Professional Documents

Culture Documents

DRY WELL Beam Calculation

DRY WELL Beam Calculation

Uploaded by

afiqOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DRY WELL Beam Calculation

DRY WELL Beam Calculation

Uploaded by

afiqCopyright:

Available Formats

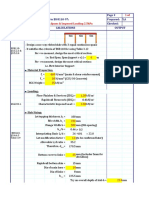

One V Project Management & Consultancy Sdn. Bhd. Client : PARAMOUNT Job Ref.

Structure : DRY WELL Calc.sheet No. 1

Drawing Computed Checked

No. By By Date : 18-May-17

BEAM RB1 (125X750) AR IR. WOON 5:12 PM

BEAM MARK: RB1

CodeOfPractice fcu fys fyv cover span cantilever

BS8110:1985 25 460 250 35 1 Nil

Span No Span-m Width-mm Depth-mm F-width F-depth

1 5.2 125 750 125 0

Maximum Concrete strain, Ecc = 0.0035

Average Concrete Stress Above Neutral Axis, k1 = 10.20 N/mm^2

Concrete Lever Arm Factor, k2 = 0.4557

Limiting Effective Depth Factor, cb = 0.50

Limiting Concrete Moment Capacity Factor, kk1

= cb*k1*(1-cb*k2) = 0.50*10.20(1-0.50*0.4557) = 3.9379 N/mm^2

k2/k1 Factor, kkk = 0.0447

Span No = 1 ; Location = 1/4 Span ; Bending Moment, M: -0.0

kNm

kk1 = cb*k1*(f1-cb*k2) = 0.50*10.200*(1-0.50*0.456) = 3.938

Mu/bd^2 = -0.0*1000000/(125*707^2) = -0.000

For Singly Reinforced Design, limit Mu/bd^2 < kk1 ; Mu/bd^2 = -0.000 ; kk1

= 3.938

Design as Singly Reinforced Rectangular Beam : b = 125 mm; d = 707 mm

Concrete Neutral Axis, x = 0.0 mm

Concrete Compression Force, Fc = k1.b.x/1000 = 10.20*125*0.0 = 0.00 kN

Steel area required, As = Fc*1000/(fyy*fy) = 0.00/(0.87*460) = 0 mm^2

Moment capacity = Fc(d-k2.x) = 0.00(707-0.4557*0.0)/1000 = 0.0 kNm

Tension Steel area required, As = 0 mm^2

Compression Steel area required, As = 0 mm^2

Tension Steel area provided, As = 141 mm^2

Compression Steel area provided, As = 122 mm^2

One V Project Management & Consultancy Sdn. Bhd. Client : PARAMOUNT Job Ref.

Structure : DRY WELL Calc.sheet No. 2

Drawing Computed Checked

No. By By Date : 18-May-17

BEAM RB1 (125X750) AR IR. WOON 5:12 PM

Span No = 1 ; Location = Span ; Bending Moment, M: 79.8 kNm

kk1 = cb*k1*(f1-cb*k2) = 0.50*10.200*(1-0.50*0.456) = 3.938

Mu/bd^2 = 79.8*1000000/(125*707^2) = 1.277

For Singly Reinforced Design, limit Mu/bd^2 < kk1 ; Mu/bd^2 = 1.277 ; kk1 =

3.938

Design as Singly Reinforced Rectangular Beam : b = 125 mm; d = 707 mm

Concrete Neutral Axis, x = 94.3 mm

Concrete Compression Force, Fc = k1.b.x/1000 = 10.20*125*94.3 = 120.17 kN

Steel area required, As = Fc*1000/(fyy*fy) = 120.17/(0.87*460) = 300 mm^2

Moment capacity = Fc(d-k2.x) = 120.17(707-0.4557*94.3)/1000 = 79.8 kNm

Tension Steel area required, As = 300 mm^2

Compression Steel area required, As = 0 mm^2

Tension Steel area provided, As = 300 mm^2

Compression Steel area provided, As = 122 mm^2

Span No = 1 ; Location = Left Support ; Bending Moment, M: 0.0

kNm

kk1 = cb*k1*(f1-cb*k2) = 0.50*10.200*(1-0.50*0.456) = 3.938

Mu/bd^2 = 0.0*1000000/(125*707^2) = 0.000

For Singly Reinforced Design, limit Mu/bd^2 < kk1 ; Mu/bd^2 = 0.000 ; kk1 =

3.938

Design as Singly Reinforced Rectangular Beam : b = 125 mm; d = 707 mm

Concrete Neutral Axis, x = 0.0 mm

Concrete Compression Force, Fc = k1.b.x/1000 = 10.20*125*0.0 = 0.00 kN

Steel area required, As = Fc*1000/(fyy*fy) = 0.00/(0.87*460) = 0 mm^2

Moment capacity = Fc(d-k2.x) = 0.00(707-0.4557*0.0)/1000 = 0.0 kNm

Tension Steel area required, As = 0 mm^2

Compression Steel area required, As = 0 mm^2

Tension Steel area provided, As = 141 mm^2

Compression Steel area provided, As = 122 mm^2

One V Project Management & Consultancy Sdn. Bhd. Client : PARAMOUNT Job Ref.

Structure : DRY WELL Calc.sheet No. 3

Drawing Computed Checked

No. By By Date : 18-May-17

BEAM RB1 (125X750) AR IR. WOON 5:12 PM

Span No = 1 ; Location = Right Support ; Bending Moment, M: 0.0

kNm

kk1 = cb*k1*(f1-cb*k2) = 0.50*10.200*(1-0.50*0.456) = 3.938

Mu/bd^2 = 0.0*1000000/(125*707^2) = 0.000

For Singly Reinforced Design, limit Mu/bd^2 < kk1 ; Mu/bd^2 = 0.000 ; kk1 =

3.938

Design as Singly Reinforced Rectangular Beam : b = 125 mm; d = 707 mm

Concrete Neutral Axis, x = 0.0 mm

Concrete Compression Force, Fc = k1.b.x/1000 = 10.20*125*0.0 = 0.00 kN

Steel area required, As = Fc*1000/(fyy*fy) = 0.00/(0.87*460) = 0 mm^2

Moment capacity = Fc(d-k2.x) = 0.00(707-0.4557*0.0)/1000 = 0.0 kNm

Tension Steel area required, As = 0 mm^2

Compression Steel area required, As = 0 mm^2

Tension Steel area provided, As = 141 mm^2

Compression Steel area provided, As = 122 mm^2

DEFLECTION CHECK FOR SPAN NO. 1:

Refer to BS8110:Part 1: Table 3.10, Table 3.11 & Table 3.12

Eqn. 8, fs = 5fy*As,reqd/(8As,prov) = 5*460*300/(8*402) = 214.7 N/mm^2

Eqn. 7, Tension Modification Factor, TMF = 0.55 + (477-fs)/(120*(0.9+M/bd^2))

= 0.55 + (477-214.7)/(120*(0.9+79801239/(125*707.0^2))) = 1.55

Actual Beam span/depth ratio = 5274/707.0 = 7.5

Eqn. 9, Compression Modification Factor, MF1 = 1+As/(3+As/) =

1+0.26/(3+0.26) = 1.08

Allowable span/depth ratio = TMF*MF1*BasicRatio = 1.55*1.08*20 = 33.5

Modification fac = 1.68; Deflection ratio = 4.49; Steel = 0.26

percent

Actual Beam span/depth ratio < Allowable span/depth ratio, i.e.

7.5 < 33.5 --> Deflection O.K.

One V Project Management & Consultancy Sdn. Bhd. Client : PARAMOUNT Job Ref.

Structure : DRY WELL Calc.sheet No. 4

Drawing Computed Checked

No. By By Date : 18-May-17

BEAM RB1 (125X750) AR IR. WOON 5:12 PM

CALCULATE THE MOMENT CAPACITY OF NOMINAL TOP REBAR OF LEFT END BEAM SUPPORT:

To back calculate end column moment from nominal steel provided:

From p.53 of Examples of The Design of buildings to CP110 and allied codes

Mu/bd^2 = p.fyd(1-k2.p.fyd/k1) -> Mu =

Steel provided, p = As/bd = 3.1416*2*12*12/(4*125*707.0) = 0.0026

Mu/bd^2 = p.fyd(1-k2.p.fyd/k1) = 0.0026*400.2(1-0.4557*0.0026*400.2/10.20) =

0.9774

Mu = 0.9774*125*707.0*707.0/1000000 = 61.1 kNm

Lower Column Stiffness, LCk = b*h*h*h/Lh = 0.125*0.125*0.125*0.125/3.000 =

0.0001

Beam Stiffness, LCk = b*h*h*h/l = 0.125*0.750*0.750*0.750/5.274 = 0.0100

Total Fixed End Moment = 1.40*20.3 + 1.60*12.1 = 47.9 kNm

Fixed End Moment Transfered to Column =

47.9(0.0000+0.0001)/(0.0000+0.0001+0.0100) = 0.4 kNm

Moment Transfered to Upper Column = 0.4*0.0000/(0.0000+0.0001) = 0.0 kNm

Moment Transfered to Lower Column = 0.4*0.0001/(0.0000+0.0001) = 0.4 kNm

DL Reaction Transfered Between Adjacent Supports = 20.3*0.4/47.9/5.274 = 0.0

kN

LL Reaction Transfered Between Adjacent Supports = 12.1*0.4/47.9/5.274 = 0.0

kN

CALCULATE THE MOMENT CAPACITY OF NOMINAL TOP REBAR OF RIGHT END BEAM SUPPORT:

To back calculate end column moment from nominal steel provided:

From p.53 of Examples of The Design of buildings to CP110 and allied codes

Mu/bd^2 = p.fyd(1-k2.p.fyd/k1) -> Mu =

Steel provided, p = As/bd = 3.1416*2*12*12/(4*125*707.0) = 0.0026

Mu/bd^2 = p.fyd(1-k2.p.fyd/k1) = 0.0026*400.2(1-0.4557*0.0026*400.2/10.20) =

0.9774

Mu = 0.9774*125*707.0*707.0/1000000 = 61.1 kNm

Lower Column Stiffness, LCk = b*h*h*h/Lh = 0.125*0.125*0.125*0.125/3.000 =

0.0001

Beam Stiffness, LCk = b*h*h*h/l = 0.125*0.750*0.750*0.750/5.274 = 0.0100

Total Fixed End Moment = 1.40*20.3 + 1.60*12.1 = 47.9 kNm

Fixed End Moment Transfered to Column =

(47.8896+0.0000)/(0.0001+0.0000+0.0001) = 0.0 kNm

Actual moment Transfered to Column = minimum of 61.1 and 0.4 = 0.4 kNm

Moment Transfered to Upper Column = 0.4*0.0000/(0.0000+0.0001) = 0.0 kNm

Moment Transfered to Lower Column = 0.4*0.0001/(0.0000+0.0001) = 0.4 kNm

DL Reaction Transfered Between Adjacent Supports = 20.3*0.4/47.9/5.274 = 0.0

kN

LL Reaction Transfered Between Adjacent Supports = 12.1*0.4/47.9/5.274 = 0.0

kN

One V Project Management & Consultancy Sdn. Bhd. Client : PARAMOUNT Job Ref.

Structure : DRY WELL Calc.sheet No. 5

Drawing Computed Checked

No. By By Date : 18-May-17

BEAM RB1 (125X750) AR IR. WOON 5:12 PM

SHEAR CHECK:

Span No 1 at Left Support ; Shear, V = 43.8 kN

Shear Stress, v = V/bd = 43.8*1000/(125*707) = 0.496 N/mm^2

Refer to BS8110:Part 1:1985 Table 3.9

Shear Capacity,vc = 0.79*((100As/(bd))^1/3)*(400/d)^1/4)*((fcu/25)^1/3)/1.25

Effective depth ratio = max(1,400/d) = max(1,400/707) = 1.000

Concrete Grade ratio = min(40,fcu)/25 = min(40,25)/25 = 1.000

Steel Percentage, 100As/(bd) = min(3,0.46) = 0.46

vc = ( 0.79*(0.46)^1/3*(1.000)^1/4*(1.000)^1/3 )/1.25 = 0.486 N/mm^2

Shear Stress - Shear Capacity = v - vc = vd = 0.496 - 0.486 = 0.010 N/mm^2

vd < 0.40 N/mm^2 --> Design for vd = 0.40 N/mm^2

Steel area provided by Link size 6 = 2*pie*dia*dia/4 = 2*3.1416*6*6/4 = 56.5

mm^2

Link spacing required for dia. 6 = 216

Shear Capacity provided by Link = 0.87*220*56.5/(216*125) = 0.400 N/mm^2

Link provided = 1R-6-200

Span No 1 at 1/4 Span ; Shear, V = 32.6 kN

Shear Stress, v = V/bd = 32.6*1000/(125*707) = 0.369 N/mm^2

Refer to BS8110:Part 1:1985 Table 3.9

Shear Capacity,vc = 0.79*((100As/(bd))^1/3)*(400/d)^1/4)*((fcu/25)^1/3)/1.25

Effective depth ratio = max(1,400/d) = max(1,400/707) = 1.000

Concrete Grade ratio = min(40,fcu)/25 = min(40,25)/25 = 1.000

Steel Percentage, 100As/(bd) = min(3,0.46) = 0.46

vc = ( 0.79*(0.46)^1/3*(1.000)^1/4*(1.000)^1/3 )/1.25 = 0.486 N/mm^2

Shear Stress - Shear Capacity = v - vc = vd = 0.369 - 0.486 = -0.117 N/mm^2

vd < 0.40 N/mm^2 --> Design for vd = 0.40 N/mm^2

Steel area provided by Link size 6 = 2*pie*dia*dia/4 = 2*3.1416*6*6/4 = 56.5

mm^2

Link spacing required for dia. 6 = 216

Shear Capacity provided by Link = 0.87*220*56.5/(216*125) = 0.400 N/mm^2

Link provided = 1R-6-20

One V Project Management & Consultancy Sdn. Bhd. Client : PARAMOUNT Job Ref.

Structure : DRY WELL Calc.sheet No. 6

Drawing Computed Checked

No. By By Date : 18-May-17

BEAM RB1 (125X750) AR IR. WOON 5:12 PM

Span No 1 at Right Support ; Shear, V = 43.8 kN

Shear Stress, v = V/bd = 43.8*1000/(125*707) = 0.496 N/mm^2

Refer to BS8110:Part 1:1985 Table 3.9

Shear Capacity,vc = 0.79*((100As/(bd))^1/3)*(400/d)^1/4)*((fcu/25)^1/3)/1.25

Effective depth ratio = max(1,400/d) = max(1,400/707) = 1.000

Concrete Grade ratio = min(40,fcu)/25 = min(40,25)/25 = 1.000

Steel Percentage, 100As/(bd) = min(3,0.46) = 0.46

vc = ( 0.79*(0.46)^1/3*(1.000)^1/4*(1.000)^1/3 )/1.25 = 0.486 N/mm^2

Shear Stress - Shear Capacity = v - vc = vd = 0.496 - 0.486 = 0.010 N/mm^2

vd < 0.40 N/mm^2 --> Design for vd = 0.40 N/mm^2

Steel area provided by Link size 6 = 2*pie*dia*dia/4 = 2*3.1416*6*6/4 = 56.5

mm^2

Link spacing required for dia. 6 = 216

Shear Capacity provided by Link = 0.87*220*56.5/(216*125) = 0.400 N/mm^2

Link provided = 1R-6-200

You might also like

- Two Way Slab DesignDocument9 pagesTwo Way Slab DesignChan Kin Cheung100% (1)

- Base Plate With Shear KeyDocument3 pagesBase Plate With Shear Keyvpjagannaath100% (1)

- RCC62 Retaining WallDocument15 pagesRCC62 Retaining WallanbukgiNo ratings yet

- RC Column Design (BS8110) - Part2Document1 pageRC Column Design (BS8110) - Part2Himura_No ratings yet

- EA - Design of Rectangular Beams With Compression Reinforcement ACI 318M-14 v1.0Document2 pagesEA - Design of Rectangular Beams With Compression Reinforcement ACI 318M-14 v1.0engrjassmaruizoNo ratings yet

- PilecapDocument2 pagesPilecapBudi SimatupangNo ratings yet

- Structural Steel Design Project: Calculation SheetDocument18 pagesStructural Steel Design Project: Calculation Sheetrameshbabu_1979No ratings yet

- Concrete Column DesignDocument2 pagesConcrete Column Designheherson juanNo ratings yet

- Ref. Calculations Output: The Capacity of The Slab Basic MeshDocument3 pagesRef. Calculations Output: The Capacity of The Slab Basic MeshOmar MokhtarNo ratings yet

- EA - Design of Isolated Footings Subjected To Vertical Load Only ACI 318M-14 v1.2Document6 pagesEA - Design of Isolated Footings Subjected To Vertical Load Only ACI 318M-14 v1.2engrjassmaruizoNo ratings yet

- CES522 RC BEAM - DESIGN - Topic 2b - CB Example (Lecturer Vers)Document11 pagesCES522 RC BEAM - DESIGN - Topic 2b - CB Example (Lecturer Vers)muizzey aufaNo ratings yet

- 230kV DS Foundation DesignDocument5 pages230kV DS Foundation Designelkhalfi100% (1)

- Project Job Ref.: H H Dia ColDocument6 pagesProject Job Ref.: H H Dia ColIk Einstein Ojogan0% (1)

- Mat Foundation Y Dir Rebar DesignDocument4 pagesMat Foundation Y Dir Rebar DesignGaneshalingam Ramprasanna2No ratings yet

- One-Way Ribbed Slab Design As Per BS8110Document5 pagesOne-Way Ribbed Slab Design As Per BS8110yusuf abdinasir100% (5)

- Durabilty and Fire ResistanceDocument6 pagesDurabilty and Fire ResistanceMohafisto SofistoNo ratings yet

- Bolt Calculation-AFC AwDocument64 pagesBolt Calculation-AFC Awpilar gilangNo ratings yet

- Beam DesignDocument7 pagesBeam DesignAlexs DiazNo ratings yet

- DG Bim Consulting: RC Beam Analysis & Design Bs8110Document8 pagesDG Bim Consulting: RC Beam Analysis & Design Bs8110cheligp1981No ratings yet

- Slab DesignDocument7 pagesSlab Designnhulugalla0% (1)

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsMohit VatsNo ratings yet

- Min AxisDocument3 pagesMin AxisjasekanNo ratings yet

- Ribbed Slab DesignDocument4 pagesRibbed Slab Designyusuf abdinasir100% (1)

- Slab Design Full Report: Material and Design DataDocument22 pagesSlab Design Full Report: Material and Design DataazwanNo ratings yet

- Tedds RC Beam DesignDocument5 pagesTedds RC Beam DesignHor Ka WaiNo ratings yet

- EC - Pilegroup - BLK 226A - PC2A - P80Document2 pagesEC - Pilegroup - BLK 226A - PC2A - P80JONHCENA13No ratings yet

- Grade SlabDocument16 pagesGrade SlabVinay Kumar100% (3)

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsJule LobresNo ratings yet

- Concrete Column DesignDocument2 pagesConcrete Column Designheherson juanNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsNaziemi AhmadNo ratings yet

- Column CalcsDocument3 pagesColumn CalcsRODNEY EDDIE ZEPHENIANo ratings yet

- 3 Pile Cap DesignDocument7 pages3 Pile Cap DesignSheikh Mizanur RahmanNo ratings yet

- 132/11Kv Al Sadd 3 Substation: Updated Structural Stair DesignDocument4 pages132/11Kv Al Sadd 3 Substation: Updated Structural Stair Designmuhammed sabir v aNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - Columnsfeiz asgarNo ratings yet

- Type in Your Company Name Here: Span No 1 Location 1/4 Span Bending Moment, M: 39.8 KNMDocument5 pagesType in Your Company Name Here: Span No 1 Location 1/4 Span Bending Moment, M: 39.8 KNMAsraf MuidinNo ratings yet

- RC Stair Designrc Stair Design (Bs8110-1:1997) : Project Job RefDocument3 pagesRC Stair Designrc Stair Design (Bs8110-1:1997) : Project Job RefAyodele Oluwaseyi DinaNo ratings yet

- Report Sambungan - Kolonial R.01Document40 pagesReport Sambungan - Kolonial R.01Lukman SitanggangNo ratings yet

- Project Job Ref.: CK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3Document4 pagesProject Job Ref.: CK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3Buvanendran SanjeevanNo ratings yet

- (Engineersdaily - Com) RCC62 Retaining WallDocument15 pages(Engineersdaily - Com) RCC62 Retaining WallAdenilson SwokowskiNo ratings yet

- Ret Wall-4.5mDocument26 pagesRet Wall-4.5mMonirul Islam EstiakNo ratings yet

- Final Pile Design - ResultantDocument3 pagesFinal Pile Design - Resultantvishnumani3011No ratings yet

- RC Beam Design Only (AS3600) - 1Document1 pageRC Beam Design Only (AS3600) - 1Anonymous 0x2pwMCWgjNo ratings yet

- Pile Cap Design SolutionDocument42 pagesPile Cap Design Solutionkhantha velNo ratings yet

- New Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateDocument4 pagesNew Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateGirinathNo ratings yet

- EA - Design of Isolated Footings Subjected To Vertical Load Only ACI 318M-14 v1.0Document2 pagesEA - Design of Isolated Footings Subjected To Vertical Load Only ACI 318M-14 v1.0engrjassmaruizoNo ratings yet

- RCC Details Design of Bridge No. 422 of N F RailwayDocument26 pagesRCC Details Design of Bridge No. 422 of N F Railwayshashibhushan singhNo ratings yet

- Steel Design - SAP 2000Document5 pagesSteel Design - SAP 2000Nayolle CoelhoNo ratings yet

- One Way Slab DesignDocument16 pagesOne Way Slab DesignAssad Mohammed AliNo ratings yet

- 2.pile - Cap.design ColumnsDocument9 pages2.pile - Cap.design Columnstaha abu el hanaNo ratings yet

- RC Beam Design To EC2Document3 pagesRC Beam Design To EC2suman_civilNo ratings yet

- Calculation Colomn: Design Column (2H)Document17 pagesCalculation Colomn: Design Column (2H)ahmed almhjaniNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- RC SLAB DESIGN (BS8110:PART1:1997) : Project Job RefDocument9 pagesRC SLAB DESIGN (BS8110:PART1:1997) : Project Job RefAkela RichardNo ratings yet

- Roof Slab A-C 1-2Document8 pagesRoof Slab A-C 1-2Mohamad Syamsul HizhamNo ratings yet

- BS8110 97 PDFDocument50 pagesBS8110 97 PDFimranmehfoozNo ratings yet

- BS8110 97Document50 pagesBS8110 97mgdarioNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- AavqeDocument4 pagesAavqeafiqNo ratings yet

- 1) Column Design 1) Column DesignDocument4 pages1) Column Design 1) Column DesignafiqNo ratings yet

- AavqeDocument4 pagesAavqeafiqNo ratings yet

- AavqeDocument4 pagesAavqeafiqNo ratings yet

- Vertices F 1Document3 pagesVertices F 1afiqNo ratings yet

- Checklist For Internal PlasteringDocument2 pagesChecklist For Internal Plasteringyash shah100% (1)

- Summary of Structural Design Review g+4Document2 pagesSummary of Structural Design Review g+4EyerusNo ratings yet

- Stairs Part 1-2023 PDFDocument12 pagesStairs Part 1-2023 PDFjjoopk ooopppNo ratings yet

- Sangath Conversion Gate01Document21 pagesSangath Conversion Gate01Åyushi ShankhdharNo ratings yet

- Book 1Document128 pagesBook 1Daniel SebastianNo ratings yet

- Retaining Wall: Analysis and Design by SAP 2000Document15 pagesRetaining Wall: Analysis and Design by SAP 2000qwerty qwertyNo ratings yet

- Drawing ContentsDocument1 pageDrawing ContentsJaycee PagadorNo ratings yet

- Mohsen Uta 2502M 12609Document108 pagesMohsen Uta 2502M 12609Daniele NephtysNo ratings yet

- Datasheet: Delcrete With Del Agg Elastomeric Concrete Patching SystemDocument2 pagesDatasheet: Delcrete With Del Agg Elastomeric Concrete Patching SystemAnkita Baban GavadeNo ratings yet

- Plumbing Code of The PH SummaryDocument7 pagesPlumbing Code of The PH SummaryapinnapinnNo ratings yet

- Material Properties C28-35 & C32-40 (EC2)Document4 pagesMaterial Properties C28-35 & C32-40 (EC2)a96lhfNo ratings yet

- Combined Footing Design Based On ACI 318-02Document2 pagesCombined Footing Design Based On ACI 318-02my09No ratings yet

- Precommissioning & Commissioning Procedure For Vavs & CavsDocument3 pagesPrecommissioning & Commissioning Procedure For Vavs & Cavsvin ssNo ratings yet

- Amhara Water Works Construction Enterprise/AWWCE/: TotalDocument45 pagesAmhara Water Works Construction Enterprise/AWWCE/: TotalJamalNo ratings yet

- Faculty of Engineering & TechnologyDocument12 pagesFaculty of Engineering & TechnologySachin HarriramNo ratings yet

- Module1 - Basics of HVACDocument7 pagesModule1 - Basics of HVACanita shindeNo ratings yet

- Siphonic Roof Drainage SystemDocument3 pagesSiphonic Roof Drainage SystemNwachukwu UmehNo ratings yet

- Power Layout Lighting Layout: Riser Diagram Electrical LegendDocument1 pagePower Layout Lighting Layout: Riser Diagram Electrical LegendAngely LudoviceNo ratings yet

- Concrete Beam DesignDocument3 pagesConcrete Beam Designheherson juanNo ratings yet

- Lecture 6 Zoning in HvacDocument32 pagesLecture 6 Zoning in HvacBhaskar BhatiaNo ratings yet

- S2XX - 50 X 60Document3 pagesS2XX - 50 X 60mohamed hassanNo ratings yet

- GRP TankDocument3 pagesGRP TankAdnan AkhtarNo ratings yet

- QCDD Fire Safety Standards Civil Defense CommentsDocument7 pagesQCDD Fire Safety Standards Civil Defense CommentsjaimonjoyNo ratings yet

- Concrete Blocks: Product & Technical GuideDocument44 pagesConcrete Blocks: Product & Technical GuideamandeepsuperanNo ratings yet

- Screed Bases and In-Situ FlooringsDocument28 pagesScreed Bases and In-Situ Flooringsrekcah ehtNo ratings yet

- Roofing Materials: M O D U L E 1 1 BT 2 1 3Document49 pagesRoofing Materials: M O D U L E 1 1 BT 2 1 3Darwin AquinoNo ratings yet

- Area StatementDocument6 pagesArea StatementSougata DasNo ratings yet

- Project Two Storey Residence Subject BilDocument6 pagesProject Two Storey Residence Subject BilEdgar LavapiezNo ratings yet

- Rate Analysis Part 2Document17 pagesRate Analysis Part 2rajendraNo ratings yet

- Capital Gate TowerDocument29 pagesCapital Gate TowerUmesh KhampariaNo ratings yet