Professional Documents

Culture Documents

Microformer GHTC 2012 Final Part 1

Microformer GHTC 2012 Final Part 1

Uploaded by

fsilassie8012Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microformer GHTC 2012 Final Part 1

Microformer GHTC 2012 Final Part 1

Uploaded by

fsilassie8012Copyright:

Available Formats

Reuse of Post-Consumer E-Waste for

Micropower Distribution

Daniel Ludois

Patricio Mendoza

Jonathan Lee

Giri Venkataramanan

Oct. 31st 2011

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011

Recycling and the e-waste problem

Municipal Solid

Waste composition:

8.4% Metals

12% Plastics

Waste management

statistics: E-Waste in 2007

(Source: EPA, 2007)

33.2% recovered 250

(recycled) 200

12.6% combusted

Millions of units

150 Recycled

with energy Trashed

100

recovery

50

54.2% discarded

0

Televisions Computer Products Cell Phones

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 2

Recycling and the e-waste problem

Major appliances in municipal waste stream

Municipal solid waste 4000

(Source: EPA, 2009)

categories:

3500

3000

Thousands of tons

2500

18.3% Durable goods 2000

1500

This includes small 1000

and large appliances 500

0

1960 1970 1980 1990 2000 2003 2005 2007 2008

Recovered Discarded

Small appliances in municipal waste stream

(Source: EPA, 2009)

1800

1600

1400

Thousands of tons

1200

1000

800

600

400

200

0

1990 2000 2003 2005 2007 2008

Recovered Discarded

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 3

Recycling and the e-waste problem

Microwave oven industrial statistics

(Source: US Census Bureau)

Microwave oven Microwave oven

20000

18000

recycling recycling

16000

14000

Thousands of units

Donate it (if it is 12000 Donate it (if it is

10000

working) 8000 working)

6000

Take it to a recycling 4000 Take it to a recycling

center 2000

0

center

2003 2004 2005 2006 2007 2008 2009

Leave it on the street? Leave it on the

Mfr Shipments Exports Imports

street?

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 4

The Microformer

Microwave oven

transformer (MOT)

Microformer

Typical MOT:

120/2400 V, 1 kVA

Purpose:

Energize the

Magnetron

Half-wave rectifier at

output

Low duty cycle

Daniel Ludois Jonathan Lee Patricio Mendoza

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 5

The Microformer

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 6

The Microformer idea

Low voltage transmission

High losses

Advantages

Intermediate voltage

Copper wire

Wood poles

Pros Cons Quality:

Easy to build Expensive, thick copper wire

- Medium-voltage No transformers needed

Consumers and producers

High distribution losses, low

efficiency

Cost:

easily connected 100 meter range Efficiency:

performance

High voltage transmission

- Lov-voltage cost Low losses

Right-sized solution High power

distribution Steel or aluminum

- 1 kW 1 Pros

transformer

Cons

wire Concrete or steel poles

household Low distribution losses, high Expensive, bulky Quality:

efficiency transformers

Thin wire Expensive poles Cost:

Enabling tool for High power capacity (typical)

10 to 100 km range

Added complexity in

connecting consumers and

producers

Efficiency:

renewable energies Microformer transmission

Low losses

Social benefits

Microformer

Environmental Pros Cons

Steel or aluminum

wire

Wood poles

Quality:

benefits

Easy, low-cost construction Modest amounts of power

Consumers and producers 1 to 5 km range

easily connected Cost:

Low system losses, average

to high efficiency Efficiency:

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 7

The MOT behind the Microformer

1:20 approx. turns

ratio

High magnetizing

impedance

High flux density (by

design)

Self-limiting under

fault conditions

X1 X2

R1 R2

Typical parameters in Ohms

R1, R2 X 1, X 2 RM XM

Vin=120V Vout2.4kV

0.44 2.5 305.7 36.0

N1:N220

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 8

The MOT behind the Microformer

Transformer testing at Grainger Lab

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 9

The MOT behind the Microformer

Comprehensive transformer study 60

mm

Geometry m

19m

Parameters 38

mm

95mm

Efficiency

57mm

Open Circuit Test m

19m

140.000

120.000 m

19m

mm

100.000 114

Short Circuit Test

Voltage (V)

80.000

60.000

60.000

50.000

40.000

40.000

Transformer Temp. over time

Voltage (V)

20.000 120.00 120.00

0.000 30.000

100.00 100.00

0.000 2.000 4.000 6.000 8.000 10.000

20.000

Current (A) 80.00 80.00

10.000

Temp (C)

60.00 60.00

0.000

0.000 2.000 4.000 6.000 8.000 10.000 12.000

40.00 40.00

Current (A) Core

Primary Winding

20.00 20.00

Secondary Wind-

ing

0.00 0.00

0 10 20 30 40 50 60 70 80 90

Time (min)

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 10

The MOT behind the Microformer

MOT improvements

and modifications

Magnetic shunts

removal

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 11

The MOT behind the Microformer

MOT improvements

and modifications

Add new primary turns

IEEE GHTC Conference, Oct. 30th -Nov. 1st 2011 12

You might also like

- Energy Performance: Energy Demand and Socialeconomic DevelopmentDocument10 pagesEnergy Performance: Energy Demand and Socialeconomic Developmentrigoletto007No ratings yet

- China Report enDocument6 pagesChina Report enomartaha79No ratings yet

- L3 - Electricity As Key Commodity For The Energy TransitionDocument61 pagesL3 - Electricity As Key Commodity For The Energy Transitiondamiano zeferinoNo ratings yet

- Kan Kana DubeyDocument17 pagesKan Kana DubeyMobi NurembergNo ratings yet

- Local Opportunities To Influence Carbon Footprints: Andrea Sarzynski March 19, 2009 Montgomery County Speaker SeriesDocument28 pagesLocal Opportunities To Influence Carbon Footprints: Andrea Sarzynski March 19, 2009 Montgomery County Speaker SeriesM-NCPPCNo ratings yet

- Demolition vs. Refurbishment For The Old Houses: A Regional Cost-Benefit AnalysisDocument18 pagesDemolition vs. Refurbishment For The Old Houses: A Regional Cost-Benefit AnalysisJet ToledoNo ratings yet

- Interfaces For Renewable Energy SourcesDocument6 pagesInterfaces For Renewable Energy SourcesAmr MahdyNo ratings yet

- 3-Temalista Angol MuszakiDocument7 pages3-Temalista Angol MuszakistormillaNo ratings yet

- Article Yakabe KhanDocument11 pagesArticle Yakabe KhanMorgen GumpNo ratings yet

- Mobile Communication Industry - Sri LankaDocument5 pagesMobile Communication Industry - Sri Lankalashanj2No ratings yet

- OLS - Forecasting Daily Monthly Demand PowerDocument20 pagesOLS - Forecasting Daily Monthly Demand PowerRajat AggarwalNo ratings yet

- Septic Tank CapacityDocument1 pageSeptic Tank CapacityTon Sy100% (1)

- 3R Implementation in Indonesia Asia 3R ConferenceDocument20 pages3R Implementation in Indonesia Asia 3R ConferenceAndre SuitoNo ratings yet

- Chapter 7 Ecological Limits and Economic DevlopmentDocument48 pagesChapter 7 Ecological Limits and Economic DevlopmentGanesh ThapaNo ratings yet

- Paper Reference For Report ContentDocument9 pagesPaper Reference For Report ContentDileep GuptaNo ratings yet

- Construction of Industrial Electron Beam Plant For Wastewater TreatmentDocument6 pagesConstruction of Industrial Electron Beam Plant For Wastewater Treatmentsamershamot200No ratings yet

- UPLB's Agricultural Engineering Research and Development ProgramDocument29 pagesUPLB's Agricultural Engineering Research and Development ProgramUPLB Office of the Vice Chancellor for Research and Extension100% (1)

- TDFSummaryrev 2Document1 pageTDFSummaryrev 2danielNo ratings yet

- 2018 6 Natural Resource Usage and SustainabilityDocument51 pages2018 6 Natural Resource Usage and SustainabilityNirob MahmudNo ratings yet

- The Way Concrete Recycling Should Be: Fuminori Tomosawa, Takafumi Noguchi and Masaki TamuraDocument14 pagesThe Way Concrete Recycling Should Be: Fuminori Tomosawa, Takafumi Noguchi and Masaki TamuraToni ArangelovskiNo ratings yet

- Environmental Impact 5Document1 pageEnvironmental Impact 5AvinashNo ratings yet

- Dr. Kamel Ben Naceur Paris, 21 September: © OECD/IEA 2016Document10 pagesDr. Kamel Ben Naceur Paris, 21 September: © OECD/IEA 2016Sri HarshaNo ratings yet

- National Energy Map For India: Technology Vision 2030 and Low Carbon PathsDocument29 pagesNational Energy Map For India: Technology Vision 2030 and Low Carbon PathsRaveesh SrinivasNo ratings yet

- Tabangao LNG Plant: Bartolo, Jeremy Allan C. Layug, Nicole L. Memije, Raymund Angelo CDocument60 pagesTabangao LNG Plant: Bartolo, Jeremy Allan C. Layug, Nicole L. Memije, Raymund Angelo CNicole LayugNo ratings yet

- Life Cycle Assessment of Different Types of Cement ConcreteDocument29 pagesLife Cycle Assessment of Different Types of Cement ConcreteEmre TokenNo ratings yet

- MASAD630REV02ENDocument48 pagesMASAD630REV02ENmzizo831No ratings yet

- Chemistry Higher Level Paper 3: Instructions To CandidatesDocument36 pagesChemistry Higher Level Paper 3: Instructions To CandidatesHUI GABRIEL YAN LUNG G10L-13No ratings yet

- Energy and Material Recovery and Reuse in Municipal Wastewater SystemsDocument56 pagesEnergy and Material Recovery and Reuse in Municipal Wastewater SystemsmarijaNo ratings yet

- Final Defense PPT (Wajid Ali)Document33 pagesFinal Defense PPT (Wajid Ali)wajidali454No ratings yet

- Production Requirements For Combine Warehouse (Variable Cost) Production Requirements For Combine Warehouse (Fixed Cost) SR - NoDocument4 pagesProduction Requirements For Combine Warehouse (Variable Cost) Production Requirements For Combine Warehouse (Fixed Cost) SR - NoJoginder ChhikaraNo ratings yet

- 8 - Nuclear Waste ExerciseDocument1 page8 - Nuclear Waste ExerciseAndy EngNo ratings yet

- MIT8 21s09 Lec01Document19 pagesMIT8 21s09 Lec01Golam ZakariaNo ratings yet

- Techno EconomiDocument20 pagesTechno EconomiFebri5awalsyahNo ratings yet

- 16 22 PTKI-i PDFDocument1 page16 22 PTKI-i PDFPrima Jaya Telolet 082233218700No ratings yet

- Riprap Scour Protection For Monopiles in O Wind Farms: FfshoreDocument18 pagesRiprap Scour Protection For Monopiles in O Wind Farms: FfshoreWilliam HoNo ratings yet

- Iata Steele eDocument31 pagesIata Steele ePabloNo ratings yet

- E Waste Final UKDocument18 pagesE Waste Final UKLizMarquezNo ratings yet

- EDR Technical Training-PublicDocument80 pagesEDR Technical Training-PublicHassan Feki100% (1)

- The State of The Philippine Environment - FinalDocument84 pagesThe State of The Philippine Environment - FinalRamon D HernandezNo ratings yet

- Phase PDFDocument3 pagesPhase PDFsurajNo ratings yet

- Climate Crisis - Communication ExamDocument1 pageClimate Crisis - Communication ExamrasvinrajasegarNo ratings yet

- VanottiDocument61 pagesVanottijeff dingleNo ratings yet

- Sustainability and Energy ?Document26 pagesSustainability and Energy ?DaisyNo ratings yet

- International Islamic University: Faculty of Management SciencesDocument17 pagesInternational Islamic University: Faculty of Management SciencesSyeda AimaNo ratings yet

- Suez Circular Polymer-Commercial Presentation v2Document10 pagesSuez Circular Polymer-Commercial Presentation v2Pairot ChukhadeeNo ratings yet

- Power Development Oppourtunites in MyanmarDocument36 pagesPower Development Oppourtunites in MyanmarArun KumarNo ratings yet

- Plastic CratesDocument9 pagesPlastic CratesfawwazNo ratings yet

- Process CostingDocument8 pagesProcess CostingBTS 007No ratings yet

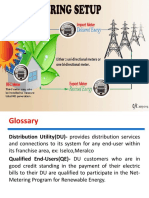

- Solar Net-Metering and Grid Tie SystemDocument30 pagesSolar Net-Metering and Grid Tie SystemBilly Twaine Palma Fuerte100% (1)

- Water Resources of Suadi ArabiaDocument35 pagesWater Resources of Suadi ArabiaAbu Muhsin Al NgapakyNo ratings yet

- WaterQualityStandardsAndRegulationsInSaudiArabia PME PDFDocument16 pagesWaterQualityStandardsAndRegulationsInSaudiArabia PME PDFAdly Al-SaafinNo ratings yet

- Indicadores Setor Eletrico COsta RIca ARESEPDocument20 pagesIndicadores Setor Eletrico COsta RIca ARESEPFelipe FerreiraNo ratings yet

- Dr. Nikhil PPT On Start UP Program - NISEDocument68 pagesDr. Nikhil PPT On Start UP Program - NISEShadifNo ratings yet

- Rbain1209 PDFDocument31 pagesRbain1209 PDFRopiudin EnergiNo ratings yet

- Introduction To Combustion: Lessons CoveredDocument8 pagesIntroduction To Combustion: Lessons CoveredAaron Choco De GuzmanNo ratings yet

- Lighting Lighting: Actinic BL TL (-K) / TL-D (-K)Document2 pagesLighting Lighting: Actinic BL TL (-K) / TL-D (-K)The1LegendNo ratings yet

- Lithium-Ion Battery Raw Material Supply and Demand 2016-2025 C. Pillot - M. Sanders Presentation at AABC-US San Francisco June 2017Document40 pagesLithium-Ion Battery Raw Material Supply and Demand 2016-2025 C. Pillot - M. Sanders Presentation at AABC-US San Francisco June 2017Estevão GomesNo ratings yet

- Sustainable HabitatDocument35 pagesSustainable HabitatAr Nizya NoushadNo ratings yet

- GNN3 - M. Roco, NSF, USDocument52 pagesGNN3 - M. Roco, NSF, USMaterials Research InstituteNo ratings yet

- Timetravel Practical ApplicationDocument1 pageTimetravel Practical Applicationfsilassie8012No ratings yet

- Djibouti: Risk & Compliance Report DATE: May 2017Document30 pagesDjibouti: Risk & Compliance Report DATE: May 2017fsilassie8012No ratings yet

- Armco Pure Iron: Stock ProgramDocument1 pageArmco Pure Iron: Stock Programfsilassie8012No ratings yet

- Electromagnetic Brakes ClutchesDocument8 pagesElectromagnetic Brakes Clutchesfsilassie8012100% (1)

- Gesture - Card Desing SparkDocument1 pageGesture - Card Desing Sparkjefe_e578726No ratings yet

- Armco Pure Iron Stockprogram 38 62 PDFDocument1 pageArmco Pure Iron Stockprogram 38 62 PDFfsilassie8012No ratings yet

- ADIB-Business - Trade Services - SOCDocument9 pagesADIB-Business - Trade Services - SOCfsilassie8012No ratings yet

- Power MOSFET Basics Understanding Superjunction Technology: MosfetsDocument5 pagesPower MOSFET Basics Understanding Superjunction Technology: Mosfetsfsilassie8012No ratings yet

- Select Orient Dimension: SpacebarDocument2 pagesSelect Orient Dimension: Spacebarfsilassie8012No ratings yet

- DC Main Distribution Bus: 12VDC Start BatteryDocument1 pageDC Main Distribution Bus: 12VDC Start Batteryfsilassie8012No ratings yet

- Item: Dual Bearing Shaft 01 Material: 1045 SteelDocument1 pageItem: Dual Bearing Shaft 01 Material: 1045 Steelfsilassie8012No ratings yet

- Parallel LCR-tank: Hz s rad s mH μF ΩDocument1 pageParallel LCR-tank: Hz s rad s mH μF Ωfsilassie8012No ratings yet

- Krayon Numerology ScriptDocument33 pagesKrayon Numerology Scriptfsilassie8012No ratings yet

- Flyer ROTOCAV - Hydrodynamic CavitatorDocument2 pagesFlyer ROTOCAV - Hydrodynamic Cavitatorfsilassie8012No ratings yet

- Dipole Transformer Generator PDFDocument9 pagesDipole Transformer Generator PDFfsilassie8012No ratings yet

- Digitally Tunable Capacitors-Pe64101dsDocument13 pagesDigitally Tunable Capacitors-Pe64101dsfsilassie8012No ratings yet

- Bismuth Magnet Core GeneraterDocument3 pagesBismuth Magnet Core Generaterfsilassie8012No ratings yet

- Bottle OpenerDocument6 pagesBottle OpenerLewis KimJr100% (1)

- Air Cooled Chiller NotesDocument3 pagesAir Cooled Chiller NotesaxelNo ratings yet

- 2UEB000487 v1 Drive On GeneratorDocument19 pages2UEB000487 v1 Drive On GeneratorSherifNo ratings yet

- 2013 US Tape Oil Gauge Price SheetDocument6 pages2013 US Tape Oil Gauge Price Sheet90032568393No ratings yet

- Gejzir VazduhDocument9 pagesGejzir VazduhssteticNo ratings yet

- 16216l5 16494Document2 pages16216l5 16494Saul AlbertoNo ratings yet

- 50/60/70/80D-7E ACE: Please ContactDocument8 pages50/60/70/80D-7E ACE: Please ContactDomain AdminNo ratings yet

- Lifan Breez 1.6Document334 pagesLifan Breez 1.6Denis_1969100% (1)

- Mobile InstallationDocument38 pagesMobile Installationdot16eNo ratings yet

- GE Fanuc IC694PWR321: Power Supply 120/240 VAC 125 VDC Standard IC694P IC694PW IC694PWRDocument4 pagesGE Fanuc IC694PWR321: Power Supply 120/240 VAC 125 VDC Standard IC694P IC694PW IC694PWRErasmo Franco SNo ratings yet

- U151E Rav4 Transmission Repair ManualDocument155 pagesU151E Rav4 Transmission Repair ManualJean-Max Rigaud100% (1)

- NECP05 CommentsDocument263 pagesNECP05 Commentsjturner170No ratings yet

- LSG ManualDocument32 pagesLSG ManualAnonymous yugocxnNo ratings yet

- User Manual / Functional Description: IC: 267T-5WK47594 FCC ID:KR55WK47594Document5 pagesUser Manual / Functional Description: IC: 267T-5WK47594 FCC ID:KR55WK47594Astrid PintoNo ratings yet

- Instructions For Making The Inflatable Kite PDFDocument15 pagesInstructions For Making The Inflatable Kite PDFJavier Vich BerlangaNo ratings yet

- Hydraulic Symbology 201 - Industrial Directional Valves PDFDocument5 pagesHydraulic Symbology 201 - Industrial Directional Valves PDFsumitsinha89No ratings yet

- Transducers (ShortDocument34 pagesTransducers (ShortiamgeniousNo ratings yet

- General Engine Info Aircraft Information Limiting Part InformationDocument1 pageGeneral Engine Info Aircraft Information Limiting Part InformationAHAMEDNo ratings yet

- Part List Ricoh 305+ D259 - EXPDocument168 pagesPart List Ricoh 305+ D259 - EXParnezguidogonzaloNo ratings yet

- Rotel RB-1090 Service ManualDocument10 pagesRotel RB-1090 Service ManualzektorNo ratings yet

- Instruction Manual: EN IWDocument42 pagesInstruction Manual: EN IWJátékra CsakNo ratings yet

- Datasheet PDFDocument5 pagesDatasheet PDFMarcio BispoNo ratings yet

- Digital Servo Amplifier Servo Star 601... 620: Assembly, Installation, SetupDocument100 pagesDigital Servo Amplifier Servo Star 601... 620: Assembly, Installation, SetupPaul RidgeNo ratings yet

- MR 360 Clio 6Document29 pagesMR 360 Clio 6eutraNo ratings yet

- AC Power Plugs and Sockets PDFDocument31 pagesAC Power Plugs and Sockets PDFZercNo ratings yet

- DatasheetDocument1 pageDatasheetAang SetiawanNo ratings yet

- Fi Xlr8 Mechanical Splice Fiber Connector IIDocument8 pagesFi Xlr8 Mechanical Splice Fiber Connector IIguideoNo ratings yet

- Wheatstone BridgeDocument5 pagesWheatstone Bridgepm1511No ratings yet

- 7 2 A HolesholenotesDocument11 pages7 2 A Holesholenotesapi-234212327No ratings yet

- New Latest QuatationDocument5 pagesNew Latest QuatationAmogh InfraNo ratings yet