Professional Documents

Culture Documents

Nextreme Whitepaper Use of Thin-Film Thermoelectrics in PCR Thermal Cycling

Nextreme Whitepaper Use of Thin-Film Thermoelectrics in PCR Thermal Cycling

Uploaded by

nisargOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nextreme Whitepaper Use of Thin-Film Thermoelectrics in PCR Thermal Cycling

Nextreme Whitepaper Use of Thin-Film Thermoelectrics in PCR Thermal Cycling

Uploaded by

nisargCopyright:

Available Formats

Nextreme Thermal Solutions, Inc.

Whitepaper

Use of Thin-Film Thermoelectrics in

PCR Thermal Cycling

NWP005.1

3908 PATRIOT DR., SUITE 140 DURHAM, NC 27703-8031 919-597-7300 919-597-7301 www.nextreme.com

Nextreme Thermal Solutions, Inc.

Background

Polymerase chain reaction (PCR) is a scientific

technique that amplifies a single or a few copies of a

specific piece of DNA by several orders of magnitude,

generating thousands to millions of copies of a particular

DNA sequence. Developed in 1983, PCR has rapidly

become one of the most widely used techniques in

molecular biology and for good reason: it is a rapid,

inexpensive and simple means of producing relatively

large quantities of whole or fractional DNA strands

copied from minute quantities of source DNA material

even when the source DNA is of relatively poor quality.

Applications for PCR include DNA cloning for

sequencing, DNA-based phylogeny, or functional

analysis of genes; the diagnosis of hereditary diseases;

the identification of genetic fingerprints (used in forensic

sciences and paternity testing); and the detection and

diagnosis of infectious diseases.

The broad life science division has witnessed rapid

growth and technological improvements varying from

sector to sector for the past three to five years. Even

during the recent recession years, the PCR industry has

experienced an accelerating growth rate confirming the

positive growth prospects. Molecular diagnostics and the

Human Genome Project (HGP) are two of the main Figure 1: During DNA

drivers contributing to the growth of gene amplification replication, each strand of

technology. It covers all segments such as drug the original molecule acts

discovery, DNA amplification, forensic identification, as a template for the

gene therapy and diagnosis. Newly developed PCR synthesis of a new,

instruments for detecting life threatening diseases also complementary DNA

signal positive growth. [1] strand. Source: National

Institute of General

Market Drivers Medical Sciences,

nigms.nih.gov.

Smaller, faster, cheaper is the rallying cry for virtually

every successful product on the market, and the PCR market is no exception. It is clear

that the PCR market has and will continue to have significant near or above double-digit

growth year after year. One of the significant trends in the PCR market today is a

movement towards smaller, individually addressable wells (containing the DNA).

Historically, systems were comprised of large 96-well thermal cyclers for large industry

applications. Companies are now developing applications that require individually

addressable wells, where only a few samples are tested at a time. An additional

requirement would be that each well be individually programmable. The requirement to

have individually addressable wells enables different reagents to be simultaneously

applied to identical DNA samples with different outcomes intended. [2]

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 2

Another rapidly developing market is food safety and security. According to a recently

published report by Strategic Consulting Inc. (SCI), the market for microbiological testing

in the food sector has been growing at nearly 9% every year since 1998. The food sector

now accounts for nearly half of the total industrial microbiology market. The SCI report

estimates that by 2013, the number of tests carried out worldwide will be nearly 970

million, up from 740 million in 2008. The drivers for this growth are identified as an

overall increase in food production, food safety concerns, demands from retailers and an

increase in regulatory requirements. [3-4]

Thermal Cycling and the PCR Process

The PCR process is very versatile. Many types of samples can be analyzed for nucleic

acids. Most PCR uses DNA as a target, rather than RNA, because of the stability of the

DNA molecule and the ease with which DNA can be isolated. By following a few basic

rules, problems can be avoided in the preparation of DNA for the PCR. The essential

criteria for any DNA sample is that it contains at least one intact DNA strand

encompassing the region to be amplified, and that any impurities are sufficiently diluted

so as not to inhibit the polymerization step of the PCR reaction.

PCR requires thermal cycling, i.e., alternately heating and cooling the DNA sample in a

defined series of temperature steps. These thermal cycling steps are necessary first to

physically separate the two strands in a DNA double helix at a high temperature in a

process called DNA melting. At a lower temperature, each strand is then used as the

template in DNA synthesis by the DNA polymerase to selectively amplify the target DNA.

As the PCR process progresses, the DNA generated is used as a template for

replication, setting in motion a chain reaction in which the DNA template is exponentially

amplified. Table 1 describes the thermal cycling steps, temperatures, and hold times

required in a typical PCR process. The selectivity of PCR results from the use of primers

that are complementary to the DNA region targeted for amplification under specific

thermal cycling conditions.

A thermal cycler is an automated instrument specifically designed to generate the

requisite thermal cycles for PCR. A typical device consists of a metal block with holes

where plastic vials holding the PCR reaction mixtures are inserted. The instrument has

an integrated heating/cooling unit that is used to systematically raise and lower the

temperature of the block. Thermoelectric coolers (TEC) are used for a large number of

these systems.

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 3

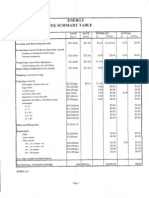

Table 1: Typical thermal cycling steps used in the PCR Process [3-5]

Step Reaction Hold time Purpose

Temperature

Denaturation Heat to 94C to 20 to 30 seconds Causes DNA melting of the DNA

98C template by disrupting the hydrogen

bonds between complementary

bases, yielding single-stranded DNA

molecules.

Annealing Cool to 50C to 20 to 40 seconds Allows annealing of the primers to the

65C single-stranded DNA template.

Extension/ Heat to 75C to Depends on DNA Polymerase synthesizes a new DNA

elongation 80C polymerase used and strand

on the length of the

DNA fragment to be

amplified.

Final Cool to 70C to Five to 15 minutes Ensures that any remaining single-

elongation 74C stranded DNA is fully extended.

How Thermoelectric Coolers Function

Thermoelectric cooling makes use of the Peltier effect to create a heat flux between the

junctions of two different types of materials. A Peltier cooler, heater, or thermoelectric

heat pump is a solid-state heat pump that transfers heat from one side of the device to

the other side against a temperature gradient (from cold to hot). To do this, electrical

energy is required. The electrical energy used for the pumping is converted into

additional heat that must be removed from the system (much like the heat from a home

air-conditioner unit). A device that operates in this manner may also be called a Peltier

device, Peltier diode, Peltier heat pump, solid state refrigerator, or thermoelectric cooler.

Figure 2: The cooling curve of a thermoelectric cooler at three different heat loads (10%,

30% and 50% of the Qmax or maximum allowable heat load. TEC

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 4

The most basic representation of a thermoelectric cooling device is a cooling curve

(Figure 2). The cooling curve represents the T (or temperature difference between the

cold and hot sides of the TEC) as a function of the input electrical current to the TEC.

There is a different curve for each unique amount of heat being pumped. Figure 2 shows

three different examples. As the heat pumped (Q) increases, the amount the TEC can

cool is reduced. For all cases, the maximum drive current for the module, Imax, provides

the most cooling achievable from that TEC under the given load conditions.

Thin-film thermoelectric coolers (eTECs) operate in the same manner as conventional

ones but offer several key advantages that are particularly well suited for PCR. These

advantages are:

Smaller footprint and thickness for the same heat pumping capacity (Fig. 3).

More rapid thermal response (up to 10X greater)

Advanced integration capability. The small size enables integration into systems

with minimal impact.

Figure 3: Size comparison of a 4 W Nextreme eTEC to a conventional TEC with the

same heat pumping capacity.

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 5

Thermoelectrics for the PCR Process

The market for PCR is changing. New applications pushing for portability and reduced

analysis time offer the promise of large new markets. In order to meet these

requirements, systems having smaller lighter quicker TECs are required. Due to their low

mass, thin-film thermoelectric devices are particularly well suited for producing rapid

temperature changes while also achieving a uniform temperature distribution throughout

the block, or enabling different temperatures in different parts of the block. This is

particularly useful when testing suitable annealing temperatures for primers, which are

required for initiation of the DNA replication sequence.

Thermal cyclers with thin-film technology inside can offer significantly shorter throughput

times for DNA amplification. Precision temperature control takes the guesswork out of

the traditional "trial and error" methods used in DNA amplification and reduces the need

to run multiple trials to get the desired results. Thin-film technology can enable a new

generation of thermal cyclers for equipment manufacturers that lower barrier-to-entry

and increase opportunities for differentiation.

In 2008, Nextreme successfully demonstrated short cycle time temperature control for

PCR using two eTEC thermoelectric modules that behave as microscopic Peltier heat

pumps. Figure 4 shows example thermal profiles of the fluid in the well (Water) and the

temperature of the sample holder (Cu Cup) that indicates how the TEC overdrives

temperature to produce the desired thermal profile in the sample.

Figure 4: Transient temperature measurement using thin-films in PCR thermal cycling

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 6

As discussed above, each PCR step occurs at a different temperature, thus precision

control is one the key features of a thermal cycler.

Implementation of eTECs in PCR amplification provides the following advantages:

Shorter throughput times for DNA amplification

o Fast temperature transition (10C per second)

o Small mass of thermal cycler

Higher density of wells per machine

o Physical size of conventional TEC prevents this versus the micro-size of

eTECs

Precise temperature control

o Ultra-fast response time

o Uniquely high power pumping capability

Thin-Film Thermoelectrics Integration (Faster Cycles, Higher Throughput)

Thermal cycle times in PCR thermal cyclers are determined both by the dwell times

during the denaturation, annealing, and extension phases and the thermal transition time

between these phases. Thermal cycle time is minimized and throughput maximized by

minimizing the transition time between the phases. Conventional PCR systems use large

individual sample volumes (e.g.; 100 L) and temperature transitions at 1 - 5 C/s.

However, while most PCR protocols are performed at the 25 L to 50 L scale, sample

volume as low as 5 L have also been shown to be successful.

SampleCartridge

20WTEC

PlasticPlatform

FlecInterconnect

COOLINOVATIONS

HeatSink

HotSideHeatSpreader

Fan

Figure 5: Typical structure of a PCR thermal cycler using thin-film thermoelectric

devices.

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 7

A typical PCR thermal cycler using thin-film thermoelectric devices is shown in Figure 5.

The thermal subsystem consists of a sample cartridge holder, support platform, thin-film

thermoelectric module with integrated heat spreader interface, and heat sink (shown with

fan). This subsystem is designed to provide rapid thermal cycling for single well or lab-

on-chip designs. In conventional PCR systems intended for laboratory usage, multiple

samples (e.g., 96 or more) are cycled simultaneously using a single large heat spreader

and bulk thermoelectric device. Current market shifts towards doctor's office or patient

side usage systems that handle 1 - 4 samples at a time are leading to a need for smaller

and more rapid thermal cyclers.

The temperature transition rates (C/s) between phases can be increased by the

following:

1. minimizing the thermal capacity of the load (all components that must be heated

and cooled)

2. minimizing the volume of the sample

3. minimizing the thermal resistance (conversely increase of thermal conductance)

of the heat transfer structure on the sample side of the thermoelectric module. \

4. optimizing the sample geometry to maximize the area for heat transfer into the

sample cartridge and sample and to minimize the heat transmission distance in

the sample. This can be achieved by integrating the sample side heat spreader

into the thermoelectric module itself and matching its area with that of the sample

area of the cartridge.

The high heat pumping capacity per unit area (typically measured in watts/cm2) of the

thin-film modules, along with their inherent rapid response, enables extremely rapid

temperature transitions in the sample. For optimized designs, temperature transition

rates in the range of 20C/s to 30C/s are feasible for currently used sample volumes.

For smaller sample volumes, even faster temperature transitions rates are possible.

A thermal cycler for a 50 L sample volume was designed using a standard heat sink

and fan with the sample chamber diameter of 16 mm and height of 0.25 mm. Typically

used materials were assumed for the sample cartridge and film seal for the cycler shown

in Figure 5. The thin-film thermoelectric module was optimized for the selected heat sink

to minimize the thermal transition times. The modeled thermal response of the system

achieves the 70C to 95C transition in the sample in 1 second and 95C to 50C

transition in 2 seconds. The simulated temperatures of the sample (red line), sample

side spreader (blue line), and heat sink (green line), are shown in Figure 6.

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 8

Figure 6: Simulated thermal cycle using thin-film thermoelectric modules with a 50 L

sample volume and thermal cycler shown in Figure 5. The plot shows the sample

temperature in red, the integrated sample side spreader temperature in blue, and the

heat sink temperature in green

Electrical Considerations

The thin-film thermoelectric assembly as referenced in the PCR application above

contains four eTEC HV56 modules connected electrically in series. The optimal drive

current for these modules in a PCR application is likely to be in the -0.9A to 0.6A range.

The range is achieved by applying negative (-) voltage to the assembly, which puts the

eTEC into heating mode to achieve the 95C rise temperature, and then switching the

polarity to put the eTEC into cooling mode to drive the device to the desired hold

temperature.

Several off-the-shelf thermoelectric cooler controllers or temperature controllers are

available to drive and control Nextreme eTEC modules. These controllers use current

sensing to control the eTEC current. The devices rely on an external NTC thermistor to

sense the load temperature and provide a control loop to adjust the eTEC current and

maintain a desired load temperature.

Nextreme's eTEC module assemblies can easily be connected electrically in series or

parallel configurations to match system voltages and drive current requirements.

Reliability of Thin-Film Thermoelectric Technology in PCR Thermal Cycling

Nextreme has conducted rigorous reliability tests on the HV-family of thermoelectric

modules. The devices have surpassed baseline test in mechanical shock, thermal

storage and power cycling. In all cases, the results strongly indicate HV modules are

reliable in use in PCR thermal cycling applications.

Non-Powered Environmental Stress

High-temperature storage provides a good indicator of long-term reliability, particularly

as it relates to diffusion-based failure modes and interface stability. The requirements

for this test were 85C for 2000 hours. To further stress the module and accelerate

temperature dependent failure mechanisms, Nextreme subjects thermoelectric modules

to temperatures well above maximum operating conditions (typically 150C). Figure 7

shows the results of 150C storage with read-points on the AC resistance at 254, 432,

1190, 1526 and 2534 hours. The AC resistance varied less than 1% from the starting

resistance in all cases. This indicates there are no temperature driven changes in the

thermoelectric material, contacts or interconnects under these conditions and the

modules are stable.

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 9

Figure 7: Percent change in AC resistance of the HV14 modules taken at different

times (hours) up to 2534 hours. Less the 1% change in ACR was observed.

Powered Environmental Stress

Power cycling provides one of the most useful thermoelectric reliability tests as it

simulates extreme usage by inducing large current pulses that simultaneously induce

large thermal gradients in the device. These gradients produce expansion and

contraction of the module that can lead to fatigue failures. Conducting power cycling at

elevated temperatures can also induce diffusion-based failures. Figure 8 shows power

cycling data of three HV14 modules at 90% of Imax for 100,000 cycles. In this test, the

cycle period was 5 seconds on and 5 seconds off. This rapid cycling is enabled by the

fast response time of the thin-film module and enables more rapid accumulation of data.

It also results in a rapid change in the internal stress of the devices that contributes to

accelerated aging and fatigue. The T of the module was monitored throughout the

testing and exhibited less than a 4% change over the entire 100,000 cycle test.

Figure 8: Change in module T over 100,000 cycles at 90% of Imax.

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 10

Summary

Rapid thermal cycling time is becoming increasingly important as PCR becomes more

widely used in point-of-service applications. The use of Nextremes thin-film

thermoelectric eTECs provides two key attributes that enable this quickly emerging

market, namely higher thermal response time and smaller size. Nextreme has modeled

and designed a thermal cycler capable of 1-2 second transition times for 50 l sample

sizes that dramatically improves on the existing conventional Peltier solutions. Further

optimization is possible when considering the details of the end application including

sample size, sample holder configuration, system size and cost.

For More Information

For more information on Nextreme PCR thermal cycling, visit www.nextreme.com/pcr.

More information on Nextreme's thermoelectric technology can be found at

www.nextreme.com. Contact Nextreme at 3908 Patriot Drive, Suite 140, Durham, NC

27703-8031; call (919)-597-7300; e-mail info@nextreme.com; or go to

www.nextreme.com.

References

[1] "European PCR Reagent Market for Research Applications and Clinical Diagnostics,"

Frost & Sullivan, June 2011, http://www.frost.com/sublib/display-

report.do?bdata=bnVsbEB%2BQEJhY2tAfkAxMzQ1NDg3NjE1OTQy&id=M6DD-01-00-

00-00 (accessed August 27, 2012).

[2] "DNA Sequencing and PCR Markets," TriMark Publications, June 2012,

http://www.trimarkpublications.com/products/DNA-Sequencing-and-PCR-Markets.html

(accessed August 27, 2012).

[3] "Polymerase Chain Reaction (PCR) In Medical Applications - An Analytical Report,

2009-2015," November 2011, http://www.axisresearchmind.com/market-research-

reports/market-research-report-83-

Polymerase%20Chain%20Reaction%20(PCR)%20In%20Medical%20Applications%20-

%20An%20Analytical%20Report,%202009-2015 (accessed August 27, 2012).

[4] Tom Weschler, "Blog, Market Insights, Pharma & PCP," Strategic Consulting Inc.,

October 25, 2011, http://www.strategic-consult.com/2011/10/use-of-rapid-

microbiological-methods/ (accessed August 27, 2012).

[5] Wikipedia contributors, "Polymerase chain reaction," Wikipedia, The Free

Encyclopedia,

http://en.wikipedia.org/w/index.php?title=Polymerase_chain_reaction&oldid=507870899

(accessed August 27, 2012).

Use of Thin-Film Thermoelectrics in PCR Thermal Cycling - NWP005.1 11

You might also like

- Kundalini Reiki Manual - REIKIDocument24 pagesKundalini Reiki Manual - REIKINur Anuar Mohamed96% (53)

- PCR LectureDocument42 pagesPCR LectureNoor Khan100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Transfer PricingDocument8 pagesTransfer PricingAnamir Bello Carillo50% (2)

- 4 - Hydro Jetting and Sludge RemovalDocument18 pages4 - Hydro Jetting and Sludge RemovalPerwez21100% (2)

- Nature of PlanningDocument2 pagesNature of Planningjaanaan92% (24)

- Sequence of Operation of FahuDocument1 pageSequence of Operation of FahuahmedNo ratings yet

- PCR PDFDocument43 pagesPCR PDFAmirNo ratings yet

- Cam PCR Definition and DescriptionDocument3 pagesCam PCR Definition and Descriptioncsh5213100% (1)

- 6273 ArticleText 11076 1 10 20200422Document7 pages6273 ArticleText 11076 1 10 20200422Alcides Gabriel Armas PerezNo ratings yet

- Polymerase Chain ReactionDocument13 pagesPolymerase Chain Reactionvamshibommi3477No ratings yet

- Molecular Diagnostics Techniques Polymerase Chain ReactionDocument7 pagesMolecular Diagnostics Techniques Polymerase Chain ReactionJamesNo ratings yet

- PCRDocument34 pagesPCRSumitNo ratings yet

- Methods and Instruments For Continuous-Flow PCR On A Chip: Fig. 1: Diagram of The PCR ProcessDocument7 pagesMethods and Instruments For Continuous-Flow PCR On A Chip: Fig. 1: Diagram of The PCR ProcessnanateNo ratings yet

- Uswa PCR 1Document8 pagesUswa PCR 1api-748952308No ratings yet

- Anishnu Mukhopadhyay - Sec 1 Assignment - 704Document17 pagesAnishnu Mukhopadhyay - Sec 1 Assignment - 704Anjishnu Mukhopadhyay BIOTECH SXCBNo ratings yet

- Polymerase Chain ReactionDocument13 pagesPolymerase Chain Reactionahmad ghNo ratings yet

- Radio Immuno As SayDocument6 pagesRadio Immuno As SayhardmanpersonNo ratings yet

- PCR (Midterms)Document13 pagesPCR (Midterms)emem ememNo ratings yet

- KOD Xtreme™ Hot Start DNA PolymeraseDocument8 pagesKOD Xtreme™ Hot Start DNA Polymerase1pisco1No ratings yet

- Polymerase Chain Reaction - WikipediaDocument36 pagesPolymerase Chain Reaction - Wikipedia93428ZEFHDNo ratings yet

- Biology PPT - Polymerase Chain ReactionDocument34 pagesBiology PPT - Polymerase Chain ReactionJay MandalNo ratings yet

- Polymerase Chain ReactionDocument8 pagesPolymerase Chain ReactionAdigun TaofeeqatNo ratings yet

- Polymerase Chain Reaction (PCR) - Principle, Steps, ApplicationsDocument10 pagesPolymerase Chain Reaction (PCR) - Principle, Steps, ApplicationsDr Praveen PrashantNo ratings yet

- Bio Project-Polymerase Chain ReactionDocument21 pagesBio Project-Polymerase Chain ReactionS.AbiniveshNo ratings yet

- DNA Amplification 2020Document5 pagesDNA Amplification 2020Blameless ArikoNo ratings yet

- Biology PPT - Polymerase Chain ReactionDocument32 pagesBiology PPT - Polymerase Chain ReactionJay MandalNo ratings yet

- Polymerase Chain ReactionDocument27 pagesPolymerase Chain ReactionundalliNo ratings yet

- Polymerase Chain Reaction 243Document1 pagePolymerase Chain Reaction 243Garcia RaphNo ratings yet

- Polymerase Chain ReactionDocument16 pagesPolymerase Chain ReactionIshikaNo ratings yet

- Primer Designing For PCRDocument13 pagesPrimer Designing For PCRiftikharsubha5No ratings yet

- PCR Process Steps Explained - Cole-ParmerDocument3 pagesPCR Process Steps Explained - Cole-ParmerRavin KumarNo ratings yet

- Polymerase Chain Reaction (PCR) : A Short Review: February 2013Document8 pagesPolymerase Chain Reaction (PCR) : A Short Review: February 2013Anggun RosalitaNo ratings yet

- Polymerase Chain Reaction (PCR) - Principle, Steps, ApplicationsDocument5 pagesPolymerase Chain Reaction (PCR) - Principle, Steps, ApplicationsMokhtarCheikhNo ratings yet

- PCR and Primer Design CorrectedDocument23 pagesPCR and Primer Design CorrectedAkinade AdetolaNo ratings yet

- PCR Musajuhanybsmt1bDocument3 pagesPCR Musajuhanybsmt1bJuhany MusaNo ratings yet

- PCR TechniqueDocument28 pagesPCR TechniqueSagar Das ChoudhuryNo ratings yet

- Biotechnology: A. S. M. GiasuddinDocument4 pagesBiotechnology: A. S. M. GiasuddinDespoina ChatziNo ratings yet

- PCR and Agarose Gel ElectrophoresisDocument6 pagesPCR and Agarose Gel ElectrophoresisÍrisNo ratings yet

- BiotechnologyDocument65 pagesBiotechnologyrifat7412548No ratings yet

- DNA Amplification and PCR: by Sara Haydar Mohammed Hasan Fourth Stage A2 Morning StudyDocument9 pagesDNA Amplification and PCR: by Sara Haydar Mohammed Hasan Fourth Stage A2 Morning Studydaloo dmdmNo ratings yet

- Polymerase Chain ReactionDocument6 pagesPolymerase Chain ReactionMuzzamil HussainNo ratings yet

- Polymerase Chain ReactionDocument27 pagesPolymerase Chain ReactionJulie Ann Pineda BalichaNo ratings yet

- KOD Hot Start PolymeraseDocument8 pagesKOD Hot Start PolymeraseJen LeiNo ratings yet

- Polymerase Chain ReactionDocument22 pagesPolymerase Chain ReactionPoornaBasuri100% (1)

- Erasmus+ Stage Practice June-July 2017Document24 pagesErasmus+ Stage Practice June-July 2017Bianca BujderNo ratings yet

- Polymerase Chain ReactionDocument47 pagesPolymerase Chain ReactionshvnagaNo ratings yet

- Polymerase Chain ReactionDocument14 pagesPolymerase Chain ReactionDavidMugambi100% (1)

- Activity # 1 - Introduction To Molecular TechniquesDocument14 pagesActivity # 1 - Introduction To Molecular TechniquesJhenica D. NonanNo ratings yet

- MB36172T - AssignmentDocument3 pagesMB36172T - AssignmentSounak DasNo ratings yet

- Pta, Which Encodes The Enzyme Phosphoacetyltransferase, Revealed The Presence of An Mboi RestrictionDocument5 pagesPta, Which Encodes The Enzyme Phosphoacetyltransferase, Revealed The Presence of An Mboi RestrictionANNAALTSHULERNo ratings yet

- Polymerase Chain ReactionDocument55 pagesPolymerase Chain ReactionFareeha ZahoorNo ratings yet

- Experiment No. 15 Practical: Polymerase Chain ReactionDocument8 pagesExperiment No. 15 Practical: Polymerase Chain ReactionAnura BandaraNo ratings yet

- Polymerase Chain Reaction (PCR) Lecture 11Document26 pagesPolymerase Chain Reaction (PCR) Lecture 11Sasa AbassNo ratings yet

- Polymerase Chain ReactionDocument5 pagesPolymerase Chain ReactionAman MishraNo ratings yet

- Polymerase Chain ReactionDocument5 pagesPolymerase Chain ReactionAman MishraNo ratings yet

- PCRDocument5 pagesPCROh RoopzNo ratings yet

- Polymerase Chain ReactionDocument5 pagesPolymerase Chain ReactionAaryan DeswalNo ratings yet

- Nucleic Acid TestingDocument55 pagesNucleic Acid TestingShaiji ShahidNo ratings yet

- The Polymerase Chain Reaction (PCR)Document13 pagesThe Polymerase Chain Reaction (PCR)api-19641337No ratings yet

- @@represented To - Sir Khizr-1Document58 pages@@represented To - Sir Khizr-1Alina RajputNo ratings yet

- PCRDocument1 pagePCRpqrk55dpk6No ratings yet

- PCR Lab ReportDocument3 pagesPCR Lab ReportoisinodonaillNo ratings yet

- Chaudhary Charan Singh University Meerut (U.P.) : "PCR & Microarray"Document33 pagesChaudhary Charan Singh University Meerut (U.P.) : "PCR & Microarray"desma elitaNo ratings yet

- Introduction To Object Oriented Programming and Hardware Abstraction LayersDocument56 pagesIntroduction To Object Oriented Programming and Hardware Abstraction LayersnisargNo ratings yet

- Advanced LabVIEW For FTC 2014Document34 pagesAdvanced LabVIEW For FTC 2014nisargNo ratings yet

- Starling ResistorDocument4 pagesStarling ResistornisargNo ratings yet

- Labview Multicore SystemsDocument86 pagesLabview Multicore SystemsnisargNo ratings yet

- PH Observation TableDocument2 pagesPH Observation TablenisargNo ratings yet

- Customizing LabVIEWDocument8 pagesCustomizing LabVIEWm_ramas2001No ratings yet

- Clustering 1Document6 pagesClustering 1nisargNo ratings yet

- Souce Najib LeadershipDocument12 pagesSouce Najib LeadershipSharanya Ramasamy100% (1)

- HELIOSOFT Presentation Webinar EMEADocument24 pagesHELIOSOFT Presentation Webinar EMEASvetlana ChiganovaNo ratings yet

- International StandardDocument24 pagesInternational Standardalvaro cardenas100% (1)

- Amendment of Information, Formal Vs SubstantialDocument2 pagesAmendment of Information, Formal Vs SubstantialNikkoCataquiz100% (3)

- Radio MirchiDocument7 pagesRadio MirchiRahul KasliwalNo ratings yet

- ATS Broussard User ManualDocument33 pagesATS Broussard User ManualMarv d'ar saoutNo ratings yet

- Insta Grid Investors OpportunityDocument14 pagesInsta Grid Investors OpportunityShawn Paul BoikeNo ratings yet

- PRELIM Fire Technology and Arson InvestigationDocument6 pagesPRELIM Fire Technology and Arson InvestigationIgnacio Burog RazonaNo ratings yet

- A Hybrid Intrution Detection Approach Based On Deep LearningDocument16 pagesA Hybrid Intrution Detection Approach Based On Deep LearningVictor KingbuilderNo ratings yet

- Fuel Oil Supply System (Double Station) (Worm Screw Pumps) : DS 1/150 ... 1/1000, DS 4/650 ... 4/4000Document1 pageFuel Oil Supply System (Double Station) (Worm Screw Pumps) : DS 1/150 ... 1/1000, DS 4/650 ... 4/4000徐玉坤No ratings yet

- Content Marketing Workflow EbookDocument39 pagesContent Marketing Workflow Ebookjuan gutierrez100% (1)

- Draft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleDocument2 pagesDraft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleRica Carmel Lanzaderas100% (3)

- BCG GE McKinsey MatrixDocument22 pagesBCG GE McKinsey MatrixAthmanath SR KrishnanNo ratings yet

- Surface WarfareDocument65 pagesSurface WarfareLobbyist_Myo100% (5)

- Prof. Gandeza - Review Notes in Civil LawDocument58 pagesProf. Gandeza - Review Notes in Civil LawFlorenz Efren CacatianNo ratings yet

- The 2020 Lithium-Ion Battery Guide - The Easy DIY Guide To Building Your Own Battery Packs (Lithium Ion Battery Book Book 1)Document101 pagesThe 2020 Lithium-Ion Battery Guide - The Easy DIY Guide To Building Your Own Battery Packs (Lithium Ion Battery Book Book 1)Hangar Graus75% (4)

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet

- Franchise Application Form: (I) APPLICANT INFORMATION (For Individuals, Please Fill in Applicable Fields)Document2 pagesFranchise Application Form: (I) APPLICANT INFORMATION (For Individuals, Please Fill in Applicable Fields)Nha Nguyen HoangNo ratings yet

- Sylvania Lumalux Ordering Guide 1986Document2 pagesSylvania Lumalux Ordering Guide 1986Alan MastersNo ratings yet

- GRAVE DISHONESTY: JurisprudenceDocument1 pageGRAVE DISHONESTY: JurisprudenceNielgem Beja0% (1)

- UMAM Fee Structure EditedVer2Document1 pageUMAM Fee Structure EditedVer2AKMA SAUPINo ratings yet

- Berlin BlocadeDocument2 pagesBerlin BlocadeRitik TyagiNo ratings yet

- PNP ACG - Understanding Digital ForensicsDocument76 pagesPNP ACG - Understanding Digital ForensicsTin TinNo ratings yet

- Malinta PDFDocument8 pagesMalinta PDFAngelina CruzNo ratings yet

- Performance Task 1. Piecewise FunctionDocument3 pagesPerformance Task 1. Piecewise FunctionKatherine Jane GeronaNo ratings yet

- Introduction To Surface EngineeringDocument31 pagesIntroduction To Surface Engineeringlogeshboy007No ratings yet