Professional Documents

Culture Documents

KLAUS P110 - 2 Level Pit Type Puzzle

KLAUS P110 - 2 Level Pit Type Puzzle

Uploaded by

OrianaFernandezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KLAUS P110 - 2 Level Pit Type Puzzle

KLAUS P110 - 2 Level Pit Type Puzzle

Uploaded by

OrianaFernandezCopyright:

Available Formats

Page 1

KLAUS Multiparking Systems Pvt. Ltd.

- Section

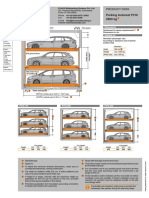

5/3, Prashant Apartments, Erandwane, PRODUCT DATA

- Dimensions

Pune 411 004 INDIA

- Car data

Phone +91-20-2545 0378 / 8662 Parking Automat P110

Page 2 Fax +91-20-2544 6360

- Door

E-mail info@klausmultiparking.in

2000 kg 1

- Width

dimensions

Website www.klausindia.com

Page 3 Dimensions

25 Free space

- Width 145 +3

3

dimensions Tolerances for space requirements 0.

- Approach Dimensions in cm.

- Free Suitable for

45

spaces

Standard passenger cars:

Page 4 EG (ground floor) For PW 2.3 m according to clearance and maximal

Detail doors

see page 2

- Function surface load.

- Load plan

Standard

Page 5 Width 190 cm 4

- Electrical

data Weight max. 2000 kg

- Technical Wheel load max. 500 kg

data

- To be

performed

by the

UG (lower floor) Clearance profile

customer 30

Grounding 6 160

45

55

Page 6

see table

- Description

15

0

130

10 6

0

100 125

500 (520)

2% 2%

40 8 Water drainage 7 25 8

+5

550 0 for vehicle up to 5.00 m = 164 long

+5

(570 0 for vehicle up to 5.20 m = 17 long) 9

P110-175 P110-200

220 5

220 5

175

200

Car height Car height

Height EG UG Height EG UG

220 200 150 220 200 175

1 Standard type 7 Slope with drainage channel and sump.

2 Spare no. 8 These floor areas need to be horizontal and equal level across

Parking Automat 110 | Indian Version 01.2014

3 To follow the minimum finished dimensions, make sure to

the full width of the pit

consider the tolerances, during construction. 9 For convenient use of your parking space and due to the fact

4 Car width for platform width 230 cm. If wider platforms are

that the cars keep becoming longer we recommend a pit

used, it is also possible to park wider cars. length of 570 cm.

10 At the transition section between pit floor and walls no hollow

5 If height H is larger, vehicles with the maximum height as

applicable for the EG can be parked on the UG, otherwise mouldings/ coves are possible. If hollow mouldings/ coves are

there will be free space available on the ceiling. required, the systems must be designed smaller or the pits

accordingly wider.

6 Potential equalization from foundation grounding connection

to system (provided by the customer). If sprinklers are required, make sure to provide the

! necessary free spaces during the planning stage.

Parking Automat P110 | Indian Version 01.2014 Page 2 of 6

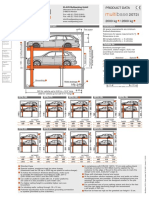

Page 1 Garages with sliding doors (standard) | Width dimensions

- Section

- Dimensions Sliding door behind columns Sliding door between columns Sliding door in front of columns

- Car data

25 13 25 13 25 13

Page 2

- Door

- Width

dimensions

H111

H111

H111

H

H

H3

H2

H2

H2

Page 3

30

- Width

dimensions

- Approach

PD

PD

PD

- Free

spaces

Page 4

550 (570) 550 (570) 550 (570)

- Function

- Load plan Type PD H H1 H2 Type PD H H1 H2 Type PD H H1 H2 H3

P110 175 220 200 210 P110 175 220 200 220 P110 175 220 200 210 220

Page 5 P110 200 220 200 220 P110 200 220 200 220 P110 200 220 200 210 220

- Electrical

data

- Technical

data

- To be Columns per each grid unit Columns per each grid unit Columns per each grid unit

performed

by the

customer

Not available

RB RB RB RB RB RB

Page 6

(25) 13

- Description

10 10

(B2) 20 20

(B2)

B1 B2 B1 B2

no. of grids x RB + 20 no. of grids x RB + 20

Driveways in accordance Driveways in accordance

with local regulations with local regulations

Usable platform width RB 12 B1 B2 Usable platform width RB 12 B1 B2

220 240 240 220 220 240 240 220

230 250 250 230 230 250 250 230

240 260 260 240 240 260 260 240

250 270 270 250 250 270 270 250

260 280 280 260 260 280 280 260

270 290 290 270 270 290 290 270

Columns every second grid unit Columns every second grid unit Columns every second grid unit

RB RB RB RB RB RB RB RB RB RB RB RB

(25) 13

10 10 10

(B4) 20

(B4) 20 B3 B4 20

(B4)

B3 B4 no. of grids x RB + 20

B3 B4

no. of grids x RB + 20

no. of grids x RB + 20

Driveway in accordance Driveway in accordance Driveway in accordance

with local regulations with local regulations with local regulations

Usable platform width RB 12 B3 B4 Usable platform width RB 12 B3 B4 Usable platform width RB 12 B3 B5

220 240 480 460 220 240 480 460 220 240 480 460

230 250 500 480 230 250 500 480 230 250 500 480

240 260 520 500 240 260 520 500 240 260 520 500

250 270 540 520 250 270 540 520 250 270 540 520

260 280 560 540 260 280 560 540 260 280 560 540

270 290 580 560 270 290 580 560 270 290 580 560

End parking spaces are generally more difficult to drive into. Therefore, we recommend our wider platforms for end parking

! spaces. Parking larger vehicles on standard width platforms may make getting into and out of the vehicle difficult. This

depends on the type of the vehicle, approach and above all, on the drivers skill.

11 H1 = Height of the vehicle on ground floor platform.

12 RB = Grid unit width must strictly conform to dimensions quoted.

13 Applies to manually operated doors only. The electricity driven doors must have 35 cm.

Parking Automat P110 | Indian Version 01.2014 Page 3 of 6

Page 1 Garages with roll doors | Width dimensions

- Section

- Dimensions Roll door behind columns Columns per each grid unit

- Car data

50

Page 2

RB RB RB

- Door

- Width

dimensions

2220

10

Page 3

- Width

dimensions

- Approach

- Free

20 20 20 20

spaces B5 B5

no. of grids x RB + 20

Page 4

Driveway in accordance

- Function 550 (570)

with local regulations

- Load plan

Usable platform width RB 12 B5

Page 5

220 240 220

- Electrical

data

230 250 230

240 260 240

- Technical

data

250 270 250

260 280 260

- To be

performed 270 290 270

by the

customer

Page 6

- Description ! End parking spaces are generally more difficult to drive into. Therefore, we recommend our wider platforms for end parking

spaces. Parking larger vehicles on standard width platforms may make getting into and out of the vehicle difficult. This

depends on the type of the vehicle, approach and above all, on the drivers skill.

12 RB = Grid unit width must strictly conform to dimensions quoted.

Approach

!

Maximum Maximum

descending ascending

slope 3% slope 5%

! The illustrated maximum approach angles must not be exceeded. Incorrect approach angles will cause serious maneuvering &

positioning problems on the parking system for which the local agency of KLAUS Multiparking accepts no responsibility.

Longitudinal free space

Free space above the door

varying acc. to

garage height

Empty

space Entrance level

10 RB 12 RB RB RB

12 RB = Grid unit width must strictly conform to dimensions quoted.

Parking Automat P110 | Indian Version 01.2014 Page 4 of 6

Page 1 Function with standard numbering and identification of parking levels

- Section

- Dimensions e.g. for parking space No. 5:

Entrance level

- Car data Check first that all doors are closed, then select No. 5 on operating panel.

Page 2

- Door

- Width EG 2 4 2 4 2 4 5

dimensions

Page 3

UG 1 3 5 1 3 5 1 3

- Width

dimensions

- Approach

- Free

spaces

For driving the vehicle off platform The empty space is now below the The vehicle on platform No. 5 can

Page 4 No. 5 the upper parking platforms are vehicle which shall be driven off now be driven off the platform.

- Function shifted to the left. platform. Platform No. 5 will be lifted.

- Load plan

Page 5

Load plan

- Electrical

data

P110-175 P110-200

- Technical

data

- To be

performed

by the

customer F1 F1

120

120

Page 6

- Description

F1 F2 F6 F1 F2 F6

175

165

165

200

F3 F4 F5

190

F7 F8 190

F3 F4 F5 F7 F8

6 6

6 6

550 (570)

550 (570)

Load plan-top view

RB2 RB RB RB RB

F3 F4 F5 F4 F5 F4 F5 F4 F5 F4 F3

F2 F1 F2 F1 F2 F1 F2 F1 F2 F1 F2

F6 F6 F6 F6 F6 F6

F7 F8 F8 F8 F8 F7

RB1 RB RB RB RB1

Usable platform width RB 12 RB1 Rb2 Platform load F1 F2 F3 F4 F5 F6 F7 F8 13

220 240 250 130 2000 kg 5 2,5 9 +40 18 2,5 15 +30

230 250 260 135

240 260 270 140

250 270 280 145

260 280 290 150

270 290 300 155

! The system is doweled to floor and walls. The drilling depth in the floor is approx. 15 cm. The drilling depth in the walls is approx. 12 cm.

Floor and walls are to be made of concrete (grade of concrete min. C20/25).

The dimensions for the points of support are rounded values. If the exact position is required, please contact KLAUS Multiparking.

12 RB = Grid unit width must strictly conform to dimensions quoted.

13 All forces in kN (static loads)

Parking Automat P110 | Indian Version 01.2014 Page 5 of 6

Page 1

Electrical data

- Section

- Dimensions Control box Electrical supply to the control box/Foundation earth

- Car data connector

The control box must be accessible at all times from outside.

Page 2

Dimensions approx. 100 x 100 x 30 cm. A 3phase, 415V (10%), 50Hz (2%), 4 wire (3PH+N+PE) electrical

- Door supply to the control box through a 4 pole RCBO (or MCB+ELCB),

- Width Cutting through of wall from control box to parking system (contact the 25 Amp. IDN (sensitivity/leakage current)100 mA.

dimensions local agency of KLAUS Multiparking for clarification).

Supply line cable 5x4.0 mm2, copper (3PH+N+PE) with marked wire

Page 3 and protective conductor. Local regulations must be taken inti

- Width consideration.

dimensions

- Approach Cutting through Electrical supply to the control box must be provided by the customer

during installation. The functionality can be monitored on site by our

- Free

spaces fitters together with the electrician. If this cannot be done during

installation for some reason for which the customer is responsible, the

Page 4 customer must commission an electrician at his own expense and risk.

- Function Safety of Machinery. Electrical Equipment, grounding of the steel

- Load plan structure is necessary, provided by the customer (distance between

grounding max. 10 m).

Page 5 Parking system fully visible

- Electrical from control box

data Operating device

- Technical

data Easy-to-survey positioning (e.g. on column).

- To be Protection against unauthorized use.

performed

by the May also be recessed in wall if required.

customer

Page 6

Technical data

- Description

Field of application Numbering

Generally parking system is suitable for the same car length for which Standard numbering of the parking spaces:

the wheel stop is adjusted at the time of installation. In case different Initial position: lower floor platform No. 1 at entrance level (covering of

car is to be parked, wheel stop adjustment/confirmation from KLAUS pit, safety regulation).

shall be required.

Care Empty 7 Entrance level

space 2 4 6

To avoid damages resulting from corrosion, make sure to fallow our

cleaning and care instructions and to provide good ventilation of your 8

1 3 5 7

garage.

Environmental conditions

Environmental conditions for the area of multiparking systems: Different numbering is only possible at extra cost

Temperature range 50 C to +400 C. Maximum outside temperature of Please take note of the following specifications:

+450 C.

- In general, the empty space must be arranged to the left.

If the local circumstances differ from the above, please contact

KLAUS Multiparking. - The numbers must be provided 8-10 weeks before the delivery date.

To be performed by the customer

Safety fences Strip footings

Any constraints that may be necessary in order to provide protection If due to structural conditions strip footings must be effected, the

for the park pits for pathways directly in front, next to or behind the unit. customer shall provide an accessible platform reaching to the top of

This is also valid during construction. the said strip footings to enable and facilities the mounting work.

Numbering of parking spaces Electrical supply to the control box/foundation earth

connector

Consecutive numbering of parking spaces.

Suitable electrical supply to the control box must be provided by the

Building services

customer during installation. The functionality can be monitored on

Any required lighting, ventilation, fire extinguishing and fire alarm site by our fitters together with the electrician. If this cannot be done

systems as well as clarification and compliance with the relevant during installation for some reason for which the customer is

regulatory requirements. responsible, the customer must commission an electrician at their own

Drainage expense and risk.

Safety of machinery, electrical equipments, grounding of the steel

For the middle area of the pit we recommend a drainage channel, structure is necessary, provided by the customer (distance between

which you connect to a floor drain system or sump (50 x 50 x 20 cm). grounding max. 10 m).

The drainage channel may be inclined to the side, however not the pit

floor itself (longitudinal incline is available). In the interests of Door suspension

environmental protection we recommend painting the pit floor. Oil and

petrol separators must be provided according to the statutory The lintel height H2 (see page 2) is absolutely necessary. With

provisions when connecting to the public sewage system. differing heights, additional fixings are required at extra cost.

Door shields

Wall cuttings

Door shields that may be necessary. If desired, they can be ordered

Any necessary wall cuttings. from KLAUS Multiparking for an additional cost.

If the following are not included in the quotation, they will

also have to be provided/paid for by the customer

- Costs for final technical approval by an authorized body

Parking Automat P110 | Indian Version 01.2014 Page 6 of 6

Page 1 Description

- Section

- Dimensions General description Hydraulic unit consists of

- Car data

Multiparking system providing independent parking spaces for cars, - Hydraulic power unit (low-noise, installed onto a console with a

Page 2 one on top of the other and side by side. rubber-bonded-to-metal mounting)

- Door Dimensions are in accordance with the underlying dimensions of - Hydraulic oil reservoir

- Width parking pit, height and width.

dimensions - Oil filling

The parking bays are accessed horizontally (installation deviation - Internal geared wheel pump

Page 3 1%).

- Width - Pump holder

dimensions Along the complete width of the parking automat an approach lane

- Approach (during lane in accordance with local regulations) must be available. - 3-phase-AC-motor (3.0kW, 230/400 V, 50 Hz)

- Free Parking spaces are arranged on two different levels, one level on top - Motor circuit breaker

spaces

of the other. - Pressure gauge

Page 4 The platforms of the lower floor (UG) are moved vertically, the - Pressure relief valve

- Function platforms on the ground floor (EG) horizontally. At approach level there

is always one parking space less available. This vacant space is used - Hydraulic hoses (which reduce noise transmission onto the

- Load plan

for shifting the ground floor (EG) parking spaces sideways, thus hydraulic pipe)

Page 5 enabling an lower platform (UG) parking space located below to be

- Electrical lifted to approach/ground level. Consequently, a unit of three parking

data spaces (1 on the ground floor, 2 on the lower floor) is the smallest unit Control system

- Technical available for this parking system.

data - Central control panel (operating device ) used to select the desired

- To be The parking automat P110 allows parking of passenger cars and parking space

performed station wagons.

by the - With series installation, the doors are opened manually

customer For safety reasons the platforms can only be moved behind

magnetically locked doors, installed at the entrance. If desired, this can also be done using electric motors

Page 6

All necessary safety devices are installed. This consists mainly of a - Electric wiring is made from the electric cabinet by the manufacturer

- Description

chain monitoring system, locking lever for the lower platforms and Laterally movable doors

magnetic door locks.

The doors can only be opened if the selected parking space has Size

reached the park position and all openings are secured. Sliding door, dimensions: approx. 2500 mm x 2000 mm

A steel framework mounted inside the pit consists of (width x height).

- Supports Frame

- Steel pillars with sliding platform supports - Frame construction with vertical centre stay made from extruded

aluminium sections

- Cross and longitudinal members

Safety doors

- running rails for the transversely movable ground floor (EG) platform

Doors and door suspensions are not included in the standard version

Platforms consist of but can be delivered at additional cost as special equipment.

- Side members Door actuation

- Cross members - Manually, i.e. the door is opened and closed by hand

- Platform base sections For safety reasons the movement of the platforms as always mode

behind locked doors.

- 1 wheel stop (on the left per parking space)

Door rails

- Screws, small parts, etc.

- The running gear of each door consists of 2 twin-pair rolling gadgets,

Lifting device for lower floor (UG) platforms adjustable in height

- Hydraulic cylinder with solenoid value - The running rails of the doors are fixed to brackets or the concrete

lintel, or on a building-specific door suspension using ceiling fittings

- Chain wheel

- The guide consists of 2 plastic rollers mounted to a base late, which is

- Chains doweled to the floor

- Limit switches

- The platforms are suspended on four points and guided along the

supports using plastic sliding bearings.

Drive unit of transversely movable platforms on the ground

floor (EG)

- Gear motor with chain wheel

- Chains

- Running and guide rollers (low-noise)

- Power supply via cable

We reserve the right to change these specifications without prior notice.

KLAUS Multiparking reserves the right in the course of the technical progress to use newer or other technologies, system, processes, procedures

or standards in the fulfillment of their obligations other than those originally offered.

You might also like

- SAP Shortcut Keys PDFDocument5 pagesSAP Shortcut Keys PDFHarish KumarNo ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentEhab Yahia Khalel100% (2)

- KLAUS P310 - 3 Level PuzzleDocument6 pagesKLAUS P310 - 3 Level PuzzleOrianaFernandezNo ratings yet

- KlausDocument5 pagesKlausSimona RotunduNo ratings yet

- Catalog KlaussDocument5 pagesCatalog Klaussmalboro111No ratings yet

- KLAUS G61 M - 2 Level Dependent StackDocument4 pagesKLAUS G61 M - 2 Level Dependent StackOrianaFernandezNo ratings yet

- Product Data: Garage Without Door (Basement Garage) DimensionsDocument4 pagesProduct Data: Garage Without Door (Basement Garage) DimensionsDragos Cristian SmauNo ratings yet

- Product Data: Loadable Up To 2600 KG!Document7 pagesProduct Data: Loadable Up To 2600 KG!Le DucNo ratings yet

- Klaus DetailsDocument7 pagesKlaus DetailsCristina ChișNo ratings yet

- Product DataDocument7 pagesProduct DataCatalin GhermanNo ratings yet

- Multibase 2072i - CarparkDocument7 pagesMultibase 2072i - CarparkLe DucNo ratings yet

- Pq-Dc/Pq-Ac: Parking PalletDocument5 pagesPq-Dc/Pq-Ac: Parking PalletRafael SalgadoNo ratings yet

- Date Tehnice Sistem - MultiBase G82Document7 pagesDate Tehnice Sistem - MultiBase G82Ranete FlorinNo ratings yet

- Product Data: Garage Without Door (Basement Garage) Loadable Up To 2600 KG! DimensionsDocument7 pagesProduct Data: Garage Without Door (Basement Garage) Loadable Up To 2600 KG! DimensionsMarija SekulovicNo ratings yet

- Automated Parking 2Document7 pagesAutomated Parking 2Vebi FazliuNo ratings yet

- Mechanical Parking5Document4 pagesMechanical Parking5ArkglaiveNo ratings yet

- Stacparking 2062 Standard DatasheetDocument5 pagesStacparking 2062 Standard DatasheetJulie CezarNo ratings yet

- TV4000 PDFDocument6 pagesTV4000 PDFLe DucNo ratings yet

- Product Data: Parkdisc D450 (Below Floor Level) Top Edge Finished FloorDocument4 pagesProduct Data: Parkdisc D450 (Below Floor Level) Top Edge Finished FloorFlorin FlorinNo ratings yet

- MXU Cargo Pod DatasheetDocument1 pageMXU Cargo Pod Datasheethanie.zomorodiNo ratings yet

- Chapter-11 DRAFT DESIGN STANDARDS - R3Document18 pagesChapter-11 DRAFT DESIGN STANDARDS - R3qtiyapaNo ratings yet

- Standard Field Quality Plan: Appendix-IIDocument39 pagesStandard Field Quality Plan: Appendix-IINishant GuptaNo ratings yet

- 2042 155 310 PDFDocument5 pages2042 155 310 PDFCristina ChișNo ratings yet

- Product Data: Dimensions, Technical Information and Performance SpecificationDocument13 pagesProduct Data: Dimensions, Technical Information and Performance SpecificationMarius PetrescuNo ratings yet

- Master Gatway Profinet VBG-PN-K20-DMD - 219010 - EngDocument2 pagesMaster Gatway Profinet VBG-PN-K20-DMD - 219010 - EngMarcos ViniciusNo ratings yet

- Stacparking StandardDocument4 pagesStacparking StandardMahithaKrishnaNo ratings yet

- Asi Bus, Basics: Training Centre, Service Engineering 1Document14 pagesAsi Bus, Basics: Training Centre, Service Engineering 1Fernando M ChaccaraNo ratings yet

- KLAUS G61 EV - 2 Level Dependent StackDocument4 pagesKLAUS G61 EV - 2 Level Dependent StackKoteeswari JanakiramanNo ratings yet

- Vissim Training - 12. Dynamic RoutesDocument18 pagesVissim Training - 12. Dynamic Routesachmad andhikaNo ratings yet

- TCS - R4 (6 Lane) - 4.9.2019 PDFDocument8 pagesTCS - R4 (6 Lane) - 4.9.2019 PDFChandanNo ratings yet

- Binaryfullo229638v89 SUPER 19005 (I) Brochure EnGB PDFDocument23 pagesBinaryfullo229638v89 SUPER 19005 (I) Brochure EnGB PDFmarcos1.limaNo ratings yet

- Era of Hyper-ScalingDocument9 pagesEra of Hyper-ScalingGabriel DonovanNo ratings yet

- The Power of Communications - Everything IPDocument149 pagesThe Power of Communications - Everything IPRajesh RajendranNo ratings yet

- Infographic A220 FamilyDocument1 pageInfographic A220 Familyromanduffort.lyaNo ratings yet

- Eng VBG-PB-K25 HOJA DE DATOSDocument2 pagesEng VBG-PB-K25 HOJA DE DATOSEdison RiosNo ratings yet

- Avant LeafletDocument7 pagesAvant Leafletinfo4826No ratings yet

- Course 3 1xEV-DO Rev A Coverage PlanningDocument29 pagesCourse 3 1xEV-DO Rev A Coverage PlanningDoTrongLinhNo ratings yet

- Self Erector BrochureDocument17 pagesSelf Erector BrochureBruceHowardNo ratings yet

- Bulkscan® LMS511 - FertilizerDocument14 pagesBulkscan® LMS511 - FertilizerranjeetNo ratings yet

- Creating and Using Effective IT Strategic Plans: Louis Boyle Vice President Gartner Executive ProgramsDocument30 pagesCreating and Using Effective IT Strategic Plans: Louis Boyle Vice President Gartner Executive ProgramsMd Mahboob Ghani HuqNo ratings yet

- Zoomlion Rough Terrain Cranes Spec 6f2538 PDFDocument6 pagesZoomlion Rough Terrain Cranes Spec 6f2538 PDFAlfian Lukas ArdiansyahNo ratings yet

- Informacion PLM IIIDocument6 pagesInformacion PLM IIIAle SilliéNo ratings yet

- Packaging LineDocument1 pagePackaging LinemariusNo ratings yet

- Product Data: Type Car HeightDocument5 pagesProduct Data: Type Car HeightIslam ElhabsheNo ratings yet

- Conventional Slickline With Real-Time Data: One Crew. One System. One Rig-UpDocument7 pagesConventional Slickline With Real-Time Data: One Crew. One System. One Rig-UpKoray YilmazNo ratings yet

- Ce421 Team16 Poster 1Document1 pageCe421 Team16 Poster 1api-455933965No ratings yet

- Additional Requirements For Bus Construction: Automotive Industry StandardDocument59 pagesAdditional Requirements For Bus Construction: Automotive Industry StandardVishwas VaidyaNo ratings yet

- Flexible Pavement Design - KalmboliDocument10 pagesFlexible Pavement Design - KalmboliDevendra DandotiyaNo ratings yet

- MPL NewDocument4 pagesMPL NewMohsin JavedNo ratings yet

- Innovations and Proven Equipment at The Iaf 2013Document7 pagesInnovations and Proven Equipment at The Iaf 2013Gandhie RuzendyNo ratings yet

- DO228 SpecDocument17 pagesDO228 SpecPeter Pan100% (1)

- Tubular Fabric Inspection With Precision FoldingDocument1 pageTubular Fabric Inspection With Precision FoldingAshok LakshmananNo ratings yet

- Group HighwayDocument78 pagesGroup Highway2023125787No ratings yet

- Selecting and Using Appropriate Truck Data in Design GuidelinesDocument3 pagesSelecting and Using Appropriate Truck Data in Design GuidelinesAlioune PAYENo ratings yet

- Brochure-Case Packing Line CPA-C With Collection & Drop FeedingDocument2 pagesBrochure-Case Packing Line CPA-C With Collection & Drop FeedingAmit KatariyaNo ratings yet

- Electric High-Speed Multiple Unit Smile: Schweizerische Bundesbahnen (SBB), SwitzerlandDocument2 pagesElectric High-Speed Multiple Unit Smile: Schweizerische Bundesbahnen (SBB), Switzerlandcosty_transNo ratings yet

- Product DataDocument7 pagesProduct DatabulzacheNo ratings yet

- Transport Manual V90Document28 pagesTransport Manual V90cungondaNo ratings yet

- 106 Syllabus B. Arch ProgrammeDocument56 pages106 Syllabus B. Arch ProgrammeOrianaFernandezNo ratings yet

- Elective SubmissionDocument1 pageElective SubmissionOrianaFernandezNo ratings yet

- Design BriefDocument7 pagesDesign BriefOrianaFernandezNo ratings yet

- CW2 Devpro Oriana FernandezDocument17 pagesCW2 Devpro Oriana FernandezOrianaFernandezNo ratings yet

- Technical ManualDocument16 pagesTechnical ManualOrianaFernandezNo ratings yet

- Oriana Fernandez PA100513 FinalDocument33 pagesOriana Fernandez PA100513 FinalOrianaFernandezNo ratings yet

- Sem 9 Design BriefDocument3 pagesSem 9 Design BriefOrianaFernandezNo ratings yet

- The Built Components: Streetscape Improvement PlanDocument1 pageThe Built Components: Streetscape Improvement PlanOrianaFernandezNo ratings yet

- KLAUS G61 M - 2 Level Dependent StackDocument4 pagesKLAUS G61 M - 2 Level Dependent StackOrianaFernandezNo ratings yet

- Thesis Theoretical PremiseDocument7 pagesThesis Theoretical PremiseOrianaFernandezNo ratings yet

- Completed ProjectsDocument3 pagesCompleted ProjectsOrianaFernandezNo ratings yet

- 11 Erickson 300Document26 pages11 Erickson 300OrianaFernandezNo ratings yet

- KLAUS P310 - 3 Level PuzzleDocument6 pagesKLAUS P310 - 3 Level PuzzleOrianaFernandezNo ratings yet

- Streets For People: Brief - October 8, 2013Document2 pagesStreets For People: Brief - October 8, 2013OrianaFernandezNo ratings yet

- City Centre Mall Siliguri, E-ArchitectDocument13 pagesCity Centre Mall Siliguri, E-ArchitectOrianaFernandezNo ratings yet

- Once Again Oriana FernandezDocument2 pagesOnce Again Oriana FernandezOrianaFernandezNo ratings yet

- Second Wind For Connaught Place, New Delhi - RUDI - Resource For Urban Development InternationalDocument6 pagesSecond Wind For Connaught Place, New Delhi - RUDI - Resource For Urban Development InternationalOrianaFernandezNo ratings yet

- Number of Cars Worldwide Surpasses 1 Billion Can The World Handle This Many Wheels?Document4 pagesNumber of Cars Worldwide Surpasses 1 Billion Can The World Handle This Many Wheels?OrianaFernandezNo ratings yet

- Architecture Student's Corner - Lutyen's Delhi - Part 2 - Connaught PlaceDocument13 pagesArchitecture Student's Corner - Lutyen's Delhi - Part 2 - Connaught PlaceOrianaFernandezNo ratings yet

- Assignment 2Document1 pageAssignment 2OrianaFernandezNo ratings yet

- Maitraka TemplesDocument1 pageMaitraka TemplesOrianaFernandezNo ratings yet

- VMT CapDocument1 pageVMT CapOrianaFernandezNo ratings yet

- UD Course Structure 2013 FINAL - 1Document1 pageUD Course Structure 2013 FINAL - 1OrianaFernandezNo ratings yet

- Streets For People: ResourcesDocument2 pagesStreets For People: ResourcesOrianaFernandezNo ratings yet

- Module 2Document1 pageModule 2OrianaFernandezNo ratings yet

- The Heritage Walk Experience of The Old Walled City of Ahmedabad - Experience of Volunteer GuideDocument3 pagesThe Heritage Walk Experience of The Old Walled City of Ahmedabad - Experience of Volunteer GuideOrianaFernandezNo ratings yet

- Existence Space and ArchitectureDocument19 pagesExistence Space and ArchitectureOrianaFernandezNo ratings yet

- The Heritage Walk Experience of The Old Walled City of Ahmedabad - Experience of Volunteer GuideDocument3 pagesThe Heritage Walk Experience of The Old Walled City of Ahmedabad - Experience of Volunteer GuideOrianaFernandezNo ratings yet

- Lesson 3 Communication Vis A Vis Mass CommunicationDocument12 pagesLesson 3 Communication Vis A Vis Mass Communicationloiseabejero100% (2)

- Lecture 2 - Participants in The Construction ProjectDocument21 pagesLecture 2 - Participants in The Construction ProjectjbjuanzonNo ratings yet

- Carbotec TR-PTDocument41 pagesCarbotec TR-PTGuesh Gebrekidan100% (1)

- Concrete InternationalDocument104 pagesConcrete Internationalmchilwesa100% (1)

- OMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersDocument5 pagesOMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersdmlsfmmNo ratings yet

- RadDocument35 pagesRadabdellaNo ratings yet

- Meshless Methods For Conservation LawsDocument24 pagesMeshless Methods For Conservation LawsReginaldRemoNo ratings yet

- MCG3130 Full NotesDocument84 pagesMCG3130 Full NotesBrian Pham VuNo ratings yet

- Drawing ParametersDocument9 pagesDrawing ParametersGraham MooreNo ratings yet

- 6 OptiX OSN 1500 Hardware Description ISSUE 1.30Document128 pages6 OptiX OSN 1500 Hardware Description ISSUE 1.30Regina PazNo ratings yet

- BOP Test Procedure JE 17Document7 pagesBOP Test Procedure JE 17jvmsp100% (1)

- Air Cannon MAINTANANCEDocument26 pagesAir Cannon MAINTANANCEZahir KhiraNo ratings yet

- Code 16 swhihatPAD KIT ARDUINODocument5 pagesCode 16 swhihatPAD KIT ARDUINOBayu PriguntoroNo ratings yet

- 12-Exhibit 8 - Subcontractors and Vendors - Offshore Integrated Works - Rev GleDocument6 pages12-Exhibit 8 - Subcontractors and Vendors - Offshore Integrated Works - Rev GleIdara OkopidoNo ratings yet

- OSE 10-0196-. - 10 - Parts ListDocument51 pagesOSE 10-0196-. - 10 - Parts ListCentrifugal Separator100% (1)

- Folk MarazziDocument40 pagesFolk MarazziMarazzi GroupNo ratings yet

- Gusset Plate Connection To Round HSS Tension MembersDocument7 pagesGusset Plate Connection To Round HSS Tension MembersSergioAlcantaraNo ratings yet

- Proposed ConsultancyDocument19 pagesProposed Consultancyarlyn dimalNo ratings yet

- Corsa Lite Corsa Astra 5 Door Meriva Zafi Ra Tigra Astra GTC Astra Twin TopDocument24 pagesCorsa Lite Corsa Astra 5 Door Meriva Zafi Ra Tigra Astra GTC Astra Twin Topgqnwuqlkwnvh100% (1)

- Standard IEC 60870-5-103Document35 pagesStandard IEC 60870-5-103karoNo ratings yet

- Project - II-5th Sem FinalDocument33 pagesProject - II-5th Sem FinalKushal NepaliNo ratings yet

- Checklist King Air 350Document7 pagesChecklist King Air 350Alejo Giraldo VélezNo ratings yet

- 07 Pulleys and DriveDocument6 pages07 Pulleys and DriveJerry HukyNo ratings yet

- Pip Stc01018Document49 pagesPip Stc01018Jose Luis Velasco CadavidNo ratings yet

- Gear Box DetailsDocument3 pagesGear Box DetailsHoda HosnyNo ratings yet

- Alternating Current TechnologyDocument118 pagesAlternating Current TechnologyMadhav DeshpandeNo ratings yet

- Product Selector Guide Storage: DescriptionDocument2 pagesProduct Selector Guide Storage: DescriptionppanagosNo ratings yet