Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

136 viewsGuideline Sapex Packer

Guideline Sapex Packer

Uploaded by

imampranadipaPacker Guideline

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- BHA PicturesDocument29 pagesBHA PicturesimampranadipaNo ratings yet

- 4 6048518304547476951 PDFDocument245 pages4 6048518304547476951 PDFimampranadipaNo ratings yet

- Patrick Okimi - Casing Design Horizontal WellsDocument14 pagesPatrick Okimi - Casing Design Horizontal WellsimampranadipaNo ratings yet

- PDC Dull GradingDocument52 pagesPDC Dull GradingimampranadipaNo ratings yet

- Casing TableDocument29 pagesCasing TableTafhim HimelNo ratings yet

- Form Swab ReportDocument1 pageForm Swab ReportimampranadipaNo ratings yet

Guideline Sapex Packer

Guideline Sapex Packer

Uploaded by

imampranadipa0 ratings0% found this document useful (0 votes)

136 views19 pagesPacker Guideline

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPacker Guideline

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

136 views19 pagesGuideline Sapex Packer

Guideline Sapex Packer

Uploaded by

imampranadipaPacker Guideline

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 19

ravers | oranaze punoawos

“ gyees 104 SaUljepInyS jeieuss

‘GLI SFOIAYIS GTBNINO Xadvs

‘GLTSTOOL UO 2. XAdVS

Pa) | es 5 ee

(eas)

2. soiaos

oravorkr | i eotaae punoswoa

°“ gees J04 Sel © yelsusesy

‘GLT SIDIAYIS GISISHO

ws awe

“GLTS1001 110 @@ Xadvs XadvsS

DOWNHOLE

CONPLETIONS:

DMSON

SAPEX OIL TOOLS LTD. BD

SAPEX-DL COMPLETION EQUIPMEN T

PRGKERS & COMPLETION EQUPENT

\WORKOVER & COUPLETIN SERVICE TOOLS

MODEL “SG-II SINGLE GRIP RETRIEVABLE PACKER

The SAPEX J DL Mode! “SGul" Single Grip Retrievable Packer is an extremely

reliable single-string, single grip retrievable compression set packer. i depends

‘on compression forces irom above (tubing weight and annular pressures) to

remain set, A fage internal bypass allows the packer to be run and retrieved with

‘minimal pressure surge forces being exerted onthe packer and wel-bere,

The Model “SG-lI" Packer has an automatic, open slye J-Slo, located on the outside

of he packer body. Manual J-Siols are also available,

The Model “SG” Packer sets easly with 1 tun of righthand torque, flowed wih

set down being appli othe tubing sting. teleases wih svaghl pul being applied

on the tubing. As the tubing is cesed, the bypass sysiem opens, in order to equalize

tubing and casing pressures, aller which the Sips lease andthe packer canbe puled

from ine wel

‘The Model “SG-lII Packer is ideal for all completion and workover operations where &

dependable and cost-competiive weigh! set packer is required, and where constant

tubing weight is aveiable tobe left onthe packer, and where a hold-down system is nol

required.

KEY PERFORMANCE FEATURES :

“W? Economical for low to medium formation pressure wells where hold-down

‘systems ae no reuited

—# Full bore for unrestricted flow and passage of wireline tools

Song J-Sotloeated on ouside of boxy

“"® Heavy-Duty end subs for repeated meke-up and break-out

Sats easily in compressin, vith right hand rotation

Releases wih sight pckp on ung

Wr ‘Sinple ard Easy to Reress

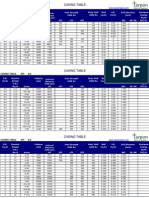

TOOL SPECIFICATIONS :

noes eer i eerie hts

saur2 | mm | 2002 | sce 125 LmoNT | 0885

ay2 | oss | smo | 4o0 | s70 | a7 23/8EUE | ans

sayz | woo [ame | soo | aes | ao as/enue | oss

sip | ass | ae | as | aos | ase 27/0EUE | asKo

saz | reas | aor | are | azo | 200 aseFue | oser

sap | mao | 47 | son | aes | 238 27/8BUE. | e368

ese | aa | soa | ons | sx | 250 2afe UE

7 | 232 | com | ex | sas | 250 27/0 EUE

7 | pa | eam | oss | eso | 250 27/9 EUE

7 mse | oon | 627 | sa75 300 542 UE

rele | 24207 | oes | 7025 | sea | 20 27/6 FUE

os_|assess| asso | a7 | exo | 250 27/0 EUE

* Other sizes and connections avallable ca request

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY... 2

DOWNHOLE

COMPLETIONS:

ONSON

SAPEX OIL TOOLS LTD. Ze

PACKERS & COUPLETION EQUPKENT

WoRKOVER & CONPLETION SERVICE TOOLS

SAPEX-DL COMPLETION EQUIPMENT

MODEL “DG-I" DOUBLE GRIP RETRIEVABLE PACKER

The SAPEX / DL Model “DG- Double Grip Packer is a single sting, double grip

telievable lock-set style packer. i ullizes the SAPEX “SYNCREL. 2000" double grip

mechanical hold-down system, which holds pressure diferentials securely both from

above and below the packer once the packer has been set. Movement of the packing

‘elements prevented and packof is maintained by his feature.

The Model ‘DG-I' Double Grp Packer may be set using either tension or compression

force and, once set, may be lft in ether mode (rin neutral) without any danger ofthe

packer releasing accidental,

‘large intemal bypass allows the packer tobe run and retrieved with minimal pressure

surge forces being exerted onthe packer and the well bore, Upon releasing the packer,

the bypass opens before the upper sips release, thereby allowing the tubing and casing

pressures to equalize slely.

‘The Model “DG-t Douible Grip Packer has an open style J-Siot, located on the oulside

of the packer body. This feature helps to prevent setting and releesing problems which

‘may be encouniered due fo sols setting out inthe well bore or annular Mui.

‘The SAPEX / DL Model °DG-1' Double Grip Packer is idea for all completion and

workover operations requiring an extremely reliable and dependable lockset ile

packer.

KEY PERFORMANCE FEATURES :

Holds diferenta pressures securely from above or below

“TF SAPEX"SYNCREL. 2000" upper sip releasing system

“—® Ful bore fo unrestricted flow and passage of wireline tools

W Large bypass for pressure equalization and debris cleaning

= Seting J-Slot located on outside of body

7 teawy-Duty end subs for repeated make-up and breakout

“"® Sets easily in tension or compression, wih 14 ght hand rotation

® Feleases vith 14 right hand turn and siraight pickup

Wr Field adjustable emergency tension sheer release

““® Simple and Easy to Recress

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

SAPEX OIL TOOLS LTD, >

TOOL SPECIFICATIONS :

‘ 3.476 | 3518 | 3250 | 150 | L900 FUE | eosao

4 3340 | 3390 | 3187 | 150 1900 ELE | ose.

aap 3010 | 3080 | 3437 | 150] L900 BUR | eo3ae

sap | rata | 370 | 3226 | 35% | 139 1900 ENE | ¢0545

aap | wr | 3.36 | 3826 | 5056 | 108 ‘25/8BUE | cosad

aa2_| 95335 | 3.920 | 4090 | 3750 | 19s 23/6EUE | 0543

ay2 | isa | 3.826,] 3@26 | 36a] 19a | 25/8 EUE | eosa6

3 | nea | age | asco | ais | 198 23/eFUE | 60350

5. | wa08 | 41s | 4279 | 4000 | 198 23/9EUE. | 0592

sy2 | 20 | 4778 | sou | soos | 200 | 25/eEUE | eosss

sie | wow | ae | ac | a6 | 238 | 27/8 EUR | cass

4670 | 47 | aso0 | 200 | 25/8EUE | 60357

02 495 | 238 | 27/8 EUE | cose

4670 4500 | 238 | 27/8 BUE | e009

5352 sige’ | 238°] 27/8EUE. | 60360

5.200 suse | 238 | a7/etuE | cox

5675 5.500..|. 250.) 27/8EUE | 6035

5575 saz | 250 | 27/8buE | 60360

5921 570° | 250. |. 27/8 EVE. | cose7

5921 570 | 300 | 3y2EUE | cose

6009 | oo | sai2 |. 300° | 3y2EUE | oso

e034 | 627 | ser | 250 | 27/eEUE | 60370

soe | ora | 582 | 250 sat

7 | wae | 627 | e288 | oo | 220 0372

7 | 2632 | ova | e270 | 5e75 | 300] > SaEUE. | 00573

7 | i726 | 6276 | 6588 | 612s" | 300 | 3a/2EUE | oo3m

75/8 | 2020.7 | 0875} 2025 | 6472 | 200 | 27/8 EUE | 60825

75a | 33739 | 0625 | 675 | oa | 250 | 27etuE | osm

75f8, | 33739 | 0625 | 675 | 6453. | 300 | sy2EUE | cosr7

75/8 | 24207 | 6875 | 7025 | 5072 | 300 | Sy2EUE | 0378

5/8 | 240 | 2725 | B07 | 7200) 400 | aaf2EUE | costa

es78 | 2s49 | 7725 | 2057 | 7500 | 250 | 27/8RUE | 60385

25/8 | atso | rou | eos | 732° | 250. | 27/8 EUE | 60396

ese | zea | 7725 | aor | 7200 | 300 | Siy2EUE | 6ose7

95/8 |435535| ass | 875 | 8250 | 400 |. axf2EUE | 60305

95j8 | 323435] 9755 | san | soa | 400 | 4if2EUE | 00896

wsya_ [3275455] 9200 | wise | 9700 | 400. -| 4y2EUE | cos

wsjs | asssi | 985 | ass | 9625 | 400 | ay2EUE | cosoz

sa 9200 | 9950 | 9512 | 400 | 4y2EUE | tomo

s/t wes | noe | ass | 400 | ayeeve | con

133/8 vas| ves | woo | ao | ay2bve | cos

DOWNHOLE

CONPLETIONS

OMSION

PACKERS & COMPLETION EGUIPHENT

‘¥ORKOVER # COUPLETION SERTCE TOOLS

“Fiveiom OD. te acneze rel

ioc drag Hels,

* Othersizes and connections avallable on request

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY. 16

SAPEX OIL TOOLS LTD. =>

SAPEX-DL COMPLETION EQUIP!

MODEL “DG-II" DOUBLE GRIP PACKER

PACKERS & COMPLETION EQUPHENT

WORKOVER & COMPLETION SERVICE TOOLS

The SAPEX / DL Model “DG:I" Double Grp Packer is @ single sting, double ip

retrievable compression set packer. ullizes the SAPEX “SYNCREL 2000° double grip

mechanical hold-down system which holds pressure diferentets securely both fom

above and below the packer. Movement of Ihe packing element is prevented and pack-

ois maintained by this double rp feature

A large intemal bypass allows the packer fo be run and retrieved with minimal pressure

surge forces being exerted on the packer end the well be. When set, the bypass

syslam uses pressure ferential frce fom below to give extra packof force on both

the bypass seal and packing elements. Upon releasing the packer, the bypass opens

belore the upper sins release, thereby alowing the lubing and casing pressures to

equalize safely. The Model ‘G:F Double Grp Packer has an automalc J-Siol, located

onthe ousie ofthe packer body, Menual Sots ae aso aval

The SAPEX / DL Model “DG-I" Double Grip Packer is ideal lor al completion and

\workaver operations requiring a dependable weight set packer. Its especialy suited for

applications where forces resulting from differential pressures from below the packer

may exceed the available tubing weight required to maintain a reable set

KEY PERFORMANCE FEATURES :

—® Holds pressure diferenials securely from above or below

“TW SAPEX"SYNCREL 2000" upper sip releasing systom

7 Full bore for unrestricted flow and passage of wireline fools

—W Laige pressure balanced bypass for pressure equalization and debris ceening

around upper slips when releasing

““W Seting J-Sit located on ouside of body

“TB Heavy-Duty end subs for repeated make-up and break-out

—W Sets easily in compression wth 1/4 right hand rotation

® Releases vith straight pickup on tubing

“WP Simple and Easy to Redes

TOOL SPECIFICATIONS :

pare

toe | aoe] aapee0E

aes | 200 | 25/s8uE

aos | os | zelennE

asm | 20 | agaeue

amo | oo | aaeave

somo | as | aa cUE

se | 2m | aaennE

vo | sco | assent

oss | 500 | syne

* ier a8; and coonestons sable on Fequert

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY... 2

SAPEX OIL TOOLS LTD, GY

PACKERS & COMPLETION EQUENT

WoRKOVER 2 CONPLENON SERUCE TOOLS

SAPEX-DL PACKERS & COMPLETIONS EQUIP.

TECH UNIT - 036 : MODEL “HD” RETRIEVABLE SERVICE|

‘The SAPEX-OL Model HD" Relrievable Packer is a heavy duty service packer ideally suited forall types of squeeze

cementing, formation fracturing, high pressure acidizing, etc.. It is a large opening compression set packer with

hydraulic button-type hold down. it withstands high pressure from above or below and uses a 3 element packing

syslem, J-slot, and a drag block mechanism for easy setting. The packer has @ builtin unloader which circulates

22c10$s the hold down buttons to improve retrievability and run in performance,

SPECIFICATION GUIDE

cASING maxiust opor

Sze, WEIGHT RECOMMENDED Toot PRopuct

wy ___|__wesien HOLE size om NUMBER

1 | 26-32 6.094-6.276 5.875 $01-81370,

*Teos sed oe lel hand eel rh hand eleose

CAUTION: Before running the tool, check the pressure affected areas chart, and consider other effects

to be certain that the unloader will remain closed during operation.

CAUTION: If the HD Packer is run with a retrievable bridge plug, make sure the bridge plug J-slot is

compatible with the J-siot on the packer. Whichever direction you set the plug, the packer

should set in the opposite direction.

SETTING PROCEDURE

Run to selting depth. The unloader remains open while running in. Pick up the tubing and rotate 1/4 turn at the

packer. Slack off weight and set down on the packer to sel the slips, close the unloader and compress the packing

elements, A minimum weight of 14,000 lbs. at the packer is required to pack off the elements.

CAUTION: Run the too! slowly, as with any hold down type packer, to help prevent dulling of the

hydraulic buttons.

RELEASING PROCEDURE

Pick up on the tubing to open the unloader, allowing time for the tubing and casing pressure to equalize. Continued

Upward movernent of the tubing unsets the slips, relaxes the packing elements and re-jays the packer. The tool may

now be moved and reset or pulled from the well

PRESSURE AFFECTED AREAS

GUIDE

Size [TUBING | ABOVE Below}

2.375 | 3.49 DOWN | 452 DOWN,

2375 | 1.40 00WN | 6.08 DOWN.

7 [3500-1473 up| 843 D0WN

45005 7.96 uP | 13.15 00WN

S000? | 11.69UP_| 1595 00WN

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

DOWNHOLE

‘COMPLETIONS

DIMSION

PACKERS & COMPLETION EQUEN

WORKOVER & COMPLETION SERUICE TOOLS

SAPEX OIL TOOLS LTD. GY

SAPEX-DL PACKERS & COMPLETIONS EQUIPME!

TECH UNIT - 036 : MODEL “HD” RETRIEVABLE SERVICE PACKI

EXAMPLE

AT’ Packer run on 2-718" tubing with a diferental hydrostatic pressure above the tool in the annulus equal o 3000

PSI. How much must be pulled to open the unloader? From the chart, 1.40 down is the factor for this packer with

differential from above. This number, when multiplied by the pressure differential, 3000 PSI, gives the force acting on

the mandrel, 1.40 x 3000 = 4200 tbs.’ This is the amount to be pulled to open the unloader.

NOTE: Most of the component parts are manufactured from heat treated alloy steel. Therefore,

‘extended exposure to corrosives can be detrimental to the metallurgy. Care in cleaning the

tool soon after removal from the well can help extend the life of component parts. Close

inspection of the parts is necessary, after removal, to identify any parts which require

replacement.

CAUTION: When running this tool with a packer, make sure the J-slots in the plug, running! retrieving

tool, and packer are all compatible.

DISASSEMBLY

41.) Place top sub (2) in vise and remove scrows (33),

2) Remove bottom sub (21) from inner mandrel (1). Remove o-ing (45).

3) Align holes in rubber retainer (19) and rubber mandrel (15). Place bar in holes and remove rubber mandrel

(18) from valve body (13), Remove rubber mandrel and conitol body assemblies from inner mandrel (1).

) Remove elements (16) and (18) and rubber spacers (17) from rubber mandrel (15).

) Remove rubber retainer (19) from lower cone (20). Remove rubber retainer (19) from rubber mandrel (18).

) Remove screws (44) and remove j-body (26) from control body (24).

)) Slide control body assembly up rubber mandrel end remove rubber mandrel cap (23)

) Remove control body assembly from rubber mandrel and remove slips (28) and slip springs (42)

) Remove drag block retainer ftom control boxy (24) and remove drag blocks (27) and drag block springs (43).

}) Remove lower cone (20) from rubber mandrel (18).

) Remove valve body (13) from central body (12).

) Remove central body (12) from hydraulic hold down body (4).

)) Remove top coupling (2) from vise and place lower end of inner mandrel (1) in vise.

DO NOT WRENCH OR CLAMP ON SEAL SURFACE

14) Remove screws (31) andl remove top coupling (2) from inner mandrel (1). Remove o-ring (34),

18.) Remove hold down extension fram hydraulic hold down body (4). Remove o-rings (35).

46.) Remove hold down cap (6) from hycrraulic hold down body (8).

47) Remove hold down straps (30) and strap retainer (6)

18) Remove hold down springs (38) and buttons (29) from hydraulic hold down (4). Remove o-Fings (37).

18) Remove hydraulic nold down (4) from mandrel (1). Remove o-rings (36) and (39),

20.) Remove compensating piston (8) from compensating mandrel (7). Remove ovings ($9) and (40).

21.) Remave compensating mandrel (7) from seal raceptacte (8)

22) Remove seat retainer (11) from seal receptacle (8).

23.) Remove seal receptacle (8) from inner mandrel (1). Remove o-rings (36) and (41)

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

DOWNHOLE

‘COMPLETIONS

DMSON

PACKERS & COMPLETION EQUPWENT

Trem QTY] PART DESCRIPTION MATERIAL

NUMBER

7 [7 _[ 61370215 INNER MANDREL Pato

24 [61370615 “TOP SUB, P10.

3) 1 [61370310 HOLD DOWN EXTENSION Pato

4 [461370320 HOLD DOWN BODY. Bato.

3_[-1 [61370370 HOLD DOWN CAP. P10

6 [71 [ 61370850 ‘STRAP RETAINER P10

7/4 [61370240 COMPENSATING MANOREL 110

3 |_1_[ 61370730 ‘SEAL RECEPTACLE P10.

9 | 1 | 61370716 COMPENSATING PISTON P10

10_|-1_[_61370520 SEAL SO DURO NITRILE,

| -4_[ 61370530, SEAL RETAINER, P10

12_|_1_| 61370385 CENTRAL BODY Pai10-

13 | 161370350 ‘VALVE BODY P10

14_[ 2 [61170830 RUBBER GAGE RING 7018

45 |__| 61370320, RUBBER MANDREL

Te [a 602 7081s ELEMENT $0 OURO. ‘SOOURG NITRILE

a7_|_2 | _ 61170840, RUBBER SPACER 1018

1g [ 4 [60270512 ELEMENT 60 OURO. BO OURO NITRILE

79 [4 _ [6117085087 RUBBER RETAINER P10)

20 _[1_|60070420KT TOWER CONE: Ha 26-36 RE

a | 1} 61370630 BOTTOM SUB, 110

2 _[1_| 61370340, ‘TBODY. P10

23 [1_| 60070230 RUGBER MANDREL CAP 1018

26 [1 | 61370335 ‘CONTROL BODY

25 [1 [ 60070876) DRAG BLOCK RETAINER 7078

26 [_1_[_6007007t RETAINING RING 7018

27_|_6_|_90709006- CARBIDE DRAG BLOGK P-110

28_| 4 | 900701350 CARBIDE LOWER SLIP Pato

29 | 6 [613701400 _| CARBIDE HOLD DOWN BUTTON. 7018

30_|_3_[|_ 61370360 HOLD DOWN STRAP. 1-80.

31_| 3) Ss803eCos5) ‘SET SCREW STEEL

32_[_3_| FHSCO31C050, ‘SET SCREW STEEL

33 [2 | 8880376080) ‘SET SCREW STEEL

3a [ 4 80236 GORING RUBEER

35_| 2 120339) RUBBER

35 | 3 ‘80241 RUBBER

37 [6 ‘80230, RUBBER

38_| 18 | 61370075 | HOLD DOWN BUTTON SPRING.

39 [2 ‘80350, O-RING RUBSER

ao 4 ‘80344 O-RING RUBBER,

a4 20243 O-RING RUBBER,

a2 le 7170901 TOWER SLIP SPRING.

43_| 36 | 9101900 DRAG BLOCK SPRING.

44[~3 | S8so31c082, SET SCREW,

[4 90233, RING RUBBER,

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

DOWNHOLE

‘COMPLETIONS:

DMSON

PACKERS & COMPLETION EQUPHENT

LWORKOVER & COMPLETION SERIICETOOLS

SAPEX OIL TOOLS LTD, GY

SAPEX-DL PACKERS & COMPLETIONS EQUIPMENT

TECH UNIT - 036 : MODEL “HD” RETRIEVABLE SERVICE

‘The SAPEX-OL Mode! "HD" Retrlevable Packer is a heavy duty service packer ideally suited for al types of squeeze

‘cementing, formation fracturing, high pressure acidizing, etc... It is a large opening compression set packer with

hydraulic Gutton-type hold down. It withsiends high pressure from above or below and uses a 3 element packing

system, J-slol. and a drag block mechanism for easy setting, ‘The packer has a buil-in unloader which circulates

across the hold down buttons to improve retrievabilty and run in performance.

SPECIFICATION GUIDE

casing maxis 00 oF

size WEIGHT RECOMMENDED Toot pRoouct

ay jwesien) MOLE Size cn NUMBER,

7 26-32 6,094-6.276, 5.875 I ‘SDL-61370

* Teas tsed ae lett nand ei

CAUTION: Before running the tool, check the pressure affected areas chart, and consider other effects

to be certain that the unloader will remain closed during operation.

bane ease

CAUTION: Ifthe HD Packer is run with a retrievable bridge plug, make sure the bridge plug J-slot is

‘compatible with the J-siot on the packer. Whichever direction you set the plug, the packer

‘should sot in the opposite direction.

SETTING PROCEDURE

Run to setting depth. The unloader remains open while running in, Pick up the tubing and rotate 1/4 turn at the

packer. Slack off weight and sel down on the packer to set the sling, lose the unloader and compress the packing

‘elements, A minimum weight of 14,000 Ibs. at the packer is required to pack off the elements.

CAUTION: — Run the too! slowly, as with any hold down type packer, to help prevent dulling of the

hydraulic buttons.

RELEASING PROCEDURE

Pick up on the tubing to open the unloader, allowing time for the tubing and casing pressure to equalize. Continued

‘upward movernent of the tubing unsets the slips, relaxes the packing elements and re-jays the packer. The tool may

now be moved and reset or pulled from the well

PRESSURE AFFECTED AREAS

GUIDE

Size [TUBING | ABOVE aeLow ——]

2st [Sas Ovni | asa OW —

2.875 | 1.40 DOWN | 6,08 DOWN

7 [3s00-[ v7aup_| 843 D0

4.50 D> | 7.96 UP_| 13.15 DOWN

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

DOWNHOLE

‘COMPLETIONS

DMSON

PACKERS & COMPLETION EQUPHENT

WORKOVER & COMPLETION SERVICE TOOLS

SAPEX-DL PACKERS & COMPLETIONS EQUIPMENT

Trem] QTY] PART DESCRIPTION MATERIAL

NUMBER

Ta | 61370215 INNER MANOREL P10

2 [1 | 61370615 TOP SUB P10

3_ [1 [61370310 HOLD DOWN EXTENSION. E110

4 _|_1_|_61370320 HOLD DOWN BODY P10

3_ [1 [ 61370370 HOLD DOWN CAP. Pato

@_| 1 [61370650 ‘STRAP RETAINER P10

7 [1 sts70240 ‘COMPENSATING MANDREL Pio

| 1_| 61370730 ‘SEAL RECEPTACLE P10.

‘| 161370715 COMPENSATING PISTON P11

70_|_1_[_61370520 ‘SEAL ‘30 DURO NITRILE

Te [ o_o 61370530. SEAL RETANER, P10

| an370886 CENTRAL BODY P10

13 |1_[_61370350 ‘VALVE BODY Pett.

4 [ 2 | et i70830 RUBBER GAGE RING 7018

16 |_1_|_61370220 RUBBER MANDREL

[a e0a708TS ELEMENT 00 OURO. DODURO NITRILE

a7_|_2 [61170840 RUBBER SPACER 1018

1e_ [1 [602 70si2, ELEMENT 80 DURO BODURO NITRILE

19 [4611 70860 RUBBER RETAINER P-110

20_[_1_|-so070s20HT LOWER CONE H1026-35 Re

21 [+ | 61370630 BOTTOM SUB, Pit10

[+ _|_a1370340 BODY. P-110

231 _| 60070230. RUBBER MANDREL CAP 7018

24 [1 [61370335 CONTROL BODY

25_[_4_| 60070010. DRAG BLOCK RETAINER oe

23_[ 1 [60070811 RETAINING RING 7018

27_[6_| 90709006 ‘CARBIDE DRAG BLOCK P110

23_[4 [500701356 ‘CARBIDE LOWER SLIP. F110

28_[_6 | 61370140C _|_GARBIDE HOLO DOWN BUTTON. 1018

ao [3_| 41370860 HOLD DOWN STRAP. 1-80,

3t_|3_| Sss038Co3 SET SCREW. Sree

32_[_3_| FHSCO31C050 SET SCREW STEEL

33_| 2] $88037C050 ‘SET SCREW STEEL

3a 4 ‘90235 RING RUBBER,

3 [2 90339, O-RING RUBBER,

3 [3 20241 O-RING RUBBER

7 6 ‘20230 O-RING RUBBER,

'38_| 18” | 61370075 | HOLD DOWN BUTTON SPRING

30 [2 90350 O-RING RUBBER

a4 20344 C-RING RUBBER,

a [4 ‘90243 O-RING RUBBER,

28 7170901 TOWER SLIP SPRING

“43_[_38_| 9101000 DRAG BLOCK SPRING

44_|_3 | Sssos1cos2 SET SCREW

e141 90233. O-RING RUBBER,

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

“"ADUINI S,AVAOL YO ADO TONHIAL S,MONYOHOL

eon

ase ese ssp

10S) #92 «d YaNOWd AOIANAS JTAVASYLAY «CH» T3COW : 9€0 - LINN HOSL

ANAWdINDA SNOILATANOD 8 SHAMOVd 10-XAdVS

‘001 30095 NOUSNAHOD BAAROWIOH

{nawtano3 NOU HOD» euBHOVS

Nasa %g@ AULT SIOOL iO XadVs

snouLaTgWoo

HIOHNVOG

SAPEX OIL TOOLS LTD. GY

PACKERS & COMPLETION EQUPHENT

lwoRKOvER £ COMPLETION SERUCE TOOLS

‘a high pressure packer type plug used for multiple zone

and selective zone treating arel testing operations (Including for fracturing, wsting, cementing snd acidizing). The

plug is designed wi -ge intemal bypass (0 prevent swabbing when running and eetrieving. The bypass closes

uring the setting of the plug anc opens prior (o releasing the upper slips to equalize pressu ‘The

bypass is positioned directly below the upper slips to help debris wash when the bypass is open, The AS-RBP plug

has the added feature of being able to sot and packolT the element in tension, making it ideal for setting shallow to

test well head equipment and also deep. high pressure walls.

B) SPECIFICATION GUIDE

T

CASING MAXIMUM | ovor

WE RECOMMENDED | tooL PRODUCT,

(unsiery HOLE SIZ | ux NUMBER

17226 6.276 = 6538 [3.969 70

[36732 6.094 = 6276 I 5.875 7257)

* Tools listed are left hand set!

CAUTION:

Ite AS-RBP Packer is run with a Model HD Service Packer, make sure the bridge pl

compatible with the J-slot on the packer. Whichever direction you set the plug, the packer should set

in the opposite direction.

Nort

Most of the component parts are manufactured from heat treated alloy steel. Therefore, extended

‘expositre co corrasives can be detrimental tothe metallurgy. Care in cleaning the tool soon after

removal from tae woll ean help extend the life of component parts. Close inspection of the parts is

necessary. alter removal, to identify any pasts which require replacement.

©) SETTING PROCEDURES

CD Tension Set

Ran to sett

Jepth white latched to its spring loaded retrieving tool. Pick up, rotate 1/4 turn to the left at

the plu lower slips. Relieve left hand torque and apply right hand torque. Pull

tension (© pack-off elements, slackoff, then pick up again to assure plug setting (14,000 tbs minimum.

Ate play, slack off tubing weigh, hola fet hand torque and pick up to free tubing from plug,

and lower tubing

©2) Compression Set

‘Rus to setting depth while latched to its spring londed retrieving (ool. Pick up, rotate 1/4 tum to the left at

the plug, and lover tubing to set lower slips. Slack off sufficient weight to pack-off elements, hen pick up to

firmly set upper slips and skackoff again (14,000 Ibs minimum). After seting plug, slack off tubing weight,

hold left hand torque and pick up the free tubing from ph

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

COWNHOLE

COMPLETIONS

DMSION

PACKERS 4 cOWPLETION EQUPENT

WoRxOVER & COMPLETION SERGE TOOLS

SAPEX PACKERS & COMPLETIONS EQUIPMENT Le

TECH UNIT - 044R2 : MODEL “AS-REP” RETRIEVABLE BRIl

SAPEX OIL TOOLS LTD, GY

D) RELEASING PROCEDURE

Lower tubing until the retrieving tool automatically latches to the AS-RBP Bridge Plug, Sand may be washed from

the upper slip by circulating through the upper portion of the plug. Slack off weight. hold right hand (orque pick up

{0 open the bypass valve, and wait until differential pressure has equalized. Continue upward movement to release

upper slips, relax packing elements and re-latch. ‘The plug may now be removed or re-located. IF the plug will not

rolease conventionally, slack off re-set then pick straight up to shear J-pins and refease the plug (J-Pins will shear at

50.000 Ibs each). Once the J-pins are sheared the too! eannot be moved down hole,

E) DISASSEMBLY

E-1) Clap center coupling (10) sa vise

E-L 1) Unscrew and remove set stews (37) from lover end of body extension (28)

E-1 2) Unscrew and separate body extension (28) {rom J-pin body (23) (NOTEy’ Leftchand theends)

NOTEe Drag block body assembly must be fiee 0 rotate

E-1.21) Remove J-pins (15) from J-pm body (23)

Esl 2.2) Remove J-pin body (23) from Jslot mandrel (20)

E-1 3) Compress drag blocks (22) using drag block bedy assembly tool (T1. 72).

E-Ls) Rotate diag block retaer (21) a ceded to waserew and reniove set screws (35) fiom upper ead of body

extension (28)

Er 5) Unscrew and remove body extension (28) from drag block body (18) (NOTE¢: Left-hand th

E-1.5 1) Remove setaning ring (81) from body extension (28)

66) Remove drag black setasier (24) from drag block body (15),

L.1) Release drag blocks (22), Remove drag blacks (22) and diag block springs (3) Gon drag block body (18).

-1 8) Unscrew and remove rubber mandrel cap (19) fiom lower shp sleeve (32)

NOTEe Ifthe lower sip sleeve (32) moves in relation (© che suber mandrel (11) - STOP! Tighten the

onmsetion before tring t0 looseu rhe cap again,

Er1.9) Wedge lower ships (17) outwards af needed), Remiove drag block body assembly anc disassemble:

E-1 9.1) Remove wedges. Remiove lower sips (17) and lower sip springs (25) fom drag block body (18).

E-1.10) Unscrew and remove set serews (36) fiom lower shp sleeve (32)

E-1 11) Unscrew and remove loser sip sleeve (32) fiom rubber mandsel (11)

1 12) Unscrew and cemove set screws (36) from J-slot maadsel 20)

E-L.13) Cascrew and remove Jslor mandeel (20) fom sealing mantel (27)

E-L 14) Caserew nibber mandrel (11) from center coupling (10).

E-1.15) Remove rubber mandrel assembly and disassemble

E-L15 1) Remove elemeats (13, 14), and suber spacers (12). and lower cone (16) from aubber mandrel

an.

Es 16) Cascrew and remove

E-2) Move to upper end of tool

E-2.1) Unserew and remove set screws (37) from pulling head (1),

E.2 2) Unsorew and remove pulling bead (1) om upper mandrel (2)

CAUTION; Compression spring

ge rung 29) from center coupling (10)

(anny be compressed with spring tension against pulling head (1)

ing (34) from pulling head (1)

2.22.1) Unscrew and remove speing resin

2.3) Remove compression spring (4) from upper mandrel (2),

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY.

COWNHOLE

COMPLETONS

DISION

PACKERS & CONPLETION EQUPHENT

woR«OvER # coup. =TION SERUGETOGLS

SAPEX OIL TOOLS LTD, GY

SAPEX PACKERS & COMPLETIONS EQUIPME

TECH UNIT ~ 044R2 : MODEL “AS-RBP” RETRIEVABL!

E) DISASSEMBLY (cont'd)

E.2.4) Remove upper ship body and disassemble

E.24d 1) Wedge releasing slip (7) and upper slips ($) ourward (if needed), Unserew and remove upper sip

picinip (33) from upper sip bod (6).

2) Remove wedges. Remove relensung shp (7). upper slips (8) and upper slip sprangs (26) fom upper

ship body (6)

andl remove set

B2

2.5) Unseve ews (36) rom ypper mandel (2)

E.2.6) Unscrew and remove upper mandrel (2) fom seating miandeel (2

7} Remove plug (5) ffom sealing mandrel (27)

E271) Remove o-ring ($1) from pls (5),

8) Remove sealing mandeel (27) fom center coupling (10),

E.2.9) Unscrew and remove set screws (36) from upper cone (9)

E-2.10) Unscrew and semore upper cose (8) from center coupling (10).

E-2,10.1) Rempve seal retaining ring (30) from upper cone (9)

-3) Unelamp and remove center coupling (10) fiom vise

of) Remove upper seal (24) from center coupling (10),

E-4.1) Remove o-nne (39) ffom upper seal 24)

E-5) Remove internal ring (38) ftom eenter coupling (10).

E-6) Remove lower seal (24) front center coupling (10)

E.6 |) Remove o-sig (39) fom lower seal (4)

E-7) Remove o-ring (40) from center coupling (19)

F) ASSEMBLY

‘OTEs: Clean and unspect all parts. Replace all wor and damaged parts, Install parts in proper order & orientation.

Fl) Install o-naug (40) in groove in center coupling (10)

F-2) Install o-n

3) Clamp center con

F-3.1) asta lower sexl (24) in center coupling (10)

CAUTION,: Do not rip of tear o-nurg during installatien,

3.2) Install internal nag (38) ta groove m center coupling (10).

F-3.3) Install upper seal (24) in center coupling (10).

CAUTIONs: Do not np oF tar o-ring during instalation

F-3 4) Set seal retaining ring (30) in place sn upper cone (9).

F-3.5) Screw wpper cone (9) snto center coupling (10).

3.6) Screw set serews (36) into upper cone (9)

F-3.7) Install sealing muandcel (27) thru seals mn center coupling (10)

CAUTION, Do not np or seals during mstallation

F-3.8) Install o-ring (41) n groove w plug (3)

F-3 9) Iasall ph mandeel (27)

n grooves n seals (24)

ag (10) in vise

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

DOWNHOLE

COMPLETONS

DIMISON

PACKERS & CONPCETION EQUPHENT

\woaKVeR # COMPLETION SERUCE TOOLS

SAPEX OIL TOOLS LTD, GY

SAPEX PACKERS & COMPLETIONS EQUIPMENT

TECH UNIT ~ 044R2 : MODEL “AS-RBP” RETRIEVABLE | BRIDGE

Seta

G)TOOLS

rem | gry DESCRIPTION PART NUMBER

[2 DRAG BLOCK ASSEMBLY TOOL ATOVOIIO

12 | 20 | SQUARE HEAD SET SCREW 12.13 UNCX# 'SQS0s0C400

HDPARTS LIST

Tew] ar DESCRIPTION waresan | PS eSGER [PR AETER

Tho POLLING HEAD Baio svo710

het CPPER MANDREL Baio Pa

3 Brac aLock sane siots00

4 1 COMPRESSION SPRING CHROME VANADIUM 72570920 ~|

sho HES Bao peas

6 1 ‘UPPER SLIP BODY 1-80 72570320 73871320 |

The RELEASING SEP Bao asm | ss

o [2 UPRER SP -CaRBIDE Pa wismtiec | arise

~ La TPPER CONE Pa rasan

wpa CENTER COUPLING Pn 73e7060

wp RUBBER MANDREL Pa reson

pe RUBBER SPACER Toe Fane [nas

3 1] ELEMENT 70 DURO NITRILE 72072511 72070511

wpe BLEMENT SODURONITRILE | Teoria” | Taos

7as70e7035,@5000%)

7257067030 60000)

he i fee fe 72570870-35 (35,0004)

| Tairest0-1 TD 0.009)

eho TOWER CONE Pao resreno | rasme0

f= [LOWER sLiP- CARBIDE Pao cara

wpa DRAG BLOCK BODY 00708

[tL RUBBER WaNDREL CAP aro T0339

[1 [stor saNDREL LAR Bai ream

a1 [1 | DRAG stock RETARER 1038 oor

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

NOMLVALSATHAVIINHDAL

‘1001 30/835 NOUaTaHOD AIAOMAON

anamiba NOusTeHI0D # SHENDNE

aL ‘OM1d 3OGMG FTAVASRILIY .dBU-SV, TON! ZY¥H0 — LINN HOAL

ANAWdINOA SNOILAIdNOD 8 SYSMOVd XAdVS

nosing

‘SNOUSTANOO

STIOHNMOG

fg ULISIOOL iO XadVs

DOWNHOLE

‘COMPLETIONS

DMISON

PACKERS & COMPLETION EQUIPHENT

‘WORKOVER & COUPLETION SERMCE TOOLS

SAPEX OIL TOOLS LTD, G

SAPEX PACKERS & COMPLETIONS EQUIPMENT

TECH UNIT - 044R2 : MODEL “AS-RBP” RETRIEVABLE BRIDG

E) DISASSEMBLY (cont'd)

E.24) Remove upper sip body and dissssemble

Esto 1) Wedge releasing slp (7) and upper ships (8) ounwaed (if needed). Unscrew and remove upper sip

pickup (33) fora upper skip body (6)

E-2.42) Remove wedges. Remove releasing sip (7). upper sips (8) and upper sip springs (26) from upper

ship body (6)

.2.5) Lnscrew and remove set serews (36) rom upper mandrel (2)

E-2 6) Unscrew and remove upper mandrel (2) from sealing mandrel (27)

E.2 7) Remove plug (5) fiom sealing mandrel (27)

F-2 7 1) Remove o-naig (41) ftom plug (3).

E-2.§) Remove sealing mondsel (7) fiom center coupling (10),

E.2.9) Uuscrew and remove set screws (36) from upper cone (9)

E-2.10) Unscrew and remove upper cane (9) ftom center coupling (10)

E-2 10.1) Remove seat etnining ring (30) from upper cone (9)

E-3) Celamp and remove center coupling (10) fiom vise

E-t) Remove 1 ) fom center couplang (10)

Eet.1) Remove ovting (39) fom upper seal (24),

E-5) Remove ssternal ring (38) ffom center coupling (10).

6) Remoxe lower sent (24) fom center coupling (10)

E-6 1) Remove o-ring (39) fiom lower seal (24),

E-7) Remoxe o-ring (40) from center coupling (10)

yer seal

F) ASSEMBLY

NOTEs: Clean and inspect all pats. Replace all wora and damaged paris Install pars in proper ordes & orientation.

F-1) Install o-nag (40) in groove in center coupling (10)

Install o-rings (39) in grooves in seals (24),

F-3) Clamp ceater coupling (10) in vise

F-5.1)Eastall lower seat 24) an cen

CAUTION, Do noenip oF

5.2) Install internal rng (88) in groove in center coupli

coupling (10)

uring installation

Qo)

3.3) Install upper seal (24)

CAUTIONs: Do not nip or tear o-ning during installation

3.4) Set seal setauning sing (30) in place an upper cone (9)

3.5) Serew upper cone (9) into center couplin

F-3.6) Screw set serews (36) ito upper cone (9)

F-3 7) Install sealing mandrel (27) chm seals mn center coupling (10)

CAUTION, Do not np or seals dosing mnstallation.

3.8) Install o-rmg (41) an groove is plug (5)

F-3 9) Install plng (5) anto sealing mandrel (27).

enter couphing (10)

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY...

DOWNHOLE

COMPLETIONS

SAPEX OIL TOOLS LTD. eS DVISON

PACKERS & COWDLETION EQUIPMENT

\WORKOVER # COMPLETION SERVCE TOOLS

SAPEX PACKERS & COMPLETIONS EQUIPMENT

TECH UNIT - 044R2 : MODEL “AS-RBP” RETRI =VABLI

see

F) ASSEMBLY (cont'd)

3.10) Screw upper mandeel (2) onto sealing mandrel (27)

3.11) Screw set screws (36) sto upper mandrel 2)

F-3.12) Aszemble upper sip body and tava,

3.12.1) Install releasing slp (7). upper sips (8) and upper skp springs (26) into upper slip body (6)

F3.12.2) Wedge releasing ship (7) and upper shps (8) aunsard. Screw upper slip pickup (33) into upper slip

body (6)

F-3.123) Remove wedges

F-3.12 4) Install upper shp body assembly onto upper asandse (2)

F-3.13) Install compression spring (4) onto tipper maucet (2),

F-3.14) Sctew spring retaining ring (34) onto pulling head (1)

F-3.15) Screw pulling head (1) ento upper mandeel (2,

CAUTIONy Compression spring () aay be compressed with spring tension against pulling head (1).

F-3 16) Screw set serews (37) ante ping esd (1)

Ful) Move to lower end of tool

Fret 1) Seren 1x (29) onto center coupling (10)

‘Fol 2) Assemble mubher mandrel assembly’ and install

F+42.1) Lastall elements (13,14), rubber spacers (12), and lower cone (16) outo subber mandrel (11).

4.2.2) Screw rubber niaadrel (11 ito center coupling (10).

CAUTIONy Do not np oF tear o-ring ducing installation

Fel 3) Screw Jslot manérel (20) oto rubber mandcel (11)

Ft) Screw set screws (36) sto Jslot madre (20)

Ff 5) Screw lower slip sleeve (32) outa eubber mandsel (11).

4.6) Screw set secees (36) into lower sip sleeve (32)

‘Fol.7) Assemble drag block body assembly and instal

F+4.7.1) Iastall lower ships (17) and lower slp springs (25) smo drag block body (18)

F-47.2) Install drag block body assembly onto rubber mandrel (11). Wedge lower slips (17) outwards (i

needed)

Ff 8) Screw suber mantrel cap (19) omto lover slip sleeve (32),

F-49} Install drag blocks (22) and drag block springs (3) into drag block body (18) Compress drag blocks (22)

vsing drag block body assembly tool (T1, T2)

F-4 10) Tostll drag block eetamner (21) onto deag block body (18) eaprusing ends of deag blocks (22)

Ft 11) Insal taining ring (31) onto body extension (28)

F-4.12) Clamp and hold drag block body (18) securely. Screw body extension (28) onto drag block body (18)

(NOTE, Lefttind threads)

F413) Serew set screws (35) into drag block body (18) Release drag blocks (22)

F-4.14) Install J-pin body (23) onto J-sot mandeel (20)

F-4 15) Align holes in J-pin body (23) with sot ia J-slor mandrel (20). Install J-pins (15) toto J-pia body (23).

F-4 16) Screw body extension (28) onto J-pun body (23) (NOTE Left-hand threads)

NOTEg Drag block body assembly snust be fre to rotate

F-4.17) Screw set screws (37) into body extension (28). Remove wedges.

Unclamp center coupling (10) from vise and remove assembied too

TOMORROW'S TECHNOLOGY FOR TODAY'S ENERGY.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- BHA PicturesDocument29 pagesBHA PicturesimampranadipaNo ratings yet

- 4 6048518304547476951 PDFDocument245 pages4 6048518304547476951 PDFimampranadipaNo ratings yet

- Patrick Okimi - Casing Design Horizontal WellsDocument14 pagesPatrick Okimi - Casing Design Horizontal WellsimampranadipaNo ratings yet

- PDC Dull GradingDocument52 pagesPDC Dull GradingimampranadipaNo ratings yet

- Casing TableDocument29 pagesCasing TableTafhim HimelNo ratings yet

- Form Swab ReportDocument1 pageForm Swab ReportimampranadipaNo ratings yet