Professional Documents

Culture Documents

I-Rod Adhesive: ºC 500 Hours 1,000 Hours

I-Rod Adhesive: ºC 500 Hours 1,000 Hours

Uploaded by

JustinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

I-Rod Adhesive: ºC 500 Hours 1,000 Hours

I-Rod Adhesive: ºC 500 Hours 1,000 Hours

Uploaded by

JustinCopyright:

Available Formats

i-rod.

com TECHNICAL DATASHEET

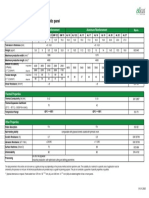

I-Rod Adhesive

General

I-Rod Adhesive is a high-strength, two-component methacrylate adhesive designed to quickly bond I-Rod thermoplastic materials to pipe supports without

pretreating their clean surfaces. It is applied using a 1:1 mix ratio, and is non-flammable once cured. It is best used by the date specified on the packaging.

Room temperature cure time is listed. For applications below room temperature, time to full strength is increased. I-Rod Adhesive should not be used on

high-heat installations exceeding 83C (181F), even if I-Rod HT or PEEK is also used.

Cartridge coverage per substrate

I-Rod size

3/4 1 1

Bond Sq. in. per

Substrate Linear feet per cartridge thickness cartridge

Concrete 21 16 10 0.125 195 sq. in.

Steel* 64 50 32 0.04 610 sq. in.

*Painted, galvanized, or bare finish

Shore hardness STM-707 (ASTM D 2240) Fixture time Properties of uncured material (when mixed)

Durometer D 39 Time needed to develop sheer strength of 0.1 N/mm Specific gravity at 25 C 0.99

Fixture time, ISO 4587: 10 to 20 minutes Working time at 25 C: 7 min.

Flash point 95 C (203 F)

Product characteristics Temperature limits I-Rod (white) lap shear strength (psi)

Appearance (mixture) Pale yellow I-Rod Adhesive functions well within the temperature Concrete 1,400 - 1,700

Cure Room temperature cure limits of I-Rod Classic, but is not recommended for Steel 2,500 - 3,000

Components Two component - high-temperature use with I-Rod HT or PEEK.

requires mixing Lowest Highest

Mix ratio, by volume - I-Rod (white) tensile strength (psi)

-110C (-166F) 83C (181F)

Part A: Part B 1:1 Concrete 500 - 600

Working time 7 minutes Steel 700 - 800

Chemical / solvent resistance at 22 C Adhesive properties of material

cured for 72 hours at 21C

(Aged under these conditions) % Strength % Strength

Environment C 500 hours 1,000 hours Impact strength (ISO 9653)

100% RH 49 130 120 21 C 5.8 J

Salt fog, 95% RH 35 115 130 100 C 3.2 J

Water 22 120 105 -40 C 6.1 J

Unleaded gasoline 22 Not recommended Not recommended T Peel strength (ISO 11339)

Motor oil (10W30) 22 100 90 Steel N/mm 8

(lb/in) (45)

Water/glycol 50/50 22 120 115

Aluminum N/mm 2

DEF (AdBlue) 22 125 145

(lb/in) (12)

Sulfuric Acid, 10% 22 100 105

Ammonia 22 120 110

Deepwater Corrosion Services Inc.

USA: +1 (713) 983 7117 | UK: +44 (0) 1483 600482 | sales@stoprust.com

2015 Deepwater Corrosion Services Inc. Specifications subject to change without notice

You might also like

- Design of Large Footings For One Way ShearDocument8 pagesDesign of Large Footings For One Way ShearAsad SohailNo ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- Cutback Asphalt (Rapid-Curing Type) : AashloDocument3 pagesCutback Asphalt (Rapid-Curing Type) : AashloNacer KisyNo ratings yet

- O&G Engineering Companies in VietnamDocument10 pagesO&G Engineering Companies in VietnamJustinNo ratings yet

- ContractDocument29 pagesContractJustinNo ratings yet

- Air and Flue Gas Ducts and DampersDocument5 pagesAir and Flue Gas Ducts and Dampersjkhan_724384No ratings yet

- Ar. Tadao Ando: The Architect of LightDocument33 pagesAr. Tadao Ando: The Architect of LightyashaswiniNo ratings yet

- EPC Model AgreementDocument17 pagesEPC Model AgreementMukul LodhiNo ratings yet

- Ceramite T: Bauxite and Silicon Carbide Based Trowellable RefractoryDocument2 pagesCeramite T: Bauxite and Silicon Carbide Based Trowellable RefractorySHRINIVASAN GTKNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- LOCTITEDocument2 pagesLOCTITEHrNo ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- Aço Uddeholm CalmaxDocument12 pagesAço Uddeholm CalmaxDanilo SilvaNo ratings yet

- Loctite 380 Black - Ficha TecnicaDocument3 pagesLoctite 380 Black - Ficha TecnicamonsepackNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- QALCO Syntholube GX 220Document1 pageQALCO Syntholube GX 220Deepak JoyNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- c95500 Spec SheetDocument2 pagesc95500 Spec SheetOrnella MancinelliNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Cho-Bond 1030Document2 pagesCho-Bond 1030Jose MYCNo ratings yet

- (Sika) Sikadur 41 CF RapidDocument6 pages(Sika) Sikadur 41 CF Rapid_at_to_No ratings yet

- Denso Protal 650 CTR Coal Tar Epoxy ReplacementDocument3 pagesDenso Protal 650 CTR Coal Tar Epoxy Replacementmohsen_267No ratings yet

- Formosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SDocument1 pageFormosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SluisalbertolvNo ratings yet

- DS Mold 2311 1Document4 pagesDS Mold 2311 1marjan banooNo ratings yet

- Resin - ABS Tairalac PDFDocument3 pagesResin - ABS Tairalac PDFDiegoTierradentroNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Afico Duct LinerDocument3 pagesAfico Duct LinerChris SolonNo ratings yet

- Abs 38Document2 pagesAbs 38mohamad mostafaviNo ratings yet

- SCG H5480SDocument2 pagesSCG H5480Sakankshas06No ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Stainless Steel 321 Technical DataDocument2 pagesStainless Steel 321 Technical Datasmith willNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- PBN DatasheetDocument1 pagePBN DatasheetLove MishraNo ratings yet

- 718 Datasheet Rev 01Document5 pages718 Datasheet Rev 01assanaiNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Roxul Comfortboard 80: Insulated SheathingDocument1 pageRoxul Comfortboard 80: Insulated SheathingMark RauNo ratings yet

- Jyoti Resin 1520F and Hardener 1758 - E Potting CompoundDocument5 pagesJyoti Resin 1520F and Hardener 1758 - E Potting CompoundBabyboy2010No ratings yet

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- Eva - RenewsysDocument1 pageEva - RenewsysShashwata ChattopadhyayNo ratings yet

- SAN - KUMHO - 350-HW - TDS FDocument4 pagesSAN - KUMHO - 350-HW - TDS FakshayNo ratings yet

- DS Mold 4140Document3 pagesDS Mold 4140reza prasetiaNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- Exelene Hdpe 5100MDocument1 pageExelene Hdpe 5100MAndres Quiroga JuarezNo ratings yet

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- 01 enDocument7 pages01 enambright mawunyoNo ratings yet

- Data Teknis Hive Honeycomb KoreaDocument70 pagesData Teknis Hive Honeycomb KoreailhamhanafyNo ratings yet

- Stellite 12 Technical DataDocument2 pagesStellite 12 Technical DataJakeTheSnake69100% (1)

- Technical Data Sheet Product 3421: Research, Development & Engineering PreliminaryDocument3 pagesTechnical Data Sheet Product 3421: Research, Development & Engineering PreliminaryAfzal ImamNo ratings yet

- Abs 60Document2 pagesAbs 60mohamad mostafaviNo ratings yet

- Mds Rheinzink-Artcolor Skygrey 04 2018 de enDocument3 pagesMds Rheinzink-Artcolor Skygrey 04 2018 de encarlosNo ratings yet

- TDS-SULFAD®-1710E 硫化极压剂Document3 pagesTDS-SULFAD®-1710E 硫化极压剂ganzhirong8No ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Epic Hydraulic Range TdsDocument2 pagesEpic Hydraulic Range Tdsapi-375685829No ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- Abs 80Document2 pagesAbs 80mohamad mostafaviNo ratings yet

- Extrusion Ingot: ApplicationDocument4 pagesExtrusion Ingot: ApplicationilkerNo ratings yet

- Ficha Tecnica Loctite Ea 3471 en GLDocument3 pagesFicha Tecnica Loctite Ea 3471 en GLproduccionNo ratings yet

- Inpex, Total Seek US$20bil Loans For Australia LNG: BusinessDocument2 pagesInpex, Total Seek US$20bil Loans For Australia LNG: BusinessJustinNo ratings yet

- Foster Wheeler Wins Contract For Petrochemical Refinery Complex in VietnamDocument2 pagesFoster Wheeler Wins Contract For Petrochemical Refinery Complex in VietnamJustinNo ratings yet

- Folder AustraliaDocument2 pagesFolder AustraliaJustinNo ratings yet

- Fluor Awarded Strategic Global EPC Agreement by The Dow Chemical CompanyDocument1 pageFluor Awarded Strategic Global EPC Agreement by The Dow Chemical CompanyJustinNo ratings yet

- 2012-09-17 Fluor Wins US Propylene Project Contract From DowDocument1 page2012-09-17 Fluor Wins US Propylene Project Contract From DowJustinNo ratings yet

- Fluor Selected For The Dow Chemical Company's Propylene Production Project in TexasDocument2 pagesFluor Selected For The Dow Chemical Company's Propylene Production Project in TexasJustinNo ratings yet

- 2012-12-21.TH - Pttep, Partners Award Mozambique LNG FEED ContractsDocument3 pages2012-12-21.TH - Pttep, Partners Award Mozambique LNG FEED ContractsJustinNo ratings yet

- Eni Australia Scalybutt Tieback Rev 1Document1 pageEni Australia Scalybutt Tieback Rev 1JustinNo ratings yet

- Mobile Mooring Systems (Endorsement of Api RP 2Sk, Api RP 2Sm and Api RP 2I)Document8 pagesMobile Mooring Systems (Endorsement of Api RP 2Sk, Api RP 2Sm and Api RP 2I)JustinNo ratings yet

- Capability Statement - GLNDDocument15 pagesCapability Statement - GLNDJustinNo ratings yet

- Husky, CNOOC Charter Floater Offshore IndonesiaDocument11 pagesHusky, CNOOC Charter Floater Offshore IndonesiaJustinNo ratings yet

- New Horizon 2015: JGC Corporation JGC Corporation Medium-Term Management PlanDocument15 pagesNew Horizon 2015: JGC Corporation JGC Corporation Medium-Term Management PlanJustinNo ratings yet

- Sample - Global Oil & Gas Asset Integrity ManagementDocument19 pagesSample - Global Oil & Gas Asset Integrity ManagementJustinNo ratings yet

- Jkgiy, Lfy, Ul, FDocument2 pagesJkgiy, Lfy, Ul, FJustinNo ratings yet

- Jurong Shipyard Bags MODEC's FPSO Contract For Ghana's TEN DevelopmentDocument1 pageJurong Shipyard Bags MODEC's FPSO Contract For Ghana's TEN DevelopmentJustinNo ratings yet

- The Star Online: Starbiz: "With The Assistance of Our Local Timorese Partner Nexus Meridian Lda, Petro-MekongDocument3 pagesThe Star Online: Starbiz: "With The Assistance of Our Local Timorese Partner Nexus Meridian Lda, Petro-MekongJustinNo ratings yet

- Appendix A.9 - (900) MC CTRDocument6 pagesAppendix A.9 - (900) MC CTRJustin0% (1)

- Important Note:: Terms and Conditions Celcom Biz - Quarter 2 2014 Offering Plan148 With Device BundleDocument4 pagesImportant Note:: Terms and Conditions Celcom Biz - Quarter 2 2014 Offering Plan148 With Device BundleJustinNo ratings yet

- Review of DevelopmentDocument43 pagesReview of DevelopmentJustinNo ratings yet

- Fluor Wins US Propylene Project Contract From DowDocument1 pageFluor Wins US Propylene Project Contract From DowJustinNo ratings yet

- LV Cable Derating Factors IEC 60364 (Europe)Document8 pagesLV Cable Derating Factors IEC 60364 (Europe)Mothafukin MorrisseyNo ratings yet

- Types of Flange End Connection-02Document6 pagesTypes of Flange End Connection-02manoj_amritkarNo ratings yet

- Embankment Dams (CH 9) - Reclamation PDFDocument126 pagesEmbankment Dams (CH 9) - Reclamation PDFMAXO44No ratings yet

- 3-Way Flanged Ball Valves: EconomicalDocument12 pages3-Way Flanged Ball Valves: EconomicalFelipe Ribeiro da CostaNo ratings yet

- Solid Pin Conversion Kits: Equipment: Cat Loaders To Suit Machines: 990, 992C, 992G, 992K, 994C, 994D & 994FDocument2 pagesSolid Pin Conversion Kits: Equipment: Cat Loaders To Suit Machines: 990, 992C, 992G, 992K, 994C, 994D & 994FMax SashikhinNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument17 pages@airbus: Component Maintenance Manual With Illustrated Part ListAnh Tuan PhamNo ratings yet

- J2020b-Preparation of Low-Cost Foam Concrete Using Detergent-UETDocument10 pagesJ2020b-Preparation of Low-Cost Foam Concrete Using Detergent-UETafaq120No ratings yet

- Gold Heat Sales Sheet 1Document2 pagesGold Heat Sales Sheet 1Vee AyeNo ratings yet

- VHM Lu01 Pi SP 001 - Piping Material SpecificationDocument7 pagesVHM Lu01 Pi SP 001 - Piping Material SpecificationchintanNo ratings yet

- Holistic ExamDocument13 pagesHolistic ExamFiraol Oromo100% (1)

- FT 20 PowerpakDocument45 pagesFT 20 PowerpaklmohamedsaddekNo ratings yet

- CBC Elect Install and Maint NC IVDocument123 pagesCBC Elect Install and Maint NC IVEva MarquezNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetGaona industrial PetroleroNo ratings yet

- Wear Rings / Bearings: Catalog EPS 5276/USADocument52 pagesWear Rings / Bearings: Catalog EPS 5276/USAÉmilie RiverinNo ratings yet

- D10 Handbook of Stormwater Drainage DesignDocument59 pagesD10 Handbook of Stormwater Drainage DesignAnonymous WqYvpVd100% (3)

- Bourdillon Presentation PowerpointDocument41 pagesBourdillon Presentation PowerpointAdedoyin LasisiNo ratings yet

- Best Interior Architects in Kolkata PDF DownloadDocument1 pageBest Interior Architects in Kolkata PDF DownloadArsh KrishNo ratings yet

- Metric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock NutsDocument4 pagesMetric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock Nutsvikram jainNo ratings yet

- Soils and Rocks: ISSN 1980-9743Document165 pagesSoils and Rocks: ISSN 1980-9743somebody404No ratings yet

- Lecture 1: Introduction To Composite Materials Lecture 1: Introduction To Composite MaterialsDocument75 pagesLecture 1: Introduction To Composite Materials Lecture 1: Introduction To Composite MaterialsUtsho DasNo ratings yet

- CEQ Capability StatementDocument20 pagesCEQ Capability StatementBonnie MacRae100% (1)

- Carrier Spec Sheet 38MHRBDocument4 pagesCarrier Spec Sheet 38MHRBZeroNo ratings yet

- HILTI KB3 Vs KBTZ2Document1 pageHILTI KB3 Vs KBTZ2vivekNo ratings yet

- Ethos 24c Maintenance ManualDocument29 pagesEthos 24c Maintenance Manualdanielteo2008No ratings yet

- PE Flange TesterDocument2 pagesPE Flange TesterPaulNo ratings yet

- DesignExample4 - Torsion and ShearDocument7 pagesDesignExample4 - Torsion and ShearMelkamu DemewezNo ratings yet