Professional Documents

Culture Documents

06616438

06616438

Uploaded by

Pradeep KunduCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06616438

06616438

Uploaded by

Pradeep KunduCopyright:

Available Formats

Bearings Prognostic using Mixture of Gaussians

Hidden Markov Model and Support Vector Machine

F. Sloukia1, M. El Aroussi1, H. Medromi2, M. Wahbi1

1

Electrical Engineering Department

SIR2C2S/LASI-EHTP

2

Laboratoire dInformatique, Systmes et nergies Renouvelables

Team Architecture of Systems, ENSEM, Hassan II University

Casablanca, Morocco

sloukia.fatimaezzahra@gmail.com, moha387@yahoo.fr, hmedromi@yahoo.fr, wahbi_mho@yahoo.fr

AbstractPrognostic of future health state relies on the The proposed methods rely on two main phases: a learning

estimation of the Remaining Useful Life (RUL) of physical phase and an exploitation phase [12]. During the first phase,

systems or components based on their current health state. the raw data are used to extract reliable features, which are

RUL estimation can be done by using three main approaches: then used to learn behavioral models representing the

model-based, experience-based and data-driven approaches.

This paper deals with a data-driven prognostics method

dynamic of the degradation in the bearing. In the second

which is based on the transformation of the data provided by phase, the learned models are exploited on line to assess the

the sensors into models that are able to characterize the current health state of the bearing and to estimate the value

behavior of the degradation of bearings. of the RUL.

For this purpose, we used Support Vector Machine (SVM) The modeling of the degradation is done by using mixture

as modeling tool. The experiments on the recently published of Gaussians Hidden Markov Model (MoG-HMM) and

data base taken from the platform PRONOSTIA clearly show Support Vector Machine (SVM).

the superiority of the proposed approach compared to well For accurate assessment of the residual life of bearings,

established method in literature like Mixture of Gaussian Kim et al. [3] proposed a machine prognostics model based

Hidden Markov Models (MoG-HMMs).

KeywordsPrognostic; RUL; MoG-HMM; SVM.

on health state estimation using Support Vector Machines

(SVM). Kankar et al. [4] have also shown the effectiveness

I. INTRODUCTION of SVM for bearing faults classification.

Markov chain model based on the transition probability

The main purpose of prognostic is estimating the

matrix is appropriate to the analysis of a random dynamic

remaining useful life (RUL) of a failing component or

system [11]. Li et al. Chinam and Baruah [13] have used

subsystem so that maintenance can be executed to avoid

hidden Markov models (HMM) to assess the degradations

catastrophic failures.

of bearings and to estimate the RUL. In their method the

The choice of bearings can be explained by the fact that

authors considered the degradation as a stochastic process

these components are considered as the most common

with several states representing different health states of

mechanical elements in industry and are present in almost

the physical component.

all industrial processes, especially in those using rotating

This work presents a comparison study of the performance

elements and machines. Moreover bearing failure is one of

of two well known methods: SVM and MoG-HMM.

the foremost causes of breakdowns in rotating machinery

The proposed failure prognostic methods are tested on a

and such failure can be catastrophic [1], resulting in costly

downtime. Many previously studies [2-4] have developed condition monitoring data base [5] taken from the platform

theoretical foundation and tools to describe bearing failure PRONOSTIA [14], related to bearings degradation tests,

modes. enabling the verification of condition monitoring, fault

In this paper, data driven approach is addressed in order to detection, fault diagnostic and prognostic approaches.

utilize the availability of condition monitoring data [5]. The remainder of this paper is organized as follows. A

They can be divided into statistical methods (multivariate

technical background is given in Section 2 in which the

statistical methods, linear and quadratic regression ) and

Artificial Intelligent (AI) methods which have been largely MoG-HMM and SVM models and the WPD feature are

applied to machinery remaining life prediction [6]. The discussed. Section 3 presents experiments an results in

most used models for prognostics are artificial neural which the proposed MoG-HMM and SVM methods are

networks (ANNs) [7], support vector machine (SVM) [8], validated using experimental vibration monitoring data

Fuzzy theory [9]. SVMs shows outstanding performance in collected from bearings. Conclusions are given in Section

the classification process compared with the other 4.

classifiers [10], Also Markov chain model based on the

transition probability matrix is appropriate to the analysis of

a random dynamic system [11].

978-1-4799-0792-2/13/$31.00 2013 IEEE

II. TECHNICAL BACKGROUND

A. Wavelet Packet Decomposition (WPD)

In the WPD analysis of a signal, the signal is filtered

with both low-pass (LP) and high-pass (HP) filters. The LP

and the HP filtered signals are referred to the

approximation (A) and the detail (D), respectively. (A) and

(D) are both half size of the original signal and represent

the low frequency and the high-frequency content of the

signal. A detailed review of WPD can be found in [15].

A third level WPD of a signal is illustrated in Fig. 1. In this

Fig. 1: Third level wavelet packet decomposition of a signal.

representation, the third level signals AAA, DAA, ADA,

DDA, AAD, DAD, ADD and DDD represent the III. EXPERIMENTS & USING BEARING

frequency content of the original signal within the bands: FAILURE DATA

2 2 3 3 4 4 5 5 6 6

A. The (WPD or RMS) and MoG-HMM prognostic method

16 16 16 16 16 16 16 16 16 16 16 16

7 7

and , respectively, where fs is the sampling rate For both learning and exploitation phases features (RMS,

16 16 2

of the signal. The energy of the signal in any layer is Crest Factor, Kurtosis, FFT, Cepstrum, WPD ...) have been

referred to as the node energy that we will later utilize as extracted from raw data (vibration signal), then we have

feature of a vibration signal. chosen two features: the RMS which is a temporal feature

B. Mixture of Gaussians Hidden Markov Model (MoG- that detect abnormally high energy dissipation in the

HMM) vibration signal [21] and the nodal energy of the WPD

which has shown great results in many previous studies

The MoG-HMMs have proved to be a suitable tool as they [16,19], it offers a richer range of possibilities for signal

model the physical components degradation by using analysis and allows the best matched analysis to a signal. It

continuous observations provided by the monitoring provides level by level transformation of a signal from the

sensors. They also permit the estimation of the stay time domain into the frequency domain. The choice of the

durations in each health state leading to the prediction of 3rd level is motivated by Eq.1 where L is the decomposition

the RUL value [16]. level, Fs is the sampling frequency, and Fd is the defect

The hidden Markov model is defined by the parameters frequency, which gives a frequency band of 3.2 KHz in

cited in [17]. A compact notation H= (A, B, ) is used for each band.

an HMM model. With A = transition probability matrix, B F

= observation probability matrix, = initial state Llog2 S - 1 (1)

3Fd

distribution. In practice, HMMs are used to solve typical

In the learning phase the features extracted have been

problems [17] (The evaluation problem, the decoding

used to estimate the (A,B,) parameters using the Baum-

problem and the learning problem).

Welch algorithm and temporal parameters (the stay

The problem with HMM approach is that it uses discrete

duration in each state) using the Viterbi algorithm of the

observations, whereas in our case we use continuous

MoG-HMM model.

features, so changes were made to the observation

Three states are defined for each MoG-HMM. The number

probability matrix B [17], in this case we talk about MoG-

of mixtures is fixed at two. The parameters (A,B,) are

HMM model. During the learning phase we used a three

firstly arbitrary initialized then the feature is used to re-

states left to right MoG-HMM model.

estimate the parameters which are adjusted by maximizing

C. Support Vector Machine (SVM) the probability P(O|H) of the model over the observation

The basic idea of SVM is to nd a hyperplane which sequence O.

separates the N dimensional data perfectly into its two Six MoG-HMMs are obtained using Baum-Welch

classes. However, since data is often not linearly separable, algorithm. The RMS feature has shown better results

SVM introduce the notion of a kernel induced feature compared to WPD because this latter need a lot of models

space which casts the data into a higher dimensional space in the same condition to give precise results. An example

where the data is separable. of estimation of the parameters of bearing 1 condition 1 is

Among the kernel functions in common use are linear illustrated hereafter:

functions, polynomials functions, gaussian basis functions

(GBF) and sigmoid functions. SVMs were originally 1 0.9985 0.0015 0 0.4176 0.5824

designed for binary classification and there are methods = 0 A= 0.0015 0.9956 0.0029 M= 1 0

which are applicable to multiclass classification, such as 0 0 0.0014 0.9986 0.1271 0.8729

"one-against-one", "one-against-all". The most suitable The Viterbi algorithm allows us to estimate the stay

method is chosen according to the application constraints, duration in each state and to identify the final state which

the number of classes and the number of training samples corresponds in our case to the degradation state. An

[18]. example of estimation of the decoded state sequence is

illustrated in Fig. 2, the x-axis represents time and y-axis

represents the state of the learning bearing.

Fig 3. The estimated RUL and the corresponding relative error of the

bearing 1_4 using MoG-HMM.

Fig.2: The decoded state sequence using Viterbi and the stay duration in

each state. For that we used svmpredict() function in the LIBSVM

library, this function gives the percentage of classification

The duration of healthy state of this bearing is 1340s, the

of test data regarding the learning model (Accuracy

average state is 719s and the faulty state is 744s. Note that

percentage), and then we made the choice of the most

the time between two measurements is 10s.

suitable model.

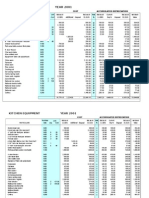

The exploitation phase allows to characterize the health The obtained results for the bearings 1_3 to 1_7 condition 1

state of test data through the selection of the model that with the model based on bearing 1_2 applied on RMS and

maximizes P (O | H), the model must be able to estimate nodal energy of WPD features are given in TABLE I.

the remaining life of the test bearing. For this we followed According to the results, we find that SVM gives more

these steps: accurate results using RMS than the nodal energy of WPD

Define the failed state that corresponds to the state S3 this is due to the fact that data provided from the WPD are

(Faulty State), correlated which degrade the performance of the SVM.

Estimate stay duration in each state from the path After selecting the models we use them to determine the

estimated by Viterbi algorithm, remaining useful life of each test bearing using the state

Make the sum of the lengths of stay durations, sequence of test data and by following the steps listed in

At every moment, we estimated the current state, at MoG-HMM.

each instant, of the test bearing using the Viterbi An example of calculation of the RUL and the

algorithm on the test data, corresponding error is shown in Fig. 4. For the same test

Estimate the time remaining before reaching the final bearing 1_4 (real RUL: 3h 58min) we find an estimated

state based on stay durations previously estimated. RUL of 3h 06min and a relative error between the two

An example of calculation of the RUL and the RULs of 21.85%.

corresponding error is shown in Fig. 3. The x-axis We note from the obtained results by using both methods

represent current time of the test bearing and y-axis (SVM and MoG-HMM) ( Figs. 3 and 4) that the estimated

represent the failure time. The red line represents real RUL

RUL using SVM is more closer to the real RUL than the

and the blue one represents the estimated RUL of the test

bearing. We obtain: an estimated RUL of 2h 26min 10s one estimated using MoG-HMM and the relative error of

and the relative error between the two RULs is 38.52%, this latter is higher than the one obtained using SVM. We

with a real RUL of 3h 58min. conclude from the obtained results that the SVM presents

better results compared to MoG-HMM because this latter

B. The (WPD or RMS) and SVM prognostic method

requires more learning models to be able to give precise

In the learning phase we form learning models based on

results and SVM is more easier to use.

the features (RMS and Nodal Energy of WPD) and using

the LIBSVM library [20], it contains many classification TABLE I: Classification results of test data (RMS, WPD) towards the

modules and supports multiclass classification and cross- learning model based on bearing 1_2 condition

validation (developed later), it also allows the use of

different kernels: linear, polynomial ... The resolution and

performance of the SVM method involves the selection of

several parameters [20]: the type of kernel, kernel

parameters (, ...) and the soft-margin constant, C, which

controls the penalty associated to the examples and set the

relative importance of maximizing the margin and

minimizing the amount of slack.

In our case we use the one against all multiclass SVM

classification (3 classes: healthy average and faulty states).

Because classifiers are sensitive to the way features are

scaled, features must be normalized before the learning

phase. The kernels chosen are polynomial and RBF kernel

because they gave the most acceptable results. The cross

validation method [20] is used to select (C, ).

After constructing learning models, we pass to the

Fig.4: The estimated RUL and the corresponding relative error of the

exploitation phase in which we classify test data based on bearing1_4 using SVM method.

the learned models.

IV. CONCLUSION [9] J. Fanegan, A. Ralescu, F. Ueda, A. Fuzzy, Model for

estimating the remaining lifetime a diesel engine, in:

This work was dedicated to the characterization of the Annual Meeting of the North American Fuzzy

health state of bearings degraded in an accelerated way by Information Processing Society, San Diego, California.

the platform PRONOSTIA, it presents a comparison of the (2007) 473476.

performance of two well known methods: SVM and [10] Niu, G., Han, T., Yang, B. S., & Tan, A. C. C.

MoG-HMM, the choice of the MoG-HMM is motivated (2007a). Multi-agent decision fusion for motor fault

by its good capacity of modeling the temporal diagnosis. Mechanical Systems and Signal Processing, 21,

dependences which exist between the observations. It 12851299.

need to make an hypothesis about the probability [11] T. Tien, A research on the prediction of machining

distribution of observations in the models states: we accuracy by the deterministic grey dynamic model

presuppose a particular form of data distribution. The DGDM(1, 1, 1), Applied Mathematics and Computation

SVM is a good classifier with a good power of 161 (2005) 923945.

generalization, but the SVM does not allow representing [12] K. Medjaher, D.A. Tobon-Mejia, N. Zerhouni,

the temporal evolution of the observations, while this Remaining useful life estimation of critical Components

temporal evolution is essential to discriminate the with application to bearings, IEEE TRANSACTIONS

vibratory signals. Our perspective thus is to exploit the ON RELIABILITY, VOL. 61, NO. 2, JUNE 2012.

advantages of SVM and HMM to construct a single hybrid [13] R.B. Chinnam, P. Baruah, Autonomous diagnostics

method: SVM-HMM. and prognostics through competitive learning driven

REFERENCES HMM-based clustering, Proceedings of the International

[1] U. Pulkkinen, S. Uryasev, Optimal operational Joint Conference on Neural Networks, vol. 4, 2003, pp.

strategies for an inspected component. In: Petersen KE, 24662471.

Rasmussen B, Eds. Safety and Reliability 92, [14] P. Nectoux, R. Gouriveau, K. Medjaher, E. Ramasso,

Proceedings of the European Safety and Reliability B. Morello, N. Zerhouni, C. Varnier, PRONOSTIA: An

Conference 92. London: Elsevier, pp. 896907, 1992. Experimental Platform for Bearings Accelerated

[2] S. Marble, B.P. Morton, Predicting the remaining life Degradation Tests in IEEE International Conference on

of propulsion system bearings, in: Proceedings of the 2006 Prognostics and Health Management, PHM'12., Denver,

IEEE Aerospace Conference, Big Sky, MT, USA, 2006. Colorado : United States (2012)".

[3] H.E. Kim, Andy C.C. Tan, J. Mathew, Eric Y. H. Kim [15] C. Rowden, S. Hall, Speech Processing, McGraw-

and B.K. Choi, Machine prognostics based on health state Hill, New York, 1992 (Chapter 5).

estimation using SVM, Proceedings Third World [16] Diego A. Tobon-Mejia, Kamal Medjaher,

Congress on Engineering Asset Management and Noureddine Zerhouni and Gerard Tripot , A Data-Driven

Intelligent Maintenance Systems, Conference, vol. 199, Failure Prognostics Method based on Mixture of

pp. 834-845, 2008. Gaussians Hidden Markov Models.

[4] P.K. Kankar, Satish C. Sharma and S.P. Harsha, Fault [17] L. R. Rabiner, A tutorial on hidden markov models

Diagnosis of Ball Bearings Using Continuous Wavelet and selected applications in speech recognition, in

Transform, Applied Soft Computing, vol. 11, pp. 2300- Proceedings of the IEEE, vol.77 (2), 1989, pp. 257286.

2312, 2011. [18] Jonathan Milgram, Mohamed Cheriet, Robert

[5] IEEE PHM 2012 Prognostic Challenge, Sabourin, One Against One or One Against All:

http://www.femto-st.fr/ieee-PHM2012-data-challenge. Which One is Better for Handwriting Recognition with

[6] A. K. Jardine, D. Lin, and D. Banjevic, A review on SVMs?

machinery diagnostics and prognostics implementing [19] H. Ocak, K. A. Loparo, and F. M. Discenzo, Online

condition-based maintenance,Mechanical Systems and tracking of bearing wear using wavelet packet

Signal Processing, vol. 20, no. 7, pp. 1483 1510, 2006. decomposition and probabilistic modeling: A method for

[7] A.K.S. Jardine, D. Lin, D. Banjevic, A review on bearing prognostics, Journal of sound and vibration, vol.

machinery diagnostics and prognostics implementing 302, pp. 951961, 2007.

condition-based maintenance, Mechanical Systems and [20] Chang, C-C. and Lin, C-J. (2001) LIBSVM: a library

Signal Processing 20 (2006) 14831510. for support vector machines. Software available at

[8] C. Li, T. Li, Y.S. Bai, Condition residual life http://www.csie.ntu.edu.tw/~cjlin/papers/libsvm.pdf

evaluation by support vector machine, in: Proceedings of [21] N.G. Gebraeel, A. Elwany, J. Pan, Residual life

the Eighth International Conference on Electronic predictions in the absence of prior degradation knowledge,

Measurement and Instruments, Xi an, China. (2007) 441 IEEE Trans. Reliab. 58 (1) (2009).

445.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Promiment Sobriquets (World) : S.No. Place SobriquetDocument6 pagesPromiment Sobriquets (World) : S.No. Place Sobriquetkausik nath100% (1)

- CrystalMaker TutorialDocument38 pagesCrystalMaker TutorialCatPapperNo ratings yet

- Dsme Piping - Practice PDFDocument117 pagesDsme Piping - Practice PDFJesus PlacedesNo ratings yet

- Gear Diagnostics in A Planetary Gearbox A Study Using Internal and External Spur GearsDocument14 pagesGear Diagnostics in A Planetary Gearbox A Study Using Internal and External Spur GearsPradeep KunduNo ratings yet

- A Statistical Methodology For The Design of Condition IndicatorsDocument38 pagesA Statistical Methodology For The Design of Condition IndicatorsPradeep KunduNo ratings yet

- Multi-Fault Classification Based On Wavelet SVM With PSO Algorithm To Analyze Vibration Signals From Rolling Element BearingsDocument12 pagesMulti-Fault Classification Based On Wavelet SVM With PSO Algorithm To Analyze Vibration Signals From Rolling Element BearingsPradeep KunduNo ratings yet

- A Review of Gear Fault Diagnosis Using Various Condition IndicatorsDocument11 pagesA Review of Gear Fault Diagnosis Using Various Condition IndicatorsPradeep KunduNo ratings yet

- Development of A Turbojet Engine Gearbox Test Rig For Prognostics and Health Management - Elsevier Enhanced ReaderDocument13 pagesDevelopment of A Turbojet Engine Gearbox Test Rig For Prognostics and Health Management - Elsevier Enhanced ReaderPradeep KunduNo ratings yet

- Gear Crack Detection Using Modified TSA and Proposed Fault Indicators For Fluctuating Speed ConditionsDocument16 pagesGear Crack Detection Using Modified TSA and Proposed Fault Indicators For Fluctuating Speed ConditionsPradeep KunduNo ratings yet

- A Nonlinear Degradation Model Based Method For Remaining Useful Life Prediction of Rolling Element BearingsDocument8 pagesA Nonlinear Degradation Model Based Method For Remaining Useful Life Prediction of Rolling Element BearingsPradeep KunduNo ratings yet

- Frequencydomainaveragingbasedexperimentalevaluationof Gear Fault Without Tachometer For Fluctuating Speed ConditionsDocument18 pagesFrequencydomainaveragingbasedexperimentalevaluationof Gear Fault Without Tachometer For Fluctuating Speed ConditionsPradeep KunduNo ratings yet

- An Integrated Bayesian Approach To Prognositics of The Remaining Useful Life and Its Application On Bearing Degradation ProblemDocument6 pagesAn Integrated Bayesian Approach To Prognositics of The Remaining Useful Life and Its Application On Bearing Degradation ProblemPradeep KunduNo ratings yet

- Art:10.1007/s00170 013 5065 ZDocument15 pagesArt:10.1007/s00170 013 5065 ZPradeep KunduNo ratings yet

- An Improved Exponential Model For Predicting Remaining Useful Life of Rolling Element BearingsDocument12 pagesAn Improved Exponential Model For Predicting Remaining Useful Life of Rolling Element BearingsPradeep KunduNo ratings yet

- Gearbox Fault Diagnosis Using RMS Based PDF and Entropy Mesasures For Fluctuating Speed ConditionsDocument15 pagesGearbox Fault Diagnosis Using RMS Based PDF and Entropy Mesasures For Fluctuating Speed ConditionsPradeep KunduNo ratings yet

- Remaining Useful Life Prediction For A Nonlinear Heterogeneous Wiener Process Model With An Adaptive DriftDocument14 pagesRemaining Useful Life Prediction For A Nonlinear Heterogeneous Wiener Process Model With An Adaptive DriftPradeep KunduNo ratings yet

- Remaining Useful Life Estimation in Rolling Bearings Utilizing Data-Driven Probabilistic E-Support Vectors RegressionDocument12 pagesRemaining Useful Life Estimation in Rolling Bearings Utilizing Data-Driven Probabilistic E-Support Vectors RegressionPradeep KunduNo ratings yet

- A Particle Filtering-Based Approach For Remaining Useful Life Predication of Rolling Element BearingsDocument8 pagesA Particle Filtering-Based Approach For Remaining Useful Life Predication of Rolling Element BearingsPradeep KunduNo ratings yet

- K 751cda5k 5fca13c ? K @a?354da5k 21B54K ? K Ca 8? ? 5ca 3K 7D 3C ? BK 1 4K 3D D 91 35K @a?8 ?BC 3BK ?45 8KDocument7 pagesK 751cda5k 5fca13c ? K @a?354da5k 21B54K ? K Ca 8? ? 5ca 3K 7D 3C ? BK 1 4K 3D D 91 35K @a?8 ?BC 3BK ?45 8KPradeep KunduNo ratings yet

- Health Monitoring and Fault Detection Using Wavelet Packet Technique and Multivariate Process Control MethodDocument4 pagesHealth Monitoring and Fault Detection Using Wavelet Packet Technique and Multivariate Process Control MethodPradeep KunduNo ratings yet

- Estimation of Remaining Useful Life of Ball Bearings Using Data Driven MethodologiesDocument7 pagesEstimation of Remaining Useful Life of Ball Bearings Using Data Driven MethodologiesPradeep KunduNo ratings yet

- Rodney K. Singleton II, Elias G. Strangas and Selin AviyenteDocument7 pagesRodney K. Singleton II, Elias G. Strangas and Selin AviyentePradeep KunduNo ratings yet

- A New Enhanced Feature Extraction Strategy For Bearing Remaining Useful Life EstimationDocument6 pagesA New Enhanced Feature Extraction Strategy For Bearing Remaining Useful Life EstimationPradeep KunduNo ratings yet

- What Is A Chest X-Ray (Chest Radiography) ?Document5 pagesWhat Is A Chest X-Ray (Chest Radiography) ?shravaniNo ratings yet

- 1986 GT CatalogDocument16 pages1986 GT CatalogtspinnerNo ratings yet

- Catalogue of Industrial Laundry EquipmentDocument8 pagesCatalogue of Industrial Laundry EquipmentTrung TrịnhNo ratings yet

- TMO Journal Pantacle - 2001-1Document29 pagesTMO Journal Pantacle - 2001-1Frater T.A.S.100% (6)

- Lesson 1 - Different Philosophical Thoughts On EducationDocument8 pagesLesson 1 - Different Philosophical Thoughts On EducationGlenn F. JoveNo ratings yet

- Two Stories About Flying (The Black Aeroplane)Document19 pagesTwo Stories About Flying (The Black Aeroplane)Fathima FaseehaNo ratings yet

- Fixed Asset RegisterDocument3 pagesFixed Asset Registerzuldvsb0% (1)

- BOQ For House Civil WorksDocument12 pagesBOQ For House Civil WorksSokkalal Natarajan0% (1)

- Assignment 3Document2 pagesAssignment 3Gaurav JainNo ratings yet

- Dyna 86l 8086 P Training Development System With LCD PDFDocument1 pageDyna 86l 8086 P Training Development System With LCD PDFSoluchanNo ratings yet

- TK Elevator India Private Limited: Tax InvoiceDocument3 pagesTK Elevator India Private Limited: Tax InvoiceNarayan Kumar GoaNo ratings yet

- Consolidation (2) - 4th SEMDocument3 pagesConsolidation (2) - 4th SEMDipankar NathNo ratings yet

- Bentonite PropertiesDocument8 pagesBentonite PropertiesJulie SpencerNo ratings yet

- Asthma Action PlanDocument1 pageAsthma Action PlanAkosNo ratings yet

- The Scientific WorkDocument24 pagesThe Scientific WorkhumanNo ratings yet

- Almost 40years Airframe Noise ResearchDocument37 pagesAlmost 40years Airframe Noise ResearchMaurizio BernasconiNo ratings yet

- HVAC Commissioning Checklist ENERGY STAR Certified Homes, Version 3 - 3.1 (RevDocument2 pagesHVAC Commissioning Checklist ENERGY STAR Certified Homes, Version 3 - 3.1 (Revorganicspolybond100% (2)

- Babar Abbasi C VDocument10 pagesBabar Abbasi C VmimrantajNo ratings yet

- 4 Exploration of Coal - IV Coal Resource EstimationDocument30 pages4 Exploration of Coal - IV Coal Resource EstimationRasmiranjan Jena RajaNo ratings yet

- AdaptiveAndLearningSystems TheoryAndApplications KumpatiSNarendraDocument410 pagesAdaptiveAndLearningSystems TheoryAndApplications KumpatiSNarendraSooperAktifNo ratings yet

- Project On Shear Strength Fly AshDocument42 pagesProject On Shear Strength Fly AshSUMIT SENAPATINo ratings yet

- Problem: Wiring, Estimation and Costing of Architecture Block (First Floor)Document18 pagesProblem: Wiring, Estimation and Costing of Architecture Block (First Floor)Anand SinhaNo ratings yet

- 236D3 Plano Hidráulico PDFDocument4 pages236D3 Plano Hidráulico PDFFerreira Anibal Paredes100% (1)

- Revised-13.8kV Cable Sizing Calc-Arar 03.03.2005Document10 pagesRevised-13.8kV Cable Sizing Calc-Arar 03.03.2005srigirisetty208No ratings yet

- Plumbing Pipe and Fitting SymbolsDocument8 pagesPlumbing Pipe and Fitting Symbolsburhansucipto0% (1)

- Pragati Maidan Exhibition DetailsDocument10 pagesPragati Maidan Exhibition DetailsDr-Amit KumarNo ratings yet