Professional Documents

Culture Documents

Operation V N P T I 108

Operation V N P T I 108

Uploaded by

Dhiraj SatyamCopyright:

Available Formats

You might also like

- Coleman Maxa 5000 ER Portable Generator Owner's ManualDocument8 pagesColeman Maxa 5000 ER Portable Generator Owner's ManualMarkNo ratings yet

- Restore Power in Case of BlackoutDocument5 pagesRestore Power in Case of Blackoutadityasahay100% (2)

- VGB-B 102 RDS-PP® Referenzkennzeichensystem Für Kraftwerke - Reference Designation System For Power Plants (Excerpt)Document12 pagesVGB-B 102 RDS-PP® Referenzkennzeichensystem Für Kraftwerke - Reference Designation System For Power Plants (Excerpt)Chris WebelmanNo ratings yet

- Handling of Turbine During EmergencyDocument17 pagesHandling of Turbine During EmergencyManohar Tatwawadi100% (1)

- Operation V N P T I 107Document1 pageOperation V N P T I 107Dhiraj SatyamNo ratings yet

- Operation V N P T I 109Document1 pageOperation V N P T I 109Dhiraj SatyamNo ratings yet

- Handling of Turbine During Emergency: Emergencies in Turbine and AuxiliariesDocument3 pagesHandling of Turbine During Emergency: Emergencies in Turbine and Auxiliariesron1234567890No ratings yet

- Boiler Turbine Protection,,,EHC, Hydraullic-2Document21 pagesBoiler Turbine Protection,,,EHC, Hydraullic-2Balvir Gangar100% (1)

- Sachin Governing System or DEHDocument38 pagesSachin Governing System or DEHNaveen100% (1)

- PWM and Pump Control ExplainedDocument1 pagePWM and Pump Control Explainedolsonjames544No ratings yet

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (3)

- 500mw Guidelines For House Load Operation 500mw SetsDocument6 pages500mw Guidelines For House Load Operation 500mw Setsthangarajm1984100% (1)

- 3.digital Electric HydraulicDocument35 pages3.digital Electric HydraulicBui Vanluong100% (1)

- Arp Malita Plant PLS CheckDocument25 pagesArp Malita Plant PLS CheckIan B. YtomNo ratings yet

- Microsoft PowerPoint - ECM660 III Hyd Info Read-OnlyDocument32 pagesMicrosoft PowerPoint - ECM660 III Hyd Info Read-OnlyJannie van Staden100% (2)

- Steam Turbine Serious Faults Operation Fault TracingDocument8 pagesSteam Turbine Serious Faults Operation Fault Tracingparthibanemails5779100% (1)

- Models S3S (D) /S4S (D) and SB3S (D) /SB4S (D) : Submersible Sewage Pump Dual Seal PumpsDocument12 pagesModels S3S (D) /S4S (D) and SB3S (D) /SB4S (D) : Submersible Sewage Pump Dual Seal PumpsGautami Ashok ArkadeNo ratings yet

- Article Turboexpander ProtectionDocument3 pagesArticle Turboexpander ProtectionAnonymous Rn6JarNo ratings yet

- Turbine Shutting Down From Full LoadDocument7 pagesTurbine Shutting Down From Full Loadrohit_0123100% (2)

- Transformer Alarms SummaryDocument8 pagesTransformer Alarms SummaryAhmed SallahNo ratings yet

- 660III HYD CircuitDocument32 pages660III HYD CircuitaugustoNo ratings yet

- Drum Level & AttemperationDocument13 pagesDrum Level & AttemperationSagar LuthraNo ratings yet

- PRM FRDocument7 pagesPRM FRGelber Norberto Gutierrez PalaciosNo ratings yet

- Pump and Motor Failure in A Hot Potassium-Carbonate SystemAiche-1981-010Document4 pagesPump and Motor Failure in A Hot Potassium-Carbonate SystemAiche-1981-010Hsein WangNo ratings yet

- EmergencyDocument24 pagesEmergencySanjeevImprove100% (1)

- 12 Series-38Document1 page12 Series-38RE musicNo ratings yet

- Second-Stage Nozzle Control: GeneralDocument4 pagesSecond-Stage Nozzle Control: GeneralSara VaccaNo ratings yet

- Turbine Operation SequenceDocument3 pagesTurbine Operation SequenceTitas titasNo ratings yet

- Important Things To Be Done Just After Tripping: ExplanationsDocument2 pagesImportant Things To Be Done Just After Tripping: Explanationsu yadavNo ratings yet

- CMCDocument32 pagesCMCAnubhav Amu Pandit100% (1)

- Turbine Speed & Load ControlDocument32 pagesTurbine Speed & Load Control06nikhil100% (2)

- 02 Cooling SystemDocument17 pages02 Cooling Systemheri setyonoNo ratings yet

- Variable frequency mode operation measures for condensate pump 凝结水泵变频运行措施Document5 pagesVariable frequency mode operation measures for condensate pump 凝结水泵变频运行措施Usman TahirNo ratings yet

- Emergency in Power PlantDocument12 pagesEmergency in Power PlantCo-gen ManagerNo ratings yet

- Hydromatic: Submersible Sewage PumpDocument10 pagesHydromatic: Submersible Sewage Pumpاحمد همامNo ratings yet

- Steam Turbine Fast Cooling Down of The Turbine OperationDocument1 pageSteam Turbine Fast Cooling Down of The Turbine Operationparthibanemails5779100% (1)

- Turbine Start UpDocument15 pagesTurbine Start Uprobiansah100% (1)

- Emergency Stop Valve PDFDocument4 pagesEmergency Stop Valve PDFMauricio GarciaNo ratings yet

- Ssss 1Document27 pagesSsss 1shahin gholamiNo ratings yet

- Control Valve Position During Air FailureDocument2 pagesControl Valve Position During Air FailureSantanu BasakNo ratings yet

- Content9732691 PDFDocument17 pagesContent9732691 PDFRaphael LemosNo ratings yet

- Shut Down1Document2 pagesShut Down1moturuappalasreenuNo ratings yet

- Governingsystem 131127063004 Phpapp01 PDFDocument38 pagesGoverningsystem 131127063004 Phpapp01 PDFhari setiawan100% (2)

- Boiler EmergencyDocument41 pagesBoiler Emergencysubrata guhaNo ratings yet

- Governing System of Gas TurbineDocument128 pagesGoverning System of Gas Turbinesaptarshi roy100% (4)

- Ajuste de La Velocidad de Movimientos Del Brazo TD40150Document6 pagesAjuste de La Velocidad de Movimientos Del Brazo TD40150RodrigoNo ratings yet

- PJDX ManualDocument9 pagesPJDX Manualshaft181No ratings yet

- Drum Level Control: Presented by Rudra Pratap SinghDocument19 pagesDrum Level Control: Presented by Rudra Pratap SinghRudra Pratap Singh100% (1)

- Locomotive Troubleshooting PrintableDocument14 pagesLocomotive Troubleshooting PrintableMuhammathali JNo ratings yet

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (2)

- PJDX C ManualDocument8 pagesPJDX C Manualshaft181No ratings yet

- DAB VAVBVS Range ManualDocument9 pagesDAB VAVBVS Range ManualgimesibalazsNo ratings yet

- TG EmergenciesDocument15 pagesTG EmergenciessasibhushanNo ratings yet

- List of Turbine Interlock and Protection ItemDocument30 pagesList of Turbine Interlock and Protection ItemAsan Ibrahim100% (2)

- FPS P SummaryDocument3 pagesFPS P SummaryGreen MichaelsNo ratings yet

- MCSI - UHGB - N6-3.43 Operation Manual - Eng PDFDocument7 pagesMCSI - UHGB - N6-3.43 Operation Manual - Eng PDFBatbayar NyandagjidNo ratings yet

- 771, 772, 773 Series ServovalvesDocument8 pages771, 772, 773 Series Servovalvesrafik1995No ratings yet

- 210 MW LMW Turbine EmergenciesDocument96 pages210 MW LMW Turbine EmergenciesAshok Rasekar100% (6)

- Generator Turbine Shutdown ProcedureDocument3 pagesGenerator Turbine Shutdown ProcedureAfifexNo ratings yet

- System Description and LimitationsDocument14 pagesSystem Description and Limitationssaman moghadamNo ratings yet

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamNo ratings yet

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamNo ratings yet

- Super Critical Power - Part85Document1 pageSuper Critical Power - Part85Dhiraj SatyamNo ratings yet

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamNo ratings yet

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamNo ratings yet

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamNo ratings yet

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamNo ratings yet

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamNo ratings yet

- Super Critical Power - Part60Document1 pageSuper Critical Power - Part60Dhiraj SatyamNo ratings yet

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamNo ratings yet

- Super Critical Power - Part41Document1 pageSuper Critical Power - Part41Dhiraj SatyamNo ratings yet

- Super Critical Power - Part42Document1 pageSuper Critical Power - Part42Dhiraj SatyamNo ratings yet

- Super Critical Power - Part59Document1 pageSuper Critical Power - Part59Dhiraj SatyamNo ratings yet

- Super Critical Power - Part56Document1 pageSuper Critical Power - Part56Dhiraj SatyamNo ratings yet

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamNo ratings yet

- Super Critical Power - Part47Document1 pageSuper Critical Power - Part47Dhiraj SatyamNo ratings yet

- Super Critical Power - Part46Document1 pageSuper Critical Power - Part46Dhiraj SatyamNo ratings yet

- Super Critical Power - Part40Document1 pageSuper Critical Power - Part40Dhiraj SatyamNo ratings yet

- Super Critical Power - Part35Document1 pageSuper Critical Power - Part35Dhiraj SatyamNo ratings yet

- Super Critical Power - Part34Document1 pageSuper Critical Power - Part34Dhiraj SatyamNo ratings yet

- Super Critical Power - Part38Document1 pageSuper Critical Power - Part38Dhiraj SatyamNo ratings yet

- Super Critical Power - Part37Document1 pageSuper Critical Power - Part37Dhiraj SatyamNo ratings yet

- EEDocument10 pagesEEJhun Michael LocusNo ratings yet

- SYNERGY - Profile (Electricals)Document9 pagesSYNERGY - Profile (Electricals)kuraimundNo ratings yet

- Department of Mechanical Engineering Faculty of Engineering Coursework Report Session 2011/2012 Hydraulic Ram PumpDocument45 pagesDepartment of Mechanical Engineering Faculty of Engineering Coursework Report Session 2011/2012 Hydraulic Ram PumpግሩምሠውአሰፋመላኩNo ratings yet

- Run Your Car On Waste Vegetable OilDocument12 pagesRun Your Car On Waste Vegetable Oilad14100% (2)

- Welding Strenx and Hardox V5 2015Document16 pagesWelding Strenx and Hardox V5 2015Rodrigo100% (1)

- Market and Policy Outlook For Renewable Energy in Europe and The CISDocument74 pagesMarket and Policy Outlook For Renewable Energy in Europe and The CISUNDP in Europe and Central AsiaNo ratings yet

- Density & Neutron LogDocument54 pagesDensity & Neutron LogHamdan Hamzah100% (1)

- EMbaffle Presentation - NLAHX June2007 PDFDocument13 pagesEMbaffle Presentation - NLAHX June2007 PDFTajul Ariffin Abdul GhaniNo ratings yet

- Report ProjectDocument17 pagesReport ProjectMAGUDESWARAN PNo ratings yet

- Kaplan Turbines S-160 PDFDocument8 pagesKaplan Turbines S-160 PDFdrbasit93No ratings yet

- SolarPro2 2Document100 pagesSolarPro2 2lgv2No ratings yet

- Padeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsDocument5 pagesPadeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsKarun Das0% (1)

- Ieee Pes T&D La 2018 - HVDC by Gabriel OlguinDocument51 pagesIeee Pes T&D La 2018 - HVDC by Gabriel OlguingmolguinpNo ratings yet

- Chapter 4 ReviewerDocument8 pagesChapter 4 ReviewerMARREN JEIRELLE PENAFLORNo ratings yet

- Transformers KuestionDocument13 pagesTransformers KuestionAnonymous RwJdmJ100% (1)

- EPDB Scienne Inverter 2011Document134 pagesEPDB Scienne Inverter 2011Szabina Dudás0% (1)

- ES21 Q1 Mod5 Earths Energy and Water ResourcesDocument17 pagesES21 Q1 Mod5 Earths Energy and Water ResourcesFrancine CañasNo ratings yet

- Power Projects in IndiaDocument6 pagesPower Projects in IndiaSandeep KohliNo ratings yet

- DC To AC LossesDocument23 pagesDC To AC LossesAditia Putra KurniawanNo ratings yet

- MV Design Guide PDFDocument83 pagesMV Design Guide PDFClaro Dal PianNo ratings yet

- 2016 Constituency ProjectsDocument186 pages2016 Constituency ProjectsEfosa AigbeNo ratings yet

- Refrigerant Recovery UnitDocument20 pagesRefrigerant Recovery UnitAhmed AzadNo ratings yet

- Alcohol Recovery in Falling Film EvaporatorDocument6 pagesAlcohol Recovery in Falling Film EvaporatorphelyciiaNo ratings yet

- Solar Business CaseDocument11 pagesSolar Business CasePrasad Kishor Naik0% (1)

- Instruction Manual: General-Purpose InverterDocument74 pagesInstruction Manual: General-Purpose InverterkrekersonNo ratings yet

- Solar Power SatelliteDocument21 pagesSolar Power Satellitenarenkrish242100% (2)

- Heating Ventilation and Air-Conditioned Configurations For Hotels An Approach Review For The Design and ExploitationDocument11 pagesHeating Ventilation and Air-Conditioned Configurations For Hotels An Approach Review For The Design and ExploitationVaradrajNo ratings yet

Operation V N P T I 108

Operation V N P T I 108

Uploaded by

Dhiraj SatyamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation V N P T I 108

Operation V N P T I 108

Uploaded by

Dhiraj SatyamCopyright:

Available Formats

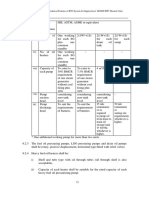

One C.W.

pump in case both are If the partial load relay fails/not in circuit reduce

running. the turbine load and inform the boiler operator to

control steam parameter in case one CW pump or

one condensate pump trip. Careful watch may be

kept on vacuum. Inform the local operator to check

the cause of tripping. Maintain the deaerator and

hotwell level.

One BFP in case two are

running and standby does not

come on auto remote/not available.

One condensate pump in case

two are running and standby

does not come on auto/remote

not available.

And also due to tripping of

any one of I.D. fan, F.D. fan

P.A. fan.

In case of full load throw Unit trip on protection if it is kept on T".

off (due to opening generator

breaker).

The turbine may trip due to over- Close the control gear handwheel

speeding (if the speed can be

controlled by closing control valve Check that ESV and Control valves are closed.

immediately otherwise trip the

turbine by emergency trip button) Close the valves in the M.S. line. Close the Extr.

steam valves.

Sudden Increase of Load- from Pull Load

Low frequency Since the turbine is on governor control the load

will increase due to fall in speed. Reduce the load

by the control gear and bring the boiler parameter

andload to normal.

Due to sudden rise of boiler drum Bring back the load/governing wheel pressure to

pressure normal by control gear and inform the boiler opera-

tor.

Vibration High

Normally the vibration in bearings Check the turbine cylinder drain should not be

should be within 40 microns. If cold (if necessary open the drain valve for few

it exceeds the limit, turbine should minutes if turbine is on load).

be shut down

Check brg. oil press flow and temp, to be normal.

Check for any rubbing sound'etc.

104

You might also like

- Coleman Maxa 5000 ER Portable Generator Owner's ManualDocument8 pagesColeman Maxa 5000 ER Portable Generator Owner's ManualMarkNo ratings yet

- Restore Power in Case of BlackoutDocument5 pagesRestore Power in Case of Blackoutadityasahay100% (2)

- VGB-B 102 RDS-PP® Referenzkennzeichensystem Für Kraftwerke - Reference Designation System For Power Plants (Excerpt)Document12 pagesVGB-B 102 RDS-PP® Referenzkennzeichensystem Für Kraftwerke - Reference Designation System For Power Plants (Excerpt)Chris WebelmanNo ratings yet

- Handling of Turbine During EmergencyDocument17 pagesHandling of Turbine During EmergencyManohar Tatwawadi100% (1)

- Operation V N P T I 107Document1 pageOperation V N P T I 107Dhiraj SatyamNo ratings yet

- Operation V N P T I 109Document1 pageOperation V N P T I 109Dhiraj SatyamNo ratings yet

- Handling of Turbine During Emergency: Emergencies in Turbine and AuxiliariesDocument3 pagesHandling of Turbine During Emergency: Emergencies in Turbine and Auxiliariesron1234567890No ratings yet

- Boiler Turbine Protection,,,EHC, Hydraullic-2Document21 pagesBoiler Turbine Protection,,,EHC, Hydraullic-2Balvir Gangar100% (1)

- Sachin Governing System or DEHDocument38 pagesSachin Governing System or DEHNaveen100% (1)

- PWM and Pump Control ExplainedDocument1 pagePWM and Pump Control Explainedolsonjames544No ratings yet

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (3)

- 500mw Guidelines For House Load Operation 500mw SetsDocument6 pages500mw Guidelines For House Load Operation 500mw Setsthangarajm1984100% (1)

- 3.digital Electric HydraulicDocument35 pages3.digital Electric HydraulicBui Vanluong100% (1)

- Arp Malita Plant PLS CheckDocument25 pagesArp Malita Plant PLS CheckIan B. YtomNo ratings yet

- Microsoft PowerPoint - ECM660 III Hyd Info Read-OnlyDocument32 pagesMicrosoft PowerPoint - ECM660 III Hyd Info Read-OnlyJannie van Staden100% (2)

- Steam Turbine Serious Faults Operation Fault TracingDocument8 pagesSteam Turbine Serious Faults Operation Fault Tracingparthibanemails5779100% (1)

- Models S3S (D) /S4S (D) and SB3S (D) /SB4S (D) : Submersible Sewage Pump Dual Seal PumpsDocument12 pagesModels S3S (D) /S4S (D) and SB3S (D) /SB4S (D) : Submersible Sewage Pump Dual Seal PumpsGautami Ashok ArkadeNo ratings yet

- Article Turboexpander ProtectionDocument3 pagesArticle Turboexpander ProtectionAnonymous Rn6JarNo ratings yet

- Turbine Shutting Down From Full LoadDocument7 pagesTurbine Shutting Down From Full Loadrohit_0123100% (2)

- Transformer Alarms SummaryDocument8 pagesTransformer Alarms SummaryAhmed SallahNo ratings yet

- 660III HYD CircuitDocument32 pages660III HYD CircuitaugustoNo ratings yet

- Drum Level & AttemperationDocument13 pagesDrum Level & AttemperationSagar LuthraNo ratings yet

- PRM FRDocument7 pagesPRM FRGelber Norberto Gutierrez PalaciosNo ratings yet

- Pump and Motor Failure in A Hot Potassium-Carbonate SystemAiche-1981-010Document4 pagesPump and Motor Failure in A Hot Potassium-Carbonate SystemAiche-1981-010Hsein WangNo ratings yet

- EmergencyDocument24 pagesEmergencySanjeevImprove100% (1)

- 12 Series-38Document1 page12 Series-38RE musicNo ratings yet

- Second-Stage Nozzle Control: GeneralDocument4 pagesSecond-Stage Nozzle Control: GeneralSara VaccaNo ratings yet

- Turbine Operation SequenceDocument3 pagesTurbine Operation SequenceTitas titasNo ratings yet

- Important Things To Be Done Just After Tripping: ExplanationsDocument2 pagesImportant Things To Be Done Just After Tripping: Explanationsu yadavNo ratings yet

- CMCDocument32 pagesCMCAnubhav Amu Pandit100% (1)

- Turbine Speed & Load ControlDocument32 pagesTurbine Speed & Load Control06nikhil100% (2)

- 02 Cooling SystemDocument17 pages02 Cooling Systemheri setyonoNo ratings yet

- Variable frequency mode operation measures for condensate pump 凝结水泵变频运行措施Document5 pagesVariable frequency mode operation measures for condensate pump 凝结水泵变频运行措施Usman TahirNo ratings yet

- Emergency in Power PlantDocument12 pagesEmergency in Power PlantCo-gen ManagerNo ratings yet

- Hydromatic: Submersible Sewage PumpDocument10 pagesHydromatic: Submersible Sewage Pumpاحمد همامNo ratings yet

- Steam Turbine Fast Cooling Down of The Turbine OperationDocument1 pageSteam Turbine Fast Cooling Down of The Turbine Operationparthibanemails5779100% (1)

- Turbine Start UpDocument15 pagesTurbine Start Uprobiansah100% (1)

- Emergency Stop Valve PDFDocument4 pagesEmergency Stop Valve PDFMauricio GarciaNo ratings yet

- Ssss 1Document27 pagesSsss 1shahin gholamiNo ratings yet

- Control Valve Position During Air FailureDocument2 pagesControl Valve Position During Air FailureSantanu BasakNo ratings yet

- Content9732691 PDFDocument17 pagesContent9732691 PDFRaphael LemosNo ratings yet

- Shut Down1Document2 pagesShut Down1moturuappalasreenuNo ratings yet

- Governingsystem 131127063004 Phpapp01 PDFDocument38 pagesGoverningsystem 131127063004 Phpapp01 PDFhari setiawan100% (2)

- Boiler EmergencyDocument41 pagesBoiler Emergencysubrata guhaNo ratings yet

- Governing System of Gas TurbineDocument128 pagesGoverning System of Gas Turbinesaptarshi roy100% (4)

- Ajuste de La Velocidad de Movimientos Del Brazo TD40150Document6 pagesAjuste de La Velocidad de Movimientos Del Brazo TD40150RodrigoNo ratings yet

- PJDX ManualDocument9 pagesPJDX Manualshaft181No ratings yet

- Drum Level Control: Presented by Rudra Pratap SinghDocument19 pagesDrum Level Control: Presented by Rudra Pratap SinghRudra Pratap Singh100% (1)

- Locomotive Troubleshooting PrintableDocument14 pagesLocomotive Troubleshooting PrintableMuhammathali JNo ratings yet

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (2)

- PJDX C ManualDocument8 pagesPJDX C Manualshaft181No ratings yet

- DAB VAVBVS Range ManualDocument9 pagesDAB VAVBVS Range ManualgimesibalazsNo ratings yet

- TG EmergenciesDocument15 pagesTG EmergenciessasibhushanNo ratings yet

- List of Turbine Interlock and Protection ItemDocument30 pagesList of Turbine Interlock and Protection ItemAsan Ibrahim100% (2)

- FPS P SummaryDocument3 pagesFPS P SummaryGreen MichaelsNo ratings yet

- MCSI - UHGB - N6-3.43 Operation Manual - Eng PDFDocument7 pagesMCSI - UHGB - N6-3.43 Operation Manual - Eng PDFBatbayar NyandagjidNo ratings yet

- 771, 772, 773 Series ServovalvesDocument8 pages771, 772, 773 Series Servovalvesrafik1995No ratings yet

- 210 MW LMW Turbine EmergenciesDocument96 pages210 MW LMW Turbine EmergenciesAshok Rasekar100% (6)

- Generator Turbine Shutdown ProcedureDocument3 pagesGenerator Turbine Shutdown ProcedureAfifexNo ratings yet

- System Description and LimitationsDocument14 pagesSystem Description and Limitationssaman moghadamNo ratings yet

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamNo ratings yet

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamNo ratings yet

- Super Critical Power - Part85Document1 pageSuper Critical Power - Part85Dhiraj SatyamNo ratings yet

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamNo ratings yet

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamNo ratings yet

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamNo ratings yet

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamNo ratings yet

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamNo ratings yet

- Super Critical Power - Part60Document1 pageSuper Critical Power - Part60Dhiraj SatyamNo ratings yet

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamNo ratings yet

- Super Critical Power - Part41Document1 pageSuper Critical Power - Part41Dhiraj SatyamNo ratings yet

- Super Critical Power - Part42Document1 pageSuper Critical Power - Part42Dhiraj SatyamNo ratings yet

- Super Critical Power - Part59Document1 pageSuper Critical Power - Part59Dhiraj SatyamNo ratings yet

- Super Critical Power - Part56Document1 pageSuper Critical Power - Part56Dhiraj SatyamNo ratings yet

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamNo ratings yet

- Super Critical Power - Part47Document1 pageSuper Critical Power - Part47Dhiraj SatyamNo ratings yet

- Super Critical Power - Part46Document1 pageSuper Critical Power - Part46Dhiraj SatyamNo ratings yet

- Super Critical Power - Part40Document1 pageSuper Critical Power - Part40Dhiraj SatyamNo ratings yet

- Super Critical Power - Part35Document1 pageSuper Critical Power - Part35Dhiraj SatyamNo ratings yet

- Super Critical Power - Part34Document1 pageSuper Critical Power - Part34Dhiraj SatyamNo ratings yet

- Super Critical Power - Part38Document1 pageSuper Critical Power - Part38Dhiraj SatyamNo ratings yet

- Super Critical Power - Part37Document1 pageSuper Critical Power - Part37Dhiraj SatyamNo ratings yet

- EEDocument10 pagesEEJhun Michael LocusNo ratings yet

- SYNERGY - Profile (Electricals)Document9 pagesSYNERGY - Profile (Electricals)kuraimundNo ratings yet

- Department of Mechanical Engineering Faculty of Engineering Coursework Report Session 2011/2012 Hydraulic Ram PumpDocument45 pagesDepartment of Mechanical Engineering Faculty of Engineering Coursework Report Session 2011/2012 Hydraulic Ram PumpግሩምሠውአሰፋመላኩNo ratings yet

- Run Your Car On Waste Vegetable OilDocument12 pagesRun Your Car On Waste Vegetable Oilad14100% (2)

- Welding Strenx and Hardox V5 2015Document16 pagesWelding Strenx and Hardox V5 2015Rodrigo100% (1)

- Market and Policy Outlook For Renewable Energy in Europe and The CISDocument74 pagesMarket and Policy Outlook For Renewable Energy in Europe and The CISUNDP in Europe and Central AsiaNo ratings yet

- Density & Neutron LogDocument54 pagesDensity & Neutron LogHamdan Hamzah100% (1)

- EMbaffle Presentation - NLAHX June2007 PDFDocument13 pagesEMbaffle Presentation - NLAHX June2007 PDFTajul Ariffin Abdul GhaniNo ratings yet

- Report ProjectDocument17 pagesReport ProjectMAGUDESWARAN PNo ratings yet

- Kaplan Turbines S-160 PDFDocument8 pagesKaplan Turbines S-160 PDFdrbasit93No ratings yet

- SolarPro2 2Document100 pagesSolarPro2 2lgv2No ratings yet

- Padeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsDocument5 pagesPadeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsKarun Das0% (1)

- Ieee Pes T&D La 2018 - HVDC by Gabriel OlguinDocument51 pagesIeee Pes T&D La 2018 - HVDC by Gabriel OlguingmolguinpNo ratings yet

- Chapter 4 ReviewerDocument8 pagesChapter 4 ReviewerMARREN JEIRELLE PENAFLORNo ratings yet

- Transformers KuestionDocument13 pagesTransformers KuestionAnonymous RwJdmJ100% (1)

- EPDB Scienne Inverter 2011Document134 pagesEPDB Scienne Inverter 2011Szabina Dudás0% (1)

- ES21 Q1 Mod5 Earths Energy and Water ResourcesDocument17 pagesES21 Q1 Mod5 Earths Energy and Water ResourcesFrancine CañasNo ratings yet

- Power Projects in IndiaDocument6 pagesPower Projects in IndiaSandeep KohliNo ratings yet

- DC To AC LossesDocument23 pagesDC To AC LossesAditia Putra KurniawanNo ratings yet

- MV Design Guide PDFDocument83 pagesMV Design Guide PDFClaro Dal PianNo ratings yet

- 2016 Constituency ProjectsDocument186 pages2016 Constituency ProjectsEfosa AigbeNo ratings yet

- Refrigerant Recovery UnitDocument20 pagesRefrigerant Recovery UnitAhmed AzadNo ratings yet

- Alcohol Recovery in Falling Film EvaporatorDocument6 pagesAlcohol Recovery in Falling Film EvaporatorphelyciiaNo ratings yet

- Solar Business CaseDocument11 pagesSolar Business CasePrasad Kishor Naik0% (1)

- Instruction Manual: General-Purpose InverterDocument74 pagesInstruction Manual: General-Purpose InverterkrekersonNo ratings yet

- Solar Power SatelliteDocument21 pagesSolar Power Satellitenarenkrish242100% (2)

- Heating Ventilation and Air-Conditioned Configurations For Hotels An Approach Review For The Design and ExploitationDocument11 pagesHeating Ventilation and Air-Conditioned Configurations For Hotels An Approach Review For The Design and ExploitationVaradrajNo ratings yet