101 Print ABEDUARDO100% (1)

- Atuador pneumatico-TYCO-RENMC-0111-USDocument4 pagesAtuador pneumatico-TYCO-RENMC-0111-USNueude PachecoNo ratings yet

- Aerocheck Hydraulic Valve Eng BulletinDocument8 pagesAerocheck Hydraulic Valve Eng BulletinAlper SakalsizNo ratings yet

- ServosaverseriesEHYDF2 Hydraulic Filtration CAT2300-13 HP6Document8 pagesServosaverseriesEHYDF2 Hydraulic Filtration CAT2300-13 HP6GChandraSekharaRaoNo ratings yet

- Primeroyal Series: API 675 Metering PumpDocument6 pagesPrimeroyal Series: API 675 Metering PumpDavid GarciaNo ratings yet

- Sp20 DescripcionDocument2 pagesSp20 DescripcionJuan Pablo Moreno Téllez Moreno TéllezNo ratings yet

- Parker Serie P1+PDDocument84 pagesParker Serie P1+PDRodrigo IglesiasNo ratings yet

- PCR ManualDocument12 pagesPCR ManualAwadh100% (1)

- LIT Sullair DR13 Sell Sheet - PAPDR13201804-1 - EN - 0Document2 pagesLIT Sullair DR13 Sell Sheet - PAPDR13201804-1 - EN - 0greatestNo ratings yet

- GT Datasheet DuraShieldDocument2 pagesGT Datasheet DuraShieldJuan carlosNo ratings yet

- RG282-357Document4 pagesRG282-357ivan.mehanikNo ratings yet

- Octave Ultrasonic Water Meter BrochureDocument4 pagesOctave Ultrasonic Water Meter BrochureOsamaNo ratings yet

- Air Line Network: Filter Regulator LubricatorDocument5 pagesAir Line Network: Filter Regulator LubricatorZeckNo ratings yet

- Sevcon Mos90 DC Traction and Pump Controller Datasheet1 1734225600 PDFDocument41 pagesSevcon Mos90 DC Traction and Pump Controller Datasheet1 1734225600 PDFPertti Hänninen100% (1)

- TF100-53B 3900 Series QD CouplingsDocument6 pagesTF100-53B 3900 Series QD CouplingsrrrrNo ratings yet

- Check ValvesDocument2 pagesCheck ValvesEagle1968No ratings yet

- Poclaim PM10Document56 pagesPoclaim PM10dial94902No ratings yet

- Valvulas Gemu DB C60 67HPS GBDocument9 pagesValvulas Gemu DB C60 67HPS GBejrfjxhjtntauuwtfcNo ratings yet

- Emflon FMDocument2 pagesEmflon FMArthurNo ratings yet

- DFE1Document12 pagesDFE1PrasantaKumarMallikaNo ratings yet

- Metering Pumps: (Gear Driven & Direct Drive)Document20 pagesMetering Pumps: (Gear Driven & Direct Drive)melihozdoganNo ratings yet

- B52513DDocument40 pagesB52513DHappy StephenNo ratings yet

- BE/BE12: ISO 5599/1 ValvesDocument12 pagesBE/BE12: ISO 5599/1 ValvesDaniel MilenkovicNo ratings yet

- Flexflo Surge Relief BrochureDocument8 pagesFlexflo Surge Relief BrochureOscar DelgadoNo ratings yet

- OptiLobe Rotary Lobe PumpDocument4 pagesOptiLobe Rotary Lobe PumpRemus-Mihai GheorghitaNo ratings yet

- Ampliflow T-Boost Ssfly000029-Ena4Document2 pagesAmpliflow T-Boost Ssfly000029-Ena4carburoNo ratings yet

- Series CRV Brass Product Literature 1Document2 pagesSeries CRV Brass Product Literature 1enghassanain6486No ratings yet

- AHLSTAR End Suction Single Stage Close Coupled Centrifugal PumpDocument8 pagesAHLSTAR End Suction Single Stage Close Coupled Centrifugal PumpMichael PiñaNo ratings yet

- Lit Circpac HP DataDocument2 pagesLit Circpac HP Databillel limaneNo ratings yet

- 200706-PD-Overview-for Distributor TrainingDocument96 pages200706-PD-Overview-for Distributor TrainingChester Dalitso MwanzaNo ratings yet

- VT IPH 21 BDI 90115 enDocument16 pagesVT IPH 21 BDI 90115 enwag008No ratings yet

- KAT-A 5512 EKN-HYsec Edition1 en 07-11Document4 pagesKAT-A 5512 EKN-HYsec Edition1 en 07-11Sonny LuuNo ratings yet

- Proact™ Itb: Integrated Actuator and Throttle Body For Large Bores (85 MM To 180 MM)Document4 pagesProact™ Itb: Integrated Actuator and Throttle Body For Large Bores (85 MM To 180 MM)JerNo ratings yet

- Learning Activity 2 / Actividad de Aprendizaje 2 Evidence: Expressing Advice / Evidencia: Dando ConsejosDocument4 pagesLearning Activity 2 / Actividad de Aprendizaje 2 Evidence: Expressing Advice / Evidencia: Dando Consejosratatrampa25No ratings yet

- Learning Activity 2 / Actividad de Aprendizaje 2 Evidence: Health Solutions / Evidencia: Soluciones para La SaludDocument4 pagesLearning Activity 2 / Actividad de Aprendizaje 2 Evidence: Health Solutions / Evidencia: Soluciones para La Saludratatrampa25No ratings yet

- Support Material / Material de Apoyo Learning Activity 2 / Actividad de Aprendizaje 2 Presentation / PresentaciónDocument8 pagesSupport Material / Material de Apoyo Learning Activity 2 / Actividad de Aprendizaje 2 Presentation / Presentaciónratatrampa25No ratings yet

- Minerals Engineering ConferencesDocument1 pageMinerals Engineering Conferencesratatrampa25No ratings yet

- Clariant Presentation Decorative Color Trends 2021 ENDocument27 pagesClariant Presentation Decorative Color Trends 2021 ENratatrampa25No ratings yet

- Acc PDFDocument5 pagesAcc PDFratatrampa25No ratings yet

- Meter, Warning Lamp & Indicator: SectionDocument55 pagesMeter, Warning Lamp & Indicator: Sectionratatrampa25No ratings yet

- STCDocument37 pagesSTCratatrampa25No ratings yet

- Srs Airbag: SectionDocument34 pagesSrs Airbag: Sectionratatrampa25No ratings yet

- Section: Driver ControlsDocument6 pagesSection: Driver Controlsratatrampa25No ratings yet

- Door & Lock: SectionDocument319 pagesDoor & Lock: Sectionratatrampa25No ratings yet

- Clutch: SectionDocument21 pagesClutch: Sectionratatrampa25No ratings yet

- Charging System: SectionDocument31 pagesCharging System: Sectionratatrampa25No ratings yet

- CCS PDFDocument3 pagesCCS PDFratatrampa25No ratings yet

- دائرة المشحمة لونش مانتوكDocument138 pagesدائرة المشحمة لونش مانتوكMohamed Rashed100% (1)

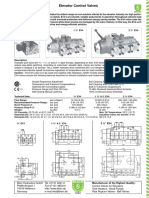

- Elevator Control Valves: EN ISO 9001Document4 pagesElevator Control Valves: EN ISO 9001Bantu BantuNo ratings yet

- AM2832 - Instrumentation and Controls StandardsDocument25 pagesAM2832 - Instrumentation and Controls StandardsAbdul RazzaqNo ratings yet

- Detailed Design - Bill of Quantities (Template)Document55 pagesDetailed Design - Bill of Quantities (Template)Ntseuoa100% (1)

- Especificación Tecnica de Materiales de PipingDocument61 pagesEspecificación Tecnica de Materiales de PipingDaniel Lopez100% (1)

- Weco Pneumatic Actuator Safety AlertDocument2 pagesWeco Pneumatic Actuator Safety AlertRafael GranadoNo ratings yet

- Noida MMD Viva QuestionsDocument61 pagesNoida MMD Viva QuestionsSameerFernandezNo ratings yet

- Machine Design Final Coaching Shuffled PDFDocument385 pagesMachine Design Final Coaching Shuffled PDFJaypes ManzanoNo ratings yet

- Brochure Hygienic RangeDocument8 pagesBrochure Hygienic Rangedingobk1No ratings yet

- Triac We SeriesDocument16 pagesTriac We SeriesjohnfranksNo ratings yet

- High Purity Piping Systems: AsahiDocument20 pagesHigh Purity Piping Systems: AsahiJOSE GABRIELNo ratings yet

- Parker Oil X 2.1 User Guide - Online - EN 1Document24 pagesParker Oil X 2.1 User Guide - Online - EN 1febbyyandraNo ratings yet

- Technical Specification 800 MWDocument581 pagesTechnical Specification 800 MWRINJU100% (1)

- Hydraulic AmplifierDocument4 pagesHydraulic AmplifierLuis Jonathan Bahamaca FernandezNo ratings yet

- Air Bleeder Valves: Model ABVDocument1 pageAir Bleeder Valves: Model ABVSanthosh KumarNo ratings yet

- fm2798 818 819 820 PDFDocument4 pagesfm2798 818 819 820 PDFOrellana Zeballos Luis CristianNo ratings yet

- Final Pre-Board Practical ProblemsDocument10 pagesFinal Pre-Board Practical ProblemsMarco Dela CruzNo ratings yet

- 3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enDocument6 pages3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enQuyết Bạch ĐìnhNo ratings yet

- Specification For Centrifugal Pumps White Oil TerminalDocument96 pagesSpecification For Centrifugal Pumps White Oil TerminalJackfusion100% (1)

- Reservoir and Wellheads: Crude Oil and Natural GasDocument15 pagesReservoir and Wellheads: Crude Oil and Natural GasИрина ДовгунNo ratings yet

- E4 Accessories PDFDocument72 pagesE4 Accessories PDFDavid C HouserNo ratings yet

- Kalendar Kursus 1 Jangka Pendek 2017Document18 pagesKalendar Kursus 1 Jangka Pendek 2017SenyumSajerNo ratings yet

- Pump Division: Types: ERPN - M Horizontal, End Suction Magnetic Driven Centrifugal PumpsDocument34 pagesPump Division: Types: ERPN - M Horizontal, End Suction Magnetic Driven Centrifugal Pumpstexwan_No ratings yet

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNo ratings yet

- Western Cabinet Inner and Outer Forming Line Operation MannualDocument50 pagesWestern Cabinet Inner and Outer Forming Line Operation Mannualvikrant singhNo ratings yet

- REGULADOR 143 203 Dixi AP Ct-S-Emay 14Document12 pagesREGULADOR 143 203 Dixi AP Ct-S-Emay 14Edson BlancoNo ratings yet

- SAIC-A-2013 Rev 0Document4 pagesSAIC-A-2013 Rev 0qazi12No ratings yet

- XC-Series: Cordless Hydraulic Pump Instruction ManualDocument14 pagesXC-Series: Cordless Hydraulic Pump Instruction ManualJesus MontielNo ratings yet

- Tamper Switch OS&Y ULDocument4 pagesTamper Switch OS&Y ULGiordano TuanamaNo ratings yet

- Series 44 Self-Operated Pressure Regulators Type 44-1 B Pressure Reducing Valve Type 44-6 B Excess Pressure ValveDocument8 pagesSeries 44 Self-Operated Pressure Regulators Type 44-1 B Pressure Reducing Valve Type 44-6 B Excess Pressure ValveCornel DumitruNo ratings yet