Professional Documents

Culture Documents

05 2013 1072 Sredanovic 04 PDF

05 2013 1072 Sredanovic 04 PDF

Uploaded by

Octa RioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 2013 1072 Sredanovic 04 PDF

05 2013 1072 Sredanovic 04 PDF

Uploaded by

Octa RioCopyright:

Available Formats

Strojniki vestnik - Journal of Mechanical Engineering 59(2013)12, 748-754

Received for review: 2013-02-22

2013 Journal of Mechanical Engineering. All rights reserved. Received revised form: 2013-05-15

DOI:10.5545/sv-jme.2013.1072 Original Scientific Paper Accepted for publication: 2013-09-05

Influence of Different Cooling and Lubrication Techniques on

Material Machinability in Machining

Sredanovic, B. Globocki-Lakic, G. Cica, D. Kramar, D.

Branislav Sredanovic1,* Gordana Globocki-Lakic1 Djordje Cica1 Davorin Kramar2

1 University of Banja Luka, Faculty of Mechanical Engineering, Bosnia and Herzegovina

2 University of Ljubljana, Faculty of Mechanical Engineering, Slovenia

In this paper, a novel approach to the definition of universal machinability is presented. The machinability model is based on analysing

the vector of the cutting process performance. The machinability of C45E steel was analysed and evaluated according to the developed

machinability definition. As the machinability criteria, cutting force, intensity of tool wear and surface roughness were used.

Analysis of machinability was performed using different cooling and lubrication conditions: conventional flooding, minimum quantity

lubrication (MQL) and high-pressure jet-assisted machining (HPJAM). Technological parameters were adjusted to the semi-finish regime, with

the use of the highest parameter values possible. During the research, cutting forces, chip shapes, tool wear and surface roughness were

monitored and measured. The influence of different cooling and lubrication techniques and the relationships between process performance

indicators on C45E steel machinability are analysed.

Keywords: machinability model, high-pressure jet assisted machining, cooling and lubrication

0 INTRODUCTION The necessity to machine using less harmful

cutting fluids has prompted many researchers to

Material machinability is defined as the ease of investigate the use of minimum quantity lubrication

material machining with different tools and conditions (MQL). In MQL, lubrication is obtained via the

within economic regimes [1]. As a general definition lubricant, while a minimum cooling action is

of material machinability, the following is used: achieved by the pressurised air that reaches the

the greatest values of machinability are with those tool/workpiece interface [3]. In MQL, however,

materials with which the smallest cutting forces, secondary characteristics are important. These

vibrations, tool wear and surface roughness processing include their safety properties in environmental

occur [1]. The goal of machinability testing is pollution and human contact as well as properties in

finding the optimal regime of material processing biodegradability, oxidation and storage stability [4].

and the effective management of the cutting process.

The improvement of existing technologies and

the developments of new cutting technologies

through experimental research are ongoing tasks for

researchers.

Analysing machinability is a complicated task

because of the large number of influencing factors.

Such factors on the material machinability in cutting

are the parameters that significantly affect the ease

of processing: workpiece material, tool material and

geometry, tool machine, processing type, cooling and

lubrication fluids properties and delivery, machining Fig. 1. Jet setup in HPJAM

condition, etc.

The basic functions of cutting fluid are the Compared to conventional cooling, the concept

reduction of the friction, the reduction of generated of high-pressure jet-assisted machining (HPJAM) is to

heat and the improvement of chip evacuation [2]. inject a high pressure jet of cutting fluid in the cutting

The positive effects on machinability are reflected zone. The jet is normally directed to the cutting edge

in increasing tool life, reducing energy consumption, at a low angle directly between the rake face and the

improving of the surface roughness, etc. The chip (Fig. 1). HPJAM is beginning established as a

effect of cooling and lubricating depends on fluid method for a substantial increase of removal rate and

flow parameters, fluid characteristics and delivery productivity in machining of advanced materials such

technique. as hardened steels used for moulds and constructions,

748 *Corr. Authors Address: University of Banjaluka, Faculty of Mechanical Engineering,

Stepe Stepanovica 75, 78000 Banja Luka, Bosnia and Herzegovina, e-mail: sredanovic@gmail.com

Strojniki vestnik - Journal of Mechanical Engineering 59(2013)12, 748-754

Ti-based alloys used in gas turbines and in the

aerospace industry. The advantage of this method is

reduction of cutting temperature, reduction of tool

wear, improvement of chip breakability, etc. [5] and

[6].

In this paper, the influence of different cooling

and lubrication techniques in turning process with

coated carbide tool on steel C45E machinability is

analyzed.

1 METHOD FOR UNIVERSAL MATERIAL MACHINABILITY

DEFFINIG

Material machinability is defined according to the

Fig. 2. Machinability vector definition

main criteria. These criteria are the output parameters

of the cutting process: tool wear, surface roughness,

Based on the criterion values and the

cutting forces, chip shape, etc., which depend on the

input-cutting parameters [1]. corresponding unit vectors, the criterion vector that

Based on analyses of previous approaches of lies in the appropriate coordinate axis is formed as a

machinability definition, it can be concluded that scalar product of the unit vector and criterion vector:

machinability is defined by one criterion only.

Machinability is defined via machinability indexes as K iKO = kiko K i . (1)

the relative estimate of machinability, without units [1].

Some material may have considerable machinability The machinability vector is the sum of all

according to one criterion, but exceptionally poor individual criteria vectors:

machinability when the other criteria are considered. n

A complete definition of machinability or absolute M j = K iKO . (2)

machinability is based on the consideration of many i =1

criteria simultaneously [1]. In general, the material whose machinability

In [7], the author described Boulgers specific vector has less intensity and closes smaller angles

test for machinability estimation based on process with a control vector has better machinability [11].

economy. In that paper, Lees machinability evaluation The size of the parallelogram area formed by the

based on the thermodynamic number was described.

machinability vector and its control vector is related

Enache et al. [8] developed a global model of

to the machinability of materials (Fig. 3.). It can be

relative machinability, which contained more criteria.

Rao and Gandhi [9] used the matrix and graph theory concluded: material with a smaller parallelogram

in a model developed for absolute machinability surface area has better machinability in compare to

defining, termed the matrix model. material with a larger parallelogram surface area.

In this paper, a novel method of machinability

definition, based on vector analysis, is introduced.

It considers several machinability criteria [10] and

requires a three-axes rectangular coordinate system.

Each axis in the system represents an aforementioned

criterion (Fig. 2). The criterion values (Ki) are set on

the corresponding axis. Criteria whose increasing

values decrease the machinability are taken as inputs

values in the model.

Each axis has a corresponding

unit vector ( kiko ) whose length corresponds to the

unit value of criterion value (infinite length). The

sum of unit vectors yields the control vector ( C ), Fig. 3. Area of the parallelogram related to machinability of

whose direction determines the best uniformity of materials j and j+1

machinability criteria or the best machinability (Fig.

2).

Influence of Different Cooling and Lubrication Techniques on Material Machinability in Machining 749

Strojniki vestnik - Journal of Mechanical Engineering 59(2013)12, 748-754

The size of parallelogram area can be expressed

through the value of vector product between the

machinability vector and control vector:

(

Pj = C M j = C M j sin C , M j . (3) )

It can be concluded that universal machinability

(Mu) is inversely proportional to the area of

parallelogram formed by the machinability vector and

control vector. Based on established relationships, on

Eqs. (3) and (4), it can be written in its final form:

M u = Pj1 = Fig. 4. Experimental setup

1

( K + K 2 + K3 )

2

= K12 + K 22 + K 32 1 12 . (4) With the MQL technique, an external spray

(K1 + K 22 + K 32 )

system with a was used. Pressure of pMQL = 0.3 MPa

and a flow rate of QMQL = 0.0005 lmin-1 was set. The

In Eq. (4), as criteria values can be take the mixed jet was directed in the cutting zone with its

measured or calculated values. This values depend nozzle located Hn = 30 mm away from tool tip, at an

on input parameters, on example cutting force is angle of MQL = 90 of the cutting edge and at an angle

F = f (ap, f, vc). Eq. (4) has two parts: the first part of MQL = 30 from clearance face (Fig. 5).

represents the influence of criteria values and the

second part shows the influence of criteria values

uniformity on machinability.

2 EXPERIMENTAL SETUP

In the experimental research, longitudinal turning

operations with different types of cooling and

lubrication techniques were used: conventional

flooding, MQL and HPJAM. Experiments were

conducted on a universal Boehringer lathe with

the following characteristics: power of P = 8 kW,

maximum spindle speed n = 2240 revmin-1 and Fig. 5. MQL nozzle setup

feed f = 1.6 mmrev-1. An SNMG 1204 08 NMX

carbide cutting tool for semi-machining was used. In HPJAM, a conventional lathe was fitted with

The clearance angle was 10, and the rake angle 0; a Hammelmann high pressure plunger pump. The

the radius of the tool tip was 0.8 mm with a simple pressure was set at pHP = 50 MPa and the flow rate at

chip breaker. A PSDN 2525 M12 tool holder with an QHP = 2.0 lmin-1. A standard sapphire orifice with a

inclination angle of 45 was chosen (Fig. 4.). diameter of dHP = 0.4 mm (commonly used in waterjet

The workpiece material used in experimental cutting applications) was installed at a distance of

research was C45E carbon steel. Experimental Hn = 30 mm from the tool cutting edge in order to

research was performed on a workpiece with assure its use in the core zone of the jet and to avoid

dimensions of 150250 mm. The tensile straight variations in the diameter of the jet and the radial

of this material is = 820 Nmm-, the module of distribution of the pressure. The jet was directed

elasticity is E = 210 MPa, and the hardness of steel to the cutting edge (HP = 90), and HP = 30 from

is 45 HRC. clearance face at a low angle (about 5 to 6) with the

All experiments (over 108 experimental tool rake face (Fig. 1).

measurements with repeating) were carried out using With the goal of achieving an effective material

cutting fluid with a 3% emulsion of vegetable oil. removal process, the cutting speeds and feeds were set

In conventional flooding, a free fall from above is higher than recommended. Turning was investigated

used. A pressure of pCON = 0.3 MPa and flow rate of according to the following input process parameters

QCON = 2.0 lmin-1 was applied. and levels:

750 Sredanovic, B. Globocki-Lakic, G. Cica, D. Kramar, D.

Strojniki vestnik - Journal of Mechanical Engineering 59(2013)12, 748-754

Depth of cut ap [mm]: 1.5, 2.0, 2.5. conditions for different depths of cut and feed rates is

Feed f [mmrev-1]: 0.224, 0.280, 0.355, 0.400. shown.

Cutting speed vc [mmin-1]: 210, 320, 400.

a)

b)

c)

Fig. 6. Flank tool wear and chip shape

(ap = 2 mm, f = 0.28 mmrev-1, vc=320 mmin-1) for:

a) conventional, b) MQL and c) HPJAM

During the experimental research, crucial process

output parameters that describe cutting processes and

material machinability were monitored: main cutting

force (Fc), feed cutting force (Ff) and passive cutting

force (Fp); flank tool wear land width (VBB) and

intensity of tool wear (IVB); as the surface roughness

parameters: arithmetic average height (Ra) and

maximum height of the profile (Rz); and chip shape. Fig. 7. Values of cutting forces for different cooling and lubrication

conditions in machining of C45E with vc = 320 [mmin-1]

3 ANALYSIS OF EXPERIMENTAL RESULTS

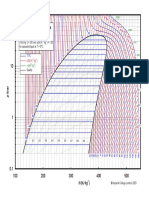

From the diagrams (Fig. 7), it can be concluded

The best chip shape was obtained via HPJAM (Fig. that the values of the main cutting forces for all three

6) according the ISO classification [1]. According cooling and lubrication condition are almost equal.

to its colour, it can be concluded that the impact of The values of the feed and passive forces were the

generated heat was reduced. Chip shape (conventional smallest in the case of HPJAM. In comparison, the

and MQL) was similar and was acceptable. Flank tool values of the aforementioned forces in the MQL

wear in the conventional and MQL at the end of tool were smaller than in the conventional technique. The

life was extremely poor, as could be observed in the differences are greater for smaller cutting depths.

chip shape. Fig. 8 shows the results of tool wear on flank

In Fig. 7, a comparison of the three cutting faces for different cooling and lubrication techniques.

force components values for turning in conventional MQL and conventional techniques show almost the

flooding, MQL and HPJAM cooling and lubrication same values of tool wear, about T = 8 min, while

Influence of Different Cooling and Lubrication Techniques on Material Machinability in Machining 751

Strojniki vestnik - Journal of Mechanical Engineering 59(2013)12, 748-754

HPJAM had a four-times longer tool life. Other than was analysed. Furthermore, a comparison with

this tool wear in HPJAM, conditions are uniform, Enaches global model [8] and Rao-Ghandis matrix

while in conventional flooding and in MQL conditions model [9] and a comparison for different parameter

some notch wear is recognized (Fig. 6). This is a result input combinations were performed. In theory of

of intensive lubrication between the tool rake face and machining, machinability evaluation values are

chip, chip deforming and evacuation in the case of relative values and there are no unit for it.

HPJAM.

Fig. 8. Tool wear for different cooling and lubrication conditions

Fig. 10. Comparison of different machinability models for C45E

(ap = 2 mm, f = 0.28 mmrev-1, vc = 320 mmin-1)

In Fig. 10, a comparison of different material

machinability evaluation models is shown. For

calculation of machinability evaluation values,

cutting force, intensity of flank tool wear and surface

roughness were used. The order tendency of input

combinations for the new model corresponds to

previously developed models. It can be concluded that

the output of the newly developed model correspond

to the outputs of the matrix and the global model [11].

Fig. 9. Surface roughness parameters for different cooling and

lubrication conditions

Values of surface roughness for different cooling

and lubrication techniques are shown in Fig. 9. For

conventional lubrication, surface finish is better than

in case of other two techniques used, but surface

roughness in MQL and HPJAM is also acceptable.

Predictive regression models for monitored

and measured machinability criteria values were

developed, and a database was formed. The

aforementioned prediction regression models take

into account the cutting input parameters: workpiece

material, depth of cut, feed, cutting speed, tool Fig. 11. Comparison of different machinability models for C45E

geometry, cooling and lubrication type, etc. [11]. (f = 0.28 mmrev-1, vc = 320 mmin-1)

According to the new theory described in this

paper (the vector model), material machinability

752 Sredanovic, B. Globocki-Lakic, G. Cica, D. Kramar, D.

Strojniki vestnik - Journal of Mechanical Engineering 59(2013)12, 748-754

The machinability evaluation for combinations of highest values of the process parameters can be used

investigated inputs is shown in Figs. 11 and 12. With in HPJAM.

increased feed and depth of cut, increasingly poorer The same conclusions about the machinability

machinability was calculated. The reason for this the evaluation values for the studied cooling and

highest values of cutting force, tool wear and surface lubrication techniques using the various criteria of

roughness. HPJAM yields the best machinability machinability, such as cutting energy, productivity,

during machining with the same cutting parameters, chip shape, material removal rate (MMR), etc. can be

because of lower cutting force values and lower flank achieved [12].

tool wear values.

4 CONCLUSIONS

Machinability is an extremely significant factor

in industry. It can be estimated by output cutting

parameters / machinability criteria, which depend on

input cutting parameters. Cutting force, intensity of

flank tool wear and parameters of surface roughness

were used as the machinability criteria. The newly

developed machinability evaluation model shows

considerable congruence with previously developed

models [8] and [9]. Based on experimental research

and using the new model, the machinability of

different cooling lubrication techniques can be

calculated.

The analysis shows that turning with HPJAM

provides the best machinability. Experiments

Fig. 12. Machinability evaluation values for different conditions in

machining of C45E (ap = 2 mm, vc = 320 mmin-1)

were performed in the use of higher technological

parameters values than in previous research and

recommendation [5] and [6]. Based on experimental

studies, it can be concluded that the tool life during

HPJAM turning is four times higher than with MQL

and conventional techniques. The same surface

roughness was obtained in all three cooling and

lubrication techniques. In HPJAM, feed and passive

cutting forces are 5 to 10% lower than with MQL

and conventional flooding. Moreover, HPJAM

has significant contributions for chip breakability.

Based on these facts, we can conclude that HPJAM

yields the best results. The operational area for the

investigated tool-workpiece combination can be

expanded approximately 35 to 40% in comparison

with conventional technology. This expansion is

in the increasing of depth of cut, feed and cutting

Fig. 13. Machinability evaluation values for different conditions in speed. Moreover, a study shown that MQL, as an

machining of C45E (vc = 320 mmin-1) ecological technology, has slightly better results than

conventional lubrication technique.

As shown by the experiments and calculations, In the future research, developing of machinability

turning with conventional flooding at a depth of cut evaluation model in terms of using greater a number

of ap = 1.5 mm, MQL at a depth of cut of ap = 2 mm of machinability criteria will be investigated. Also,

and with HPJAM at a depth of cut of ap = 2.5 mm has properly inputs and its description in novel model will

approximately the same universal machinability (Fig. be investigated. Based on the experimental research,

13). Based on the values of the developed model of database of technology parameters will be developed.

universal machinability, it can be concluded that the

Influence of Different Cooling and Lubrication Techniques on Material Machinability in Machining 753

Strojniki vestnik - Journal of Mechanical Engineering 59(2013)12, 748-754

5 ACKNOWLEDGMENTS Journal of Machine Tools & Manufacture,

vol. 49, no. 14, p. 1114-1125, DOI:10.1016/j.

This research is the result of a bilateral project BI- ijmachtools.2009.07.010.

BA/12-13-001 between Slovenia and Bosnia and [6] Kramar, D., Kopac, J. (2009). High pressure cooling in

the machining of hard-to-machine materials. Strojniki

Herzegovina with collaboration between Laboratory

vestnik - Journal of Mechanical Engineering, vol. 55,

for Cutting from Faculty of Mechanical Engineering no. 11, p. 685-694.

in Ljubljana and Laboratory for Cutting Technology [7] Theile, E.W., Kuding, K.J., Murphy, D.W., Soloway,

from Faculty of Mechanical Engineering in Banja G., Duffin, B. (1990). Comparative machinability of

Luka. brasses, steel and aluminum alloy: CDAs universal

machinability index, Publication of CDA, New York.

6 REFERENCES [8] Enache, S., Strjescu, E., Opran, C., Minciu, C.,

Zamfirache M. (1995). Mathematical model for the

[1] Grzesik, W. (2008). Advanced Machining Processes of establishment of material machinability. Annals of

Metallic Materials: Theory, Modelling and Application. CIRP, vol. 44, no. 1, p. 79-82, DOI:10.1016/S0007-

Elsevier, Amsterdam. 8506(07)62279-3.

[2] Kopa, J. (2002). Cutting forces and their influence [9] Rao, R.V., Gandhi, O.P. (2002). Diagraph and matrix

on the economics of machining. Strojniki vestnik - methods for machinability evaluation of works

Journal of Mechanical Engineering, vol. 48, no. 3, p. material. International Journal of Machine Tools &

121-132. Manufacture, vol. 42, no. 2, p. 321-330.

[3] Dhar, N.R., Ahmed, M.T., Islam, S (2007). An [10] Sredanovic, B., Globocki, L.G. (2010). Quality

experimental investigation on effect of minimum monitoring of production systems and processes in form

quantity lubrication (MQL) in machining AISI 1040 of vector of power. Proceedings of 9th International

steel. International Journal of Machine Tools & Scientific and Practical Conference: Research,

Manufacture, vol. 47, p. 748-753, DOI:10.1016/j. Development and Application High Technologies in

ijmachtools.2006.09.017. Industry, Saint Petersburg, p. 418-420.

[4] Leppert, T. (2011). Effect of cooling and lubrication [11] Globocki, L.G., Sredanovic, B., Nedic, B., Cica, Dj.,

conditions on surface topography and turning process Catic, D. (2011). Development of mathematical model

of C45 steel. International Journal of Machine Tools of universal material machinability. Journal of the

& Manufacture, vol. 51, p. 120-126, DOI:10.1016/j. Balkan Tribological Association, vol. 17, no. 4, p. 501-

ijmachtools.2010.11.001. 511.

[5] Courbon, C., Kramar, D., Krajnik, P., Pusavec, F., [12] Kramar, D., Sredanovi, B., Globoki, L. G., Kopa,

Rech, J., Kopac, J. (2009). Investigation of machining J. (2012). Contribution to material machinability

performance in high-pressure jet assisted turning of definition. Journal of Production Engineering, vol. 15,

Inconel 718: an experimental study. International no. 2, p. 27-32.

754 Sredanovic, B. Globocki-Lakic, G. Cica, D. Kramar, D.

You might also like

- CH 23Document13 pagesCH 23onlydlonly100% (5)

- Pump DrawingDocument1 pagePump DrawingOcta RioNo ratings yet

- Rigging2002 PDFDocument89 pagesRigging2002 PDFJimmy Aleman0% (1)

- 05 2013 1072 Sredanovic 04 PDFDocument7 pages05 2013 1072 Sredanovic 04 PDFOcta RioNo ratings yet

- Economic and Product Design Considerations in Machining: Chapter ContentsDocument19 pagesEconomic and Product Design Considerations in Machining: Chapter Contentsbenedict polodisNo ratings yet

- A Review On Laser Beam Machining Process ModelingDocument9 pagesA Review On Laser Beam Machining Process Modelingnitin kumar halduniyaNo ratings yet

- 03 Jaer V2N1Document6 pages03 Jaer V2N1Joker 246No ratings yet

- An Overview of Optimization Techniques For CNC Milling MachineDocument4 pagesAn Overview of Optimization Techniques For CNC Milling MachineAllaboyinamahidharNo ratings yet

- KLOCKE Et Al, Capability Profile of Hard Cutting and Grinding ProcessesDocument24 pagesKLOCKE Et Al, Capability Profile of Hard Cutting and Grinding ProcessesLuis Fillipe Lopes TorresNo ratings yet

- Mmscience - 2019 12 - Material Selection of Blanking Tool by Using A Statistical MethodDocument5 pagesMmscience - 2019 12 - Material Selection of Blanking Tool by Using A Statistical MethodEngineerNo ratings yet

- Machinability Improvement and Sustainability AssessmentDocument14 pagesMachinability Improvement and Sustainability AssessmentChantum FonsecaNo ratings yet

- An Overview of Optimization Techniques For CNC Milling MachineDocument4 pagesAn Overview of Optimization Techniques For CNC Milling MachineArif NurrohmanNo ratings yet

- Metals 11 00565 v2Document14 pagesMetals 11 00565 v2PRO TECHNo ratings yet

- Coatings 12 01553 v3Document22 pagesCoatings 12 01553 v31DA20ME449 Siddesh MSNo ratings yet

- Analysis of Tool WearDocument12 pagesAnalysis of Tool Wearaswinkrishnakjkd02No ratings yet

- 1 s2.0 S2212827117303487 MainDocument5 pages1 s2.0 S2212827117303487 MainSanchit Kumar KhareNo ratings yet

- Modeling of Surface Hardening and Roughness Induced by TurningDocument6 pagesModeling of Surface Hardening and Roughness Induced by TurningChantum FonsecaNo ratings yet

- Numerical and Experimental Investigation of Cutting Forces in Turning of Nimonic 80A SuperalloyDocument10 pagesNumerical and Experimental Investigation of Cutting Forces in Turning of Nimonic 80A Superalloymustafa sertNo ratings yet

- Analysis and Modeling of The Effects of Process Parameters On Specific Cutting Energy in Abrasive Waterjet CuttingDocument12 pagesAnalysis and Modeling of The Effects of Process Parameters On Specific Cutting Energy in Abrasive Waterjet CuttingАО НИИТ АО НИИТNo ratings yet

- Monitoring The Surface Quality For Various Deep Rolling Proces - 2022 - ProcediaDocument6 pagesMonitoring The Surface Quality For Various Deep Rolling Proces - 2022 - Procedialelag96085No ratings yet

- LM 13Document12 pagesLM 13api-3832526No ratings yet

- Yıldırım2017 Article DeterminationOfMQLParametersCoDocument15 pagesYıldırım2017 Article DeterminationOfMQLParametersCoilknur karaNo ratings yet

- Cutting Force 1Document20 pagesCutting Force 118P202 - AJAY SIVARAMAN ANo ratings yet

- 9 GaitondeDocument6 pages9 GaitondeAshwani VermaNo ratings yet

- Electrochemical DeburringDocument8 pagesElectrochemical DeburringraulNo ratings yet

- MachinabilityDocument46 pagesMachinabilityAnoop kumar YadavNo ratings yet

- EFFECT OF DIFFERENT MACHINING PARAMETERS ON DRY MACHINING Ijariie23623Document7 pagesEFFECT OF DIFFERENT MACHINING PARAMETERS ON DRY MACHINING Ijariie23623ntsuandihNo ratings yet

- Optimizacija Elemenata Rezima Obrade Pomocu Planiranog Eksperimenta Kopcic O. Ekinovic S.Document10 pagesOptimizacija Elemenata Rezima Obrade Pomocu Planiranog Eksperimenta Kopcic O. Ekinovic S.wonder landNo ratings yet

- Schneider2019 Article SustainabilityInUltraPrecisionDocument10 pagesSchneider2019 Article SustainabilityInUltraPrecisionMOHAN KUMARNo ratings yet

- Metal Cutting Lubricants and Cutting ToolsDocument25 pagesMetal Cutting Lubricants and Cutting ToolsAbhishek BihariNo ratings yet

- 1 s2.0 S0890695522000827 MainDocument45 pages1 s2.0 S0890695522000827 Mainfarhan handikaNo ratings yet

- A Study of The Effects of Machining Parameters On The Surface Roughness in The End-Milling ProcessDocument7 pagesA Study of The Effects of Machining Parameters On The Surface Roughness in The End-Milling ProcessDesalegn DgaNo ratings yet

- Optimization of Broaching Tool Design: Intelligent Computation in Manufacturing Engineering - 4Document6 pagesOptimization of Broaching Tool Design: Intelligent Computation in Manufacturing Engineering - 4Rishikesh GunjalNo ratings yet

- Comparison OF Lubricant Properties in Minimum Quantity Lubrication MachiningDocument17 pagesComparison OF Lubricant Properties in Minimum Quantity Lubrication MachiningAmbati TejaswararaoNo ratings yet

- Study On Surface Roughness Minimization in Turning of Dracs Using Surface Roughness Methodology and Taguchi Under Pressured Steam Jet ApproachDocument9 pagesStudy On Surface Roughness Minimization in Turning of Dracs Using Surface Roughness Methodology and Taguchi Under Pressured Steam Jet ApproachMuhamadAmirNo ratings yet

- Manufacturing Process Lab Report 4Document5 pagesManufacturing Process Lab Report 4Jack DanielsNo ratings yet

- Machines 09 00192 v2Document16 pagesMachines 09 00192 v2Mateusz RojewskiNo ratings yet

- 1 s2.0 S2307187723002912 MainDocument11 pages1 s2.0 S2307187723002912 MainYUSUFNo ratings yet

- Residual StressDocument17 pagesResidual StressAbhishek BihariNo ratings yet

- Box Behnken design-IJESR: October 2015Document24 pagesBox Behnken design-IJESR: October 2015Robert Larry Cordova DiazNo ratings yet

- Journal of Cleaner Production: Rajesh Kumar BhushanDocument13 pagesJournal of Cleaner Production: Rajesh Kumar BhushannagarajNo ratings yet

- 1 s2.0 S1877705813016949 MainDocument10 pages1 s2.0 S1877705813016949 MainAbdoel SiregarNo ratings yet

- Effect and Optimization of Machining Parameters On Cutting Force and Surface Finish in Turning of Mild Steel and AluminumDocument8 pagesEffect and Optimization of Machining Parameters On Cutting Force and Surface Finish in Turning of Mild Steel and AluminumIzzah HzmhNo ratings yet

- The Effect of Portable MQL Applicator Onto Carbide Insert During Turning Inconel 718Document10 pagesThe Effect of Portable MQL Applicator Onto Carbide Insert During Turning Inconel 718adarshgitamNo ratings yet

- Çakıroğlu2022 Article AnalysisOfRanqueHilschVortexTuDocument18 pagesÇakıroğlu2022 Article AnalysisOfRanqueHilschVortexTuramazan çakıroğluNo ratings yet

- Durability Assessment of Welded Structures Based On Welding Simulation With LS-DYNADocument13 pagesDurability Assessment of Welded Structures Based On Welding Simulation With LS-DYNAAmir IskandarNo ratings yet

- Permormance of TiAIN PVD Coated Carbide Tool in Machining AISI 4340 With Minimum Quantity Lubrication (MQL) ConditionDocument11 pagesPermormance of TiAIN PVD Coated Carbide Tool in Machining AISI 4340 With Minimum Quantity Lubrication (MQL) ConditionAditya AfNo ratings yet

- Optimization of Cutting Fluid Supply Based On The Motor CurrentDocument10 pagesOptimization of Cutting Fluid Supply Based On The Motor CurrentAynamawNo ratings yet

- Design of Experiment Based Analysis For Sheet Metal Blanking Processes OptimisationDocument9 pagesDesign of Experiment Based Analysis For Sheet Metal Blanking Processes OptimisationMD Al-AminNo ratings yet

- Simulation of The Effect of Die Radius On Deep Drawing ProcessDocument6 pagesSimulation of The Effect of Die Radius On Deep Drawing ProcessSac ChoNo ratings yet

- A New Method For Circular Testing of Machine Tools Under Loaded ConditionDocument6 pagesA New Method For Circular Testing of Machine Tools Under Loaded ConditionTaufiq Wahyu MNo ratings yet

- Comprehensive Study On Effect of Orthogonal Turn - 2021 - International JournalDocument11 pagesComprehensive Study On Effect of Orthogonal Turn - 2021 - International JournalRaka Dika9No ratings yet

- Ijetae 0212 07Document7 pagesIjetae 0212 07Paul GambleNo ratings yet

- CNC Machine ToolDocument9 pagesCNC Machine ToolNaing Lin ooNo ratings yet

- AdvancedWearSimulationforBulkMetalFormingProcesses NUMIFORM2016 Final PDFDocument4 pagesAdvancedWearSimulationforBulkMetalFormingProcesses NUMIFORM2016 Final PDFSeif eddine Ben hammoudaNo ratings yet

- Ijaiem 2014 03 15 042Document12 pagesIjaiem 2014 03 15 042International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Structural Modeling of End Mills For Form Error and Stability AnalysisDocument11 pagesStructural Modeling of End Mills For Form Error and Stability AnalysisAkhileshwar_singh88No ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Sodium SilicateDocument3 pagesSodium SilicateOcta RioNo ratings yet

- Sodium SilicateDocument3 pagesSodium SilicateOcta RioNo ratings yet

- GFPS 4066 5 PVC U L W Final HighresDocument2 pagesGFPS 4066 5 PVC U L W Final HighresOcta RioNo ratings yet

- Red Screw PumpDocument2 pagesRed Screw PumpOcta RioNo ratings yet

- Mechseal Chesterton 255 PDFDocument8 pagesMechseal Chesterton 255 PDFOcta RioNo ratings yet

- Laser Alignment: Angular Misalignment Offset MisalignmentDocument1 pageLaser Alignment: Angular Misalignment Offset MisalignmentOcta RioNo ratings yet

- Blackmer LG Series Vane PumpsDocument2 pagesBlackmer LG Series Vane PumpsOcta RioNo ratings yet

- Chart P H R134a PDFDocument1 pageChart P H R134a PDFDianNo ratings yet

- A Pump Performance CurveDocument6 pagesA Pump Performance CurveOcta RioNo ratings yet

- Skema Perpipaan Water ChillerDocument1 pageSkema Perpipaan Water ChillerOcta RioNo ratings yet

- No h1 h2 h3 h4 h5 h6 KJ/KG KJ/KG KJ/KG KJ/KG KJ/KG KJ/KGDocument5 pagesNo h1 h2 h3 h4 h5 h6 KJ/KG KJ/KG KJ/KG KJ/KG KJ/KG KJ/KGOcta RioNo ratings yet

- PumpWorks 610 PWD Brochure1Document6 pagesPumpWorks 610 PWD Brochure1Octa RioNo ratings yet

- Experimental Studies On The Effect of Viscosity Grade On Mechanical Vibration Behavior of Deep Groove Ball BearingDocument5 pagesExperimental Studies On The Effect of Viscosity Grade On Mechanical Vibration Behavior of Deep Groove Ball BearingOcta RioNo ratings yet

- Introduction To Non Destructive TestingDocument49 pagesIntroduction To Non Destructive TestingOcta RioNo ratings yet

- 05 2013 1072 Sredanovic 04 PDFDocument7 pages05 2013 1072 Sredanovic 04 PDFOcta RioNo ratings yet

- Applied Energy: Rogério Gomes de Oliveira, Daniel João GenerosoDocument9 pagesApplied Energy: Rogério Gomes de Oliveira, Daniel João GenerosoOcta RioNo ratings yet

- Bab IV. Analisa Hasil PercobaanDocument13 pagesBab IV. Analisa Hasil PercobaanOcta RioNo ratings yet

- 5 Threats To Chiller EfficiencyDocument57 pages5 Threats To Chiller EfficiencyOcta RioNo ratings yet

- Accepted Manuscript: International Journal of RefrigerationDocument31 pagesAccepted Manuscript: International Journal of RefrigerationOcta RioNo ratings yet

- Centralized Oil Lubrication System: N.Ashok KumarDocument5 pagesCentralized Oil Lubrication System: N.Ashok KumarOcta RioNo ratings yet

- Maejo International Journal of Science and TechnologyDocument9 pagesMaejo International Journal of Science and TechnologyOcta RioNo ratings yet

- Optimization of Standalone Solar Heat Fired Absorption Chiller For Typical Australian HomesDocument10 pagesOptimization of Standalone Solar Heat Fired Absorption Chiller For Typical Australian HomesOcta RioNo ratings yet

- On Time Taxi Co LTD Get DirectionsDocument5 pagesOn Time Taxi Co LTD Get DirectionsVaughn BantonNo ratings yet

- Resistance Welding ProcessesDocument47 pagesResistance Welding ProcessesJohan ZraghozNo ratings yet

- Catalohgo Geral Belimo 2015 PGPLDocument398 pagesCatalohgo Geral Belimo 2015 PGPLSergio HitcarNo ratings yet

- Company: 4 Seasons Climate ComfortDocument39 pagesCompany: 4 Seasons Climate ComforttvassilopoulosNo ratings yet

- Mint-Made Errors - WikipediaDocument67 pagesMint-Made Errors - WikipediaHeather Stephanie SchweitzerNo ratings yet

- A Presentation On Group Communication NetworkDocument12 pagesA Presentation On Group Communication NetworkManiruzzaman TanvirNo ratings yet

- Electrostatic Sensitive DevicesDocument7 pagesElectrostatic Sensitive Devicesvinay100% (1)

- Robotic Arm Packaging and ParrelitizingDocument12 pagesRobotic Arm Packaging and ParrelitizingAdeel Ahmad WattooNo ratings yet

- Rajesh Konathala,: Curriculum VitaeDocument3 pagesRajesh Konathala,: Curriculum VitaeRAJESHNo ratings yet

- MT174 TD v1 - 2 Ang PDFDocument36 pagesMT174 TD v1 - 2 Ang PDFVadimNo ratings yet

- J2 - PILING WORK AND FDN FOR BANGLOWDocument9 pagesJ2 - PILING WORK AND FDN FOR BANGLOWShahrirNo ratings yet

- Manual de CalibraciónDocument76 pagesManual de CalibracióndaironNo ratings yet

- Electrical MachinesDocument6 pagesElectrical MachinesPranav TripathiNo ratings yet

- Nitin Gupta For WoodNewsDocument3 pagesNitin Gupta For WoodNewsNichole L. ReberNo ratings yet

- Part 2Document20 pagesPart 2rkNo ratings yet

- Student: Gerrick Edward Gomez Course/Yr: Bsme-5Document31 pagesStudent: Gerrick Edward Gomez Course/Yr: Bsme-5GerkNo ratings yet

- Blow Moulded Plastic Product: Profile No.: 91 NIC Code: 22207Document8 pagesBlow Moulded Plastic Product: Profile No.: 91 NIC Code: 22207Sabhaya ChiragNo ratings yet

- Result Revaluation Be Fisrt PH Chem Bce BmeDocument70 pagesResult Revaluation Be Fisrt PH Chem Bce BmeAdarsh AgrawalNo ratings yet

- RSSHSMGR PartsDocument4 pagesRSSHSMGR PartsMarcos ErazoNo ratings yet

- Extracting MetalsDocument27 pagesExtracting MetalsJojo Hany100% (1)

- Cross Function PresentationDocument46 pagesCross Function Presentationraja parulian halomoan100% (1)

- Comparison Between Boeing 777 and Airbus A380Document14 pagesComparison Between Boeing 777 and Airbus A380Anonymous 2gHUkjGNo ratings yet

- Gs 31Document7 pagesGs 31memep1No ratings yet

- 8017031Document4 pages8017031alisuseNo ratings yet

- Finite Elememnt Analysis of Pitman Arm: Sijith PM, Prof Shashank Gawade, Prof S.S KelkarDocument3 pagesFinite Elememnt Analysis of Pitman Arm: Sijith PM, Prof Shashank Gawade, Prof S.S KelkarSai reddyNo ratings yet

- Tejas Faulty Cards& CPEsDocument6 pagesTejas Faulty Cards& CPEsritesh kumar singhNo ratings yet

- Rubber 0047Document2 pagesRubber 0047huda245No ratings yet

- Manual PJH 9000Document8 pagesManual PJH 9000franz9798No ratings yet

- Approved Design Codes For SingaporeDocument77 pagesApproved Design Codes For SingaporeDlorah OalZepol0% (1)