Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

28 viewsInspection of Torque Converter Clutch and Drive Plate

Inspection of Torque Converter Clutch and Drive Plate

Uploaded by

Mayobanex Moya MartinezThis document provides inspection instructions for a torque converter clutch and drive plate in 3 steps:

1. Inspect the one-way clutch using two special tools to check that it locks in one direction and freely rotates in the other. Clean and retest or replace the converter if it fails.

2. Measure the drive plate runout and inspect the ring gear, replacing the drive plate if runout exceeds 0.20mm or the ring gear is damaged.

3. Measure the torque converter clutch sleeve runout using a dial indicator mounted on the drive plate, reorienting or replacing the clutch if runout exceeds 0.30mm.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Engine Valve Lash - Inspect - Adjust c9Document3 pagesEngine Valve Lash - Inspect - Adjust c9Antonio78% (9)

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn Martin100% (1)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- AE111 Engine ManualDocument60 pagesAE111 Engine ManualMohammad Faizal50% (2)

- Valve Clearance (1Hd Fte) : InspectionDocument2 pagesValve Clearance (1Hd Fte) : InspectionArief SoehartoNo ratings yet

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- Toyota 2azfe Valve Clearance PDFDocument9 pagesToyota 2azfe Valve Clearance PDFMarcos EmmanuelNo ratings yet

- Engine Valve Lash - Inspect - AdjustDocument5 pagesEngine Valve Lash - Inspect - AdjustVictor NunezNo ratings yet

- Valve Lash C13Document4 pagesValve Lash C13Jose F Rivera Morales100% (1)

- CONVERTER AND DRIVE PLATE INSPECTIONlDocument2 pagesCONVERTER AND DRIVE PLATE INSPECTIONlDhammikaNo ratings yet

- Torque Converter InspectionDocument2 pagesTorque Converter InspectionTilleya MadramootooNo ratings yet

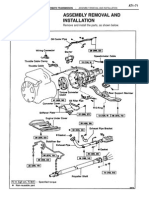

- Assembly Removal and Installation: Remove and Install The Parts, As Shown BelowDocument5 pagesAssembly Removal and Installation: Remove and Install The Parts, As Shown BelowHugoE.TorresNo ratings yet

- 2zzge Valve Clearance PDFDocument6 pages2zzge Valve Clearance PDFGullwing Motor ServiceNo ratings yet

- Insp Valve Clearance 2.7 3rz PDFDocument5 pagesInsp Valve Clearance 2.7 3rz PDFEdwin Versteeg100% (1)

- 1 AzDocument7 pages1 AzEdU RECTIFICANo ratings yet

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (4)

- Httplexus - Solar3.eurmrm684em em 0026 PDFDocument5 pagesHttplexus - Solar3.eurmrm684em em 0026 PDFWiz KingNo ratings yet

- Ajuste Valvulas Motor 336DDocument5 pagesAjuste Valvulas Motor 336Djuan sebastianNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- 03 - Valve Clearance - AdjustmentDocument5 pages03 - Valve Clearance - AdjustmentjordantNo ratings yet

- QuickServe Online - (4021499) K19 Service ManualDocument10 pagesQuickServe Online - (4021499) K19 Service Manualengmohsen.ramadanhotmail.com100% (1)

- 4JG2 Timing Spec PDFDocument3 pages4JG2 Timing Spec PDF650LNo ratings yet

- Cat C11-C13-C15-C18 MANUAL DE CALIBRACIONESDocument27 pagesCat C11-C13-C15-C18 MANUAL DE CALIBRACIONESclaudio80% (5)

- Engine Valve Lash - Inspect/AdjustDocument4 pagesEngine Valve Lash - Inspect/AdjustHrvoje ŠkaricaNo ratings yet

- Catalogo Foton - Bj3319dmpkc-Abza02Document5 pagesCatalogo Foton - Bj3319dmpkc-Abza02Jhean PhierNo ratings yet

- Clutch Actuator & TCM AssemblyDocument13 pagesClutch Actuator & TCM AssemblyVinh XuânNo ratings yet

- Valve Clearance: AdjustmentDocument6 pagesValve Clearance: AdjustmentBoncu BoncuNo ratings yet

- 1HD-T 2Document37 pages1HD-T 2HERMAWAN100% (2)

- 950H - Ajuste de Luz de VálvulasDocument4 pages950H - Ajuste de Luz de VálvulasRenato Assis da Silva100% (2)

- Valve Clearance (1Hz, 1Hd T) : InspectionDocument4 pagesValve Clearance (1Hz, 1Hd T) : InspectionArief SoehartoNo ratings yet

- Docslide - Us - Corolla Eng Chassis Manual rm821 E1047 PDFDocument1 pageDocslide - Us - Corolla Eng Chassis Manual rm821 E1047 PDFIngrid Garcia de JaureguiNo ratings yet

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliNo ratings yet

- Calibracion de Valvulas Toyota 6V Hi Lux 1GRDocument19 pagesCalibracion de Valvulas Toyota 6V Hi Lux 1GRcpaolinodNo ratings yet

- Removal of AlternatorDocument11 pagesRemoval of AlternatorvixentdNo ratings yet

- 324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsDocument5 pages324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsjhonNo ratings yet

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Shutdown SISDocument5 pagesEngine Valve Lash - Inspect/Adjust: Shutdown SISChakrouneNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- Generator Assy (1Az-Fe) : OverhaulDocument5 pagesGenerator Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Ajuste Valvulas Motor 730Document5 pagesAjuste Valvulas Motor 730juan sebastianNo ratings yet

- Engine Valve Lash - Inspect Adjust (SENR9939-32)Document3 pagesEngine Valve Lash - Inspect Adjust (SENR9939-32)Guido Emanuel SteinbachNo ratings yet

- 10 - Timing Chain - Installation PDFDocument11 pages10 - Timing Chain - Installation PDFbakriramzi100% (2)

- Pruebas y Ajustes C27 and C32 GeneratorDocument5 pagesPruebas y Ajustes C27 and C32 GeneratorMuhammad Ary safarta100% (1)

- Calibracion Valvulas Motor C12 CaterpillarDocument5 pagesCalibracion Valvulas Motor C12 CaterpillarRamón José Aponte Franco100% (9)

- Calibracion Valvulas Motor c12 CaterpillarDocument5 pagesCalibracion Valvulas Motor c12 CaterpillarOmar Diaz Segura100% (1)

- CAT C27 - C32 Ajuste La Luz de ValvulasDocument5 pagesCAT C27 - C32 Ajuste La Luz de ValvulasGdar KbzaNo ratings yet

- AlternatorDocument19 pagesAlternatorcpgmotors100% (1)

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- Testing & Adjusting Valve Lash C18Document4 pagesTesting & Adjusting Valve Lash C18Sapar SouzaNo ratings yet

- Tilt Steering Column: A: RemovalDocument4 pagesTilt Steering Column: A: RemovalmiguelNo ratings yet

- Valve LashDocument1 pageValve LashJose Luis Poma MNo ratings yet

- Folga Valvula c9Document4 pagesFolga Valvula c9Victor NoschangNo ratings yet

- Regulagem de Válvulas (C15 C18)Document3 pagesRegulagem de Válvulas (C15 C18)caiocunhaconquistaNo ratings yet

- Service Training and Publication Bulletin: Date: 2011/3/9Document5 pagesService Training and Publication Bulletin: Date: 2011/3/9galmetronikNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Automatic Shift Schedule: Inspection of Park/Neutral Position SwitchDocument1 pageAutomatic Shift Schedule: Inspection of Park/Neutral Position SwitchMayobanex Moya MartinezNo ratings yet

- 45diagnosi 1Document5 pages45diagnosi 1hybrid_motorsports_llcNo ratings yet

- Electrically Controlled Shift Lock SystemDocument3 pagesElectrically Controlled Shift Lock SystemMayobanex Moya MartinezNo ratings yet

- Manual Shifting Test: Automatic TransmissionDocument1 pageManual Shifting Test: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- On-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionDocument6 pagesOn-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Automatic Shift Schedule: Inspection of Park/Neutral Position SwitchDocument1 pageAutomatic Shift Schedule: Inspection of Park/Neutral Position SwitchMayobanex Moya MartinezNo ratings yet

- Mechanical System Tests: Automatic TransmissionDocument7 pagesMechanical System Tests: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Automatic Shift ScheduleDocument4 pagesAutomatic Shift ScheduleMayobanex Moya MartinezNo ratings yet

- 43basictro PDFDocument1 page43basictro PDFMayobanex Moya MartinezNo ratings yet

- Mechanical System Tests: Stall TestDocument8 pagesMechanical System Tests: Stall TestMayobanex Moya MartinezNo ratings yet

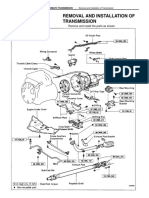

- Removal and Installation of Transmission: Remove and Install The Parts As ShownDocument2 pagesRemoval and Installation of Transmission: Remove and Install The Parts As ShownMayobanex Moya MartinezNo ratings yet

- 29basictro PDFDocument1 page29basictro PDFMayobanex Moya MartinezNo ratings yet

- Inspection of Park/Neutral Position SwitchDocument1 pageInspection of Park/Neutral Position SwitchMayobanex Moya MartinezNo ratings yet

- Removal and Installation of Transmission: Remove and Install The Parts As ShownDocument2 pagesRemoval and Installation of Transmission: Remove and Install The Parts As ShownMayobanex Moya MartinezNo ratings yet

- Inspection of Torque Converter Clutch and Drive PlateDocument1 pageInspection of Torque Converter Clutch and Drive PlateMayobanex Moya MartinezNo ratings yet

- Manual Shifting Test: Automatic TransmissionDocument2 pagesManual Shifting Test: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- On-Vehicle Repair: Valve Body Removal of Valve BodyDocument10 pagesOn-Vehicle Repair: Valve Body Removal of Valve BodyMayobanex Moya MartinezNo ratings yet

- Preliminary Check: Automatic TransmissionDocument4 pagesPreliminary Check: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Operation: Mechanical Operation Operating ConditionsDocument6 pagesOperation: Mechanical Operation Operating ConditionsMayobanex Moya MartinezNo ratings yet

- General Troubleshooting: Possible Cause Remedy ProblemDocument2 pagesGeneral Troubleshooting: Possible Cause Remedy ProblemMayobanex Moya MartinezNo ratings yet

- Troubleshooting Basic Troubleshooting: Automatic TransmissionDocument1 pageTroubleshooting Basic Troubleshooting: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Preliminary Check: Automatic TransmissionDocument3 pagesPreliminary Check: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Removal and Installation of Transmission: Remove and Install The Parts As ShownDocument2 pagesRemoval and Installation of Transmission: Remove and Install The Parts As ShownMayobanex Moya MartinezNo ratings yet

- Automatic Shift ScheduleDocument2 pagesAutomatic Shift ScheduleMayobanex Moya MartinezNo ratings yet

- Inspection of Park/Neutral Posiiton SwitchDocument1 pageInspection of Park/Neutral Posiiton SwitchMayobanex Moya MartinezNo ratings yet

- 13descript PDFDocument3 pages13descript PDFMayobanex Moya MartinezNo ratings yet

- Manual Shifting Test: Automatic TransmissionDocument2 pagesManual Shifting Test: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Operation: Mechanical Operation Operating ConditionsDocument7 pagesOperation: Mechanical Operation Operating ConditionsMayobanex Moya MartinezNo ratings yet

- Electronic Control System: PrecautionDocument11 pagesElectronic Control System: PrecautionMayobanex Moya MartinezNo ratings yet

Inspection of Torque Converter Clutch and Drive Plate

Inspection of Torque Converter Clutch and Drive Plate

Uploaded by

Mayobanex Moya Martinez0 ratings0% found this document useful (0 votes)

28 views1 pageThis document provides inspection instructions for a torque converter clutch and drive plate in 3 steps:

1. Inspect the one-way clutch using two special tools to check that it locks in one direction and freely rotates in the other. Clean and retest or replace the converter if it fails.

2. Measure the drive plate runout and inspect the ring gear, replacing the drive plate if runout exceeds 0.20mm or the ring gear is damaged.

3. Measure the torque converter clutch sleeve runout using a dial indicator mounted on the drive plate, reorienting or replacing the clutch if runout exceeds 0.30mm.

Original Description:

Original Title

12torqueco.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides inspection instructions for a torque converter clutch and drive plate in 3 steps:

1. Inspect the one-way clutch using two special tools to check that it locks in one direction and freely rotates in the other. Clean and retest or replace the converter if it fails.

2. Measure the drive plate runout and inspect the ring gear, replacing the drive plate if runout exceeds 0.20mm or the ring gear is damaged.

3. Measure the torque converter clutch sleeve runout using a dial indicator mounted on the drive plate, reorienting or replacing the clutch if runout exceeds 0.30mm.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

28 views1 pageInspection of Torque Converter Clutch and Drive Plate

Inspection of Torque Converter Clutch and Drive Plate

Uploaded by

Mayobanex Moya MartinezThis document provides inspection instructions for a torque converter clutch and drive plate in 3 steps:

1. Inspect the one-way clutch using two special tools to check that it locks in one direction and freely rotates in the other. Clean and retest or replace the converter if it fails.

2. Measure the drive plate runout and inspect the ring gear, replacing the drive plate if runout exceeds 0.20mm or the ring gear is damaged.

3. Measure the torque converter clutch sleeve runout using a dial indicator mounted on the drive plate, reorienting or replacing the clutch if runout exceeds 0.30mm.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

AT40

AUTOMATIC TRANSMISSION Torque Converter Clutch and Drive Plate

TORQUE CONVERTER CLUTCH AND

DRIVE PLATE

INSPECTION OF TORQUE CONVERTER

CLUTCH AND DRIVE PLATE

1. INSPECT ONEWAY CLUTCH

(a) Install SST into the inner race of the oneway clutch.

SST 0935020015 (0939722020)

(b) Install SST so that it fits in the notch of the con

verter hub and outer race of the oneway clutch.

SST 0935020015 (0939722020)

(c) With the torque converter clutch standing on its

side, the clutch locks when turned counterclock

wise, and rotates freely and smoothly clockwise.

If necessary, clean the converter and retest the clutch.

Replace the converter if the clutch still fails the test.

2. MEASURE DRIVE PLATE RUNOUT AND INSPECT RING

GEAR

Set up a dial indicator and measure the drive pIate

runout.

If runout exceeds 0.20 mm (0.0079 in.) or if the ring gear

is damaged, replace the drive plate. If installing a new

drive plate, note the orientation of spacers and tighten

the bolts.

Torque: 83 Nm (850 kgfcm, 61 ftlbf)

3. MEASURE TORQUE CONVERTER CLUTCH SLEEVE

RUNOUT

(a) Temporarily mount the torque converter clutch to

the drive plate. Set up a dial indicator.

If runout exceeds 0.30 mm (0.0118 in.), try to correct by

reorienting the installation of the converter. If excessive

runout cannot be corrected, replace the torque converter

clutch.

HINT: Mark the position of the converter to ensure cor

rect installation.

(b) Remove the torque converter clutch.

You might also like

- Engine Valve Lash - Inspect - Adjust c9Document3 pagesEngine Valve Lash - Inspect - Adjust c9Antonio78% (9)

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn Martin100% (1)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- AE111 Engine ManualDocument60 pagesAE111 Engine ManualMohammad Faizal50% (2)

- Valve Clearance (1Hd Fte) : InspectionDocument2 pagesValve Clearance (1Hd Fte) : InspectionArief SoehartoNo ratings yet

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- Toyota 2azfe Valve Clearance PDFDocument9 pagesToyota 2azfe Valve Clearance PDFMarcos EmmanuelNo ratings yet

- Engine Valve Lash - Inspect - AdjustDocument5 pagesEngine Valve Lash - Inspect - AdjustVictor NunezNo ratings yet

- Valve Lash C13Document4 pagesValve Lash C13Jose F Rivera Morales100% (1)

- CONVERTER AND DRIVE PLATE INSPECTIONlDocument2 pagesCONVERTER AND DRIVE PLATE INSPECTIONlDhammikaNo ratings yet

- Torque Converter InspectionDocument2 pagesTorque Converter InspectionTilleya MadramootooNo ratings yet

- Assembly Removal and Installation: Remove and Install The Parts, As Shown BelowDocument5 pagesAssembly Removal and Installation: Remove and Install The Parts, As Shown BelowHugoE.TorresNo ratings yet

- 2zzge Valve Clearance PDFDocument6 pages2zzge Valve Clearance PDFGullwing Motor ServiceNo ratings yet

- Insp Valve Clearance 2.7 3rz PDFDocument5 pagesInsp Valve Clearance 2.7 3rz PDFEdwin Versteeg100% (1)

- 1 AzDocument7 pages1 AzEdU RECTIFICANo ratings yet

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (4)

- Httplexus - Solar3.eurmrm684em em 0026 PDFDocument5 pagesHttplexus - Solar3.eurmrm684em em 0026 PDFWiz KingNo ratings yet

- Ajuste Valvulas Motor 336DDocument5 pagesAjuste Valvulas Motor 336Djuan sebastianNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- 03 - Valve Clearance - AdjustmentDocument5 pages03 - Valve Clearance - AdjustmentjordantNo ratings yet

- QuickServe Online - (4021499) K19 Service ManualDocument10 pagesQuickServe Online - (4021499) K19 Service Manualengmohsen.ramadanhotmail.com100% (1)

- 4JG2 Timing Spec PDFDocument3 pages4JG2 Timing Spec PDF650LNo ratings yet

- Cat C11-C13-C15-C18 MANUAL DE CALIBRACIONESDocument27 pagesCat C11-C13-C15-C18 MANUAL DE CALIBRACIONESclaudio80% (5)

- Engine Valve Lash - Inspect/AdjustDocument4 pagesEngine Valve Lash - Inspect/AdjustHrvoje ŠkaricaNo ratings yet

- Catalogo Foton - Bj3319dmpkc-Abza02Document5 pagesCatalogo Foton - Bj3319dmpkc-Abza02Jhean PhierNo ratings yet

- Clutch Actuator & TCM AssemblyDocument13 pagesClutch Actuator & TCM AssemblyVinh XuânNo ratings yet

- Valve Clearance: AdjustmentDocument6 pagesValve Clearance: AdjustmentBoncu BoncuNo ratings yet

- 1HD-T 2Document37 pages1HD-T 2HERMAWAN100% (2)

- 950H - Ajuste de Luz de VálvulasDocument4 pages950H - Ajuste de Luz de VálvulasRenato Assis da Silva100% (2)

- Valve Clearance (1Hz, 1Hd T) : InspectionDocument4 pagesValve Clearance (1Hz, 1Hd T) : InspectionArief SoehartoNo ratings yet

- Docslide - Us - Corolla Eng Chassis Manual rm821 E1047 PDFDocument1 pageDocslide - Us - Corolla Eng Chassis Manual rm821 E1047 PDFIngrid Garcia de JaureguiNo ratings yet

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliNo ratings yet

- Calibracion de Valvulas Toyota 6V Hi Lux 1GRDocument19 pagesCalibracion de Valvulas Toyota 6V Hi Lux 1GRcpaolinodNo ratings yet

- Removal of AlternatorDocument11 pagesRemoval of AlternatorvixentdNo ratings yet

- 324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsDocument5 pages324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsjhonNo ratings yet

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Shutdown SISDocument5 pagesEngine Valve Lash - Inspect/Adjust: Shutdown SISChakrouneNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- Generator Assy (1Az-Fe) : OverhaulDocument5 pagesGenerator Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Ajuste Valvulas Motor 730Document5 pagesAjuste Valvulas Motor 730juan sebastianNo ratings yet

- Engine Valve Lash - Inspect Adjust (SENR9939-32)Document3 pagesEngine Valve Lash - Inspect Adjust (SENR9939-32)Guido Emanuel SteinbachNo ratings yet

- 10 - Timing Chain - Installation PDFDocument11 pages10 - Timing Chain - Installation PDFbakriramzi100% (2)

- Pruebas y Ajustes C27 and C32 GeneratorDocument5 pagesPruebas y Ajustes C27 and C32 GeneratorMuhammad Ary safarta100% (1)

- Calibracion Valvulas Motor C12 CaterpillarDocument5 pagesCalibracion Valvulas Motor C12 CaterpillarRamón José Aponte Franco100% (9)

- Calibracion Valvulas Motor c12 CaterpillarDocument5 pagesCalibracion Valvulas Motor c12 CaterpillarOmar Diaz Segura100% (1)

- CAT C27 - C32 Ajuste La Luz de ValvulasDocument5 pagesCAT C27 - C32 Ajuste La Luz de ValvulasGdar KbzaNo ratings yet

- AlternatorDocument19 pagesAlternatorcpgmotors100% (1)

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- Testing & Adjusting Valve Lash C18Document4 pagesTesting & Adjusting Valve Lash C18Sapar SouzaNo ratings yet

- Tilt Steering Column: A: RemovalDocument4 pagesTilt Steering Column: A: RemovalmiguelNo ratings yet

- Valve LashDocument1 pageValve LashJose Luis Poma MNo ratings yet

- Folga Valvula c9Document4 pagesFolga Valvula c9Victor NoschangNo ratings yet

- Regulagem de Válvulas (C15 C18)Document3 pagesRegulagem de Válvulas (C15 C18)caiocunhaconquistaNo ratings yet

- Service Training and Publication Bulletin: Date: 2011/3/9Document5 pagesService Training and Publication Bulletin: Date: 2011/3/9galmetronikNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Automatic Shift Schedule: Inspection of Park/Neutral Position SwitchDocument1 pageAutomatic Shift Schedule: Inspection of Park/Neutral Position SwitchMayobanex Moya MartinezNo ratings yet

- 45diagnosi 1Document5 pages45diagnosi 1hybrid_motorsports_llcNo ratings yet

- Electrically Controlled Shift Lock SystemDocument3 pagesElectrically Controlled Shift Lock SystemMayobanex Moya MartinezNo ratings yet

- Manual Shifting Test: Automatic TransmissionDocument1 pageManual Shifting Test: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- On-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionDocument6 pagesOn-Vehicle Repair Valve Body Removal of Valve Body: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Automatic Shift Schedule: Inspection of Park/Neutral Position SwitchDocument1 pageAutomatic Shift Schedule: Inspection of Park/Neutral Position SwitchMayobanex Moya MartinezNo ratings yet

- Mechanical System Tests: Automatic TransmissionDocument7 pagesMechanical System Tests: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Automatic Shift ScheduleDocument4 pagesAutomatic Shift ScheduleMayobanex Moya MartinezNo ratings yet

- 43basictro PDFDocument1 page43basictro PDFMayobanex Moya MartinezNo ratings yet

- Mechanical System Tests: Stall TestDocument8 pagesMechanical System Tests: Stall TestMayobanex Moya MartinezNo ratings yet

- Removal and Installation of Transmission: Remove and Install The Parts As ShownDocument2 pagesRemoval and Installation of Transmission: Remove and Install The Parts As ShownMayobanex Moya MartinezNo ratings yet

- 29basictro PDFDocument1 page29basictro PDFMayobanex Moya MartinezNo ratings yet

- Inspection of Park/Neutral Position SwitchDocument1 pageInspection of Park/Neutral Position SwitchMayobanex Moya MartinezNo ratings yet

- Removal and Installation of Transmission: Remove and Install The Parts As ShownDocument2 pagesRemoval and Installation of Transmission: Remove and Install The Parts As ShownMayobanex Moya MartinezNo ratings yet

- Inspection of Torque Converter Clutch and Drive PlateDocument1 pageInspection of Torque Converter Clutch and Drive PlateMayobanex Moya MartinezNo ratings yet

- Manual Shifting Test: Automatic TransmissionDocument2 pagesManual Shifting Test: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- On-Vehicle Repair: Valve Body Removal of Valve BodyDocument10 pagesOn-Vehicle Repair: Valve Body Removal of Valve BodyMayobanex Moya MartinezNo ratings yet

- Preliminary Check: Automatic TransmissionDocument4 pagesPreliminary Check: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Operation: Mechanical Operation Operating ConditionsDocument6 pagesOperation: Mechanical Operation Operating ConditionsMayobanex Moya MartinezNo ratings yet

- General Troubleshooting: Possible Cause Remedy ProblemDocument2 pagesGeneral Troubleshooting: Possible Cause Remedy ProblemMayobanex Moya MartinezNo ratings yet

- Troubleshooting Basic Troubleshooting: Automatic TransmissionDocument1 pageTroubleshooting Basic Troubleshooting: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Preliminary Check: Automatic TransmissionDocument3 pagesPreliminary Check: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Removal and Installation of Transmission: Remove and Install The Parts As ShownDocument2 pagesRemoval and Installation of Transmission: Remove and Install The Parts As ShownMayobanex Moya MartinezNo ratings yet

- Automatic Shift ScheduleDocument2 pagesAutomatic Shift ScheduleMayobanex Moya MartinezNo ratings yet

- Inspection of Park/Neutral Posiiton SwitchDocument1 pageInspection of Park/Neutral Posiiton SwitchMayobanex Moya MartinezNo ratings yet

- 13descript PDFDocument3 pages13descript PDFMayobanex Moya MartinezNo ratings yet

- Manual Shifting Test: Automatic TransmissionDocument2 pagesManual Shifting Test: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Operation: Mechanical Operation Operating ConditionsDocument7 pagesOperation: Mechanical Operation Operating ConditionsMayobanex Moya MartinezNo ratings yet

- Electronic Control System: PrecautionDocument11 pagesElectronic Control System: PrecautionMayobanex Moya MartinezNo ratings yet