Professional Documents

Culture Documents

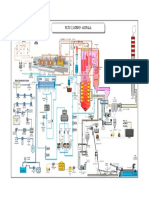

Adipala Power System Diagram (660 MW)

Adipala Power System Diagram (660 MW)

Uploaded by

Robiansah Tri AchbarCopyright:

Available Formats

You might also like

- Vacuum - Condenser Presentasi 2Document17 pagesVacuum - Condenser Presentasi 2Neon Phoerba100% (2)

- Boiler HydrolicDocument17 pagesBoiler HydrolicYudha Andrie Sasi ZenNo ratings yet

- Boiler-1 Aditya Cement Works Sept 21Document7 pagesBoiler-1 Aditya Cement Works Sept 21ameer meerNo ratings yet

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Document1 pageDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliNo ratings yet

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDocument23 pagesSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINo ratings yet

- Test for Half of Condenser Operation冷凝器半面运行试验Document2 pagesTest for Half of Condenser Operation冷凝器半面运行试验erwin5sambas5aryanaNo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- 125 - Performance Guarantee - Maan - R4Document4 pages125 - Performance Guarantee - Maan - R4Ahmad ShekhNo ratings yet

- IESR Flexible Thermal Power Plant 2022Document66 pagesIESR Flexible Thermal Power Plant 2022jonny herbartNo ratings yet

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesDocument9 pagesDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesgermantoledo244596No ratings yet

- SteamDocument40 pagesSteamRupesh Anand100% (2)

- Heat Rate Calculation - JITPLDocument8 pagesHeat Rate Calculation - JITPLbnswain1No ratings yet

- Power Plant Boiler EfficiencyDocument15 pagesPower Plant Boiler EfficiencyMarcJexsonDeGuzmanNo ratings yet

- Pltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)Document5 pagesPltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)sandrositohangNo ratings yet

- Sch7 m200 Steam TurbineDocument7 pagesSch7 m200 Steam Turbinetri wibisono100% (1)

- Coal Blending With Fly Ash-An ApproachDocument28 pagesCoal Blending With Fly Ash-An ApproachcaptainrajneeshNo ratings yet

- A4 Desuperheater PDFDocument6 pagesA4 Desuperheater PDF련서긔No ratings yet

- Overiew of Comb Cycle Rev 6.0 - Part 1Document73 pagesOveriew of Comb Cycle Rev 6.0 - Part 1SamNo ratings yet

- NPHRDocument9 pagesNPHRAndreas Sahat P. SinagaNo ratings yet

- Errors in Boiler Efficiency Standards - SlideshowDocument23 pagesErrors in Boiler Efficiency Standards - Slideshowmrex511No ratings yet

- TR 109546Document301 pagesTR 109546Piyush AgarwalNo ratings yet

- Mroy Pump Catalogue PDFDocument6 pagesMroy Pump Catalogue PDFTitus FelixNo ratings yet

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- Summary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdDocument5 pagesSummary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdidilfitriNo ratings yet

- My Boiler Efficiency ReportDocument6 pagesMy Boiler Efficiency ReportRufus D SNo ratings yet

- Spray Cooling Enhancement of Air - Cooled CondensersDocument142 pagesSpray Cooling Enhancement of Air - Cooled CondensersRicardo OrtizNo ratings yet

- 055 NOX ReductionDocument57 pages055 NOX ReductionSammy-papa Maropeng ShikaNo ratings yet

- HMBD Review Check ListDocument4 pagesHMBD Review Check Listctraminst_81No ratings yet

- HRSG DesignDocument11 pagesHRSG DesignVennila Rangith100% (1)

- Turbine Bypass SystemDocument20 pagesTurbine Bypass Systemamer_arauf100% (18)

- 1a Natural Circulation BoilersDocument44 pages1a Natural Circulation BoilersFraser LamontNo ratings yet

- 3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+Document34 pages3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- PWR1059 Thermal Power Plant Performance Testing - May 2022Document11 pagesPWR1059 Thermal Power Plant Performance Testing - May 2022nguyenhuutan91No ratings yet

- Balancing of LP Rotor at Site PDFDocument5 pagesBalancing of LP Rotor at Site PDFsanjeevchhabra0% (1)

- GS Bindra BHEL Ultra Supercritical Power Plants PDFDocument46 pagesGS Bindra BHEL Ultra Supercritical Power Plants PDFBKumrNo ratings yet

- Ash ReinjectionDocument22 pagesAsh Reinjectiongaol_bird009No ratings yet

- Heat Rate CalculationsDocument22 pagesHeat Rate CalculationsPankaj TipramwarNo ratings yet

- Bahan Presentasi Bahasa Inggris-Superheater-In EnglishDocument2 pagesBahan Presentasi Bahasa Inggris-Superheater-In EnglishPangestu Try WibowoNo ratings yet

- Supercritical Benson BoilerDocument18 pagesSupercritical Benson BoilerJerry Mateo100% (2)

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Training Report TOYEB PDFDocument39 pagesTraining Report TOYEB PDFDevesh Pratap YadavNo ratings yet

- Triveni Turbines AR2018-19Document228 pagesTriveni Turbines AR2018-19Arpit GuptaNo ratings yet

- ASME PTC 6a - 2000 Appendix PTC 6 Steam TurbineDocument175 pagesASME PTC 6a - 2000 Appendix PTC 6 Steam TurbineKristianNo ratings yet

- Supercritical Technology in BoilersDocument17 pagesSupercritical Technology in Boilersamit joshi100% (4)

- Mds HPH 1 - Skoda PowerDocument3 pagesMds HPH 1 - Skoda PoweridilfitriNo ratings yet

- Boiler Chemical CleaningDocument24 pagesBoiler Chemical CleaningYudha Andrie Sasi ZenNo ratings yet

- Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)Document6 pagesJob No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)A N MadhavanNo ratings yet

- Ejector Performance Test Procedure: Quality AssuranceDocument8 pagesEjector Performance Test Procedure: Quality AssuranceManan gujjarNo ratings yet

- Hydrazine DosingDocument2 pagesHydrazine DosingAnonymous 3HTgMDO100% (1)

- 015.B.0 - Blow Down Quench Water CalculationDocument2 pages015.B.0 - Blow Down Quench Water Calculationmkchy12No ratings yet

- ME6701-Power Plant EngineeringDocument16 pagesME6701-Power Plant EngineeringNizam MANo ratings yet

- Boiler & Turbin CFK #3 Flow ProsesDocument2 pagesBoiler & Turbin CFK #3 Flow ProsesNur Ali Said100% (1)

- For Information: Doosan Heavy Industries & ConstructionDocument9 pagesFor Information: Doosan Heavy Industries & ConstructionĐể MaiNo ratings yet

- Adipala Power System Diagram (660 MW)Document1 pageAdipala Power System Diagram (660 MW)Budi WahyonoNo ratings yet

- DC Lts TMR DC LTS: OFF Reset Emergency StopDocument1 pageDC Lts TMR DC LTS: OFF Reset Emergency Stopwillian100% (1)

- John Deere 4024TF281 Installation DrawingDocument1 pageJohn Deere 4024TF281 Installation DrawingRamon Pujol PerramonNo ratings yet

- PP Aaa PP1 111Document18 pagesPP Aaa PP1 111Rabah AmidiNo ratings yet

- EMC Truck Service: HeadlightsDocument3 pagesEMC Truck Service: HeadlightsWalterNo ratings yet

- API 579-2 - 13.1 Rev1Document50 pagesAPI 579-2 - 13.1 Rev1osbertodiaz100% (2)

- Api 579-2 - 4.4Document22 pagesApi 579-2 - 4.4Robiansah Tri AchbarNo ratings yet

- Api 579-2 - 4.2Document28 pagesApi 579-2 - 4.2Robiansah Tri AchbarNo ratings yet

- Api 579-2 - 5.1Document63 pagesApi 579-2 - 5.1Robiansah Tri Achbar67% (3)

- Api 579-2 - 4.2Document28 pagesApi 579-2 - 4.2Robiansah Tri AchbarNo ratings yet

- Calculating PCN Using The FAA MethodDocument43 pagesCalculating PCN Using The FAA MethodRobiansah Tri AchbarNo ratings yet

Adipala Power System Diagram (660 MW)

Adipala Power System Diagram (660 MW)

Uploaded by

Robiansah Tri AchbarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adipala Power System Diagram (660 MW)

Adipala Power System Diagram (660 MW)

Uploaded by

Robiansah Tri AchbarCopyright:

Available Formats

To PLN Substation Kesugihan 1 PLTU

PLTU 22 JATENG

JATENG -- ADIPALA

ADIPALA

To PLN Substation Kesugihan 2

562-1

562-1PJ/121/DIR/2008

PJ/121/DIR/2008

To PLTU S2P 1

To PLTU S2P 2

45.13 kg/ , 569 , 1731 T/h (BMCR) Hot Reheat

500 kV GIS 245.8 kg/ , 566 , 2069 T/h (BMCR)

HP Desuperheater

Bypass Desuperheater

Valve

70 % MCR

Cold Reheat Separator

Vert.

22kV Reheater

LP

Bypass

Valve

660 MW

To Switchgear:

P1 BBA Generator Horiz.

Generator P1 BBB UAT LP II Turbine Reheater

Transformer LP I Turbine IP Turbine

HP Turbine Water Final SH Low Superheater

(LSH) Economizer

2 x 43 MVA Strorage

800 MVA Tank

Platen Middle

Atm SH SH

Condenser Shell B Condenser Shell A To BFPT

Condensate

Vaccum Pump Furnace

width: 23.7 m

LP HTR B Condenser LP HTR A From All

Water Desalination System 0.0785 barg

Flash Boiler

depth: 16.3 m

height: 68.0 m

Economizer

Water feeding Tank Drain

To Out Fall 90 m3 Ignition

Demin Water To WWTP

Pump Boiler

Sump

Boiler Circulation

Mix Bed Resin Anion Bed Stack

Mix Bed Condensate Pump (Height 275 M)

Trap Resin Trap ( 787.8 T/hr) ESP

Pump Dust Content <

(2x50%) 100 mg/Nm3

Air Heater

Burner

Cation Bed Cation Bed Anion Bed Condensate

Resin Trap Polishing

Second Stage Unit Bottom

SWRO Modul Ash ID FAN Gas Flow : 598.5 /s

Second Stage (2x50% BMCR)

Catridge Filter Deaerator

Desuperheater

Second Stage Submarged

RO HPP Gland

scrapper Chain

Steam HP No.8 HTR

Cond. Feed Water Tank Conveyor

FD FAN

(2x50% BMCR

Condensate 217.4 m3/s) From WWT

SecondStage Recirc FCV Ash Silo

HP No.7 HTR From EP Ash

Feed Pump

Clinker

Bunker Bay From Bottom

BC#6 A/B 1250 T/h PA FAN Ash

Gland Steam (2x50% BMCR

Exauster Booster Booster Booster Ash 163.9 m3/s) Wet

Pump Pump Pump HP No.6 HTR Dry Ash Ash

2 x 50 % Container ESP Ash

First Stage First Stage First Stage Coal Silo

SWRO HPP SWRO Modul Product Water (6 x 560 ton)

To To

Tank Condenser Condenser

ASH POND

From Cold From Cold Bottom Ash.

Reheat Reheat

First Stage Double Sea Water Pre-

Catridge Filter Chamber Multi Treatment

Medium Filter BC#5 A/B 1250 T/h

System M

Coal Feeder

(6 x 73.8 T/hr)

From Cold

LP No.3 HTR BFPM Primary Air

(1x35%) BFPT

(2x50%) Coal Crusher

LP No.4 HTR Pulverizer

Ship

C.W Pump Unloader

(2x50%) (2 x 1600 T/hr)

From Cold

Primary Air BC#8 700 T/h

BC#4 A/B1250 T/h Stacker/ BC#7 A/B 1600 T/h

Raclamer TT 2

Unloading Pump Main Fuel Tank TT 1

BC#2 1600 T/h BC#1 A/B 1600

50 m3/h Cap: 5000 TT 3 T/h

Chlorination

Hindia Ocean Chlorination Plant BC#3 3200 T/h

Fuel Pump

Tank Fuel Truck Daily Fuel 30 m3/h Pulverizer Sealing Air Fan

2 x 60 m (130 kg /hr) Tank (2 x 100%) (35000 DWT)

Cap: 750

Ship

Underground Hopper

You might also like

- Vacuum - Condenser Presentasi 2Document17 pagesVacuum - Condenser Presentasi 2Neon Phoerba100% (2)

- Boiler HydrolicDocument17 pagesBoiler HydrolicYudha Andrie Sasi ZenNo ratings yet

- Boiler-1 Aditya Cement Works Sept 21Document7 pagesBoiler-1 Aditya Cement Works Sept 21ameer meerNo ratings yet

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Document1 pageDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliNo ratings yet

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDocument23 pagesSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINo ratings yet

- Test for Half of Condenser Operation冷凝器半面运行试验Document2 pagesTest for Half of Condenser Operation冷凝器半面运行试验erwin5sambas5aryanaNo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- 125 - Performance Guarantee - Maan - R4Document4 pages125 - Performance Guarantee - Maan - R4Ahmad ShekhNo ratings yet

- IESR Flexible Thermal Power Plant 2022Document66 pagesIESR Flexible Thermal Power Plant 2022jonny herbartNo ratings yet

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesDocument9 pagesDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesgermantoledo244596No ratings yet

- SteamDocument40 pagesSteamRupesh Anand100% (2)

- Heat Rate Calculation - JITPLDocument8 pagesHeat Rate Calculation - JITPLbnswain1No ratings yet

- Power Plant Boiler EfficiencyDocument15 pagesPower Plant Boiler EfficiencyMarcJexsonDeGuzmanNo ratings yet

- Pltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)Document5 pagesPltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)sandrositohangNo ratings yet

- Sch7 m200 Steam TurbineDocument7 pagesSch7 m200 Steam Turbinetri wibisono100% (1)

- Coal Blending With Fly Ash-An ApproachDocument28 pagesCoal Blending With Fly Ash-An ApproachcaptainrajneeshNo ratings yet

- A4 Desuperheater PDFDocument6 pagesA4 Desuperheater PDF련서긔No ratings yet

- Overiew of Comb Cycle Rev 6.0 - Part 1Document73 pagesOveriew of Comb Cycle Rev 6.0 - Part 1SamNo ratings yet

- NPHRDocument9 pagesNPHRAndreas Sahat P. SinagaNo ratings yet

- Errors in Boiler Efficiency Standards - SlideshowDocument23 pagesErrors in Boiler Efficiency Standards - Slideshowmrex511No ratings yet

- TR 109546Document301 pagesTR 109546Piyush AgarwalNo ratings yet

- Mroy Pump Catalogue PDFDocument6 pagesMroy Pump Catalogue PDFTitus FelixNo ratings yet

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- Summary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdDocument5 pagesSummary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdidilfitriNo ratings yet

- My Boiler Efficiency ReportDocument6 pagesMy Boiler Efficiency ReportRufus D SNo ratings yet

- Spray Cooling Enhancement of Air - Cooled CondensersDocument142 pagesSpray Cooling Enhancement of Air - Cooled CondensersRicardo OrtizNo ratings yet

- 055 NOX ReductionDocument57 pages055 NOX ReductionSammy-papa Maropeng ShikaNo ratings yet

- HMBD Review Check ListDocument4 pagesHMBD Review Check Listctraminst_81No ratings yet

- HRSG DesignDocument11 pagesHRSG DesignVennila Rangith100% (1)

- Turbine Bypass SystemDocument20 pagesTurbine Bypass Systemamer_arauf100% (18)

- 1a Natural Circulation BoilersDocument44 pages1a Natural Circulation BoilersFraser LamontNo ratings yet

- 3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+Document34 pages3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- PWR1059 Thermal Power Plant Performance Testing - May 2022Document11 pagesPWR1059 Thermal Power Plant Performance Testing - May 2022nguyenhuutan91No ratings yet

- Balancing of LP Rotor at Site PDFDocument5 pagesBalancing of LP Rotor at Site PDFsanjeevchhabra0% (1)

- GS Bindra BHEL Ultra Supercritical Power Plants PDFDocument46 pagesGS Bindra BHEL Ultra Supercritical Power Plants PDFBKumrNo ratings yet

- Ash ReinjectionDocument22 pagesAsh Reinjectiongaol_bird009No ratings yet

- Heat Rate CalculationsDocument22 pagesHeat Rate CalculationsPankaj TipramwarNo ratings yet

- Bahan Presentasi Bahasa Inggris-Superheater-In EnglishDocument2 pagesBahan Presentasi Bahasa Inggris-Superheater-In EnglishPangestu Try WibowoNo ratings yet

- Supercritical Benson BoilerDocument18 pagesSupercritical Benson BoilerJerry Mateo100% (2)

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Training Report TOYEB PDFDocument39 pagesTraining Report TOYEB PDFDevesh Pratap YadavNo ratings yet

- Triveni Turbines AR2018-19Document228 pagesTriveni Turbines AR2018-19Arpit GuptaNo ratings yet

- ASME PTC 6a - 2000 Appendix PTC 6 Steam TurbineDocument175 pagesASME PTC 6a - 2000 Appendix PTC 6 Steam TurbineKristianNo ratings yet

- Supercritical Technology in BoilersDocument17 pagesSupercritical Technology in Boilersamit joshi100% (4)

- Mds HPH 1 - Skoda PowerDocument3 pagesMds HPH 1 - Skoda PoweridilfitriNo ratings yet

- Boiler Chemical CleaningDocument24 pagesBoiler Chemical CleaningYudha Andrie Sasi ZenNo ratings yet

- Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)Document6 pagesJob No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)A N MadhavanNo ratings yet

- Ejector Performance Test Procedure: Quality AssuranceDocument8 pagesEjector Performance Test Procedure: Quality AssuranceManan gujjarNo ratings yet

- Hydrazine DosingDocument2 pagesHydrazine DosingAnonymous 3HTgMDO100% (1)

- 015.B.0 - Blow Down Quench Water CalculationDocument2 pages015.B.0 - Blow Down Quench Water Calculationmkchy12No ratings yet

- ME6701-Power Plant EngineeringDocument16 pagesME6701-Power Plant EngineeringNizam MANo ratings yet

- Boiler & Turbin CFK #3 Flow ProsesDocument2 pagesBoiler & Turbin CFK #3 Flow ProsesNur Ali Said100% (1)

- For Information: Doosan Heavy Industries & ConstructionDocument9 pagesFor Information: Doosan Heavy Industries & ConstructionĐể MaiNo ratings yet

- Adipala Power System Diagram (660 MW)Document1 pageAdipala Power System Diagram (660 MW)Budi WahyonoNo ratings yet

- DC Lts TMR DC LTS: OFF Reset Emergency StopDocument1 pageDC Lts TMR DC LTS: OFF Reset Emergency Stopwillian100% (1)

- John Deere 4024TF281 Installation DrawingDocument1 pageJohn Deere 4024TF281 Installation DrawingRamon Pujol PerramonNo ratings yet

- PP Aaa PP1 111Document18 pagesPP Aaa PP1 111Rabah AmidiNo ratings yet

- EMC Truck Service: HeadlightsDocument3 pagesEMC Truck Service: HeadlightsWalterNo ratings yet

- API 579-2 - 13.1 Rev1Document50 pagesAPI 579-2 - 13.1 Rev1osbertodiaz100% (2)

- Api 579-2 - 4.4Document22 pagesApi 579-2 - 4.4Robiansah Tri AchbarNo ratings yet

- Api 579-2 - 4.2Document28 pagesApi 579-2 - 4.2Robiansah Tri AchbarNo ratings yet

- Api 579-2 - 5.1Document63 pagesApi 579-2 - 5.1Robiansah Tri Achbar67% (3)

- Api 579-2 - 4.2Document28 pagesApi 579-2 - 4.2Robiansah Tri AchbarNo ratings yet

- Calculating PCN Using The FAA MethodDocument43 pagesCalculating PCN Using The FAA MethodRobiansah Tri AchbarNo ratings yet