Professional Documents

Culture Documents

API 610 10th Edition (Iso 13709) Pump Datasheet

API 610 10th Edition (Iso 13709) Pump Datasheet

Uploaded by

Muhammad AzkaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 610 10th Edition (Iso 13709) Pump Datasheet

API 610 10th Edition (Iso 13709) Pump Datasheet

Uploaded by

Muhammad AzkaCopyright:

Available Formats

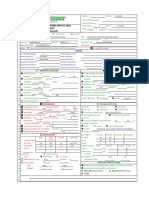

API 610 10TH EDITION (ISO 13709) MR No. MR95-G-8-1 Item No. 95G-3215 Rev.

CENTRIFUGAL PUMP PROCESS DATA SHEET Inquiry No. MR95-G-8-1

(SI UNITS) By: C.Yu Date: 31-Jan-08

1 APPLICABLE TO: PROPOSAL PURCHASE AS BUILT

2 FOR Suncor Energy UNIT Steam Generation

3 SITE Firebag Stage 5, Fort McMurray, Alberta SERVICE LP BFW Pump

4 NOTES: INFORMATION BELOW TO BE COMPLETED: BY PURCHASER BY MANUFACTURER BY MANUFACTURER OR PURCHASER

5 DATA SHEETS (6.1.1) Pump Information

6 ITEM NO.(S) / DATA SHEET NO.(S) ATTACHED Manufacturer Flowserve. Desio, Italy

7 PUMP 95G-3215 Model UZDL

8 MOTOR 95GM-3215 Size 6 UZDL 25

9 GEAR No. of Stages 2

10 TURBINE Serial No.'s D66893 1B

11 APPLICABLE STANDARD(S): Firebag Project standard FB-G-5616

12 OPERATING CONDITIONS (5.1.3) @ SG = 0.97 LIQUID (5.1.3)

13 CAPACITY, NORMAL 545 (m3 / h) RATED 654

3

(m / h) LIQUID TYPE OR NAME Boiler Feed Water

14 OTHER HAZARDOUS FLAMMABLE (5.1.5)

15 SUCTION PRESS. MAX. / RATED 143.4 / 20 (kPag) MIN. NORMAL MAX.

16 DISCHARGE PRESSURE 2,763 (kPag) PUMPING TEMP (C) 10 85 98

17 DIFFERENTIAL PRESSURE 2,743 (kPa) VAPOR PRESS. kPa (Abs.) 1.2 57.8 94.3

18 DIFF. HEAD 288.3 (m) NPSHA 5.96 (m) RELATIVE DENSITY (SG): 1 0.97 0.96

19 PROCESS VARIATIONS (5.1.4) VISCOSITY (mPa.s) 1.3 0.3301 0.2849

20 STARTING CONDITIONS (5.1.4) SPECIFIC HEAT, Cp 4.2 @ 85C (kJ / kg K)

21 SERVICE: CONT. INTERMITTENT (STARTS / DAY) CHLORIDE CONCENTRATION 3000 (ppmw)

22 PARALLEL OPERATION REQ'D (5.1.13) HYD. POWER 498 (kW) H2S CONCENTRATION (6.5.2.4) (PPMW) WET (5.2.1.12c)

23 SITE DATA (5.1.3) CORROSIVE / EROSIVE AGENT TDS < 8000 ppmw (5.12.1.9)

24 LOCATION: (5.1.30) MATERIALS

25 INDOOR HEATED OUTDOOR UNHEATED ANNEX H CLASS (5.12.1.1) S-6

26 ELECTRICAL AREA CLASSIFICATION (5.1.24 / 6.1.4) UNCLASSIFIED MIN. DESIGN METAL TEMP. (5.12.4.1) -29 (C)

27 CL. GR. Zone REDUCED HARDNESS MATERIALS REQ'D. (5.12.1.12)

28 WINTERIZATION REQ'D TROPICALIZATION REQ'D. BARREL / CASE A216WCB IMPELLER A487CA6NM

29 SITE DATA (5.1.30) CASE / IMPELLER WEAR RINGS A473-420

30 ALTITUDE 593.4 (m) BAROMETER 94.4 kPa (Abs.) SHAFT A276-410 1B

31 RANGE OF AMBIENT TEMP, MIN. / MAX. +5 / + 40 (C) DIFFUSERS

32 RELATIVE HUMIDITY: MIN. / MAX. / (%)

33 UNUSUAL CONDITIONS: (5.1.30) DUST FUMES PERFORMANCE: @ 1.00 SG

34 OTHER PROPOSAL CURVE NO. 6UZDL25-BS1-F 1783 RPM 1B

35 Refer to Site Conditions Data Sheet DS93-A-1-1 for more IMPELLER DIA. RATED 593 MAX. 650.0 MIN. 500.0 (mm) 1B

36 information. IMPELLER TYPE CLOSED

37 DRIVER TYPE RATED POWER 687.4 (kW) EFFICIENCY 72.5 (%) 1B

38 INDUCTION MOTOR STEAM TURBINE GEAR MINIMUM CONTINUOUS FLOW:

3 3

39 OTHER THERMAL (m / h) STABLE 300 (m / h)

40 PREFERRED OPER. REGION 438 TO 750 (m3 / h)

3

41 MOTOR DRIVER (6.1.1 / 6.1.4) ALLOWABLE OPER. REGION 300 TO 750 (m / h)

42 MANUFACTURER TECO - Westinghouse MAX HEAD @ RATED IMPELLER 342 (m) 1B

43 (1000 HP) 745.7 (kW) 1800 (RPM) MAX POWER @ RATED IMPELLER 745 (kW) 1B

44 FRAME 4010 ENCLOSURE WPII NPSHR AT RATED FLOW 4.0 (m) (5.1.10) 1B

45 HORIZONTAL VERTICAL SERVICE FACTOR 1.15 MAX. SUCTION SPECIFIC SPEED 9204 (5.1.11)

46 VOLTAGE / PH. / HZ. 4000 / 3 / 60 MAX. SOUND PRESS. LEVEL REQ'D. <85 (dBA) (5.1.16)

47 TYPE Squirrel Cage Induction EST. MAX. SOUND PRESS. LEVEL 92.2 (dBA) (5.1.16) 1B

48 MINIMUM STARTING VOLTAGE (6.1.5) EST. MAX. SOUND POWER LEVEL (dBA) (5.1.16)

49 INSULATION Class F TEMP. RISE Class B UTILITY CONDITIONS

50 FULL LOAD AMPS ELECTRICITY VOLTAGE PHASE HERTZ

51 LOCKED ROTOR AMPS DRIVERS 4160 3 60

52 STARTING METHOD Across the line HEATER 120 1 60

53 LUBE See Note 2 SYSTEM VOLTAGE DIP 80% OTHER (6.1.5)

54 BEARINGS (TYPE / NUMBER): STEAM N/A MAX. PRESS. MAX. TEMP. MIN. PRESS. MIN. TEMP.

55 RADIAL split - sleeve / DRIVERS

56 THRUST split - sleeve / HEATER

57 VERTICAL THRUST CAPACITY COOLING TEG: (5.1.19) SOURCE Plant Cooling Glycol System 1B

58 UP (N) DOWN (N) SUPPLY TEMP. 45 (C) MAX. RETURN TEMP. (C) 1B

59 See Motor Data Sheet DS95-P-GM3215-1. NORM. PRESS. 2100 (kPag) DESIGN PRESS. 2400 @ 80oC (kPag) 1B

60 MIN. RET. PRESS. (kPag) MAX. ALLOW. D.P. 70 (kPag) 1B

61 CHLORIDE CONCENTRATION: (mg / kg)

1B 31-Jan-08 Re-issued For Purchase CY NS CY TP SD DATA SHEET FOR

1A 1-Jun-07 Issued For Purchase GO ES CY TP SD 95G-3215

No. DATE REVISION BY CHK ENG. APPR. OTHER

FOR: Suncor Energy Project No. 03-00061A 1B

LOCATION: Firebag Stage 5, Fort McMurray, Alberta DOCUMENT NO. REV.

SERVICE: LP BFW Pump

DS95-A-G3215-1 1B

EQUIPMENT NO. 95G-3215

SM 23/01/2006 DS-Pump-API 610 10th Ed. Centrifugal Template REV 0 PROCESS DATA SHEET SHT 1 OF 5

API 610 10TH EDITION (ISO 13709) MR No. MR95-G-8-1 Item No. 95G-3215

CENTRIFUGAL PUMP PROCESS DATA SHEET Inquiry No. MR95-G-8-1

(SI UNITS) By: C.Yu Date: 31-Jan-08

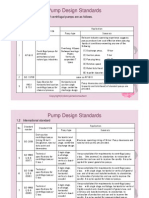

1 NOTES

2 1. Pump lube oil shall be Mobil SCH 626 (ISO VG68)

3

4 2. Motor lubrication shall be Mobil SCH 626 (ISO VG68)

5

6 3. Seller shall provide casing drains and vents in accordance to the detail below and Suncor Piping Material Class ES on the low point 1B

7 of the pump casing. Seller shall provide a Gate Valve, i.e., Class 300 RF to ASME B16.5, Forged Body w/integral flanges,

8 Bolted Bonned, OS & Y, Solid Wedge, API Trim 8, Integral or Renewable seats, Regular Port, Design to API 602.

9 Seller shall attach a Suncor valve tag number of VGA0315#8.

10 All casing drains shall be terminated at one common skid edge flanged connection. All casing vents shall be terminated at one 1B

11 common skid edge flanged connection. Each casing drain and vent line shall have provision for individual isolation valve. 1B

12

CASING DRAIN AND VENT DETAILS

13

14

15

16

17 Nipple shall be combined with other

Pump Casing casing drain and vent lines (as

18 Gussets in 2 planes shall be

of the same metallurgy as applicable), and extended to the

19 pump casing, 90 apart. 1B

edge of baseplate, terminated in a

20 common skid connection

21

22

23

24

25 1B

26

27 VGA-0315#8

28

29

30

31 S.W. Gaskets shall be spiral wound

316SS graphite filled, c/w CS S.W.

32 outer ring per ASME 16.20

33

34

35 Valves shall be tagged with metal tags stamped with Suncor valve number.

36 The metal tags shall be stainless steel, minimum size 18mm x 50mm and

shall be attached to valves with minimum 20 gauge strand SS wire.

37

38 4. NPSHR at normal flow of 545 m3/h is 2.0 m. The NPSHA shown is based on the normal temperature of 85C. 1B

39

40 5. Baseplate for pump and motor shall be engineered and designed for non-grout construction. However, grout holes shall be

41 provided.

42

43 6. Content for this Data Sheet is based on Suncor Firebag Stage 3 Data Sheet DS93-A-G3215-1 Rev 1D 1B

44

45 7. This pump 95G-3215 is identical to Stage 3 Pump 93G-3215. 1B

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

FOR: Suncor Energy Project No. 03-00061A 1B

LOCATION: Firebag Stage 5, Fort McMurray, Alberta DOCUMENT NO. REV.

SERVICE: LP BFW Pump

DS95-A-G3215-1 1B

EQUIPMENT NO. 95G-3215

SM 23/01/2006 DS-Pump-API 610 10th Ed. Centrifugal Template REV 0 PROCESS DATA SHEET SHT 2 OF 5

You might also like

- Api 618 4th Ed Si DatasheetsDocument17 pagesApi 618 4th Ed Si Datasheetshmshawki100% (5)

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- Pump DatasheetDocument10 pagesPump DatasheetPaulusIwan100% (1)

- Rotary Compressor API 619Document26 pagesRotary Compressor API 619EDUARDO25% (4)

- API 676 3rd Edition Comparative Summary-FinalDocument35 pagesAPI 676 3rd Edition Comparative Summary-Finaltarunvarshneya50% (2)

- ULC UL142 Comparison SpreadsheetDocument43 pagesULC UL142 Comparison Spreadsheetdiv_misNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- API 675 Data Sheet SIDocument2 pagesAPI 675 Data Sheet SIhappale2002100% (3)

- API 676 DatasheetDocument2 pagesAPI 676 DatasheetTony_Black9950% (2)

- API Standard 619 - Rotary-Type Displacement Compressors For Petroleum, Chemical, and Gas Industry ServicesDocument2 pagesAPI Standard 619 - Rotary-Type Displacement Compressors For Petroleum, Chemical, and Gas Industry ServicesmishraenggNo ratings yet

- API 610 11th Edition (New Items)Document12 pagesAPI 610 11th Edition (New Items)Tirta Budiawan100% (2)

- IPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpDocument4 pagesIPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpsudjonoNo ratings yet

- Pump Standards ComparisonDocument4 pagesPump Standards ComparisonAnish Dani50% (2)

- Stahl' Essential Psychopharmacology 275 PDFDocument1 pageStahl' Essential Psychopharmacology 275 PDFMuhammad AzkaNo ratings yet

- API 570 Exam June 1Document24 pagesAPI 570 Exam June 1Sudarshan79% (14)

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNo ratings yet

- API 610 Data Sheet 1 PDFDocument6 pagesAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNo ratings yet

- Pressure Vessel Nozzle LoadsDocument2 pagesPressure Vessel Nozzle Loadsrenji_danny100% (2)

- Centrifugal Pump Data SheetDocument4 pagesCentrifugal Pump Data SheetJohnNo ratings yet

- Centrifugal Pump - Horizontal End Suction - Asme B73.1Document3 pagesCentrifugal Pump - Horizontal End Suction - Asme B73.1wado11No ratings yet

- EXAMPLE SIZING OWS Calculation Per API 421 PDFDocument1 pageEXAMPLE SIZING OWS Calculation Per API 421 PDFarnel_ado4412No ratings yet

- Ficha Técnica - ElectricaDocument8 pagesFicha Técnica - ElectricainspeccionestecnicasnfpaNo ratings yet

- Centrifugal Pump Data SheetDocument1 pageCentrifugal Pump Data Sheetpkitchen25No ratings yet

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- Native Data Sheet Asme b73.1Document4 pagesNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Document14 pagesA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNo ratings yet

- BB3 Vs BB5Document10 pagesBB3 Vs BB5kambleyogNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- 1 - Ansi Flange CheckDocument3 pages1 - Ansi Flange CheckJorge Hugo CorreaNo ratings yet

- Guidelines For The Preparation of Strainer SpecificationDocument10 pagesGuidelines For The Preparation of Strainer Specificationssmith2007No ratings yet

- Is 5120Document52 pagesIs 5120Otavio123No ratings yet

- API 610 11th Ed DatasheetDocument13 pagesAPI 610 11th Ed DatasheetHatem ShawkiNo ratings yet

- TBE Pumps CP 16Document21 pagesTBE Pumps CP 16ivomNo ratings yet

- (GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Document3 pages(GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Said ArjonaNo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- Data Sheet P-0560 - Hot Oil Drain Tank Sump PumpDocument2 pagesData Sheet P-0560 - Hot Oil Drain Tank Sump Pumpcygnus marine panamaNo ratings yet

- 1.tbe1 Fire PumpDocument11 pages1.tbe1 Fire Pumpvinoj chandranNo ratings yet

- Cold Venting As API 521 To Discharge HCDocument4 pagesCold Venting As API 521 To Discharge HCkenoly123100% (1)

- G-Pi-230 (Strainers and Filters)Document23 pagesG-Pi-230 (Strainers and Filters)arianaseriNo ratings yet

- DHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageDocument61 pagesDHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageThanh Tin NguyenNo ratings yet

- Specification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessDocument30 pagesSpecification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessFrancisco Gonzalez100% (2)

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- RR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction OrificeDocument16 pagesRR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction Orificemohsen ranjbar100% (1)

- Flat To Steep Curve - Orifice Plate at Pump DischargeDocument1 pageFlat To Steep Curve - Orifice Plate at Pump Dischargeorchids28No ratings yet

- Data SheetDocument6 pagesData Sheetmkfe2005No ratings yet

- GIS 34-302 - 11 January, 2010 PDFDocument21 pagesGIS 34-302 - 11 January, 2010 PDFYT100% (1)

- Preview of API 610 12th EditionDocument7 pagesPreview of API 610 12th EditionHatem ShawkiNo ratings yet

- 610 10th Ed Datasheets (SI)Document11 pages610 10th Ed Datasheets (SI)sjois_hsNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Api 671Document6 pagesApi 671ecsuperalNo ratings yet

- Pump Sizing (Si Units) : Equipment Number Service Fluid Pumped DutyDocument2 pagesPump Sizing (Si Units) : Equipment Number Service Fluid Pumped Dutydeion29No ratings yet

- Specification For Firewater Pump Package S 721v2020 08Document90 pagesSpecification For Firewater Pump Package S 721v2020 08Serge RINAUDONo ratings yet

- 01-Apiflo Oh2 80-365-9-S-6-DS - RaDocument4 pages01-Apiflo Oh2 80-365-9-S-6-DS - RapaachangaNo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- Data Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / BeyDocument8 pagesData Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / Beyrajindo1No ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Data Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- CWC Mec DTS P002abDocument8 pagesCWC Mec DTS P002abAlonso1593No ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Roy Tronic CatalogueDocument4 pagesRoy Tronic CatalogueMuhammad AzkaNo ratings yet

- Research Article Candida RugosaDocument8 pagesResearch Article Candida RugosaMuhammad AzkaNo ratings yet

- 12NitbaniEtal2016OJC Vol32 No6 P 3113-3120Document9 pages12NitbaniEtal2016OJC Vol32 No6 P 3113-3120Muhammad AzkaNo ratings yet

- Membangun Kembali Organisasi Berbasis Gerakan: Ippa As A Movement Based OrganizationDocument27 pagesMembangun Kembali Organisasi Berbasis Gerakan: Ippa As A Movement Based OrganizationMuhammad AzkaNo ratings yet

- 0 1618472994 - Company Profile DHCDocument16 pages0 1618472994 - Company Profile DHCMuhammad AzkaNo ratings yet

- Transmittal Sheet 1808-T-RJ-PJ-099SDocument2 pagesTransmittal Sheet 1808-T-RJ-PJ-099SMuhammad AzkaNo ratings yet

- Pltu Sorong (Ex. Timika) 4 X 7 MW Sorong, Papua Barat: Quality Control Plan Turbine & CondenserDocument96 pagesPltu Sorong (Ex. Timika) 4 X 7 MW Sorong, Papua Barat: Quality Control Plan Turbine & CondenserMuhammad AzkaNo ratings yet

- Transmittal Sheet 1808-T-RJ-PJ-102SDocument3 pagesTransmittal Sheet 1808-T-RJ-PJ-102SMuhammad AzkaNo ratings yet

- Pi Is 0015028202048008Document13 pagesPi Is 0015028202048008Muhammad AzkaNo ratings yet

- Keehbauch Menopause HRT 4.2.16 SCDocument55 pagesKeehbauch Menopause HRT 4.2.16 SCMuhammad AzkaNo ratings yet

- Hoistcrane Quotation: Technical Specification, Features and Descriptions of QuotationDocument6 pagesHoistcrane Quotation: Technical Specification, Features and Descriptions of QuotationMuhammad AzkaNo ratings yet

- Management of Uterine Inversion: Operative TechniquesDocument4 pagesManagement of Uterine Inversion: Operative TechniquesMuhammad AzkaNo ratings yet

- Total and Acute Uterine Inversion After Delivery: A Case ReportDocument5 pagesTotal and Acute Uterine Inversion After Delivery: A Case ReportMuhammad AzkaNo ratings yet

- Stahl' Essential Psychopharmacology 291Document1 pageStahl' Essential Psychopharmacology 291Muhammad AzkaNo ratings yet

- Stahl' Essential Psychopharmacology 274Document1 pageStahl' Essential Psychopharmacology 274Muhammad AzkaNo ratings yet

- Stahl' Essential Psychopharmacology 276 PDFDocument1 pageStahl' Essential Psychopharmacology 276 PDFMuhammad AzkaNo ratings yet

- Stahl' Essential Psychopharmacology 273Document1 pageStahl' Essential Psychopharmacology 273Muhammad AzkaNo ratings yet

- Extract Goodwin Dual Plate Tech CatDocument32 pagesExtract Goodwin Dual Plate Tech Catالم زمانNo ratings yet

- 03 PAES Master Catalog 39th Edition Aeration PDFDocument66 pages03 PAES Master Catalog 39th Edition Aeration PDFjcbobedaNo ratings yet

- Piping Class Spec. - 1c23pe (Lurgi)Document5 pagesPiping Class Spec. - 1c23pe (Lurgi)otezgidenNo ratings yet

- CAIRN-TSG-M-SP-0026-B1-Specification For Basket FilterDocument10 pagesCAIRN-TSG-M-SP-0026-B1-Specification For Basket FilterMurli RamchandranNo ratings yet

- Astm B 306 - 2002 PDFDocument12 pagesAstm B 306 - 2002 PDFSSSoomroNo ratings yet

- Boletin 751 Doble Interlock Electrico-MecanicoDocument18 pagesBoletin 751 Doble Interlock Electrico-MecanicoL ONo ratings yet

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDocument1 pageBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNo ratings yet

- Magnetrol 961Document8 pagesMagnetrol 961Andres LeonNo ratings yet

- TRHT TB PL 18 OO 202 - 0 - SignedDocument20 pagesTRHT TB PL 18 OO 202 - 0 - Signedbelhaska100% (1)

- PN Series ManualDocument23 pagesPN Series ManualgminayasNo ratings yet

- Purchase A Qualified Valve For Your Operation: Back To BasicsDocument8 pagesPurchase A Qualified Valve For Your Operation: Back To BasicsasdrumelNo ratings yet

- OM 80 DatasheetDocument2 pagesOM 80 Datasheetamirhosseine00No ratings yet

- Toyo - Heat Exchanger-1Document70 pagesToyo - Heat Exchanger-1alokbdas100% (1)

- 15CSTL NaDocument3 pages15CSTL NaVipin NairNo ratings yet

- QT1-0-Q-030-05-00062 - A - ITP For Duct InstallationDocument29 pagesQT1-0-Q-030-05-00062 - A - ITP For Duct InstallationLâm HuyNo ratings yet

- How Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedDocument2 pagesHow Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedTay Hua SetNo ratings yet

- Manuals 167d 167da 167ds 167das Switching Valves Instruction Manual Fisher en en 6075304Document12 pagesManuals 167d 167da 167ds 167das Switching Valves Instruction Manual Fisher en en 6075304shb soomroNo ratings yet

- Tts Crane GPK 260-6-17Document31 pagesTts Crane GPK 260-6-17serg_i_usNo ratings yet

- 2011 VND O&M ManualDocument12 pages2011 VND O&M Manualsequeira.cedric6742No ratings yet

- Hydraulic System For Stacker Instruction ManualDocument367 pagesHydraulic System For Stacker Instruction ManualTuấn100% (1)

- Method Statement For HRSG Works PDFDocument116 pagesMethod Statement For HRSG Works PDFJyoti TturboNo ratings yet

- EN 1092-1 PN-40 Steel Pipe Flange - Valvias PDFDocument5 pagesEN 1092-1 PN-40 Steel Pipe Flange - Valvias PDFHoria ZecheruNo ratings yet

- SOW Dan SOS Hydrotest. R.0Document2 pagesSOW Dan SOS Hydrotest. R.0Adi PurnomoNo ratings yet

- Mega Parts Book - Vol 2Document102 pagesMega Parts Book - Vol 2Mohamed Cheikh100% (1)

- Destec G RangeBrochureDocument16 pagesDestec G RangeBrochureltrongluanvn100% (2)

- Specification FOR Non Metallic Expansion Joints (Flue Gas Duct)Document22 pagesSpecification FOR Non Metallic Expansion Joints (Flue Gas Duct)liNo ratings yet

- CR, CRN High Pressure: Grundfos Product GuideDocument48 pagesCR, CRN High Pressure: Grundfos Product Guiderodriguez.gaytanNo ratings yet

- Vent&BlowdownCatalog PDFDocument19 pagesVent&BlowdownCatalog PDFktsnl100% (1)

- CF Hydraulic Sampling Products.01Document18 pagesCF Hydraulic Sampling Products.01Patrick FoNo ratings yet