Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

17 viewsUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986

United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986

Uploaded by

wahaha06This patent describes an apparatus for automatically underfiling the curved vanes of centrifugal impellers. The apparatus holds an impeller and uses cams and motors to move a cutting tool along a predetermined curved path to remove material from the vanes. This shapes each vane so it tapers from a thinner edge to a thicker central portion. The impeller is indexed to sequentially position each vane under the cutting tool.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Phonic MQ3300, 3400, 3600 EQ Service Manual PDFDocument58 pagesPhonic MQ3300, 3400, 3600 EQ Service Manual PDFdanielvepNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- US4335764Document7 pagesUS4335764Jorge ArbelaezNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Document4 pagesAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1No ratings yet

- Diseño ElectricoDocument5 pagesDiseño ElectricoemernelsonmanNo ratings yet

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- US20010024927A1Document7 pagesUS20010024927A1MahnooshNo ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- United States Patent (191 (11) Patent Number: 4,857,881Document9 pagesUnited States Patent (191 (11) Patent Number: 4,857,881Harish MahadevanNo ratings yet

- US2447117Document6 pagesUS2447117MahnooshNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Document8 pagesApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- NOV-9, 1943. A. Ca. Schneider: Planetary Turbine TransmissionDocument6 pagesNOV-9, 1943. A. Ca. Schneider: Planetary Turbine Transmissionbelchior alvaroNo ratings yet

- Nov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Document3 pagesNov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Karin AndersonNo ratings yet

- United States Patent (19) : Filed: July 27, 1976 57Document3 pagesUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNo ratings yet

- United States Patent (19) (11) Patent Number: 5,243,873Document10 pagesUnited States Patent (19) (11) Patent Number: 5,243,873Nile_JockeyNo ratings yet

- US2228469Document4 pagesUS2228469George AcostaNo ratings yet

- Nov. 22, 1932. W. D. Lpps. 1888,353Document12 pagesNov. 22, 1932. W. D. Lpps. 1888,353AGUAVIVANJNo ratings yet

- ?T T T - FT ?: April 9, 1968Document6 pages?T T T - FT ?: April 9, 1968Pooria1989No ratings yet

- PATENTDocument8 pagesPATENTHeavy Construction EquipmentNo ratings yet

- Us2333680 PDFDocument8 pagesUs2333680 PDFbelchior alvaroNo ratings yet

- Davison: United States Patent (191Document10 pagesDavison: United States Patent (191rte678No ratings yet

- Honing ToolDocument3 pagesHoning ToolKyle YsitNo ratings yet

- Sewing MachineDocument6 pagesSewing MachinesadagoapanNo ratings yet

- United States Patent (19) : SwearingenDocument6 pagesUnited States Patent (19) : SwearingenNicandroGonzalesNo ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Raschel Machine With Stitch Comb and Knock-Over BarDocument6 pagesRaschel Machine With Stitch Comb and Knock-Over Barntd1011No ratings yet

- Jurnal Bubut FixsafasfasfDocument6 pagesJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- United States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsDocument8 pagesUnited States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsUvxtalNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- Us2127655 PDFDocument5 pagesUs2127655 PDFbelchior alvaroNo ratings yet

- Sept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetDocument4 pagesSept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetLucas RaithsNo ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- W, B. Kidder. : Tree Climbing MotorDocument4 pagesW, B. Kidder. : Tree Climbing Motormonem2014No ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- United States Patent (19) : SpencerDocument5 pagesUnited States Patent (19) : SpencerKevin VillacisNo ratings yet

- Us955823 PDFDocument3 pagesUs955823 PDFSashikant SharmaNo ratings yet

- US3041830Document5 pagesUS3041830Gary ThomasNo ratings yet

- No. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70Document3 pagesNo. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70AlecsandrNo ratings yet

- Dec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoDocument4 pagesDec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoAngelica Mae LargaNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- US4458549Document8 pagesUS4458549Chandru VelNo ratings yet

- US3982767Document6 pagesUS3982767takanobu ouraNo ratings yet

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- Pantente Primer DollyDocument6 pagesPantente Primer DollyJorge SotoNo ratings yet

- Z 2 Ezzx: United States PatentDocument7 pagesZ 2 Ezzx: United States Patentjai2009No ratings yet

- Us5489169 230912 094111Document6 pagesUs5489169 230912 094111MẫnNo ratings yet

- 2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Document4 pages2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Vijayakumar G VNo ratings yet

- United States Patent (19) : Filed: Feb. 14, 1972Document5 pagesUnited States Patent (19) : Filed: Feb. 14, 1972zgregzNo ratings yet

- US4827759Document7 pagesUS4827759jonyNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- How Can I Draw A Curve On A Point Object and Then Create A Curve Object?Document7 pagesHow Can I Draw A Curve On A Point Object and Then Create A Curve Object?wahaha06No ratings yet

- DCC EngDocument1 pageDCC Engwahaha06No ratings yet

- Ansys Tips and Ansys TricksDocument54 pagesAnsys Tips and Ansys Trickssrinath_iitmNo ratings yet

- Diesel Ignition TemperatureDocument2 pagesDiesel Ignition Temperaturewahaha06No ratings yet

- Pre HeatersDocument4 pagesPre HeatersquycoctuNo ratings yet

- Scooter Power LE 5W40Document1 pageScooter Power LE 5W40Phantom RRNo ratings yet

- Memory Foam Technical DetailDocument4 pagesMemory Foam Technical DetailshahruchirNo ratings yet

- 967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)Document41 pages967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)AbysmalNo ratings yet

- Brayton Cycle PDFDocument43 pagesBrayton Cycle PDFAdly_arkim100% (2)

- MKE Bab 5 1 Turbin Aksi Dan ReaksiDocument2 pagesMKE Bab 5 1 Turbin Aksi Dan ReaksiMariaulfadamayantiNo ratings yet

- Pnd1000-3 Global FRLDocument43 pagesPnd1000-3 Global FRLPartsGopher.comNo ratings yet

- UHF PD: Non-Conventional Sensors For Measurements On GIS of Different DesignsDocument6 pagesUHF PD: Non-Conventional Sensors For Measurements On GIS of Different DesignsthetrasancosNo ratings yet

- Three-Way Regeneration of Spent V2O5 Catalyst From Sulfuric Acid ProductionDocument5 pagesThree-Way Regeneration of Spent V2O5 Catalyst From Sulfuric Acid ProductionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- B2 Public Transport LIU034: Complete The Text With ONE Word That Fits Into Each GapDocument2 pagesB2 Public Transport LIU034: Complete The Text With ONE Word That Fits Into Each GapIrma GochaleishviliNo ratings yet

- SLMR 1912 05 15Document26 pagesSLMR 1912 05 15Russell HartillNo ratings yet

- PVM (X) Series: Vertical Multistage PumpsDocument11 pagesPVM (X) Series: Vertical Multistage PumpsNelson IglesiasNo ratings yet

- PHAS0027 RevisionDocument21 pagesPHAS0027 Revisionunknown.unknown9901No ratings yet

- Centrifugal FanDocument1 pageCentrifugal FanMusheer BashaNo ratings yet

- Adafruit Capacitive Touch Sensor BreakoutsDocument32 pagesAdafruit Capacitive Touch Sensor BreakoutsCharlie HerbertNo ratings yet

- Aieee Sample PaperDocument25 pagesAieee Sample PaperEdukondalu NamepalliNo ratings yet

- Homework #1 WorkDocument5 pagesHomework #1 WorkM NabilNo ratings yet

- Si UnitsDocument18 pagesSi UnitsCy ConsularNo ratings yet

- Audi R8 GT Spyder Catalogue (UK)Document41 pagesAudi R8 GT Spyder Catalogue (UK)Fourtitude.comNo ratings yet

- Several Main Technical Issues in The Design of High RCC Gravity Dam of Longtan Hydropower StationDocument15 pagesSeveral Main Technical Issues in The Design of High RCC Gravity Dam of Longtan Hydropower StationMuhammad Mubashir QureshiNo ratings yet

- Domestic BER Technical Bulletin July 2020Document33 pagesDomestic BER Technical Bulletin July 2020Denis DillaneNo ratings yet

- Course Curriculum Course: Thermal Engineering-II Course Code: 3351901Document12 pagesCourse Curriculum Course: Thermal Engineering-II Course Code: 3351901rushibmr19785604No ratings yet

- Electric Generator Design ProjectDocument13 pagesElectric Generator Design Projectkhan.pakiNo ratings yet

- OTC-28735-MS High Speed Telemetry On Wired Drill Pipe, History, and Impact On Drilling ProcessDocument4 pagesOTC-28735-MS High Speed Telemetry On Wired Drill Pipe, History, and Impact On Drilling ProcessАлександр ГераськинNo ratings yet

- Fuel Pump Bosch 0 580 254 044 Data Sheet PDFDocument3 pagesFuel Pump Bosch 0 580 254 044 Data Sheet PDFJonni SchneiderNo ratings yet

- Turbine Vibration Proximitter Details: Diff. Expansion of High & Midium Pressure CylinderDocument5 pagesTurbine Vibration Proximitter Details: Diff. Expansion of High & Midium Pressure CylindermaheshNo ratings yet

- Oxy-Fuel Tech & FurnacesDocument22 pagesOxy-Fuel Tech & FurnacesAlirƎza Mhzd100% (1)

- LT-11a Gesamt EngDocument77 pagesLT-11a Gesamt EngPetar Nikolaev100% (3)

- P01O274001V - DH Airport Fuel Tank Farm Gate21GH - Electrical One Line DiagramDocument1 pageP01O274001V - DH Airport Fuel Tank Farm Gate21GH - Electrical One Line DiagramShahed HussainNo ratings yet

United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986

United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986

Uploaded by

wahaha060 ratings0% found this document useful (0 votes)

17 views3 pagesThis patent describes an apparatus for automatically underfiling the curved vanes of centrifugal impellers. The apparatus holds an impeller and uses cams and motors to move a cutting tool along a predetermined curved path to remove material from the vanes. This shapes each vane so it tapers from a thinner edge to a thicker central portion. The impeller is indexed to sequentially position each vane under the cutting tool.

Original Description:

Nothing new

Original Title

Us 4578006

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes an apparatus for automatically underfiling the curved vanes of centrifugal impellers. The apparatus holds an impeller and uses cams and motors to move a cutting tool along a predetermined curved path to remove material from the vanes. This shapes each vane so it tapers from a thinner edge to a thicker central portion. The impeller is indexed to sequentially position each vane under the cutting tool.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

17 views3 pagesUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986

United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986

Uploaded by

wahaha06This patent describes an apparatus for automatically underfiling the curved vanes of centrifugal impellers. The apparatus holds an impeller and uses cams and motors to move a cutting tool along a predetermined curved path to remove material from the vanes. This shapes each vane so it tapers from a thinner edge to a thicker central portion. The impeller is indexed to sequentially position each vane under the cutting tool.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

United States Patent [191 [11] - Patent Number: 4,578,006

Gray [45] Date of Patent: Mar. 25, 1986

[54] IMPELLER UNDER FILE MACHINE [56] References Cited

[75] Inventor: Stanley J. Gray, Bixby, Okla. U-S- PATENT DOCUMENTS

[73] Assignee; Borg_wamer Corporation Chicago, 2,782,691 2/ 1957 Feagans ............................. .. 409/119

In 2,909,966 10/1959 Barens ........................... .. 409/ 119 X

' 3,027,814 4/1962 Schnellmann ..................... .. 409/289

[21] Appl. NO.: 544,181 3,753,385 8/1973 Zarlengo ........................... .. 409/313

[22] Filed: Oct. 21, 1983 Primary ExaminerZ. R. Bilinsky

Attorney, Agent, or FirmJohn W. Harbst

Related US. Application Data [57] ABSTRACT

[63] Continuation of Se No' 39634 May 16' 1979 3173" Apparatus for under?ling curvelinear vanes of cast

de?ed centrifugal impellers. Such vanes are cast with gener

[51] Int. Cl.4 ............................................. .. B23D 5/02 ally uniform thickness along their length; it is desirable

[52] US. Cl. .............................. .. 409/303; 144/ 144 B; to have the vanes taper in thickness such that the radi

409/309; 409/314; 409/348 ally outward portions are thinner than the roots; also

[58] Field of Search ............. .. 409/119, 120, 289, 303, this provides a desired curve to each side of the blades.

409/309, 313, 348, 314; 144/144 B, 152;

51/126, 127 2 Claims, 2 Drawing Figures

4,578,006

1 2

Limited rotary motion is imparted to the shaft 36 by

IMPELLER UNDER FILE MACHINE a roller cam follower 44 engaging a cam 46, the fol

lower 44 being connected to the shaft 36 by a roller 48

This application is a continuation of application Ser. ?xed to the shaft. The position of the cam 46 is adjust

No. 039,634 ?led May 16, 1979, now abandoned. able by means of a motor 50. Spring means 52 between

a ?xed block 54 and an car 56 of the holder 34 insures

BACKGROUND OF THE INVENTION cam follower 44cam 46 contact.

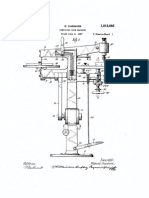

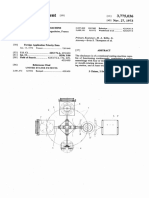

Under?ling of the vanes of centrifugal impellers has Attention is invited to FIG. 2 of the drawings which

been accomplished manually by using hand-held grind shows a typical section through an impeller 10 and the

ers. This is an expensive use of man power and the relationship of an impeller vane 16 and the cutter 20.

results are not uniform. The material to be removed by the cutter is shown in a

shaded area as indicated; as noted, the discharge end of

THE INVENTION each vane 16 is reduced in thickness to a thickness de

The invention herein described relates to apparatus sired and not obtainable when the impeller and its vanes

for under?ling the vanes of centrifugal impellers. The are cast.

apparatus is adaptable for handling different sizes of In operation, an impeller 10 is mounted on an arbor of

such impellers; generally the only manual steps are a holding fixture 12 with a vane 16 properly located

inserting an impeller in a holding ?xture and removing with respect to the cutter 20 and the vane stop 14 is

the under?led impeller therefrom. The apparatus com positioned to ?rmly support the backside of the vane 16.

prises in addition to the holding ?xture a cutter moved 20 The ram 28 is reciprocated along a ?xed axis provided

along a predetermined path of travel determined by by the guide 30, thus moving the cutter 20 vertically.

means including cam and follower means and means for However, a curvilinear motion is imparted to the cutter

sequentially indexing the vanes of the impeller to work 20 by means of the cams 40 and 46 and the respective

ing position. cam followers 38 and 44. The motors 26 and 50, respec

The apparatus of this invention can be controlled 25 tively, move the support 24 of the table 22 and the cam

manually or automatically by programmable controls 46 progressively toward and across the vane 16 to in

so that each impeller may be under?led with little or no sure the removal of the proper amount of material from

operator control. the vane 16 by the cutter 20 at each stroke.

When one vane 16 is ?nished the stop 14 is with

THE DRAWINGS 30 drawn by the motor 20, the indexing motor 18 is ener

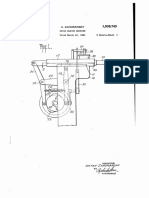

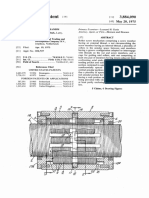

FIG. 1 is an isometric view of apparatus according to gized to rotate the impeller 10 to position another vane

this invention; and 16 for cutting and the sequence of steps is repeated. This

FIG. 2 is a partial sectional view of an impeller show sequence is repeated until all vanes are under?led.

ing the cutter means and indicating the material of one I claim:

of the vanes which is removed by the cutter. 35 1. Apparatus for under?ling curvilinear vanes on

centrifugal pump impellers which are cast with vanes of

DETAILED DESCRIPTION substantially uniform thickness and which are ?led to

In FIG. 1 of the drawing, an impeller 10 to be under vanes which taper from a relatively thin edge to a

?led is supported on an arbor (not shown) ofa holding thicker and unchanged central thickness comprising:

?xture 12. A vane stop 14 provides ?rm support to the a non rotating cutting tool movable along a predeter

back side of the impeller vane 16 to substantially pre mined path of travel;

vent movement of the vane 16 during the cutting opera indexing means for supporting and rotating an impel

tion. The vane stop 14 is adjustable as desired. A motor ler about its axis to sequentially position each im

18 is connected to the arbor and is used to rotate the ' peller vane so that its edge is facing upwardly be

impeller 10 to properly position it and each vane thereof 45 neath the cutting tool;

for engagement by a cutting tool 20. The motor 18 may actuating means to move said cutting tool vertically

be associated with electrical means, not shown, to pro downward toward and into engagement with a

gram the motor for the positioning operation. The vane vane for an initial portion of its predetermined path

stop 14 is moved from its vane engaging position manu of travel and then in a curvilinear direction for the

ally or by a servo motor 21 when the impeller 10 is remainder of its movement along the predeter

positioned or repositioned by the motor 18. The holding mined path of travel so that it shapes one surface

?xture 12 is supported by a table 22 having a movable only of the vane therebeneath to provide the taper

supporting top 24, the position of which is adjustable in to said vane; said actuating means comprising ?rst

the direction of its length by a motor 26. Manual means - operative means for imparting generally vertical

for adjusting the top 24 can be provided in lieu of the 55 movement to said cutting tool along a spatially

motor 26. ?xed generally vertical axis, second operative

The cutting tool 20 is carbide tipped or of a hard means including a ?rst cam and follower for con

grade of cutting steel and is supported on a ram assem trolling the movement of said cutting tool gener

bly 28 which reciprocates along a spatially ?xed axis in ally downwardly and then in a curvilinear direc

a generally vertical path determined by a guide 30 pow 60 tion, third operative means including a second cam

ered by means 32. A cutting tool holder 34 is connected and follower for moving said cutting tool laterally

to an axially movable shaft 36, the axial movement of across said vane to insure that the entire vane is

the shaft 36 being controlled by a roller cam follower 38 under?led, and means to resiliently urge each cam

supported on the shaft 36 and engaging a cam 40. En into engagement with its respective follower.

gagement of the roller cam follower 38 and the cam 40 65 2. Apparatus as recited in claim 1, further comprising

is insured by a coil spring 42 surrounding the shaft 36 means for supporting the back surface of each vane

and urging the shaft and thus the cam roller 38 toward during the cutting of said one surface.

* * * Ii *

the cam 40.

You might also like

- Phonic MQ3300, 3400, 3600 EQ Service Manual PDFDocument58 pagesPhonic MQ3300, 3400, 3600 EQ Service Manual PDFdanielvepNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- US4335764Document7 pagesUS4335764Jorge ArbelaezNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Document4 pagesAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1No ratings yet

- Diseño ElectricoDocument5 pagesDiseño ElectricoemernelsonmanNo ratings yet

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- US20010024927A1Document7 pagesUS20010024927A1MahnooshNo ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- United States Patent (191 (11) Patent Number: 4,857,881Document9 pagesUnited States Patent (191 (11) Patent Number: 4,857,881Harish MahadevanNo ratings yet

- US2447117Document6 pagesUS2447117MahnooshNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Document8 pagesApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- NOV-9, 1943. A. Ca. Schneider: Planetary Turbine TransmissionDocument6 pagesNOV-9, 1943. A. Ca. Schneider: Planetary Turbine Transmissionbelchior alvaroNo ratings yet

- Nov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Document3 pagesNov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Karin AndersonNo ratings yet

- United States Patent (19) : Filed: July 27, 1976 57Document3 pagesUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNo ratings yet

- United States Patent (19) (11) Patent Number: 5,243,873Document10 pagesUnited States Patent (19) (11) Patent Number: 5,243,873Nile_JockeyNo ratings yet

- US2228469Document4 pagesUS2228469George AcostaNo ratings yet

- Nov. 22, 1932. W. D. Lpps. 1888,353Document12 pagesNov. 22, 1932. W. D. Lpps. 1888,353AGUAVIVANJNo ratings yet

- ?T T T - FT ?: April 9, 1968Document6 pages?T T T - FT ?: April 9, 1968Pooria1989No ratings yet

- PATENTDocument8 pagesPATENTHeavy Construction EquipmentNo ratings yet

- Us2333680 PDFDocument8 pagesUs2333680 PDFbelchior alvaroNo ratings yet

- Davison: United States Patent (191Document10 pagesDavison: United States Patent (191rte678No ratings yet

- Honing ToolDocument3 pagesHoning ToolKyle YsitNo ratings yet

- Sewing MachineDocument6 pagesSewing MachinesadagoapanNo ratings yet

- United States Patent (19) : SwearingenDocument6 pagesUnited States Patent (19) : SwearingenNicandroGonzalesNo ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Raschel Machine With Stitch Comb and Knock-Over BarDocument6 pagesRaschel Machine With Stitch Comb and Knock-Over Barntd1011No ratings yet

- Jurnal Bubut FixsafasfasfDocument6 pagesJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- United States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsDocument8 pagesUnited States Patent (19) : Meyer 11 Patent Number: 45 Date of Patent: Foreign Patent DocumentsUvxtalNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- Us2127655 PDFDocument5 pagesUs2127655 PDFbelchior alvaroNo ratings yet

- Sept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetDocument4 pagesSept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetLucas RaithsNo ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- W, B. Kidder. : Tree Climbing MotorDocument4 pagesW, B. Kidder. : Tree Climbing Motormonem2014No ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- United States Patent (19) : SpencerDocument5 pagesUnited States Patent (19) : SpencerKevin VillacisNo ratings yet

- Us955823 PDFDocument3 pagesUs955823 PDFSashikant SharmaNo ratings yet

- US3041830Document5 pagesUS3041830Gary ThomasNo ratings yet

- No. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70Document3 pagesNo. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70AlecsandrNo ratings yet

- Dec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoDocument4 pagesDec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoAngelica Mae LargaNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- US4458549Document8 pagesUS4458549Chandru VelNo ratings yet

- US3982767Document6 pagesUS3982767takanobu ouraNo ratings yet

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- Pantente Primer DollyDocument6 pagesPantente Primer DollyJorge SotoNo ratings yet

- Z 2 Ezzx: United States PatentDocument7 pagesZ 2 Ezzx: United States Patentjai2009No ratings yet

- Us5489169 230912 094111Document6 pagesUs5489169 230912 094111MẫnNo ratings yet

- 2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Document4 pages2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Vijayakumar G VNo ratings yet

- United States Patent (19) : Filed: Feb. 14, 1972Document5 pagesUnited States Patent (19) : Filed: Feb. 14, 1972zgregzNo ratings yet

- US4827759Document7 pagesUS4827759jonyNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- How Can I Draw A Curve On A Point Object and Then Create A Curve Object?Document7 pagesHow Can I Draw A Curve On A Point Object and Then Create A Curve Object?wahaha06No ratings yet

- DCC EngDocument1 pageDCC Engwahaha06No ratings yet

- Ansys Tips and Ansys TricksDocument54 pagesAnsys Tips and Ansys Trickssrinath_iitmNo ratings yet

- Diesel Ignition TemperatureDocument2 pagesDiesel Ignition Temperaturewahaha06No ratings yet

- Pre HeatersDocument4 pagesPre HeatersquycoctuNo ratings yet

- Scooter Power LE 5W40Document1 pageScooter Power LE 5W40Phantom RRNo ratings yet

- Memory Foam Technical DetailDocument4 pagesMemory Foam Technical DetailshahruchirNo ratings yet

- 967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)Document41 pages967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)AbysmalNo ratings yet

- Brayton Cycle PDFDocument43 pagesBrayton Cycle PDFAdly_arkim100% (2)

- MKE Bab 5 1 Turbin Aksi Dan ReaksiDocument2 pagesMKE Bab 5 1 Turbin Aksi Dan ReaksiMariaulfadamayantiNo ratings yet

- Pnd1000-3 Global FRLDocument43 pagesPnd1000-3 Global FRLPartsGopher.comNo ratings yet

- UHF PD: Non-Conventional Sensors For Measurements On GIS of Different DesignsDocument6 pagesUHF PD: Non-Conventional Sensors For Measurements On GIS of Different DesignsthetrasancosNo ratings yet

- Three-Way Regeneration of Spent V2O5 Catalyst From Sulfuric Acid ProductionDocument5 pagesThree-Way Regeneration of Spent V2O5 Catalyst From Sulfuric Acid ProductionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- B2 Public Transport LIU034: Complete The Text With ONE Word That Fits Into Each GapDocument2 pagesB2 Public Transport LIU034: Complete The Text With ONE Word That Fits Into Each GapIrma GochaleishviliNo ratings yet

- SLMR 1912 05 15Document26 pagesSLMR 1912 05 15Russell HartillNo ratings yet

- PVM (X) Series: Vertical Multistage PumpsDocument11 pagesPVM (X) Series: Vertical Multistage PumpsNelson IglesiasNo ratings yet

- PHAS0027 RevisionDocument21 pagesPHAS0027 Revisionunknown.unknown9901No ratings yet

- Centrifugal FanDocument1 pageCentrifugal FanMusheer BashaNo ratings yet

- Adafruit Capacitive Touch Sensor BreakoutsDocument32 pagesAdafruit Capacitive Touch Sensor BreakoutsCharlie HerbertNo ratings yet

- Aieee Sample PaperDocument25 pagesAieee Sample PaperEdukondalu NamepalliNo ratings yet

- Homework #1 WorkDocument5 pagesHomework #1 WorkM NabilNo ratings yet

- Si UnitsDocument18 pagesSi UnitsCy ConsularNo ratings yet

- Audi R8 GT Spyder Catalogue (UK)Document41 pagesAudi R8 GT Spyder Catalogue (UK)Fourtitude.comNo ratings yet

- Several Main Technical Issues in The Design of High RCC Gravity Dam of Longtan Hydropower StationDocument15 pagesSeveral Main Technical Issues in The Design of High RCC Gravity Dam of Longtan Hydropower StationMuhammad Mubashir QureshiNo ratings yet

- Domestic BER Technical Bulletin July 2020Document33 pagesDomestic BER Technical Bulletin July 2020Denis DillaneNo ratings yet

- Course Curriculum Course: Thermal Engineering-II Course Code: 3351901Document12 pagesCourse Curriculum Course: Thermal Engineering-II Course Code: 3351901rushibmr19785604No ratings yet

- Electric Generator Design ProjectDocument13 pagesElectric Generator Design Projectkhan.pakiNo ratings yet

- OTC-28735-MS High Speed Telemetry On Wired Drill Pipe, History, and Impact On Drilling ProcessDocument4 pagesOTC-28735-MS High Speed Telemetry On Wired Drill Pipe, History, and Impact On Drilling ProcessАлександр ГераськинNo ratings yet

- Fuel Pump Bosch 0 580 254 044 Data Sheet PDFDocument3 pagesFuel Pump Bosch 0 580 254 044 Data Sheet PDFJonni SchneiderNo ratings yet

- Turbine Vibration Proximitter Details: Diff. Expansion of High & Midium Pressure CylinderDocument5 pagesTurbine Vibration Proximitter Details: Diff. Expansion of High & Midium Pressure CylindermaheshNo ratings yet

- Oxy-Fuel Tech & FurnacesDocument22 pagesOxy-Fuel Tech & FurnacesAlirƎza Mhzd100% (1)

- LT-11a Gesamt EngDocument77 pagesLT-11a Gesamt EngPetar Nikolaev100% (3)

- P01O274001V - DH Airport Fuel Tank Farm Gate21GH - Electrical One Line DiagramDocument1 pageP01O274001V - DH Airport Fuel Tank Farm Gate21GH - Electrical One Line DiagramShahed HussainNo ratings yet