Professional Documents

Culture Documents

5S Implementation Audit: 5S To-Do Items Observed Condition Improvement Action

5S Implementation Audit: 5S To-Do Items Observed Condition Improvement Action

Uploaded by

Javier GutierrezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5S Implementation Audit: 5S To-Do Items Observed Condition Improvement Action

5S Implementation Audit: 5S To-Do Items Observed Condition Improvement Action

Uploaded by

Javier GutierrezCopyright:

Available Formats

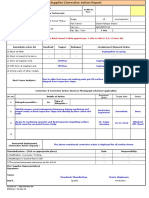

Location Being Audited:

(place cursor in red corner for INSTRUCTIONS)

5S Implementation Audit {Enter Location here}

I

5S To-Do Items Observed Condition m Improvement Action

p

l

Remove unneeded equipment, tools, e

furniture, etc. m

e

Provide information on n

department PPB Remove unnecessary items. All items not required for

Sort

t

Review excess inventory, supplies, performing operations are removed from the work area. Only 0 a

t

parts, or materials tools and products are present at workstation i

Identify existence of safety hazards o

(water, oil, chemical, machines, n

extension cords, etc.) C

h

Storage of cleaning equipment: All cleaning equipment e

stored in a neat manner; handy and readily available when 0 c

k

needed -

o

Items on floor: Work-in-process, tools and any other f

material are not left to sit directly on the floor. Large items f

such as tote boxes are positioned on the floor in clearly 0

marked area, identified by painted or taped lines.

Correct location for items are Storage and arrangement:: Boxes, containers, and materials

identified are always stored neat and at correct work angles convenient

Straighten

Items are placed in their correct to the operators where appropriate. When items are

locations stacked evenly or in a manner that would not cause them to

Aisle ways, workstations, equipment toppling over. Storage areas are provided for all necessary 0

locations are indicated items at POUS (Point-Of-Use Storage). No items are placed

Items are put away immediately on top of machines, cabinets, and equipment. Unidentified

after use items can not lean against walls or columns.

Inventory or WIP height and quantity

limits are obvious Operating equipment/machinery: Each piece of

equipment/machinery has guards and deflectors that prevent 0

debris from falling uncontained to the floor.

Document storage: Only documents necessary to the

operation are stored at the workstations and are stored in a 0

neat and orderly manner.

Tool and gauges arrangement: Tools, gages and fixtures are

arranged neatly and stored, kept clean and free of any risk of 0

damage.

Aisle ways maintenance: Aisles are always free of materials

Floors, walls, stairs, and surfaces are and obstructions; nothing is placed on the lines and objects

free of dirt, oil and grease are always placed at right angles to the aisles where 0

Equipment is kept clean and free of appropriate.

dirt, oil, and grease

Shine

Cleaning materials are easily Equipment painting: All machines and equipment are neatly

accessible painted; equipment cleaning schedule developed and 0

Lines, labels, signs, etc. are clean posted for each major piece of equipment.

and not damaged

No other cleaning problems Workbench and desk control: Kept free of objects including

(of any kind) are present records and documents (unless in use). Tools and fixtures 0

are clean and placed in their proper location.

Information boards: PPB, COBs, and PABs are arranged in a

neat and orderly manner. No outdated, torn, or soiled 0

documents are displayed

Emergency access: Fire hoses and emergency equipment

are unobstructed and stored in a prominent easy-to-locate

area with proper identification. E-Stop switches and 0

breakers are marked or color-coded for immediate visibility.

Necessary information is visible

Standardize

All standards are known and visible Aisle ways marking: Aisles and walkways are clearly

Checklists exist for all cleaning and marked and can be identified at a glance; lines are straight

TPM maintenance jobs and at right angles where appropriate with no chipped, worn 0

All quantities and limits are easily floor marking.

recognizable Equipment maintenance: Controls of machines are properly

All necessary items can be located labeled. Critical points for daily maintenance checks are

in 30 seconds clearly marked. Equipment check sheets are clean, neatly 0

displayed and completed daily.

Tool and gauges convenience: Tools, gages and fixtures are

arranged so they can be easily accessed when needed. 0

Shelves and benches arrangement: Arranged, divided and

clearly labeled it is obvious where things are stored; status 0

and condition is recorded

Document control: All documents are labeled clearly as to

content and responsibility for control and revision. Obsolete 0

or unused documents are routinely removed

All team members have had Equipment cleanliness: All machines and equipment are

5S training kept clean by routine daily care. 0

Daily 5S actions performed Floor cleaning: All floors are clean and free of debris, oil and

Sustain

Place all personal belongings

stored in a neatly maintained

dirt. Cleaning of floors is done routinely -- daily at a minimum 0

posted schedule.

location

Job aids are current and readily

5S control and maintenance: There is a disciplined system

accessible

of control and it is maintained at the highest possible level. It

Routine 5S Implementation Audit

is performed until sustained

is the responsibility of every one to maintain this system and 0

environment. Documentation exist indicating cleaning

responsibility for each team member in the work area.

Legend: <2 (RED) 2 to 4.75 >4.75 (GREEN) 5S Implementation Audit Score = 0.00

Siegel-Robert, Inc. -- Confidential CENG-LE-F016 (1)

You might also like

- 4 Ram Changeover Analysis Part 1Document2 pages4 Ram Changeover Analysis Part 1lam nguyen0% (1)

- Horse Stable and Riding Arena DesignDocument313 pagesHorse Stable and Riding Arena DesignRadu Iliescu100% (5)

- SEMA Racking User CodePDF PDFDocument47 pagesSEMA Racking User CodePDF PDFJawad RafiqNo ratings yet

- Smed Forms For Lean ProjectsDocument11 pagesSmed Forms For Lean ProjectscivanusNo ratings yet

- RCM II Decision Diagram - v2Document2 pagesRCM II Decision Diagram - v2Javier Gutierrez100% (1)

- 5S Audit Checklist - Supply StorageDocument16 pages5S Audit Checklist - Supply StorageJavier GutierrezNo ratings yet

- Welding Booth Layout DrawingDocument1 pageWelding Booth Layout DrawingJavier GutierrezNo ratings yet

- Housekeeping at WorkDocument4 pagesHousekeeping at WorkSavantNo ratings yet

- JH Checksheet AwarenessDocument13 pagesJH Checksheet AwarenesspriyankaNo ratings yet

- VSM 1hr PresentationDocument25 pagesVSM 1hr PresentationGilson Vieira100% (1)

- Improvement KaizenDocument11 pagesImprovement KaizenAnkur DhirNo ratings yet

- Equipment Name Theme Division TPM Pillar Pilllar Step Basic Work Minor Classification Classification No: Major ClassificationDocument1 pageEquipment Name Theme Division TPM Pillar Pilllar Step Basic Work Minor Classification Classification No: Major ClassificationGiö GdlNo ratings yet

- A3Document1 pageA3chavesierra20081 SierraNo ratings yet

- 5S Audit MudaMastersDocument1 page5S Audit MudaMastersManoj ShahNo ratings yet

- Small Business Safety Checking Out Your Workplace Checklist 1284Document8 pagesSmall Business Safety Checking Out Your Workplace Checklist 1284Farra CartoumNo ratings yet

- 7qc ToolsDocument38 pages7qc Toolsapi-359300000No ratings yet

- 00the 7 MFG WasteDocument15 pages00the 7 MFG WasteRohit Prakash100% (1)

- 7QC Tools - Training WorkshopDocument10 pages7QC Tools - Training Workshopb-consultant960No ratings yet

- 5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsDocument21 pages5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsAtul SharmaNo ratings yet

- Chromatography Solution: 5S AuditDocument3 pagesChromatography Solution: 5S Auditabhijit612No ratings yet

- Visual Management: Using Visual Elements To Control Work and Monitor StatusDocument9 pagesVisual Management: Using Visual Elements To Control Work and Monitor StatusFran JimenezNo ratings yet

- 5S ManualDocument26 pages5S ManualHariharan PNo ratings yet

- BP-5.1.2D OJT Effectiveness SHEET - Level-2Document1 pageBP-5.1.2D OJT Effectiveness SHEET - Level-2shinuNo ratings yet

- Poka Yoke Implementation PPTDocument31 pagesPoka Yoke Implementation PPTMURALIDHRANo ratings yet

- 5S - Check ListDocument3 pages5S - Check ListJayendra RajeshirkeNo ratings yet

- 5S EnglishDocument33 pages5S EnglishpriyankaNo ratings yet

- 5s Checklist OperationDocument1 page5s Checklist OperationDian PeshevNo ratings yet

- TPM Steps 1 JHDocument10 pagesTPM Steps 1 JHGyanesh_DBNo ratings yet

- Internal Auditor Training WorkshopC-MeyerDocument39 pagesInternal Auditor Training WorkshopC-MeyerOratexaNo ratings yet

- NAME OF COMPANY - 5S Audit ChecklistDocument2 pagesNAME OF COMPANY - 5S Audit ChecklistDũng Tây NinhNo ratings yet

- Promblem Solving Combined March 2017 AnelleDocument25 pagesPromblem Solving Combined March 2017 AnelleSravan DasariNo ratings yet

- 5S Training ModuleDocument117 pages5S Training ModulePRABHAT RANJANNo ratings yet

- Standardization Basics-24 Jul 09Document11 pagesStandardization Basics-24 Jul 09Dilfaraz KalawatNo ratings yet

- JH Step-1 & 2activitiesDocument34 pagesJH Step-1 & 2activitiesGREENEXE BUSINESS CONSULTANTNo ratings yet

- 6s Evaluation FormDocument3 pages6s Evaluation FormDhananjay PatilNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Skill Matrix: 1 - Basic Trg. AcquiredDocument4 pagesSkill Matrix: 1 - Basic Trg. AcquiredDinesh KumarNo ratings yet

- Week 10 - Autonomous Defects Control (Pokayoke Jidoka)Document43 pagesWeek 10 - Autonomous Defects Control (Pokayoke Jidoka)Nguyễn Ngọc Minh Quân100% (1)

- Implementation & Monitoring: (Work Place Improvement)Document112 pagesImplementation & Monitoring: (Work Place Improvement)Sonika SinghNo ratings yet

- 7 QC Tools - TrainingDocument27 pages7 QC Tools - TrainingRadhika GuptaNo ratings yet

- 3L and 5 Why Presentation - MKGDocument70 pages3L and 5 Why Presentation - MKGMukesh GuptaNo ratings yet

- FYP PosterDocument1 pageFYP PosterMuhammad HassanNo ratings yet

- Am Board DesignDocument1 pageAm Board DesignJoseph OrjiNo ratings yet

- GM 1927 87 Special Nonconforming Material AuditDocument6 pagesGM 1927 87 Special Nonconforming Material AuditNeumar Neumann100% (1)

- RCA SampleDocument2 pagesRCA Sampleedward tagarino100% (1)

- Clause Wise Tutorials-7.1.4 Change Control ExplanationDocument2 pagesClause Wise Tutorials-7.1.4 Change Control ExplanationBharathNo ratings yet

- Lay Out OptimizationDocument43 pagesLay Out OptimizationRagul VinothNo ratings yet

- Supplier War Room UpdatesDocument37 pagesSupplier War Room UpdatesMUNENDRA SHAKYANo ratings yet

- Measurement System AnalysisDocument2 pagesMeasurement System AnalysispsathishthevanNo ratings yet

- JH - Kaizen Training ModuleDocument19 pagesJH - Kaizen Training Moduleshariq warsi100% (1)

- 5S Visual Management Jun-20Document73 pages5S Visual Management Jun-20Vipul Jha100% (1)

- CPCL TPM AnalysisDocument67 pagesCPCL TPM AnalysisKhader HussainNo ratings yet

- Guide KaizenDocument15 pagesGuide KaizenScribdhaizanNo ratings yet

- Anand Kumar ResumeDocument3 pagesAnand Kumar ResumeArun ShishodiaNo ratings yet

- 8DDocument117 pages8DLokesh NarasimhaiahNo ratings yet

- Lean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTDocument16 pagesLean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTRohit SatijaNo ratings yet

- A Strategy For Performance ExcellenceDocument32 pagesA Strategy For Performance ExcellenceChetan GoyalNo ratings yet

- Lean Manufacturing 7 WastesDocument10 pagesLean Manufacturing 7 WastesArturo TorresNo ratings yet

- Supplier Manual-7th Revision - April 23 FinalDocument35 pagesSupplier Manual-7th Revision - April 23 FinalvishnuNo ratings yet

- Punch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20Document1 pagePunch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20R KumarNo ratings yet

- QA-SQA-003 Supplier Quality System Audit CAPA by SupplierDocument11 pagesQA-SQA-003 Supplier Quality System Audit CAPA by SupplierAbhishek AllenNo ratings yet

- Kaizen 5W 1H PDFDocument20 pagesKaizen 5W 1H PDFSUBA NANTINI A/P M.SUBRAMANIAMNo ratings yet

- Process Objectives Issues Risk Control Measure/ Action Plan REF Documented Informatio N RemarksDocument1 pageProcess Objectives Issues Risk Control Measure/ Action Plan REF Documented Informatio N RemarkstriveshNo ratings yet

- Stage Step (Nakajima's 12 Steps) : Decision To Introduce TPMDocument16 pagesStage Step (Nakajima's 12 Steps) : Decision To Introduce TPMKarisma Lumban GaolNo ratings yet

- Approximate Vibration Levels enDocument2 pagesApproximate Vibration Levels enJavier GutierrezNo ratings yet

- Lube Oil Pump B Vibration 270219Document7 pagesLube Oil Pump B Vibration 270219Javier GutierrezNo ratings yet

- Motor Bars All1Document158 pagesMotor Bars All1Javier GutierrezNo ratings yet

- Soft FootDocument1 pageSoft FootJavier GutierrezNo ratings yet

- Parameter ProfileDocument1 pageParameter ProfileJavier GutierrezNo ratings yet

- GM Motors &DELPHI Vibration STD PDFDocument66 pagesGM Motors &DELPHI Vibration STD PDFMachineryeng0% (1)

- Motor DatabaseDocument55 pagesMotor DatabaseJavier GutierrezNo ratings yet

- Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Document8 pagesGap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Javier Gutierrez100% (1)

- Gear Ring Radial AlignmentDocument2 pagesGear Ring Radial AlignmentJavier GutierrezNo ratings yet

- Horizontal Alignment FormsDocument6 pagesHorizontal Alignment FormsJavier GutierrezNo ratings yet

- Control of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsDocument3 pagesControl of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsJavier GutierrezNo ratings yet

- Kiln Maintenance ManualDocument111 pagesKiln Maintenance ManualJavier Gutierrez100% (5)

- Beck CatalogDocument88 pagesBeck CatalogJavier GutierrezNo ratings yet

- DILO TM1 - Tecnico de Molienda - 150310Document26 pagesDILO TM1 - Tecnico de Molienda - 150310Javier GutierrezNo ratings yet

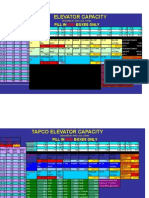

- Enigineering Capacity CalculatorDocument2 pagesEnigineering Capacity CalculatorJavier GutierrezNo ratings yet

- Product Demand SimulatorDocument50 pagesProduct Demand SimulatorJavier GutierrezNo ratings yet

- 8050T081 PDFDocument27 pages8050T081 PDFJavier GutierrezNo ratings yet

- Handbook To The Cathedrals of England-Tom1 PDFDocument540 pagesHandbook To The Cathedrals of England-Tom1 PDFPrivremenko Jedan50% (2)

- NBCDocument172 pagesNBCCnkf San Juan Chapter100% (1)

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014Document5 pagesMVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014BALACHANDAR SNo ratings yet

- Foulias The Basilica of Saint EpiphaniosDocument14 pagesFoulias The Basilica of Saint EpiphaniosARISTEIDIS VIKETOSNo ratings yet

- Impact of Imtiaz Store Design and Layout On Customer Mind: Layout/Circulation Plan: A) Inside StoreDocument4 pagesImpact of Imtiaz Store Design and Layout On Customer Mind: Layout/Circulation Plan: A) Inside StoreImamaTariqNo ratings yet

- Design & Layout of Foodservice FacilitiesDocument33 pagesDesign & Layout of Foodservice Facilitiesmanishpandey1972100% (2)

- Time Saver Standards For Building Types Chapter ClassroomDocument3 pagesTime Saver Standards For Building Types Chapter Classroomcharm_choky50% (6)

- Racetrack RMDocument3 pagesRacetrack RMVikas GuptaNo ratings yet

- Live LoadDocument2 pagesLive LoadAdil Rasheed KhanNo ratings yet

- TN Panchayat Building Rules 1997Document22 pagesTN Panchayat Building Rules 1997krish1979No ratings yet

- Aisle Directory. GalleryDocument11 pagesAisle Directory. Galleryninimania1No ratings yet

- Data CollectionDocument13 pagesData Collectionmehnaz khan100% (1)

- Fire Code TheaterDocument7 pagesFire Code TheaterCarl John CalaraNo ratings yet

- BT Optio H-Series - TMHIDocument141 pagesBT Optio H-Series - TMHIPatricio CastroNo ratings yet

- PT 2 Final ?Document23 pagesPT 2 Final ?Kimberly Dulnuan PuguonNo ratings yet

- BS6399!1!1996Loading For Buildings Part 1. Code of Practice For Dead andDocument15 pagesBS6399!1!1996Loading For Buildings Part 1. Code of Practice For Dead andEldin PepelarNo ratings yet

- Literature Study-Convection CenterDocument5 pagesLiterature Study-Convection CenterRithika Raju ChallapuramNo ratings yet

- Time-Saver Standards For Building Types - 2nd Edition Educational ChapterDocument93 pagesTime-Saver Standards For Building Types - 2nd Edition Educational ChapterAaron CansinoNo ratings yet

- Materials Management in Voluntary HospitalsDocument20 pagesMaterials Management in Voluntary HospitalsPham PhongNo ratings yet

- Four Wheeler Basement Parking Planning GDocument82 pagesFour Wheeler Basement Parking Planning GPushpak GaikarNo ratings yet

- ALL SUBJECTS - ARHITECTURE REVIEWER (Sorted)Document20 pagesALL SUBJECTS - ARHITECTURE REVIEWER (Sorted)K PNo ratings yet

- Accessible Communities CaliforniaDocument57 pagesAccessible Communities CaliforniaprowagNo ratings yet

- Facility Layout ProjectDocument17 pagesFacility Layout ProjectaakineNo ratings yet

- Krautheimer, The Constantinian BasilicaDocument33 pagesKrautheimer, The Constantinian BasilicaLady Jovana Lazic100% (1)

- Parking Lot DesignDocument29 pagesParking Lot DesignAbdurahimNo ratings yet

- 2015 IBC Chapter 10 ExcerptDocument2 pages2015 IBC Chapter 10 ExcerptLilBortNo ratings yet

- National Building Code of The Philippines (PD 1096) : Building Laws To Be AppliedDocument17 pagesNational Building Code of The Philippines (PD 1096) : Building Laws To Be AppliedRio GarciaNo ratings yet