Professional Documents

Culture Documents

Engineering Graphics For Diploma PDF

Engineering Graphics For Diploma PDF

Uploaded by

AL-Mawali87100%(3)100% found this document useful (3 votes)

4K views326 pagesOriginal Title

47028604-Engineering-Graphics-for-Diploma.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(3)100% found this document useful (3 votes)

4K views326 pagesEngineering Graphics For Diploma PDF

Engineering Graphics For Diploma PDF

Uploaded by

AL-Mawali87Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 326

antsoeity

Cen ccwa:

SY ei 0e)

Premieri2

re i K.C. John

Rs. 250.00

ENGINEERING GRAPHICS FOR DIPLOMA

KC. John

(© 2009 by PHI Learning Private Limited, New Delhi. All rights reserved. No part af this book

may be reproduced it ey form, by mimcogreph oF any ether means, without permission

in writing fern the putsiaher.

ISBN-078-81-209-9722.0

“The export rights of thie book are vated solely with the publisher.

Published by Asoke K. Ghosh, PHI Leaming Privala Limited, M-97, Connaught Circus,

New Dethi-110001 and Printed by Rajkamal Electric: Press, Piet No. 2, Phase iV, HSIDC,

Kundi-131028, Senopat, Haryana.

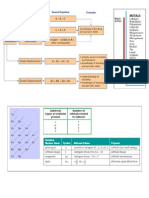

Contents

Preface

1.1 The GraphicLanguage _3

12 Traditional Drafting 3

1.3 Computer-Aided Drafting (CAD) 3

14 Graphic Instruments and TheirUse_

LS Codeof Practice forEnginceringDrawing

Lo__Lincs _#

L7__Scales _U

L8 Drawing Sheets and Title Block 7

1.9 Suggested Procedure for Drafting 12

Exercise 1

2, Lettering sssersstessnsssenenntnenestrae 18-22

21 Single Stroke Lewers 18

2.2 ‘Types and Sizes of Letters

2.3.___Vertical and Inclined Leners

a8

18

24 LeneringA 18

25 LetteringB 20

2.6 Lettering Practice 20

Exercises 2

Freehand

3.1__Imponance of Freehand Drafting

32 'ypes of Sketches 23

3.3 Materials for Sketching 24

3.4 Sketching of Straight Lines

35 SkeichingofCirles 25

3G Skewhingof Arcs 25

3.7__ Sketching of Ellipses 26

2.8 Method of Sketching Views:

Exercises az

3.

pas

26

4.2 Methods of Indicating Dimensional

Walues__i

4.3 Arrangement of Dimension Lines _32

44 Shape Indication RE]

45 Suggested Dimensioning System for Class

‘Work __34,

4.6 Rules of Dimensioning 35

Exercises _38

MODULE B: TWO-DIMENSIONAL

DRAWINGS

5G ical C ‘i ge

5.1 Geometrical Shapes J

3.2__ Revision of Simple Geometrical

Cor ns A

$.3 Dividing a Line into any Number of Equal

Parts _43.

5.4 Drawing of Tangent Arvs to Lines and

Ciks 45

5.5___ Drawing of Tangents to Circles a7

5.6 Construction af Regular Polygons 4

5.7 SeribingaCircleinoron Any Triangle $0

5.8__ Scribing of a Regular Polygon in orona

Circle _5f0

2

3.9 Construction of Ogee (Reverse) Curves

Exercises 4

Gx_Camlc Sections ss snsemessnntsnnnnnnnnsnenasnsssnnnne SST}

OL Types of Conic Sections 55.

62 —_Nomenclanre 58

6.3 Conic Defined as Loci _$7

6.4 Ellipse 58

6.5__ Methods of Construction of Ellipse __59

iv Contents

6.9 Methods of Construction of Hyperbola 6Z 10.4 __ Inclined Line Placed in First Quadrant 0

Exercises 69 10.5 Inclined Line Placed in Any One of the

Four ts dur

L_Miscellaneous Curves 71-83 Trane of an Inclinad Line Placed in ©

Li = Rouleucs a Quadrant__112

22 Cyeloid = 10.7 Trace of an Inclined Line: Placed in Ter

13 Twoehoids 23 Quadrants Ld

L& Epicyeloid 2 10.8 Three Views and Traces of an Inclined

LS Epitrochoids 2 Line___11¢

1G Hypooyeloid = 24 10.9 _Line Inclined to Both The HP and VP

LI Hypotrochoids 28 (Oblique Line) 115

ZS Involutes __76 10.10 Traces of an Oblique Line I

19 Spiral Curves 7 10.11 True Length and True Inclinations of an

710 Helixs___&2 ‘Oblique Line #22

i Exercises _125

jections of Plane Figures .......

al Wt sofPlane Figures 127

&2 Representative Fraction af 11.2 Positions of Plane Figures 128

3 Plain Scale _85 11.3 Plane Figures Parallel to One of the Reference

B4 Diagonal Scale 85 ‘Planes. ns

8.5 VemiecScales ag 11.4 _ Plane Figures Inclined to One of the Reference

&6 Scaleof Chords #8 Planes __ 30

Exercises 82

11.5 Plane Figures Inclined to the Two Reference

Planes __172

12.1 Classification of Solids _137

12.2 Position of a Solid with Respect to the

‘Reference Planes __1d

21 Systems of Projection _ 93

92 Multiview Projection __94 12.3__Method of Drawing Orthographic Projections

23 The Principle of Onhagraphic Projections of a ofSolids 140

Pointon HP and VP 9 12.4 Solids in Simple Position __I42

94 Conventional Representationof Views 97. 12.5 Axis Inclined to One of the Reference

95 Visualization ofthe Referens Planes 97. Planes 14d

9.6 Projections of a Point in the First 12.6 Axis Inclined to Both the Reference

uiadrant 98 Planes _J48

22 Projections of a Point in the Third Exercises 153

Quadrant ]

28 — Projections of Points in All the Four 13, Sections of SoMiMS iiiinnniuniis 15160

13.1 Representation of the Section Plane

9.9 — Imerpretation of Projections of Points ior and the Surface Formed by Cutting 155

210 Projections of Pointson HP, VP and PP 10n 13.2__ True and Apparent Shapes of Section 4155.

Exercises iid Suggested Procedure for Drawing a

Sectional View _156

Planes __106,

10.3_Line Perpendicular to One of the Reference Exercies = 160

Planes 108

Contents

MODULE D: DRAWING OF SURFACES

14. Intersection of Surfaces ...sssnsessnannnsnenesenn UG 3=170

14.1 Classification of Imersecting Surfaces 163

14.2 Methods Uist to Draw the Line of

Intersection __163

14.3 Line of Intersection of Prisms fit

14.4 Lines of Intersection of Cylinders 166

14.5 Lines of Intersection of Cylinder and

Cone 16

Exercises 170

15. Development of Surfaces ..... sermons 171-195,

15.1 The Principle of Development of

‘Surfaces _177

15.2 Methods for Drawing the Development of

‘Surfaces _172

15.3 Development of Polyhedra 173

15.4 Development of Cylinder and Cone __175

15.5 Development of Truncated Solids 177

15.6 Development of Solids Having Hole or

Cut__i8d

15.7 Development of Transition Pieces 184

15.8 Development ofObjects 186

15.9 Development of Spheres 187

Exercises _91

16.1 Principle of Isometric Projection __ 799

16.3 Procedure for Drawing Isometric

Projection 207

16.4 Isometric Projection and Isometric

View 207

16.5 Plane Figures 204

16.6 Solids _205

16.8 CombinationofSalids 24

16.9 Objects 204

Exercises 216

17. Oblique Projection -.rssessmerem

17.1 Principle of Oblique Projection __227

17.2 Receding Lines and Their Angles 227

I7-3 “Types of Oblique Projection 222

17-4 Method of Drawing Oblique Projection 224,

17.5 Oblique Projection of Solids 224

17.6 _ Oblique Projection of Objects 226

Esercises _227

18.1__ Principle of Perspective Projection 230

18.2 Nomenclature of Perspective Projection _2.40

18.3 Classification of Perspective Views 237

18.4 Methodsof Drawing Perspective Views 233

18.5 Visual Ray Method, Using Top and

& Views 233

18.9 Angular Perspective by Vanishing Point

Method 235

Excocises 237

MODULE F: INTRODUCTION TO

MACHINE DRAWING

19, Multiview Projection of Objects seen 241-257

19.1 Principle of Multiview (Orthographic)

Projection 247

19.2__First Angle Projection and the Locations of

he Three Views: 242

19.3__ Third Angle Projection and the Locations of

he Thies Views 242

19.6 Transparent Box and the Six Onhographie

Views oY

19.5 _ Indication of First Angle Projection 246

Vis 2

19.7_Use of Line Types and Dimensioning

of Views 247

19.8 Suggested Drafting Procedure 248

19.9 First Angle Project of Objects Having Plane

Surfaces 249"

19.10 First Angle Projection of Objects Having

Curved Surfaces

19.11 Third Angle Projection of Objects 252

Exeaci 2a

20. Auxiliary View of Objects ...senrsernsmeeren 258-264

20.2 Location of Auxiliary Views 258

20.3_TheNeedforDrawing Auxiliary Views 259

20.4 Classification of Auxiliary Views 259

20.5 Methods of Drawing Primary Auxiliary

Views: 260

20.6 Symmetrical Auxiliary Views 261

20.7 Unsymmetrical Awaliary Views 262

Exercises 263

vi

21, Visualization of Objects .. rensansssersevers 265-272,

21.1 Principle of Visualization of Objects 265

21> “The Need for Visualizat 265

isualization of Three

Dimensional Objects 266

21.4 Meaning of Lines and Areas in Orthographic

Drawings 267

2.5 Visualization of Objects from Pictorial

Views 26

21.6 Visualization of Objects from Orthographic

Views 269.

Exercises 271

22. Sectional Views of Obj saaneseensnne 273-280

22.1 __Principle of Sectional Views of Objects __273

f Secti 7?

22.3 FullSectional Views 275

224 HalfSectional Views — 276

22.5 Convention for Sectioning 276

22.6__Conventional Representation of

Materials 277

Exercises _279

MODULE G: COMPUTER AIDED

DRAFTING

23 Tntroduction 10 CAD sssnmsmasssuersmreenmenr 2-2)

23.1 Hardware forCAD = 283

‘Contents

23.3 General Features of Drawing

Generstion 286

ies

Exercises _290

24, Starting to Use CAD Software .ccccccasecou: 291-297

24.1 Setting of Workstation _ 29

24.2 Start up Dialogue Box 291

24.3_The Graphic Sereen__-291

244 Use of Function Keys 295,

245 Sening of Blank Sheet for Drawing = - 295

24.6 Saving the Blank Sheet 297

Exercises 297

25. ling of 2D sasenesorasssreeriassrennnesee 2IB—311.

25.1 Draw Commands _298

25.2 Modify Commands 301

25.3 DisplayCommands 303

25.4 ObjectSnap 304

25.5 MiscellaneousCommands 308

25.6 DimCommands 105

25.7_Drawing of Isometric Views 305

25.8 Printer Plotting of Drawings 306

Exercises _ i008

Problems and Solutions 0 dE

Selected. ‘hnic Examination Questions

Model

ic Examination Questians 0... 355-364

Preface

Engineering Graphics is the language for communication

and documentation of engineering design. With the arrival

of computers, the usage of this language has advanced into

the areas of manufacturing, assembly, inspection and

maintenance since all these functions are well executed

through computer aided drafting (CAD) and three-

dimensional modelling. Based on these developments, it is

highly recommended for the students entering the

engincering field to study the fundamentals of this language

in their first yearof the engineering course. Advanced topics

in Engineering Graphies are covered in the following years

according to their respective branches of study. Three-

dimensional objects locatedin space have tobe converted and

presented on a two-dimensional drawing sheet or monitor

screen using the ISO Standard coding system. To fully

understand the techniques used in this process, the student

should develop good visualization capacity.

Even though there are a number of textbooks available

for engineering drawing, the treatment of the subject is still

found to be difficult for an average student. This book is an

effort to overcome or reduce this difficulty.

‘The content of the textbook Engineering Graphics for

Diploma is divided into seven modules. A topic is first

introduced in each chapter of a module, with brief

explanation arid necessary pictorial views, and then mastered

gradually through a number of worked-out examples. The

examples are explained using a step-by-step procedure and

illustrating drawings. All the drawings are prepared in First

Angle Projection and strictly follow the ISO/BIS format.

Module A—Preliminaries, covers the fundamentals of

manual drafting, lettering, freehand sketching and

dimensioning of views. Module B describes two-

dimensional drawings like geometrical constructions,

conics, miscellaneous curves and drawing of scales. Three-

dimensional drawings are well explained in Module C,

starting with projections of points and then straight lines

located in all the four quadrants. Projections of plane larnina,

gcometrical solids and sections of themare also described in

detail in the same module, Module D deals with the surfaces

of solids, such as intersection of surfaces and their

developments.

Drawings of pictorial views of solids and objects are

illustrated in Module E. These include isometric projection,

oblique projection and perspective projections, The

perspective view drawing presented in first angle itself

avoids discontinuity in study, as compared to-other available

textbooks in the market. Fundamentals of machine drawing,

are covered in Module F in four chapters. The last Module G

introduces computer aided drafting (CAD) for producing

professional levelonthographic drawings. Selected questions

from various Diploma Examination question papers and

theirsolutions arealso given. This enables students to prepare

themselves for Diploma Examinations.

T am highly grateful to the eminent professors,

teachers and earnest students of various engineering

institutions for their encouragement. Their creative criticism

and suggestions helped me to prepare this book in its current

form. Textend my heartfelt thanks to PHI Learning for taking

interest and the effort to publish this textbook at intemational

standards.

Acknowledgement is also duc to the Bureau of Indian

‘Standards, whose work has been consulted for the

preparation of this book, T would also like to express my

gratitude to various Boards of Technical Education in India,

for permitting me to include their examination questions as

worked-out examples,

K.C. John.

Chapter 1

Chapter 2

Chapter3

Chapter 4

Module A

Preliminaries

Introduction to Engineering Graphics

Lettering

Freehand Drafting

Dimensioning

Introduction to

Engineering Graphics

Ersizesine graphics is the principal method of

‘ommunication in the field of engineering and science,

‘The graphics of engineering design and construction is one:

among the most important courses of all studies for

engineering. The indisputable reason why graphics is so

important is that, it is the language used by the designer,

technician and engineer, to communicate, design and

construct details to others.

1.1 THE GRAPHIC LANGUAGE

Engineering drawing is the graphic language used by

engineers and technologists. globally. The graphic

language may be defined as the graphic representation of

physical objects and their relationships. Like other

spoken and written languages, this graphic language had

also been developed through centuries. The language of

graphics is written in the form of drawings using straight and

curved lines which represent the shape, size and

specifications of physical objects, The language is read by

interpreting the drawings so that the physical objects can be

constructed exactly asconceived by the designer. Like every

language, the graphic language also has its awn rules of

grammar. These rules are governed by certain code of

practice, An engineer, should have proper understanding of

the theory of projection, dimensioning and conventions

Cc H A. P TFT ER

related to working drawings, in order to become

professionally efficient,

1.2. TRADITIONAL DRAFTING

Engineering drawings are made up of straight and curved

lines to represent the surfaces, edges and centres of objects.

Symbols, dimensional values and word-notes are added to

these lines so that they collectively make the complete

description. The traditional drafting is the preparation of

these drawings manually, by frechand sketching or with the

help of drawing instruments,

Freehand drawing is done by sketching the lines without

instruments other than peneil and eraser. They are much used

commercially as preliminary de: Preparation of

drawings to scale, using various drawing instruments is the

standard conventional drafting method. After the

preparation of the scaled drawings, they are waced using

instruments and ink pens to the tracing paper or tracing film

for taking prints

1,3. COMPUTER-AIDED DRAFTING (CAD)

In Computer-Aided Drafting (CAD) the drawings are

prepared with the help of computer and the prints of the

required size are taken, using the output devices. CAD is

defined as a process of producing drawings in which a

computer software and associated hardware are used.

Nowadays, microcomputers are widely employed for

automated drafting.

Compared to traditional drafting, CAD is faster as well

as efficient and the modifications can be brought out very

easily. Depending on the drafting task, the production of

drawings can be increased to about 2to 10 times with a good

CAD system, In modem industries the traditional deafting is

being replaced by computer aided drafting. This doesn’t

mean that traditional drafting instruments are totally

removed by computer and related output devices. The

computer (the hardware and software) is only a strong tool to

produce accurate drawings in the shortest time. Trained

designers and drafters who know engineering graphics very

well are supposed to operaic the CAD systems. This training

in drafting is given using traditional graphic instruments.

After understanding engineering graphics by traditional

drafting methods, one can have the expertise in operating

CAD system to develop the skill and speed for excellent

performance.

4.4 GRAPHIC INSTRUMENTS AND THEIR USE

To prepare a neat and scaled pencil drawing, good drafting

instruments are to be used. A list of drawing instruments and

materials required for the same is given below:

1. Drawing board

2. Minidrafter of T-square

Clomping screw

Pivot plate

browacier nese

Engineering Graphics for Diploma

3. Instrument box. containing long compass. spring

bow compass, small bow divider ete,

4. Set-squares (45° and 30-60°) and protractor

5. Engineer's scale set and steel nile (30 em)

6. Drawing pencils (standard and clutch pencils)

7. Eraser

8. Adhesive tape, drawing pins orclips

9. Sandpaper pad

10. Blade, pocket inife or pencil sharpener

11, Handkerchief, duster or dusting brush

12. Letter stencils, french curves, erasing shield and

templates

Drawing Board

Drawing board, made up of seasoned soft wood (pine, fir,

oak ete.) are used for traditional drafting. Figure 1.1 shows

drawing board with a minidrafter clamped in position. Ifa

‘T-square is used instead of minidrafier for drafting, astraight

working edge of hard wood (ebony) is also required on the

Jeft edge of the board. Figure 1.2 shows a drawing board with

a T-square in drawing position. The standard sizes of

drawing boards as per Bureau of Indian standards are shown

in Table 1.1,

Minidrafter

Drafting machines are used for professional drafting of

engineering drawings. Itmainly consists oftwascalesatright

Drawing sheet

ppOrowing board

\cScole of minidrafter

Knob

Fig.1.1. Drawing board with minidrafter clamped in position.

Introduction to Engineering Graphics

~Sel-squore

Drafting edge of T=square

_-7 Drawing sheet

Drawing board

Fig. 1.2 Drafting board with T-square in drawing position

Board Sizein'man Sheet

Designation {yeidth x length) size

Dy 1500 « 1000 Ay

D, 1000 x 700 Ay

D, 700 x 500 Ay

B 500350 Ay

angles which can dothe Function of T-square and protractor,

A simplified version of the drafting machine is called

minidrafter. Figure 1.1 shows a minidrafter fitted to a

drawing board, The unit hasaclumping end which is fixedon

‘the board by a hand screw and two mutually perpendicular

scales with protractor head on the other end. The body of the

minidrafter contains two of parallelograms made of bars

pivoted tothese ends.

‘To use the minidrafter, first of all set the protractor head

_at zero position and tighten the knob. Then clamp the drafter

to the top edge of board as shown in Fig, 1.1 using the hand

screw so thatthe horizontal scale is parallel to the horizontal

‘edges of the board.

T-square

T-square is composed of a long strip ealled blade fixed

rigidly by serews at right angles toa shorter strip called head

(stock). Figure 1.2 shows a T-square placed on a drawing.

board in its drawing position. T-squares are generally made

of wood or plastic. For wooden T-squares the top drawing

side of the blade and the inner sliding slide of the stock are

fitted with straight edges of hardwood.

A T-square is used for drafting on a drawing board fitted

with straight working edge in the left hand side (see Fig. 1.2).

The stock of the T-square is kept perfectly touching on the

working edge and is moved forward and backward by left

hand, so that different horizontal positions of the drafting

edge are obtained for drawin

Compared 10 minidrafter, T-square gives beer

accuracy in large size drawings, but the speed of drafting is

low. For small size drawings as well as for stady purpose the

use of minidrafteris recommended.

Instrument Box

The drafting instruments like compass, divider, ete. are

available in boxes called engineering drawing instrument

box. A standard three bow-set instrument box contains the

following devices:

Large size compass

Lengthening bar for large size compass

Small bow compass

Large size divider

Small bow divider

Small bow ink-pen

Inking pens.

‘The most useful types of compasses and dividers are

shown in Fig. 1.3. Inking-pens and bow ink-pen are used for

tracing of drawings with ink. The large size compass is used

todraw large size circles andarcs. A pointednecdle is fitted at

Die & bp ee

Engineering Graphics for Diploma

Lorge (Big) compess

Bow (smal

compess

Fig. 1.3. Drawing board with T=square in drawing position.

one leg while a pencil lead is inserted in the otherleg. Both the

legs are provided with knee joints so that while drawing

circles orares of radius above 60 mm, they can be bentto keep,

the lead and the pointed needle almost perpendicular to the

surface of drawing sheet. See Fig. 1.4(a), For drawing ares

and cireles of radius 180 mm and above. the lengthening bar

is tobe added to the leg, holding the ead. Circles and ares of

radius less than L5 mm are drawn, using the small bow

compass. The lead tip of a compass has to be sharpened and

set as shown in Fig, 1.4(b), This shape of point is formed by

first sharpening the outside of the lead on the sandpaper pad

to a long flat bevel approximately 6 mm long and then

finishing it with a slight rocking motion to reduce the width

of the point. A soft lead (HB) gives dark thick line which can

be used for drawing object boundaries, while a bard lead (H)

(a)

Fig. 1.4 Use of large (big) compass.

gives light coloured thin lines used forshowing construction

lines.

‘The large size divider is used to divide curved lines or

straight lines into desired number of equal parts. They are

also used te transfer a length fram the seale to the drawing

shect or to transfer a length from drawing sheet to the scale

for measurement. Small bow divider is sed as the large

divider for shorter lengths below 20 mm.

Inking pens and bow pens are also included in the

standard instrument box. They are used for tracing of

drawings with ink,

Set-squares and Protractor

Set-squares ((riangles) and protractor are made of

transparent plastic material. See Fig. 1.5. Set-squares (45°

(a) Set—squares (b) Protractor

(c) Use of set-square

Fig.1.5 Sot-squares and protracter.

Intreduction to Engineering Graphics

and 30°-60°) are used to draw vertical as well as inclined

lines. They are also used for setting combination of angles of

15°, while using T-square. Along with minidrafter set-

squares are also used to draw inclined lines of 30°, 45° and

60° as shown in Fig. 1.5(c). Protractor of circular or

semicircular type is used to set up or measure angles. Since

the size of the protractor head of a minidrafter is small, the

use of a large size protractor is recaramended for accurate

angle setup and measurements.

Engineers Scale Set and Steel Rule

A sel of 8 scales designated from MIL to MB are required to

take measurements for scaled drawings. They are made of

cither cardboard or plastic [see Fig. 1,6¢a)]. A steel rule of 30

em length is also recommended to draw inclined lines.as well

to use as full size seale for measurements.

Drawing Pencils

For the preparation of drawings, two lypes of pencils are

generally used:

(a) Wooden drawing pe

(b) Clutch pencils.

Wooden drawing pencils of hexagonal cross section are the

traditional (ypes used for engineering drawings. They are

designated as HB, H, 2H etc. Here, H stands for hardness and

B for the blackness and sofiness. They sre sharpened as

shown in Fig. 1.6¢b) to conical point or chis

and

and chisel points are shaped by grinding the eylindrieal lead

on the sandpaper pad.

(a) Pin, stip, ond tone

Mechanical cluteh pencils of lead size 0.5 mm diameter

are now available for reasonable prices [sec Fig. 1.6(d}].

‘They are preferred because they can give better uniform line

width and no sharpening is required. Lead grades of HB, H

and 2H are used in these pencils.

Eraser

Soft natural rubber or nylon rubber is used as eraser to

remove unnecessary lines on the drawing sheet [see

Fig. 1.6ic)].

Adhesive Tape, Drawing Pins or Clips

‘To fix the drawing sheet on the drawing board adhesive

tape is gencrally used [see Fig. 1.6(e)]. Use of drawing pins

will spoil the surface of the board. Use of clips may not be

possible while using a shorter drawing sheet on a large size

drawing board.

Sandpaper Pad

This consists of a small wooden block on which fine grained

sandpaper is pasted about half of its length (see Fig. 1.6). The

sandpaper pad is used to sharpen wooden pencil lead and

compass lead tip for correct line thickness.

Blade, Pocket Knife or Pencil Sharpener

These instruments are used for sharpening the wooden

pencil and cutting of drawing sheets to the required

size,

(c) Eraser

(#) Sondpeper ped

Fig. 1.6 Drawing instruments

FSbedetghltmnopgrstvenys

ASCDEFGHIIKLWNOPORSTUWWHYZ 1234567890

(a) Letter stencil

(b) French curve

Engineering Graphics for Diploma

of Q

(c) Erasing shield

ees

\S050000|

(8) Template for circles

Fig.A7

Handkerchief, Duster or Dusting Brush

Cleaning of board, and drawing sheet can be done using

duster or dusting brush. Handkerchief ean be used for this as

well as for wiping wet hands.

Letter Stencils, French Curves, Erasing Shield

and Templates

‘These items, made from transparent plastic sheets, are used to

improve the speed and finish of drawing (see Fig, 1.7), Letter

stencils are used to print letters especially in tracing. Curved

rulers called French curves or irregular curves are used for

drawing curved lines other than constant radius ares. They

are available in different forms and sizes in boxes. Erasing

shield is used to shield the required Tines while erasing the

nearby unwanted lines. Templates are plastic sheets with the

standard shapes likeciteles,cllipses. symbols ete. cutin them

so that the drawing can be made fast and accurate. Templates

are widely used for tracing of drawings.

4,8 CODE OF PRACTICE FOR ENGINEERING

DRAWING

Intemational Standards Organisation (LS.O.) Geneva,

formulated and issued international standards for

‘engineering drawings in 1982, India, approved the same and

accordingly modified the Indian Standards 1S: 696-1972 to

IS: 10714-1983. The Indian Standards Institution (ISI)

which is taking care of standards in India, has been renamed

as Bureau of Indian Standards (B.1S.). Engineering

Drawing Committee (E.D.C.) of B.1S, has adopted the

15.0, standards since 1983. As per letter No: EDC 20:1/T-

‘ST dated 17th Aptil 1984, IS: 696 -1972 has been withdrawn

by the B.1.S. The new drawing standards are now available in

19 different booklets. For the use of students, a special

publication containing all the relevant information in the

ficld of drawing standards, was brought out in March 1989.

‘This special publication is referred to as SP:46-19B8 tithe

“Engineering Drawing Practice for students of schools and

colleges”.

Allltechnical institutions should have the complete set of

Indian standards accessible to technical drawing classes for

‘the benefit of the students.

1.6 LINES

‘One of the fundamentals of good draftsmanship is line work.

For general engineering drawings, various types of lines are

recommended by 1S:10714-1983. Each line has a specific

meaning and function.

Types of Lines

Different types of lines recommended ate shown in

Table 1.2. If lines of othertypes orthickness are tobe used for

special fields ike electrical or pipe work diagrams, or if lines

‘specified in the table are tobe used for applications other than

those mentioned, the convention adopted should be

explained by notes on the drawing itself.

Anexample of the use of various types of lines is shown

in Fig. 1.8. The following are the types of lines used:

4. Type A

‘These types of lines.are continuous thick lines and are used to

represent

AL Visible out lines and

A2 Visible edges.

‘Type A Lines are also used for the following

applications:

1. Thread ends,

2. Limits of useful thread lengths, and

3. Mainrepresentation in diagrams, graphs, charts and

flow diagrams,

Introduction to Engineering Graphics

‘Table 1.2 Types of lines

H r —

Fig. 1.8 Use of various types of lines,

2. Type B

These types of lines are continuous thin lines and used to

represent:

BI Imaginary lines of intersection

B2 Dimension lines

Deserip

Continuous thick

Continuoiss thin

Continuous thin frechand

Continuous thin with zig-zags

(Chain thin, thick at ends and

changes of direction

Chain thick

Chain thin double dashed

B3 Projection

B4 Leader lines

BS Hatehing (section } lines

B6-Oulline of revolved section in place and

B7 Short centre lines.

Type B lines are also-used for the following applications:

Diagonal eross to represent flat surface

Bent lines (as in the sheet metal works)

Boxing or encieling of details

Representation of repeating details (as rootcircle af

gears)

5, Grain flow direction as in rolling.

6. Direction of lay of layers (as transformer stamp-

nes

Bene

ings) and

7. Grid lines

3. Type C

Thesetypes of lines are continuous thin lines drawn frechand

and used to represent:

CI Limits of partial views, interrupted views, and

sectional views (if limits are not chain thin lines).

10

4. Type D

‘These types of lines are continugus thin (straight or curved )

limes with zig-zags and are used Lo represent:

D1 Limits of partial views, interrupted views, and

sectional views (if limits are not chain thin lines).

5. Type E

‘These types of lines are dashed thick lines and are used to

represent:

E1 Hidden outlines and

E2 Hidden edges.

6. Type F

‘These type of lines are dashed thin lines and are used to

repeesent:

FI Hidden outlines and

F2 Hidden edges.

7. Type G

These types of lines are chain thin fines and are used to

represent:

Gi Centre lines,

G2 Lines of symmetry and

G3 Trajectories.

Type G lines are alsa used far the following applications :

L._ Pitch cirele of gears

2. Pitch cirele diameter af holes and

3. Parting-off planes.

8. Type H

Thesetypesof lines are chain thin, thick atends andchange of

direction. They are used to represent:

HI Cutting planes.

&. Type J

‘These types of lines are chain thiek lines and are used to

represent:

JI Indication of lines or surfaces to whieh a special

requirement applies.

10. Type K

‘These types of lines are chain thin double dashed and are used

to represent:

K1 Outline of adjacent parts,

K2 Alternative and extreme position of movable parts,

K3 Centroidal lines,

Kai Initial out fines peior to forming and

KS Parts situated in front of the cutting plane.

‘These types of lines are also used for the following

applications:

Engineering Graphics for Diploma

1. Outline of selective details,

2. Finish forms of raw parts and

3. Enclosure of special fieldslareas.

Thickness (width) of Lines and Their Spacing

‘The lines used in a drawing can be grouped into two types

based on their thicknesses (widths). They are:

1. Thick lines

2. Thin lines.

‘The ratio of the thick to the thin line should not be less than

2:1. The thickness of lines should be acconding to the size and

shape of thedrawingand itcan beselected from the following.

grades:

0.18, 0.25, 0.35, 0.5, 0.7, 1, L4, and 2: mm

It may be noted that the grading of these lines, is in V2

increments. The distance between parallel lines, including

hatching should be greater than twice the thickness of the

heaviest line.

Now

1. The thickness (width) of lines for different views of

an abject, should be the same, pravided the seale

used is the same.

The line thickness of 0.18 mm may be avoided.

The minimum distance between parallel lines

including hatching lines should be 0.7 mm.

4. Aline width of 0.5 mm for thick lines and 0,25 mm.

for thin lines are recommended for pencil

drawings.

eR

Order of Priority of Coinciding Lines.

‘When two or mare lines of different types shown in Fig. 1.8.

coincide, the follawing order of priority should be observ

(a) Firstpriarity for Type: visible oullinesand visible

edges.

(b) Second priority for Type Eor F: hidden outlinesand

hidden edges.

(©) Third priority for Type H. cutting planes

represented by chain thin lines thickened at ends.

(8) Forth priority for Type G: centre lines and lines of

symmetry and trajectories.

(e) Fifth priority far Type K: centroidal lines.

(f) Sixth priority for Type Bz projection lines.

Hidden Details

Interior details of an object, which are not visible from

Introduction to Engineering Graphics

outside, are represented by hidden lines, Short dashes having

an approximate length af 2 to 3 mm and a distance af 1 10

2mnubetweenthem, maybe used forhidden lines. The dashes,

of the hidden lines should touch the v le outlines or hidden

lines, both at the starting and ending points. Superimposing

of hidden details is shown in Fig, 1.9

Fig. 1.9 Superimposing of hidden details

41.7 SCALES

Seales is the ratio of the linear dimensions of one element of

an object as represented in original drawing to the real linear

dimension of the same clement of the object itself. Drawings

of small objects-can be made of the same size ax the object

itself. If the actual dimensions of the object are used to

prepare its drawing, the seale used is called fll size seale. For

full size scale, the rativis 1:1.Ln thease af very large objects,

the actual dimensions of the object cannot be used in the

preparation of its drawing. Hence, linear dimensions of the

‘object are wo be reduced for the purpose of drawing. Now, the

sealeis called reduction scale. Forreduction seale,the ratio’s

smaller than I:1. In the case of very small objects, the

drawings are to be made larger than the abject itself. The

scale used for this, is called enlargement scale, For

enlargement scale, the ratio is larger than 1:1.

‘The complete designation of scales can be indivated as

follows:

SCALE 1:1 for full size.

SCALE 1:X for reduced scale.

SCALE X:1 for enlargement scale.

If there is no chance for misunderstanding, the word

SCALE may be omitted. Scales recommended by RIS are

shown int Table 1.3.

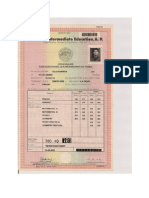

1.8 DRAWING SHEETS AND TITLE BLOCK

Drawing sheets are white papers of good quality used forthe

preparation of pencil drawings. One of the surfaces of the

drawing sheet is usually smooth, This smooth surface is used

for drawing.

Table 13 Seales for use on technical drawings ([S:46-

1988)

Category

Enlargementscales

Fullsize

n seales

Various preferred sizes of drawing sheets are available in

the market. 1.$:107 11-1983 recommends various choices of

the drawing sheetsbased on theirsizes, The preferred sizes of

the drawing sheets are given in the Table 1.4.

Table 14 Preferred sizes of drawing sheets

Designation ‘Trimmed sizes in mum (width % length)

Ao 841% 1189

Ay 504841

Ay 420594

Ay 297x420

Ag 210297

‘The ratio between the (wo adjacent sides of a drawing,

sheet is 1:2 (i.e.1:1.414). The surface area of the sheet

designated by Agis one square metre. Twasuccessive sizes of

drawing sheets are obtained either by halving ordaublingthe

areas. For example, A, size drawing sheet is obtained by

halving Ag size sheet

Selection of the size of the drawing sheet depends onthe

size of the object to be drawn and the scale used. Drawing,

sheets may be used with their longer sides placed either

horizontally or vertically,

General Features

General features of a drawing sheet is shown in Fig. 1.10,

Four centring marks given on the border facilitates the

positioning of the drawing when reproduced or microfilmed,

Grid reference permits easy location of details,

modifications, ete, The rectangular divisions of the grid are.

marked by capital letters and numerals. Length of the side of

therectangle should not be less than 25 mmand not more than

75 mm. Extra margin may be provided on the leftto facilitate

easy filing and binding.

Title Block

Title block is to be placed within the drawing space al the

bottom right hand corner of the drawing sheet and it should

be visible when prints are folded. It should consist of one or

Grd

reference

Drawing space

Engineering Graphics for Diploma

Minimums width

Title block

(20 mm for Ag & Ay

rE 0 mim tor Age gy & Ag)

Fig. 1.10 General features ofa drawing sheet

more adjoining rectangles. These rectangles may be divided

further into boxes for inserting specific information. This

information is grouped into zones as Follows,

1, Identification zone and

2. One or more zones for additional information,

In the identification zone the following basic information is,

entered (refer to Fig. 1.11):

(a) The registration or the identification number,

(b) The title of the drawing and

(c) The name of the legal owner of the drawing.

Folding of Drawing Prints

There are two methods of folding of drawing prints. First

method of folding is used for filing or binding, The second

method of folding is used for keeping the prints individually

in filing cabinet and is shown im Fig. 1.12. It should be

remembered that all the drawing prints larger than Ay size

should be folded to Ay size. The title block should be seen

‘ouside on the right bottom comer.

1.9 SUGGESTED PROCEDURE FOR DRAFTING

Engineering graphics is a subject to be studied nat only by

reading the book but also by drafting. A smdent of graphics

should manually draw the figures following the correct

procedure. With more practice he can not only get more

knowledge in the subject, but also can develop speed,

dimensional accuracy and finish of drawing.

Step by Step Procedure for Drafting

1. Set the minidrafter to its 2ero angle position and fix

it on the left top comer of the drawing board such,

el rj a a

of 2 |) LY

© } © ©

CI t

170 max | L170 max

(b) ()

‘Asrangements of information the title bolck,

You might also like

- Introducing StatisticsDocument349 pagesIntroducing StatisticsJohn Bes94% (16)

- Electrical Wiring SimplifiedDocument118 pagesElectrical Wiring Simplifiedplayontime100% (4)

- Chemistry Cheat SheetDocument10 pagesChemistry Cheat Sheetbrook93% (40)

- Anything Goes: An Advanced Reader of Modern Chinese - Revised EditionFrom EverandAnything Goes: An Advanced Reader of Modern Chinese - Revised EditionRating: 5 out of 5 stars5/5 (1)

- Workbook On Engineering Drawing 2558.7437.1439123325Document322 pagesWorkbook On Engineering Drawing 2558.7437.1439123325David Williams100% (3)

- Engineering DrawingDocument173 pagesEngineering DrawingSivasankar100% (3)

- Engineering Drawing Course BookDocument48 pagesEngineering Drawing Course Bookgirishkaundinya100% (15)

- Engineering Graphics Class XI BookDocument312 pagesEngineering Graphics Class XI Bookpranavvarma182% (11)

- Engineering Drawing Slides PDFDocument393 pagesEngineering Drawing Slides PDFMuhammad Saqib SwatiNo ratings yet

- Essentials of Mechanical DraftingDocument152 pagesEssentials of Mechanical Draftingturbinesean100% (2)

- Basic Engineering Drawing and CAD I Lesson PlansDocument233 pagesBasic Engineering Drawing and CAD I Lesson Planskrristin80% (10)

- A Textbook of Electrical Technology by RajputDocument514 pagesA Textbook of Electrical Technology by RajputsatishfactoryNo ratings yet

- Mechatronics by Nitaigour Premchand MahalikDocument117 pagesMechatronics by Nitaigour Premchand Mahalikkamdevx25% (4)

- D&D 3.5 - Dragon MagicDocument159 pagesD&D 3.5 - Dragon MagicDrake Bloodstar93% (28)

- Principles of Engineering DrawingDocument213 pagesPrinciples of Engineering DrawingSarthak Bhargava81% (21)

- Engineering Drawing.1Document231 pagesEngineering Drawing.1Sateesh Saati100% (1)

- Geometric and Engineering DrawingDocument216 pagesGeometric and Engineering DrawingHandi Rizki90% (10)

- ENGINEERING GRAPHICS (ENGINEERING DRAWING) by P.H.JainDocument8 pagesENGINEERING GRAPHICS (ENGINEERING DRAWING) by P.H.JainProf. P. H. Jain78% (9)

- Engineering Drawing by N.D BhattDocument738 pagesEngineering Drawing by N.D BhattJagadish90% (48)

- Engineering DrawingDocument136 pagesEngineering DrawingVijay Pal Singh86% (14)

- Technical DrawingDocument968 pagesTechnical DrawingWelson Jonhson97% (35)

- Drafting ExercisesDocument12 pagesDrafting ExercisesJaime Andres Velez100% (3)

- Drawing Workbook For Engineering Drawing and Design - Nodrm PDFDocument500 pagesDrawing Workbook For Engineering Drawing and Design - Nodrm PDFVrr Bordados100% (6)

- Engineering Graphics Question BankDocument47 pagesEngineering Graphics Question Bankswapnil kale86% (7)

- Exercises On Engineering DrawingDocument42 pagesExercises On Engineering Drawingdradell86% (7)

- Engineering Drawing BASICSDocument111 pagesEngineering Drawing BASICSajscad89% (18)

- Engineering Drawing: P.Radhakrishnan Cipet-HyderabadDocument88 pagesEngineering Drawing: P.Radhakrishnan Cipet-HyderabadBajni Srikar75% (4)

- Machine Drawing ManualDocument90 pagesMachine Drawing Manualmechanical 2017-2021No ratings yet

- Workbook On Engineering DrawingDocument322 pagesWorkbook On Engineering DrawingRosalie Vasquez100% (6)

- Engineering Drawing For BeginnersDocument132 pagesEngineering Drawing For BeginnersPrototype Account100% (2)

- Technical DrawingDocument140 pagesTechnical DrawingJules Ochoa Aficial100% (1)

- Engineering GraphicsDocument284 pagesEngineering GraphicsRebecca PetersNo ratings yet

- Essentials in Engineering DrawingDocument32 pagesEssentials in Engineering DrawingChelsea Ramos100% (1)

- Engineering Drawing Introductory NotesDocument13 pagesEngineering Drawing Introductory Notesvipsdgr8No ratings yet

- Graphic Science - Engineering Drawing, Descriptive Geometry, Graphical SolutionsDocument776 pagesGraphic Science - Engineering Drawing, Descriptive Geometry, Graphical SolutionsDiana Ghius93% (14)

- Engineering DrawingDocument216 pagesEngineering DrawingSandeep Saini100% (4)

- Engineering Drawing Orthographic Proj Lect 3Document121 pagesEngineering Drawing Orthographic Proj Lect 3Abdulrahman Mohammed100% (1)

- Intersection of SolidsDocument13 pagesIntersection of SolidsSuneel Kumar Meena0% (1)

- Importance of Engineering DrawingDocument24 pagesImportance of Engineering DrawingDhanis Paramaguru69% (13)

- CAD LAB - ExercisesDocument63 pagesCAD LAB - Exercisessarath761089% (9)

- Technical DrawingDocument191 pagesTechnical DrawingAbdulrazzak Aman100% (8)

- Mechanical Drawing - Projection Drawing, Isometric and Oblique Drawing, Working DrawingsFrom EverandMechanical Drawing - Projection Drawing, Isometric and Oblique Drawing, Working DrawingsNo ratings yet

- Irrigation and Water Power Engineering by B.C. Punmia - Brij Basi Lal PandeDocument8 pagesIrrigation and Water Power Engineering by B.C. Punmia - Brij Basi Lal Pandesachinmonamk06100% (1)

- Results of Saturn I Launch Vehicle Test FlightsDocument216 pagesResults of Saturn I Launch Vehicle Test FlightsBob Andrepont100% (2)

- Co 330 Amending Section 18, Series of 1974Document2 pagesCo 330 Amending Section 18, Series of 1974Royal MarjNo ratings yet

- Darkov, Kuznetsov - Structural Mechanics - MirpdfDocument710 pagesDarkov, Kuznetsov - Structural Mechanics - MirpdfIsidro Gutierrez Pari100% (1)

- PIC Microcontroller Project BookDocument220 pagesPIC Microcontroller Project Bookkalidas_29586% (7)

- ReinforcedDocument725 pagesReinforcedrubenpobaNo ratings yet

- Introductory ACCircuit TheoryDocument193 pagesIntroductory ACCircuit Theorythirumalai22No ratings yet

- President Obama's 2005 Tax ReturnDocument28 pagesPresident Obama's 2005 Tax ReturnBarack ObamaNo ratings yet

- Pioneer SX-828 Service ManualDocument54 pagesPioneer SX-828 Service ManualChris HutchingsNo ratings yet

- 94rs125 PLDocument45 pages94rs125 PLcarlitosracingNo ratings yet

- Lab ExperimentsDocument7 pagesLab ExperimentsHLMOPTUWNo ratings yet

- Rapid Prototyping - Principles and Applications by Chee Kai Chua - Kah Fai Leong - Chu Sing LimDocument87 pagesRapid Prototyping - Principles and Applications by Chee Kai Chua - Kah Fai Leong - Chu Sing LimNavin Karanth75% (8)

- Sai Kiran DocumentsDocument15 pagesSai Kiran Documentsjakson_007No ratings yet

- Draft BS en ISO 15614-9-2000 Part 9 Underwater Hyperbaric Wet WeldingDocument30 pagesDraft BS en ISO 15614-9-2000 Part 9 Underwater Hyperbaric Wet Weldingtudorteu100% (1)

- Vogue Knittign Spring-Summer 2011Document63 pagesVogue Knittign Spring-Summer 2011Mariana Conti100% (2)