Professional Documents

Culture Documents

Distillation Systems / Heat Exchanger Systems

Distillation Systems / Heat Exchanger Systems

Uploaded by

shantilal0 ratings0% found this document useful (0 votes)

23 views19 pagesThis document discusses the key components and design considerations for vertical distillation towers and heat exchanger systems. It covers topics such as vessel orientation, manholes, ladders and platforms, piping supports, instrumentation, and other factors like reboilers, trays, and fire protection. Proper design requires considering access, thermal expansion, flow conditions, safety, and ease of construction and maintenance.

Original Description:

dfgdg

Original Title

Distillation Systems

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the key components and design considerations for vertical distillation towers and heat exchanger systems. It covers topics such as vessel orientation, manholes, ladders and platforms, piping supports, instrumentation, and other factors like reboilers, trays, and fire protection. Proper design requires considering access, thermal expansion, flow conditions, safety, and ease of construction and maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

23 views19 pagesDistillation Systems / Heat Exchanger Systems

Distillation Systems / Heat Exchanger Systems

Uploaded by

shantilalThis document discusses the key components and design considerations for vertical distillation towers and heat exchanger systems. It covers topics such as vessel orientation, manholes, ladders and platforms, piping supports, instrumentation, and other factors like reboilers, trays, and fire protection. Proper design requires considering access, thermal expansion, flow conditions, safety, and ease of construction and maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 19

Distillation Systems / Heat Exchanger Systems

1. Vertical Tower: Normally vessel components are described using common

terms such as shell, head, nozzle, and support. Some vessels will also have

special terms based on function. Typical special terms include the following.

Flash Section is the area or zone of the fractionation vessel where the primary

feed enters the vessel. Fractionation Section is the portion of the vessel that

includes the trays. Stripping Section is a place in the vessel that includes the

introduction of supplementary heat such as high temperature steam. Surge

Section is the bottom portion of the vessel that normally includes the main

outlet nozzle, which is connected to the bottoms pumps.

o Common problems with vertical vessels: Most important is schedule

crunch. Vessels scheduled for purchase too early requiring firm

orientations with very little backup information. The information

required is approved and issued documents for Design P & I D,

Exchanger type and location, flare header and location of pressure safety

valves. Thin wall vessels not able to support load on pipe supports. High

wind presence requiring extra guides. Late changes to pressure safety

valve sizing, prompts changes to pipe support and guides on line to flare.

Late change to control valve location criteria, due to which flashing

service are required to be located to elevated platform on vessel, with

line downstream of valve self drain to vessel. Reboilers requiring spring

mounted supports have to be moved due to tight piping and differential

growth. High steam out temperature requires extra flexibility in the

piping. Extra heavy object removal is difficult if there is increase in

excess load of Davit load capabilities.

o Vertical Vessel Orientation: The ladder approach at grade should be

free of obstructions and easily accessible. Verify preferred location with

Project requirements. The Manhole orientation should be oriented in the

back half of the vessel toward the access way. The manholes should be

arranged with consideration to the type of load handling device. You

should maintain one centerline if monorail is used, one or two

centerlines if davit is used, no specific restriction if crane. Load drop

area should be located on the main access side. Level instruments should

be located on or near the front half of the vessel and visible from the

main operating aisle. The piping risers to and from the vessel should be

located to the front half of the vessel for easy routing to the pipe way and

equipment.

o Manholes: Manholes will influence the entire vessel orientation to a

certain degree. The location of the manholes must be compatible with

the location of the tray down comers. The down comers in turn influence

the location of the process and instrument nozzles. The preferred

elevation of manholes above the platform is 2 feet 6 inches from the

centerline. The limits are minimum 6 inches from the top of the platform

to the bottom of the flange, or maximum 4 feet from the top of the

platform to the bottom of the flange. Verify preferred location with

Project requirements. Platforms may not be required for manholes that

are 15 feet or less above grade, unless a platform is required for another

reason such as an instrument. Verify preferred location with Project

requirements. Space and clearances are important around manholes.

Check flange swing and tray lay down space.

o Ladders and Platforms: Check to see that the approach to the ladder at

grade is clear of all obstructions and hazards, the entry onto each

platform is clear and not blocked by level or other instruments, the entry

onto each platform is clear and not blocked by an open manhole flange,

there is a clear path from one down ladder to the next down ladder for

unobstructed travel during emergencies. Platforms may need to be added

or extended for access to operating valves, spec blinds, or instruments.

Special platforms are often required at the channel end of a thermo-

siphon reboiler or other equipment that is mounted directly into or onto

the vessel. Investigate lining up and connecting platforms servicing

equipment, such as Reboilers or Accumulators, which are located in

adjacent structures but related to the vessel. Maintenance criteria at

Reactors often require platforms large enough and strong enough for

large flange or head lay down in addition to catalyst storage and

handling. Check the location and size of the pipe penetration holes

through platforms. The opening is to be one inch larger in diameter than

the flange or pipe plus insulation, which ever is greater. Provide proper

routing and support for all lines regardless of size. Do not route small

lines vertically behind the ladders. Do not route small lines vertically

between the vessel shell and the inside radius of the platforms. Do not

route small lines vertically up the outside of the platforms in line with or

close to the manholes. Ladder access openings must be fitted with a

safety gate. Check for proper clearance for gate swing. Some processes

are subject to periods of hazardous operations. Ladders and ladder cages

may need to be designed for operators with self-contained suits and air

packs.

o Reboilers: Reboilers will be either Fired or Heater Type, Thermosiphon

which can be vertical or horizontal shell & tube type, or Kettle type

which can be horizontal shell & tube type. Fired Reboilers shall be

located a minimum of fifty feet from the vessel. Piping to and from any

type of reboiler will be hot, and have sensitive flow conditions. The

Kettle or Thermosiphon Reboiler elevation is set by Process and

indicated on the P&ID.

o Pipe Supports and Guides: Piping is responsible for locating the pipe

supports and guides on vessels and for defining the size and loads on the

pipe supports on vessels.

o Piping Flexibility: Piping must determine the operating thermal growth

of the vessel. The vessel will have a series of temperature zones from the

bottom to the top. The differential expansion between the piping risers

and the vessel must be checked to prevent over stressing the piping or

the vessel shell. The routing of cooler reflux lines must consider the total

growth of the hotter vessel. Potential for differential settlement needs to

be investigated. Each piping system or line needs to be considered

individually.

o Instrumentation: The high and low level alarms need to be carefully

considered because they will set the elevations of the level instruments.

Orientation of level instrument connections needs to consider the

internals. All instruments shall be accessible. Watch out for space

requirements for gage glass illuminators. Temperature indicators and

thermo well connections will require removal space.

o Electrical: Space shall be allocated for conduit runs up the vessel. These

conduits will carry power to platform lights, gage glass illuminators, and

in some cases electrical tracing. Conduits are also required for controls

and for instrumentation cables.

o Piping Valves: Valves are meant to be operated. To operate them, they

must be accessible. 2 inch and smaller valves may be considered

accessible from a platform or ladder. 3 inch and larger valves shall be

accessible on a platform.

o Miscellaneous Piping issues: Lines to and from vessels may be subject

to conditions such as 2 phase flow or vacuum. Some Pressure Safety

Valves relieving to atmosphere will require snuffing steam. The steam

pressure in the line must be adequate to reach the top of the vessel. Large

overhead lines verses location of Pressure Safety Valves, require special

attention for function and support. Vertical vessel piping needs to be

checked for heat tracing requirements. A tracer supply manifold may

need to be added at the top of the vessel.

o Ease in Construction: All vertical vessels shall be reviewed for ease in

construction. This review needs to consider receiving logistics lay down

orientation, lifting plan, pre-lift assembly items. Pre-lift assembly items

may include Piping, Platforms, Ladders, Internals, Paint, Insulation.

o Fire Protection: Some vessels may require special insulation for fire

protection, fire monitor coverage and sprinkler systems.

o The other Components include the following:

Trays: The type of trays, the number of trays, and the number of

passes are not the specific responsibility of the piping layout

designer. However, there is the need to know about it. A common

understanding of terminology will improve communications and

prevent errors. The common tray parts are

Tray support Ring: The tray support ring or Tray ledge is

technically not a part of the tray itself. The tray support ring

is only there to support the tray. If there are no trays, then

there is no need for tray support rings, therefore tray rings

are linked to the trays. Tray support rings are normally a

simple donut shaped strip welded to the inside of the

vessel. They could also be in the shape of an inverted L

welded to the vessel wall. Problems arise when the

Designer does not allow for the tray support device.

Tray Deck: One or more sections, consisting of plates,

forming a horizontal obstruction throughout all or part of

the vessel cross section. The trays will normally be

constructed to form one or more flow patterns called

passes. The purpose of tray deck is to provide a flow path

for the process commodity and contain the fractionation or

separation device. A Weir is a low dam on a tray to

maintain a liquid level on the tray. Down comer is the

primary liquid passage area from higher tray to another

lower tray. Valves are also tray hardware device. Bubble

Caps is another tray hardware device. Draw off is a way to

remove liquid from the vessel. Trough is a way to collect

and move liquid from one point to another. Riser is a

device to channel vapor from one lower point to a higher

point. Seal Pans is a device with a liquid seal that prevents

vapors from passing. Beams & Trestles is a devices that

support trays or other types of internals in very large

diameter vessels. Baffles is a separation device inside a

vessel.

Tray Pass Patterns: The trays and the related down

comers can be arranged in a wide verity of patterns.

Typical Tray arrangement is Single Pass which is a quite

common. This tray pass arrangement has one feed point,

one flow direction, and one down comer. The single pass

tray will normally be used on small diameter vessels and

the smaller diameter of a Coke Bottle vessel. Cross-Flow

and Multiple Pass trays come in two pass, three pass, four

pass, and on and on. These will normally be found in the

larger diameter vessels. Multiple pass trays require multiple

feed and draw off arrangements. The more passes, the more

complex the orientation problems. Reverse Flow or Single

Pass, Radial Flow, Circumferential Flow, Cascade Flow are

rare. The single pass tray will have a single down comer.

The 2, 3, or 4 pass tray will have the same number of down

comers as passes. The number of passes and number of

down comers will have a big effect on the orientation.

Some towers may have more than one Tray pass

configuration. They may have single pass in the top Trays

and two-pass Trays in the bottom. The change from one

pass configuration to another is chance for error. The

alignment of the single pass tray will normally be

perpendicular to the two pass trays.

Tray Types: There is what would be considered Standard

Trays, and there are also high efficiency trays. Standard

Trays have an open down comer with no separation

occurring in the down comer area. This tray is the old stand

by and has been used for many years. High efficiency

Trays have a sealed down comer with separation occurring

in the down comer. This tray type is fairly new. It will most

likely be used on most new vessels in the future. It is also

the type of tray that is favored on revamp projects to get

more out of an existing tower.

Tray hardware devices: The normal trays inside the

typical vertical vessel will contain openings or holes and

may be fitted with a fractionation or separation device. This

device is what will accomplish the purpose of the vessel. If

these devices are not present or do not function properly

then the product is not made. There are some common tray

devices. Bubble Cap which is used mostly on revamps.

Simple, and common method to facilitate the separation

process. The Bubble Cap will normally be a round cup

shaped cap inverted over a short and smaller diameter

chimney. The skirt area of the inverted cap may be plain or

have open or closed slots. Box Cap is very much like the

common Bubble Cap except it is square. Tunnel Cap will

be a long narrow rectangular shape. Uniflux Tray is a series

of overlapping and interlocking plates. In cross section the

Uniflux tray will have the shape of a reclining squared off.

The valve tray is common and has small flat metal plates

fitted over the holes in the trays. The plate is loose to move

up and down, but is retained in position by a clip type

device. Vapor pressure under the valve plate causes it to

rise and gravity brings it back down. The second common

is sieve tray which has holes and nothing else. The hole

size is calculated to provide a fragile balance between the

liquid head above the tray and the vapor pressure under the

tray.

Column Internal piping:

Weirs: There may be a number of places where weirs are

used. The simple weir to provide proper tray flooding will

normally not cause any design problems. There are also

some special purpose weirs that may effect the location of

nozzles. In most cases the existence of special purpose

weirs will not be known at the start of the Vessel

orientation activity.

Down comers: Down comers can come in a verity of

shapes also. They straight across in the horizontal direction,

or they can be bent. They can be straight up and down in

the vertical direction, they can be sloped, slanted or

tapered, or they can be a combination. These variations will

all impact the orientation to some extent. The major impact,

by the down comer on the orientation is the geometry or

location of the vertical plane itself. The orientation of the

down comers will have a direct relationship to the

orientation of certain nozzles and manholes.

Other Tray Terms: Some other terms that will be found relating

to trays. Sump is a sealed down comer type area that is designed

to provide a retention volume for some purpose. Seal Pans is a

portion of a tray that is set deeper than the rest of the tray to form

a seal for the down comer from the tray above. Side Draw Tray is

an arrangement that allows the removal of a specific liquid

product. Chimney Tray is a full circumference tray fitted with

long open pipes to allow vapor to pass from below the tray to the

space above. Baffles are plates installed in the vessel for a specific

purpose. Impingement Plates are somewhat like a baffle but

normally a plate installed in the vessel at the inlet to prevent

blowout to devices located on the opposite side of the vessel. Tray

manholes are there in most, if not all, trays, where it will have a

removable panel somewhere in the tray to allow inspection

passage without dismantling the total tray.

Vessel Support: There is a wide variety in the methods used to

support vessels. Each of these support types may also have

variations. The tall towers are generally supported by skirts.

Horizontal storage tanks are supported by integral steel saddles.

Reactors are supported on lugs. Receivers and feed tanks are

supported on legs or are portable on casters. Pads are welded on

vessels which are supported on concrete saddles. Direct bury

method is used for underground tanks. The method of vessel

support depends on various factors. These factors include process

function, operation access, maintenance clearances, ease of

constructability, and cost. Meeting the positive criteria for all or

the majority of these factors will drive the support method. Each

of these vessel support methods has their own good points and

bad points. The Tall Skirt is the most common because it meets

more of the preferred criteria than the others do. The primary

methods of support are Skirts. Tall Skirt on foundation at grade

are most common. Short Skirt on elevated pier foundation, table

support, or structure. The minimum height of the skirt is normally

set by process based on the Net Positive Suction Head

requirements of the pumps or for the reboiler hydraulic

requirements. The designer may need to increase the skirt height

due to vertical distance required by pump suction line geometry,

Vertical distance required by reboiler line geometry, Operator

aisle headroom clearance, and suction line entering the pipe rack

without pockets. The approval of the Process engineer, Project

Manager, and the Client will be required for any increase to the

skirt height. The skirt will have one or more access openings and

will have skirt vents. Skirts of vessels in refineries or other plants

processing flammable commodities will normally be fireproofed.

The fireproofing is normally a two inch thick layer of a concrete

type material applied to the outside of the skirt. Check for the

specific type. Some materials may require up to 6 inch to obtain

the required fire rating. Legs can be installed on foundation at

grade. Lugs on vessels can be put on elevated pier foundation,

table support, or structure.

Load Handling Devices: Load handling devices are required for

Vertical Vessels if the vessel is over thirty feet tall or the vessel

has removable trays and internals. The vessel has components like

Pressure Safety Valves, control valves which require frequent

removal for routine maintenance and if the components weigh 100

pounds or more. Davit is a small somewhat inexpensive device

used for lifting and supporting heavy objects up and down from

elevated platforms. Limited to a fixed reach. Monorail is a more

expensive method, which is a girder provided along floor ceiling.

Crane is a far more expensive method and is dependent on

availability. If a davit or monorail is not installed then a crane

with the required reach and load rating must be rented or an

alternate method must be jury-rigged. Any jury rig method will

have a high potential for accident and injury. When a Davit is to

be included the location, swing, the clearance height including

lifting device, the reach of the removal items, and maximum load

of external items must be determined and furnished. When a

Monorail is to be included the platform, and monorail support

configuration, the clearance height including lifting device, the

reach to the drop zone, the maximum load of external items where

vessels will determine weight of internals, must be determined

and furnished to the Vessels engineer.

Pipe supports and Guides: The Pipe Supports and Pipe Guides

for the piping that is attached to the vessel is the responsibility of

the Piping Group. You are the Piping engineer and you need to

make sure it is properly supported and guided. The rule is that all

lines shall be properly supported and guided. One key element of

the Pipe Supports and Pipe Guides is the L dimension. The L

dimension is the distance from the outer diameter of the back side

of the pipe to the outer diameter of the vessel. This dimension

should be as small as possible but not less than required for

maintenance. The rule of thumb for the L dimension is 12 inches

minimum and 20 inches maximum. Dimensions of under the 12

inches and over the 20 inches are sometimes allowed. For

example, if fitting make up results in an L dimension of 12 inches

do not add a spool piece and extra weld. Lines should be

supported as close to the nozzle as possible. The type of support is

based on the weight of what is being supported. It may be just a

straight pipe dropping down the side of the vessel. Or, it may be

much more. Pipe supports attached to a vessel must be evaluated

for the shell thickness, orientation, elevation, the L dimension, the

weight of the basic pipe and fittings based on size and wall

schedule, the weight of the water during hydro test, the weight of

the insulation if any, the weight of any added components such as

block valves, control valve stations, relief valves, etc. There

should be clearance to other objects like seams, Stiffener rings,

Nozzles, Clips, Pipe Lines, Platforms. Pipe supports and guides

should be staggered vertically for clearance from supports or

guides on other lines running parallel.

Platforms, Ladders, and Cages: Platforms with access ladders

must be provided as required for access to manholes, operating

valves, and instruments as defined in the project criteria.

Normally objects below 15 feet from grade will not require

permanent platforms and ladders. These objects are judged

assessable by portable means. Check the Project design

requirements. Platform spacing shall be even foot increments

when multiple platforms are serviced from a single ladder. The

platforms shall be arranged to allow a minimum 7 feet headroom

to underside of any obstruction, minimum 2 feet 6 inches radial

width for primary egress path which is inside distance of platform

to outside distance of platform, minimum 2 feet 6 inches clear

distance between ladders. There should be no obstructions in path

between primary egress ladders. Maximum 30 feet vertical travel

length of ladder should be between platforms. Side step off at all

platforms which is step through ladders, are considered dangerous

and therefore should be avoided. This requirement should have

been reviewed with the Client and defined in the Design Criteria.

Combining with platforms on other vessels when potential for

improved operations or maintenance exists. Flanges of top head

nozzles shall be extended to provide access to bolts. Minimum 1

foot 6 inches clearance around objects if for maintenance access

only.

Code Name Plate: Every vessel will have a Code Name Plate. On

a vertical vessel the code name plate must be on the pressure

containment part of the shell. It cannot be attached to the skirt.

The best place for the code name plate on a vertical vessel is 2

feet 6 inches above the horizontal centerline of the surge section

manhole. Make sure the location selected is accessible on grade or

on a platform.

o Transitions for Coke Bottle Vessels: The cone or transition piece for

regular and inverted Coke Bottle vessels may come in the following

shapes:

Flat side: It has a cone is cut from flat plate and formed to a

simple cone. There is no knuckle radius at the top or bottom of the

cone. The connection to the straight shell of the vessel is an

angled weld. Usually there is a reinforcing ring on the shell very

close to the shell and cone junction.

Shaped side: The cone is cut from flat plate and rolled to a

shaped cone. There is a knuckle radius at the top and bottom of

the cone. The cone has a straight tangent at the top and bottom to

match the shells. The connection to the straight shell of the vessel

is a common butt weld.

o Lined Vessels: Some vessels will be lined. Linings may be metallic,

plastic, or glass. Welding to the vessel shell after initial fabrication is not

allowed. Some vessels will have flanged connections that are larger than

24 inches. These connections will occur at connections for piping,

reboilers, or other equipment. Flanged connections over 24 inches do not

have a single standard and need to be defined for specific type.

o Maintenance Aisles at grade: Equipment maintenance aisle for

hydraulic crane with a 12 Ton capacity should have a minimum

horizontal clearance width of 10 foot or 3 meters and a minimum vertical

clearance of 12 foot or 3.5 meters. Where a fork lift and similar

equipment of 5,000 pounds or 2300 kilograms capability, is to be used

the minimum horizontal clearance should be 6 foot or 2 meters and the

minimum vertical clearance should be 8 foot or 2.5 meters. Where

maintenance by portable manual equipment like hand trucks, dollies,

portable ladders or similar equipment, is required the minimum

horizontal clearance should be 3 foot or 1 meter and the vertical

clearance 8 foot or 2.5 meters. Operating Aisle at grade should have a

minimum width of 2 foot or 800 millimeters and a headroom of 7 foot or

2.1 meters.

2. There are a number of nozzles on a reaction vessel or distillation tower.

o Overhead Vapor Outlet Nozzles: The overhead vapor outlet nozzles on

a vertical vessel can have some latitude when it comes to attachment

location. The attachment connection can be direct to the top head of the

vessel or may be from the side. When the connection is from the side

there will normally be a pipe inside the vessel angled up to the top head

area. Small vapor outlet nozzles from small diameter vessels can be

located out the side of the vessel and still be cost effective. Large

diameter vapor outlet nozzles on large diameter vessels will be more cost

effective if attached to the top head. The line is then looped over to the

selected pipe drop position to go down the vessel.

o Feed Inlet Nozzles: All vertical fractionation vessels will have a feed

inlet nozzle. This feed nozzle is special and critical on some vessels.

Refinery Crude columns and Vacuum columns are examples that have

this type of nozzle. This nozzle installation is characterized by the

attached line originated at a fired heater, High temperature, High

velocity, Mixed phase flow. It may require internals such as a distributor

pipe or impingement plate. A Feed Transfer nozzle will normally be the

key nozzle for any large fractionation vessel. Normally any side inlet

orientation is possible but in most cases this will then dictate the tray

orientation.

o Liquid (secondary) Inlet Nozzles: A normal liquid feed nozzle will not

have the same complexities as the Feed Transfer type. This nozzle

installation is characterized by the attached line originated at an

exchanger, hot but not overly high on the temperature scale, some may

have potential for mixed phase flow, normal line velocity. It may require

vessel internals such as a distributor or inlet pipe. Watch Instrument

connections should be in relationship to Inlets and reboiler returns.

o Reflux Nozzles: A normal reflux nozzle will not have the same

complexities as other nozzles. This nozzle installation is characterized by

the attached line originated at a pump, low on the temperature scale, all

liquid flow, normal line velocity. It may require internals such as a

distributor or inlet pipe. Multiple pass trays will require a more complex

distributor or inlet pipe than a single pass.

o Draw-Off Nozzles: The purpose of this nozzle is to draw-off or remove

the primary product. They are also used to Draw-off a secondary product

to side stream stripper. May be installed with a sump to remove

unwanted water in the process stream. This nozzle is located in the

down-comer area of the column, it may be in a sump. It may be a larger

size than the normal attached line size. Some of the initial vertical drop

will be the larger size. It should be as per normal line velocity and may

require internals if multiple pass trays.

o Bottom Reboiler Feed Nozzles: The liquid outlet nozzle will normally

be in the center of the bottom vessel head. This nozzle is located in the

bottom of the surge section of the column. It may be a very large size

and has normally very low line velocity.

o Side Reboiler Feed Nozzles: This is also a potential Key Nozzle. The

liquid outlet nozzle must be oriented in the same quadrant as the bottom

down comer. This nozzle is located in the down comer area of the

column and is in a sump. It may be of a larger size than the normal

attached line size. Some of the initial vertical drop will be in the larger

size. Normally liquid flow in line is at lower velocity. Relationship to

elevation of associated reboiler is critical to nozzle elevation and

internals.

o Side Reboiler Vapor Return Nozzles: One of the primary issues with

this nozzle is the orientation relative to the other internal items and

nozzles. If not placed in the right place the velocity of the return can

blow liquid out of a seal pan or can affect the readings of any

instruments attached to the far wall. This nozzle is attached to the line

originated at a thermo-siphon or kettle type reboiler. It has a very high

temperature, with moderately high velocity. All flow is vapor. It may

require internals such as a pipe or impingement plate. Relationship to

elevation of associated Reboiler is critical to nozzle elevation and

internals.

o Bottoms Out and Drain Nozzles: The bottoms nozzle is normally a

source for pump suction. The standard type is located in the bottom head

then piped through the skirt with a drain nozzle off the bottom out line

nozzle. This would be a combination nozzle. A variation of the bottoms

nozzle is the siphon or winter type. This type may be used with the

approval of process when bottom clearance is a problem. It is common

industry practice to avoid locating any flanged connections inside the

vessel support skirt. All flanges are subject to leaks, and vessel skirts are

classified as a confined space.

o Level Instrument Nozzles: Extreme care must be used when locating

level instrument nozzles. There are access and clearances problems that

must be considered on the outside of the vessel. There are sensing

location and turbulence problems associated with the inside of the

vessel. These nozzles must be attached in the same pressure volume of

the vessel. Lower nozzle should be in liquid of the surge section, and

upper nozzle should be in vapor space. It should be located in static area

or with stilling well. It requires external access for operation and

maintenance.

o Pressure Instrument Nozzles: Pressure readings are normally taken in

the vapor area of a vessel. Pressure connections shall be located in the

top head area, 3 to 6 inches under a tray, or well above any liquid level

in bottom section. These nozzle is generally located in a vapor space of

the vessel. It requires external access for operation and maintenance.

o Temperature Instrument Nozzles: Temperature readings are normally

taken in the liquid area of a vessel. Temperature connections shall be

located 2 to 3 inches above the top surface of a tray, in the down comer,

or well below any liquid level in bottom section. These nozzle should be

located in liquid in the down comer area. It requires external access for

operation and maintenance. It should not interfere with internals. Vapor

temperature readings may be required for some situations. When

required the preferred location is in the down comer area half way

between the two trays. Tangential or Hillside connections may be

required due to the thermowell length or to accommodate access from

the ladder and platform arrangement. With the Process Engineer's

approval investigate the possibility of raising or lowering the

temperature point one tray for better ladder and platform arrangement.

o Steam-Out Nozzles: Process plant vessels that contain hydrocarbon or

other volatile fluids or vapors will normally have a Steam Out Nozzle.

This nozzle has a number of options. A simple blind flanged valve on the

nozzle can be installed after the plant is shut down by Operations, the

maintenance group would remove the blind flange from the valve. They

then attach a temporary flange fitted with a hose coupling and proceed to

steam out the vessel by connecting a hose from a utility station. A blind

flanged valve and hard piped steam line configured with a steam block

valve and a swing elbow can also be installed. A fully hard piped

connection from a steam source can be provided. This method would

have double block valves, a bleed, and a spec blind for positive shutoff.

The vessel steam out nozzle should be located near the bottom surge

section manhole on vertical vessels.

o Manholes: Manholes are also considered a nozzle. They just do not have

any pipe attached to them. They are however, a very complex piece of

the vessel orientation puzzle. The types of manholes normally relate to

the method of cover handling provided. Manholes come in the following

types. A Manhole may be hinged for side mount, for top mount, or for

bottom mount. A Manhole may have davits for side mount or top mount

only. A Plain Manhole may be for side mount, for top mount, or for

bottom mount. The manhole orientation in top or non tray section of a

vertical vessel is somewhat flexible. Normally any orientation is

possible. However, the orientation of the manhole should be checked to

insure that the entry path is not blocked by any internals. The Manhole

may be located in the top head on large diameter vessels if there is a

platform that is required for other items. Top Manholes on large

diameter vessels have their built in good points and bad points. The good

point is that during shutdown the open manhole provides for better

venting. It also allows for a straight method for removal and

reinstallation of the trays. The bad point is that ladder access must be

provided down to the top tray, and the manhole is competing with the

other nozzles for the space on the vessel head. Orientation for manholes

that are located in the tray section of the vessel is more complicated. The

location of between the tray manholes has a number of restrictions.

These restrictions include the type of trays and the tray spacing. The first

choice for the location of a manhole is between the down comers. The

last choice is in the down comer space, but behind the down comer. The

down comer would be fitted with a removable panel to allow further

access into the vessel. The location to be avoided is above a down comer

where there is the potential for falling down in the down comer space

and injury. It would be better to seek approval to move the manhole up

or down one tray than placement over a down comer.

Manhole orientation in the surge section of a vessel is not as restrictive.

The surge section of a vessel is the bottom portion that, during operation

will contain a large volume of liquid. Any orientation is possible for a

manhole in this section. However, the location of all manholes should be

in the back half of the vessel away from the pipe way. The surge section

may have a large baffle plate bisecting the diameter of the vessel and

extending vertically many feet. A removable plate or hatch may be

installed in this baffle (by vessels) to allow access to the far side. The

vessel orientation of the manhole should not hit the baffle or be located

so close to the baffle that entrance is obstructed.

3. Supporting Equipment:

o Flare Stacks: Locate the flare stack upwind of process units, with a

minimum distance of 200 feet or 60 meters from process equipment,

tanks, and cooling towers. If the stack height is less than 75 feet or 25

meters, increase this distance to a minimum of 300 feet or 90 meters.

These minimum distances should be verified by Company Process

Engineering.

o Furnaces: Locate fired equipment, if practical, so that flammable gases

from hydrocarbon and other processing areas cannot be blown into the

open flames by prevailing winds. Shell to shell horizontal clearance from

hydrocarbon equipment should be 50 foot or 15 meters with the

exception of reactors or equipment in alloy systems which should be

located for economical piping arrangement. Provide sufficient access

and clearance at fired equipment for removal of tubes, soot blowers, air

pre-heater baskets, burners, fans, and other related serviceable

equipment. Clearance from edge of roads to shell should be 10 foot or 3

meters. Pressure relief doors and tube access doors should be free from

obstructions. Orient pressure relief doors so as not to blow into adjacent

equipment. The elevation of the bottom of the heater above the high

point of the finished surface, should allow free passage for operation and

maintenance. In case of furnace piping, locate snuffing steam manifolds

and fuel gas shut off valves at a minimum distance of 50 feet or 15

meters horizontally from the heaters they protect. Burner valves for a

floor fired furnaces should be a combination of oil and gas firing valves.

It should be operable from burner observation door platform. For those

fired by gas only, the valves should be near the burner and should be

operable from grade. Burner valve for a side fired furnaces should be so

located that they can be operated while the flame is viewed from the

observation door.

o Heat Exchangers: Heat exchangers come in a variety of designs. In a

process facility shell and tube exchangers are the most common and are

manufactured in accordance with the Tubular Exchanger Manufacturers

Association code. The most common type of industrial heat exchanger is

the shell and tube type where one stream, usually the one that leaves the

most deposit like cooling water, flows through the tubes and the other

stream goes through the shell side. This is because the tubes are easier to

clean than the shell. Provision must be made to withdraw the tubes for

cleaning and this area must be kept free of piping and other obstructions.

Shell and tube exchangers are manufactured in accordance with the

Tubular Exchanger Manufacturers Association code.

Shell and Tube Exchangers: Shell and tube exchangers should

be grouped together wherever possible. Keep channel end and

shell covers clear of obstructions such as piping and structural

members to allow unbolting of exchanger flanges, and removal of

heads and tube bundles.

Stacked Shell and Tube Exchangers: Stacked shell and tube

exchangers should be limited to four shells high in similar service;

however, the top exchanger should not exceed a centerline

elevation of 18 feet or 5.5 meters above high point of finished

surface, unless mounted in a structure.

Maintenance Requirements: Exchangers with removable tube

bundles should have maintenance clearance equal to the bundle

length plus 5 feet or 1.5 meters measured from the tube sheet to

allow for the tube bundle and the tube pulling equipment.

Minimum maintenance space between flanges of exchangers or

other equipment arranged in pairs should be 1 foot 6 inches or half

meter. Exchanger maintenance space from a structural member or

pipe should not be less than 1 foot or 300 millimeters.

o Piping at Shell and Tube Exchangers:

Reboilers: Locate kettle reboilers at grade and as close as possible

to the vessel they serve. This type of reboiler is identifiable by its

unique shape. It has one end much like a normal Shell and Tube

exchanger then a very large eccentric, bottom flat transition to

what looks like a normal horizontal vessel. You could also call it a

Fat exchanger. The flow characteristics on the process side of a

kettle reboiler are the reason for the requirement for the close

relationship to the related vessel. Reboilers normally have a

removable tube bundle and should have maintenance clearance

equal to the bundle length plus 5 feet or 1.5 meters measured from

the tube sheet.

Double Pipe Exchangers: These exchangers can be mounted

almost anywhere and with process engineer approval, they can be

mounted in the vertical when required. A G-Fin Exchanger is

recognizable by its shape. One segment looks like two long pieces

of pipe with a 180 degree return bend at the far end. It is one

finned pipe inside of another pipe with two movable supports.

This type of exchanger can be joined together very simply to form

multiples in series, in parallel or in a combination of series or

parallel to meet the requirements of the process. This exchanger is

not normally used in a service where there is a large flow rate or

where high heat transfer is required. The key feature with this

exchanger is the maintenance. The piping is disconnected from

the tube side, which is the inner pipe. On the return bend end of

this exchanger there is a removable cover. When the cover is

removed this allows for the tube, or inside pipe to be pulled out.

This exchanger is normally installed with the piping connections

toward the pipe rack.

Plate Heat Exchangers: A plate heat exchanger is a type of heat

exchanger that uses metal plates to transfer heat between two

fluids. This has a major advantage over a conventional heat

exchanger in that the fluids are exposed to a much larger surface

area because the fluids spread out over the plates. This facilitates

the transfer of heat, and greatly increases the speed of the

temperature change. Plate heat exchangers are now common and

very small brazed versions are used in the hot-water sections of

millions of combination boilers. The high heat transfer efficiency

for such a small physical size has increased the domestic hot

water flow rate of combination boilers. The small plate heat

exchanger has made a great impact in domestic heating and hot-

water. Larger commercial versions use gaskets between the plates,

smaller version tend to be brazed. The concept behind a heat

exchanger is the use of pipes or other containment vessels to heat

or cool one fluid by transferring heat between it and another fluid.

In most cases, the exchanger consists of a coiled pipe containing

one fluid that passes through a chamber containing another fluid.

The walls of the pipe are usually made of metal, or another

substance with a high thermal conductivity, to facilitate the

interchange, whereas the outer casing of the larger chamber is

made of a plastic or coated with thermal insulation, to discourage

heat from escaping from the exchanger.

Fin Fans (Air Coolers): Air Coolers are in typically used in the

cooling of the overhead vapor from tall vertical vessels or towers

such as Crude Fractionators and Stripper Columns. The natural

flow tends to follow gravity, where the tower overhead is the high

point then down to the Air Cooler, then down to the Accumulator

and finally the Overhead Product transfer pumps. With this in

mind the Air Coolers are normally located above pipe ways. This

conserves plot space and allows the pipe rack structure with it's

foundation to do double duty with only minor up grade to the

design. If the pipe rack is not used then plot space equal to the

size of the Air Cooler is required. In addition a totally separate

foundation and stand alone structure is required. Air coolers, or

fin fans, are utilized globally in modern process facilities. Air is

quickly moved past the tube exterior by way of a large fan system.

As the product travels through the tubes, this process transfers the

heat from the product into the atmosphere. An air cooler or fin fan

unit is constructed of several hundred to several thousand

externally finned tubes. Tube dimensions typically range from 1

inch or 25.4 millimeters to 1.5 inch or 38 millimeters in diameter

and up to 75 feet or 23 meters in length.

You might also like

- Duct Fabrication ProcedureDocument14 pagesDuct Fabrication Procedureachusanachu80% (5)

- Method Statement For Valve InstallationDocument11 pagesMethod Statement For Valve InstallationKhang Hồ Lê100% (2)

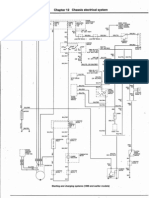

- Mitsubishi Galant Lancer - Wiring Diagrams 1994-2003Document43 pagesMitsubishi Galant Lancer - Wiring Diagrams 1994-2003Joseph Romero86% (14)

- 6-55. If The Built-Up Beam Is Subjected To An Internal Moment ofDocument5 pages6-55. If The Built-Up Beam Is Subjected To An Internal Moment ofPaula SilvaNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Control Station Piping LayoutDocument9 pagesControl Station Piping LayoutKrunalpanchal100% (1)

- Multi All Fujitsu ManualDocument93 pagesMulti All Fujitsu ManualJulio Holzbach80% (5)

- Transfer CasesDocument4 pagesTransfer CasesJuan Jose Alcaina MuñozNo ratings yet

- Piping Engineering - Piping SystemsDocument18 pagesPiping Engineering - Piping Systemskeiko davilaNo ratings yet

- Overall Plot Plan Layout (Design Considerations)Document20 pagesOverall Plot Plan Layout (Design Considerations)rahult19100% (1)

- Overall Plot Plan Layout (Design Considerations)Document20 pagesOverall Plot Plan Layout (Design Considerations)rahult19100% (2)

- Proper Installation TechniquesDocument1 pageProper Installation Techniquesmilton1987No ratings yet

- Introduction To Pipe Racks and Pipe SupportsDocument3 pagesIntroduction To Pipe Racks and Pipe SupportsprashantdhakateNo ratings yet

- Piping Interview QuestionDocument5 pagesPiping Interview Questionmithunjobs100% (3)

- Wellheads Components 1655005135Document149 pagesWellheads Components 1655005135Chandra Setiawan100% (2)

- 3) Piping Interview QuestionnaireDocument5 pages3) Piping Interview QuestionnaireAjaz MalikNo ratings yet

- 40+ Top Piping - Instrumentation Interview QuestionsDocument7 pages40+ Top Piping - Instrumentation Interview QuestionsMohammed IshaqNo ratings yet

- Inspection of The SystemsDocument12 pagesInspection of The SystemsTulen CabuldinNo ratings yet

- Production Engineering TechnologyDocument28 pagesProduction Engineering TechnologyReband AzadNo ratings yet

- Plant 1Document6 pagesPlant 1Janardhana PaiNo ratings yet

- Section II Equipment Piping and Assembly ApplicationsDocument47 pagesSection II Equipment Piping and Assembly ApplicationsAndy ChongNo ratings yet

- General Guidelines of Pump Piping LayoutDocument8 pagesGeneral Guidelines of Pump Piping LayoutbainNo ratings yet

- 1.0 Sequence of Column Piping StudyDocument31 pages1.0 Sequence of Column Piping StudyhervekumNo ratings yet

- Preparation For Start UpDocument19 pagesPreparation For Start UpArjun Shantaram ZopeNo ratings yet

- Categories of Cased Hole LogsDocument11 pagesCategories of Cased Hole LogsAG YNo ratings yet

- ACME AHX Water-Cooled Condenser - 06.10 PDFDocument3 pagesACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002No ratings yet

- LayoutDocument32 pagesLayoutDilip Yadav100% (1)

- Well Control EquipmentDocument12 pagesWell Control EquipmentSamad Ali SiddiquiNo ratings yet

- Piping Plan and Pipe Rack PDFDocument19 pagesPiping Plan and Pipe Rack PDFGiridhar ParabNo ratings yet

- Piping Design Guide-Vertical DrumsDocument9 pagesPiping Design Guide-Vertical DrumsTejas PatelNo ratings yet

- Monitoring of Cargo During VoyageDocument29 pagesMonitoring of Cargo During VoyageYap JoshuaNo ratings yet

- Works of Thomas Downloads in Dams Reservoirs-InglesDocument33 pagesWorks of Thomas Downloads in Dams Reservoirs-InglesÁnikka Quevedo GarcíaNo ratings yet

- Piping Related DocumentDocument28 pagesPiping Related DocumentTAMIZHKARTHIKNo ratings yet

- Aviation Storage TanksDocument6 pagesAviation Storage Tanksram71990No ratings yet

- Column PipingDocument53 pagesColumn PipingSomnath Laha100% (1)

- Column Piping: Study Layout, Nozzle Orientation & Platforms RequirementsDocument23 pagesColumn Piping: Study Layout, Nozzle Orientation & Platforms RequirementsArindomNo ratings yet

- Piping LayoutDocument16 pagesPiping Layoutsanmiguel000100% (1)

- Heat Exchanger Reference TheoryDocument23 pagesHeat Exchanger Reference TheoryMurugan VeluNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFSaidFerdjallahNo ratings yet

- Equipment LayoutDocument25 pagesEquipment LayoutCalNo ratings yet

- WWTP HazopDocument12 pagesWWTP HazopMarco MazzucatoNo ratings yet

- Learning For Oil and Gas PlantDocument93 pagesLearning For Oil and Gas Plantlucky yadavNo ratings yet

- Albert AST RegulationsDocument105 pagesAlbert AST RegulationsxnbsxNo ratings yet

- 4.12.1 Outlet Control IntroductionDocument5 pages4.12.1 Outlet Control IntroductionBoos yousufNo ratings yet

- Ships PipingDocument25 pagesShips Pipinggopaltry100% (1)

- Column Piping Study Layout NoDocument21 pagesColumn Piping Study Layout NoTAMIZHKARTHIKNo ratings yet

- 3D Model ReviewDocument12 pages3D Model ReviewDana GuerreroNo ratings yet

- Guides For Storage Tanks Nozzles OrientationDocument5 pagesGuides For Storage Tanks Nozzles OrientationGeethaNo ratings yet

- Assignment 3Document3 pagesAssignment 3Julian Ee Zhi HowNo ratings yet

- Area Division For Tower PipingDocument10 pagesArea Division For Tower PipingSkr9143 ShivNo ratings yet

- PlotplanDocument19 pagesPlotplanmsriref9333100% (2)

- Water Resources EngineeringDocument29 pagesWater Resources EngineeringJochelle TumambingNo ratings yet

- Piping Layout UDLDocument24 pagesPiping Layout UDLLegend Anbu100% (1)

- Well CompletionDocument64 pagesWell CompletionNidhal KahouliNo ratings yet

- Process Plant Layout and Piping DesignDocument106 pagesProcess Plant Layout and Piping DesignGaurav GuptaNo ratings yet

- 1 PiperackDocument8 pages1 PiperackDinesh Kumar JdNo ratings yet

- Use of ExchangersDocument21 pagesUse of Exchangerssteepa22No ratings yet

- Sluice CatalogueDocument40 pagesSluice CatalogueLungisaniNo ratings yet

- A Block Flow DiagramDocument35 pagesA Block Flow DiagramJerry SimonNo ratings yet

- Boiler Commissioning ProcedureDocument5 pagesBoiler Commissioning Procedurekumarmm1234No ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- Weld Procedure Summary: SR# Wps No. Process Aws No. P.No. Base Metal Thickness Range Diameter Range PWHTDocument5 pagesWeld Procedure Summary: SR# Wps No. Process Aws No. P.No. Base Metal Thickness Range Diameter Range PWHTshantilalNo ratings yet

- What's The Difference Between An RFI, An RFP, and An RFQ - Information Technology Services - Humboldt State University - Humboldt State UniversityDocument1 pageWhat's The Difference Between An RFI, An RFP, and An RFQ - Information Technology Services - Humboldt State University - Humboldt State UniversityshantilalNo ratings yet

- Piping Study - HomeDocument5 pagesPiping Study - HomeshantilalNo ratings yet

- Material P Group Table 4 PDFDocument1 pageMaterial P Group Table 4 PDFshantilalNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- Disciplinary ProcedureDocument2 pagesDisciplinary ProcedureshantilalNo ratings yet

- Flange Gasket and Bolts - Piping StudyDocument7 pagesFlange Gasket and Bolts - Piping Studyshantilal100% (1)

- Design of Tank and Tubes - TransformersDocument6 pagesDesign of Tank and Tubes - TransformersAJAY KOSHY PS 18-20No ratings yet

- Parts ListDocument2 pagesParts ListmetanirvanaNo ratings yet

- Section 230913 - Instrumentation and Control Devices For HvacDocument9 pagesSection 230913 - Instrumentation and Control Devices For HvacgolfnunoNo ratings yet

- MDC PT ChartDocument2 pagesMDC PT ChartKailas NimbalkarNo ratings yet

- Hsslive Xi Physics FY 224Document16 pagesHsslive Xi Physics FY 224Renjith Raveendran PillaiNo ratings yet

- S.E. 2019 Pattern Endsem Timetable For Nov-Dec-2022 ExamDocument21 pagesS.E. 2019 Pattern Endsem Timetable For Nov-Dec-2022 Examsudhir divekarNo ratings yet

- Control System (FS)Document44 pagesControl System (FS)Lucas RamirezNo ratings yet

- Flat Joint Contact ModelDocument14 pagesFlat Joint Contact ModelVivekChaudharyNo ratings yet

- Excitation and AvrmDocument67 pagesExcitation and AvrmAlok Ranjan Tripathi100% (2)

- Bomag BPR 35 - 42 D, BPR 35 - 60 D Operators and Maintenance ManualDocument66 pagesBomag BPR 35 - 42 D, BPR 35 - 60 D Operators and Maintenance ManualSwiduNo ratings yet

- Condenser - Valuable Book PDFDocument6 pagesCondenser - Valuable Book PDFRajesh OwaiyarNo ratings yet

- Sudare S690QLDocument16 pagesSudare S690QLgivaliNo ratings yet

- Flange ChartDocument4 pagesFlange ChartBowo Edhi WibowoNo ratings yet

- T50 A1 1 Abs Ci12 81995984542 EngDocument142 pagesT50 A1 1 Abs Ci12 81995984542 EngGonçalo Pereira100% (1)

- Fiat Croma Owner HandbookDocument258 pagesFiat Croma Owner HandbookCharles Neal0% (1)

- Design of Cond TrapDocument7 pagesDesign of Cond TrapgtdprasadNo ratings yet

- DH Parameters PDFDocument122 pagesDH Parameters PDFyash523No ratings yet

- Unit 4 - BCEM (Mechanics)Document29 pagesUnit 4 - BCEM (Mechanics)SHASHI RANJANNo ratings yet

- A419127 Generic Component DiagramDocument1 pageA419127 Generic Component DiagramjampukNo ratings yet

- Handouts MTH622 Modules 79 To 100Document44 pagesHandouts MTH622 Modules 79 To 100Muhammad AwaisNo ratings yet

- 3200E BrochureDocument2 pages3200E Brochureedi saputraNo ratings yet

- Hyster Training e KP 000007604Document62 pagesHyster Training e KP 000007604Sarwar Golam100% (1)

- Fire Pump Model Jw6h-Uf30Document10 pagesFire Pump Model Jw6h-Uf30Roronoa ZorroNo ratings yet

- CE FlowGuardLDocument1 pageCE FlowGuardLAQUILES CARRERANo ratings yet

- 318B Pump Flow TestDocument60 pages318B Pump Flow Testsaumicat100% (4)